Elk ELK-M1EZ8 User manual

INSTALLATION

MANUAL

Cross Platform Control

Part # ELK-M1EZ8

A member of the M1 Family

Specifications, Installation and Programming

Includes the SIA CP-01 Standards for False Alarm Reduction

TM

L Rev. F 12/22/05 Current with Firmware 4.3.8

WWW.DIYALARMFORUM.COM

M1EZ8 Installation and Programming

Page 2 [Effective w/Firmware 4.3.6]

Introduction

LIMITATION

This control is designed to warn against unauthorized entry and other situations. However, it is not a guarantee of protection against the

occurrence of burglary, fire, or other emergency. Any alarm system is subject to compromise or failure to warn for various reasons. For

example:

- Unauthorized access can be gained through unprotected points or by disarming or bypassing protected points.

- Sensing devices are power driven and do not operate without electrical power. Battery-operated devices will not work without batteries, with

dead batteries, or if the batteries are not put in properly. Devices powered solely by AC will not work if their AC power supply is cut off for any

reason, however briefly.

- Telephone lines over which alarm signals are transmitted may be out of service or rendered inoperable by an intruder.

- Even if the system responds to the emergency as intended, occupants may have insufficient time to protect themselves from the emergency

situation. In the case of a monitored alarm system, authorities may not respond appropriately.

- Smoke detectors have limitations and cannot detect all types of fires. According to data published by the Federal Emergency Management

Agency, while smoke detectors have played a key role in reducing residential fire deaths in the United States, they may not activate or provide

early warning for a variety of reasons in as many as 35% of all fires, . Some of the reasons some detectors used in conjunction with this

System may not work are as follows. Smoke detectors may have been improperly installed and positioned. Smoke detectors may not sense

fires that start where smoke cannot reach the detectors, such as in chimneys, in walls, or roofs, or on the other side of closed doors. Smoke

detectors also may not sense a fire on another level of a residence or building. A second floor detector, for example, may not sense a first floor

or basement fire. Finally, smoke detectors have sensing limitations. No smoke detector can sense every kind of fire every time. In general,

detectors may not always warn about fires caused by carelessness and safety hazards like smoking in bed, violent explosions, escaping gas,

improper storage of flammable materials, overloaded electrical circuits, children playing with matches, or arson. Depending an the nature of the

fire, and/or location of the smoke detectors, the detector, even if it operates as anticipated, may not provide sufficient warning to allow all

occupants to escape in time to prevent injury or death..

- Signals sent by wireless transmitters may be blocked or reflected by metal before they reach the alarm receiver. Even if the signal path

has been recently checked during a weekly test, blockage can occur if a metal object is moved into the path.

- Wireless transmitters (used in some systems) are designed to provide long battery life under normal operating conditions. Longevity of

batteries may be as much as 4 to 7 years, depending on the environment, usage, and the specific wireless device being used. External

factors such as humidity, high or low temperatures, as well as large swings in temperature, may all reduce the actual battery life in a given

installation. This wireless system, however, can identify a true low battery situation, thus allowing time to arrange a change of battery to

maintain protection for that given point within the system.

- Installing an alarm system may make the owner eligible for a lower insurance rate, but an alarm system is not a substitute for insurance.

Homeowner, property owners and renters should continue to act prudently in protecting themselves and continue to insure their lives and

property.

- A user may not be able to reach a panic or emergency button quickly enough.

- Passive Infrared Motion Detectors can only detect intrusion within the designed ranges as diagrammed in their installation manual. Passive

Infrared Detectors do not provide volumetric area protection. They do create multiple beams of protection, and intrusion can only be detected

in unobstructed areas covered by those beams. They cannot detect motion or intrusion that takes place behind walls, ceilings, floors, closed

doors, glass partitions, glass doors, or windows. Mechanical tampering, masking, painting or spraying of any material on the mirrors, windows

or any part of the optical system can reduce their detection ability. Passive Infrared Detectors sense changes in temperature; however, as the

ambient temperature of the protected area approaches the temperature range of 90 to 105F (32 to 40C), the detection performance can

decrease.

- Alarm warning devices such as sirens, bells or horns may not alert people or wake up sleepers if they are located on the other side of

closed or partly open doors. If warning devices are located on a different level of the residence from the bedrooms, they are less likely to

waken or alert people inside the bedrooms. Even persons who are awake may not hear the warning if the alarm is muffled by noise from a

stereo, radio, air conditioner or other appliance, or by passing traffic. Finally, alarm warning devices, however loud, may not warn hearing-

impaired people.

- This equipment, like other electrical devices, is subject to component failure. Even though this equipment is designed to last as long as 20

years, the electronic components could fail at any time.

- The most common cause of an alarm system not functioning when an intrusion or fire occurs is inadequate maintenance. This alarm

system should be tested weekly to make sure all sensors and transmitters are working properly.

ALL RIGHTS RESERVED

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise without the prior written permission of the manufacturer. The material in this publication is for information

purposes and subject to change without notice. The manufacturer assumes no responsibility for any errors which may appear in this publication.

Printed in U.S.A.

Use of this control for fire detection and/or annunciation may not be permitted by certain states, counties, municipalities or local jurisdiction. It is

the responsibility of the installing alarm company to check with the local A.H.J. (Authority Having Jurisdiction) or State Fire Marshal’s office prior

to using this control for fire detection.

WWW.DIYALARMFORUM.COM

M1EZ8 Installation and Programming Page 3

[Effective w/Firmware 4.3.6]

Table of Contents

Specifications, Features, and Benefits ..................................................................................................... 4

Wiring & Hookup Diagram ........................................................................................................................... 5

Section 1 - Installation and Wiring ............................................................................................................. 7

1.1 Planning the Installation ...................................................................................................................... 7

1.2 Parts Diagram & Descriptions ........................................................................................................... 7

1.3 Mounting and Wiring Preparation ....................................................................................................... 7

1.4 Control Wiring .................................................................................................................................... 8

Data Bus E.O.L. Termination - VERY IMPORTANT! ............................................................................... 11

Section 2 - Operating the System ............................................................................................................ 13

2.1 Introduction ....................................................................................................................................... 13

2.2 Powering Up (One Keypad) ............................................................................................................. 13

2.3 User Codes and Authorities .............................................................................................................. 13

2.4 Installer Program Code and Authorities ............................................................................................ 13

2.5 Keypad Overview ............................................................................................................................. 14

Keypad Menus ........................................................................................................................................ 15

Multi-area (Partition) Operation ............................................................................................................... 18

Section 3 - Programming The Control ..................................................................................................... 19

3.1 Introduction ....................................................................................................................................... 19

3.2 Local Keypad Programming ............................................................................................................. 19

3.3 Local or Remote Computer Programming (ELK-RP) and Anti-Takeover ......................................... 19

3.4 Area Partitioning ................................................................................................................................ 19

3.5 Communicator Setup Checklist ....................................................................................................... 20

3.6 Entering Installer Level Programming ............................................................................................... 20

Menu 01 - Bus Module Enrollment .......................................................................................................... 22

Menu 02 - User Code Options ................................................................................................................ 23

Menu 03 - Area Definitions ...................................................................................................................... 24

Menu 04 - Keypad Definitions ................................................................................................................. 26

Menu 05 - Zone Definitions ..................................................................................................................... 28

Menu 06 - Alarm Duration Timers ........................................................................................................... 31

Menu 07 - Global System Definitions ..................................................................................................... 32

Menu 08 - Telephone Account Setup ...................................................................................................... 36

Menu 09 - Area Reporting Codes ........................................................................................................... 38

Menu 10 - Zone Reporting Codes ........................................................................................................... 40

Menu 11 - Keypad F-Key Reporting Codes ............................................................................................ 41

Menu 12 - Sys Report Code Options & Codes ...................................................................................... 42

Menu 13 - User Report Codes................................................................................................................ 44

Menu 14 - Wireless Definitions ............................................................................................................... 45

Section 4 - PC Programming and Automation Capabilities .................................................................... 47

4.1 ELK-RP Software ............................................................................................................................ 47

4.2 Update/Verify Firmware in the Control and Peripherals ................................................................... 48

4.3 Automation Rules and Attributes ...................................................................................................... 49

Appendix A - Event Codes ........................................................................................................................ 56

Appendix B - Two Way “Listen-in/Talk” Interface (optional) ................................................................. 58

Appendix C - SIA CP-01 Compliance ........................................................................................................ 59

Appendix D - Regulatory Agency Statements ......................................................................................... 60

Appendix E - Additional Keypad Information ........................................................................................... 64

Index ............................................................................................................................. 67

WWW.DIYALARMFORUM.COM

M1EZ8 Installation and Programming

Page 4 [Effective w/Firmware 4.3.6]

General:

• Large zone capacity: 8 on-board zones expandable to 200

• Wireless capability: Up to 48 zones

• Two Way Listen-in interface

• Flash Memory - Allows field updates to firmware electronically

• Time/Date stamped 512 event history log

• Menu driven, text keypad programming

• 12 On-Board Outputs: 1 siren driver/voltage, 1 form “C” Relay,

and 10 low current (10 mA) voltage outputs

• Total Number of Outputs Supported: 204

• Supports 4 wire (any zone) and 2 wire (zone 8) smoke

detectors

• Includes Fire alarm verification routine

• Can be partitioned into 8 areas and account numbers

• User Codes: 99 (4 or 6 digit) with assignable authority levels

• Arm levels: Away, Stay, Stay Instant, Nite, Nite Instant, Vacation

• Hardware "watchdog" and nonvolatile EEPROM memory

• Supervised phone line and alarm output

• Connection for optional ELK-MSI RS-232 serial port 0 to

interface PCs and peripheral devices

• Total serial ports with expansion: 8

Communications

• True V.22 bis Modem for fast reliable upload/download

• Phone Number Capacity: 8

• Optional Ethernet int. for reporting, operation, programming

• Communicator formats: SIA, Contact ID, 4 + 2, and Pager

• Elk-RP PC programming software with conflict resolution to

easily highlight differences between control and PC

- Connect via Dial-up, Optional RS232 port, or Opt. Ethernet

- Automatic answering machine bypass

Keypad

• Backlit, Large Character LCD Display, 16 x 2 lines

• Built-in Temperature Sensor

• Optional Plug-in Prox Access reader (26 bit Weigand format)

• Menu navigation keys and 6 programmable function keys

• Plug-in connector, only 4 wires to the control

• 1 Zone input and 1 Output Programmable per Keypad

• Programmable display of time, date, & temperature

• Displays system diagnostics and settings.

• Maximum Keypads allowed: 16

Automation & Integration

• Create lifestyle enhancing comfort, convenience, and security

• Powerful “Whenever/And/Then” RULES Programming allows

almost any imaginable operation. No need to chain rules

together. Any single “Whenever” event can have one or more

ANDs and THENs (conditions and commands).

• Total number of Rules Supported: 528

• Rules utilize easy to understand text based references

• Control lighting using RS-232 serial or 2-way Power Line

Control (PLC) ports including On, Off, Dim, All On, All Off

commands

• Transmit and receive custom serial ASCII strings

• Read Temperature Sensors - Communicate with Thermostats

• Total thermostats supported: 16

•Sunset/Sunrise calculation and activation built-in

• Advanced Lighting Options (Pre-set Dim, Extended, Levels,

Scenes)

Power Supply

• Heavy duty - 2.5 Amp power supply w/ 1.5 Amp continuous

• Dynamic battery test

• PTC (fuseless) resettable overload protection

Part Numbers and Accessories:

ELK-M1EZ8CB Control “Board only”

ELK-M1EZ8 Control in 12 x 12” metal can (Base Unit)

ELK-M1EZ8KB Control KIT: Board, 12 x 12” can, Xfmr, M1KP

Keypad, 5Ah Battery, SP35 Speaker, RJSET,

ELK-M1EZ8K Control KIT - NO METAL CAN (for structured

wiring systems) Includes Board,XFMR,M1KP

Keypad, 5Ah Battery, SP35 Spkr, RJSET

Utilizes most ELK-M1 Accessories

ELK-M1KP Keypad, LCD,16 character x 2 line

ELK-M1XIN 16 Zone (input) expander

ELK-M1XOVR 16 Output expander, 8 Voltage/8 Relays

ELK-M1XOV 16 Output expander, Voltage only

ELK-M1RB Relay board, 8 form ”C” relays

ELK-M1DBH Data bus wiring hub

ELK-M1XEP Ethernet Port Exp/Interface (Qtr 2 of 05)

ELK-M1XSP Lighting, Thermostat Interface & Serial exp.

ELK-M1PR Mini prox reader for keypad

ELK-M1EZ8TWI Two Way Listen-in Int. w/3 mic inputs

ELK-M1EZ8MSI Main Serial Interface, supplies RS232 Port 0

ELK-M1TWS Speaker & Mic for Two Way Listen-in

ELK-M1ZTS Zone Temperature Sensor -50 to 140 F

ELK-RP PC software, free with 1st Control purchase

Specifications, Features, and Benefits

WWW.DIYALARMFORUM.COM

M1EZ8 Installation and Programming Page 5

[Effective w/Firmware 4.3.6]

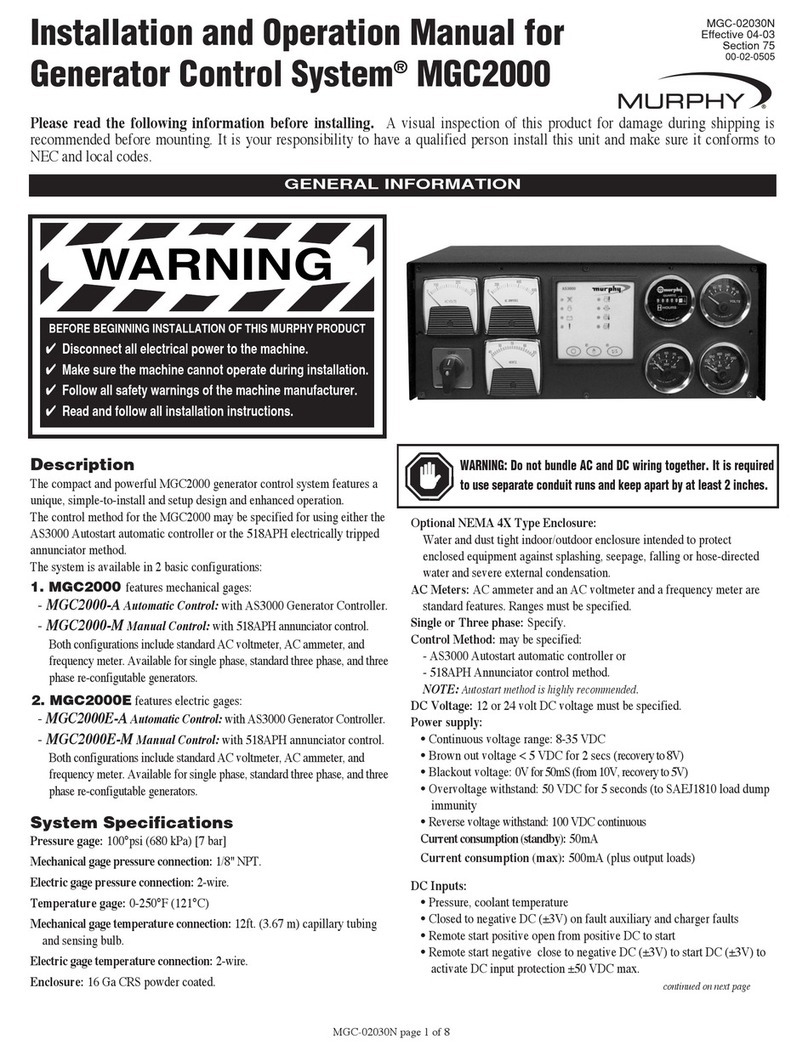

Wiring & Hookup Diagram

-

STATUS

UL Listed

Transformer,

16.5VAC, 45VA.

Class II,

(ELK-TRG1640)

LINE SEIZE

N.C.

N.O.

2200

Ohm

EOL

N.C.

N.O.

Zone

8

2200

Ohm

EOL

POWER

Data Bus-See Note in Manual

RED

BLACK

WHITE

GREEN

Keypad

+

Siren or Voltage

See Manual

Do Not Connect

to a Phone Line!

JP1

2WIRE

SMOKE

NORMAL

ZONE 8

JP3

For PLC Lighting

Interface

or M1EZ8MSI Main

Serial Port Interface

Aux Data Bus (J3)

For wireless receiver. Presently

works with GE-Caddx NX408E,

NX416E, or NX448E

Two-Way

Listen-In (J7)

Connects to

(M1EZ8TWI)

TELCO

Line

House

Phones

TR

T1 R1

RJ31X Jack

(ELK-RJSET)

54

8 1

Demark

Block

splices

Yellow

Black

Red

Green

Green Red Brown

PHONE LINE HOUSE LINE

TIP RING T1 R1

Z7NEGZ8

Compiles with FCC Part 68

Reg. Number: US:5K6AL03BELK-M1

Ringer Equivalence REN: 0.3B

Use USOC RJ-31X connector.

Complies with the limits for class B computer

devices in accordance with the specifications

of subpart J of part 15 of FCC rules.

For Voltage (open collector)

program option G26 to a Yes. Max.

Current Draw: 1 Amp If output is not

used, install a 2200 Ohm resistor to

avoid Output 2 trouble.

Out 3 - Relay Programmable

General Purpose Dry Contacts

rated: 5Amps @ 12 - 28VDC

Select PLC Mode (JP2)

Selects single or bi-directional

PLC Transmissions

Terminating Jumper (JP3)

See manual for important information

about Data Bus Termination.

Testing of this system should be performed

regularly. Control panel specifications are subject

to change without notice. Figures not to scale.

12Volt - 5Ah min.

See UL requirements

for sizes and standby

times.

16V XFMR

AC AC A B

+12V

KP NEG

OUTPUT 3

N/O N/CCOM

Line Seize LED is ON if Dialer

is in use (communicating)

Status LED:1 blink = Normal Operation.

2 fast blinks = Bootloader mode.

4 fast blinks = Initializing EEPROM memory.

5 fast blinks = Memory/Operation overflow.

Power LED is ON when AC Voltage is present.

Auxiliary +12VDC

Power Output

Protected by 1.25A PTC.

2200 Ohm EOL Resistors are part # ELK-ER2200

ELK-M1EZ8

J3

-

C

+

B

A

1

J7

1

2 WAY

1 WAY

-X10-

JP2

J5

18

+12VDC Switched

Smoke Power

1.1 Amp PTC protected

4-Wire Smoke Detector

2200

Ohm

EOL

To Zone Input

U.L. Listed EOL Supervision Relay

(ESL #204 or Equivalent).

(shown energized, contacts closed)

N.O. Alarm

Contacts

To Zone NEG

+VAUX +VSMK

Grey

Ring Tip

T1 R1

Programmable Outputs (J16)

OUT 7 thru 16 are +12V switched positive

voltage outputs rated at 10mA max.

Connect optional ELK-M1RB Relay Board

for 8 general purpose relays.

J16

OUT 16

OUT 15

OUT 14

OUT 13

OUT 12

OUT 11

OUT 10

OUT 9

OUT 8

OUT 7

+12V

NEG

Red

Black

White

Green

Brown

Blue

Yellow

Violet

Pink

Tan

Orange

Grey

(Supervised)

+ALARM -

OUTPUT 2

NEG

-

+

Connector J5 accepts either a 4 conductor modular cable for a PSC05 PLC

Lighting Interface OR an 8 conductor modular cable for a EZ8MSI Main Serial Port

Interface w/PSC05 pass through connector. (This connection not evaluated by UL)

PSC05

or

equiv.

PSC05 or

Equivalent

PC

Computer, OEM

component, etc.

RS-232

ELK-M1EZ8MSI

Main Serial Port Interface

J3

RS232

Serial

Cable

4 Conductor

Modular Cable

8 Conductor

Modular Cable

11

J1

From

EZ8

J2

Powerline

Interface

To J5

Connector

4Conductor

Modular

Cable

OR

1

Note: Test battery regularly with

ELK-BLT Battery Life Tester.

Replace every 3-5 years

BATTERY

RED BLK

Zone

7

-

+

+

-

(Sold separately)

12V

Battery

Yellow

Green

Red

Black

4 conductor modular (standard) phone

cord for PLC Lighting (not supplied).

End view

Yellow

Green

Red

Black

1

1

8 Conductor Cat5 cable from EZ8MSI Main Serial Port Interface.

End view

Brn/Wht

Wht/Brn

Grn/Wht

Wht/Blue

Blue/Wht

Wht/Grn

Org/Wht

Wht/Org

1

Wht/Org

Org/Wht

Wht/Grn

Blue/Wht

Wht/Blue

Grn/Wht

Wht/Brn

Brn/Wht

1

083005

ELK

PRODUCTS, INC.

HILDEBRAN, N.C., 28637, USA

Do not connect to switched outlet.

Out 2 - Alarm (Siren or Voltage)

Connect a UL Listed siren or bell.

Default is Siren Min. 15 watt

(4-16 Ohm) speaker ELK-SP30

or equiv.

NOTE: Maximum continuous current drain from

+VAUX, +12VKP, +VSMK, and J16 combined must

not exceed 1 Amp (2.5 Amps in alarm)

N.C.

N.O.

2200

Ohm

EOL

N.C.

N.O.

Zone

6

2200

Ohm

EOL

Z5NEG

Zone

5

Z6

N.C.

N.O.

2200

Ohm

EOL

N.C.

N.O.

Zone

4

2200

Ohm

EOL

Z3NEGZ4

Zone

3

N.C.

N.O.

2200

Ohm

EOL

N.C.

N.O.

Zone

2

2200

Ohm

EOL

Z1NEG

Zone

1

Z2

11

RS232 Serial Port Cable (9 pin male

to 9 pin female) Max. length = 50 ft.

Pin 2 < to > 2

Pin 3 < to > 3

Pin 5 < to > 5

2-Wire

Smoke

Detector

680 Ohm EOL

Zone 8 can be configured as a 2-wire smoke zone. Set JP1 to "2

WIRE SMOKE" and use 680 Ohm EOL resistor, part # ELK-ER680

Use Only Compatible Detectors:

System Sensor: 2WTA-B, 2WTR-B, 2100, 2100T

GE: 429AT, 521BXT, 521B.

Hochiki America: SLK-835.

Detection Systems: DS250, DS250TH, DS282, DS282TH,

DS282THS,DS282THC.

Maximum Number = 20 Do not mix models.

2-Wire Smoke Circuit

-

+

NEGZ8

Sealed Lead Acid

Battery (ELK-1250)

Note: Secondary phone line surge

suppression devices (ELK-950) are

recommended for areas prone to transient

or lightning strikes.

WWW.DIYALARMFORUM.COM

M1EZ8 Installation and Programming

Page 6 [Effective w/Firmware 4.3.6]

Intentionally Left Blank

WWW.DIYALARMFORUM.COM

M1EZ8 Installation and Programming Page 7

[Effective w/Firmware 4.3.6]

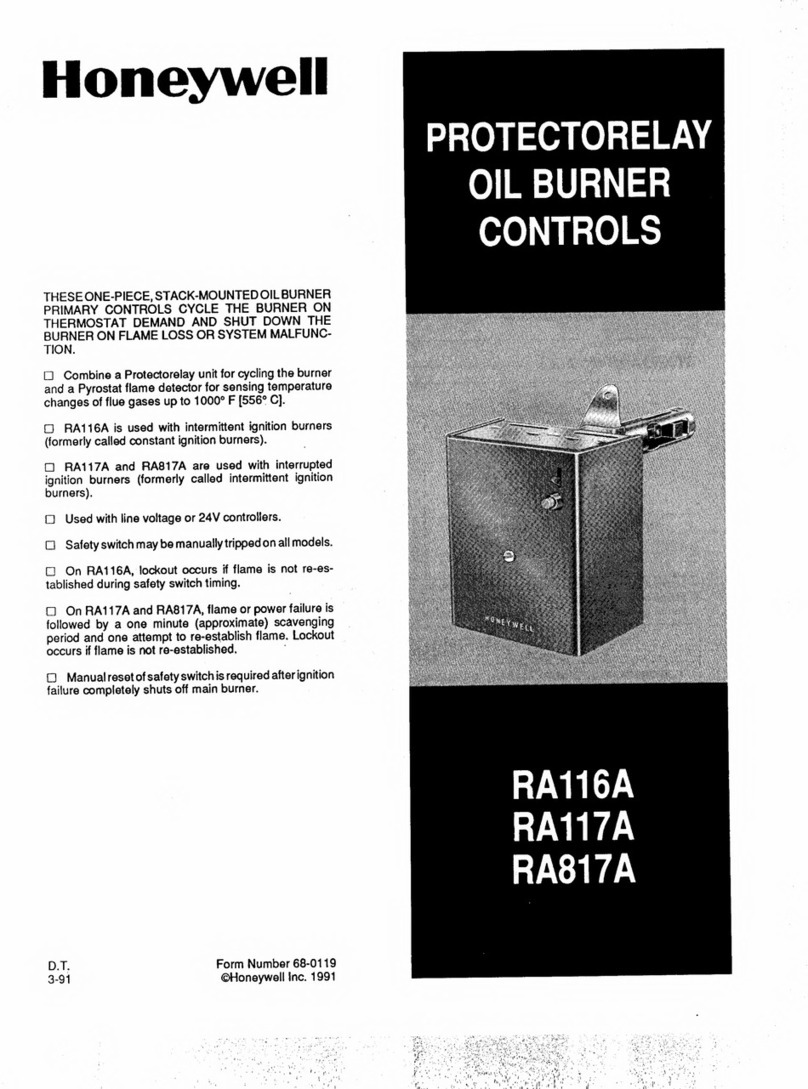

1.1 Planning the Installation

The first step in any multi-zone security system installation is planning the job.

1. Read this entire manual to familiarize yourself with all system features and procedures before actually beginning the

installation. Read all the information regarding Underwriters Laboratories (UL) and NFPA requirements.

2. Perform a physical survey of the installation site. Use the diagrams below as a guide in planning the installation.

3. Discuss the installation requirements and applications with the customer.

4. Compare the installation requirements and applications with the factory default settings to determine what customized

programming is needed to meet the specific installation requirements.

5. Bench test the system prior to installation.

1.2 Parts Diagram & Descriptions

See Wiring & Hookup Diagram on pages 5.

1.3 Mounting and Wiring Preparation

Control Mounting

Remove all packing material and familiarize yourself with the parts. Mount the control in a secure, dry location where the

ambient temperature inside the control box can remain at 32‘ to 120°Fahrenheit (0’ to +49' Celsius). Choose a location that

allows easy wiring to an unswitched power outlet and to a grounding conductor for the control. A central location makes

running system wiring easier. Remove control box knockouts that best suit your wiring needs. Mount the control using the

upper center slotted hole to level. Install and connect all necessary wiring for the power transformer, detection loops, keypads

and siren outputs.

Keypad Mounting and Wiring

Ideal keypad height is 50-58 inches above the floor. Select a location with an ambient temperature range between 32°and

120°F (0° to +49°C). Avoid direct sunlight if possible. Fasten mounting plate to electrical box (or directly to wall) using flat

head screws to prevent shorts to the back of the circuit board. Keypads have a removable wiring plug for connecting to the 4-

wire data bus. CAT5 or CAT6 eight (8) conductor cable is recommended for all Data Bus cables. The extra wires provide

data return paths. Splice the Black, Red, White, and Green wires from the removable wiring plug to the Data Bus cable. Plug

the connector into the back of the keypad. Tuck wires neatly into back plate and install Keypad on mounting plate. Each

keypad has connections for an optional programmable output and a programmable zone input.

Section 1 - Installation and Wiring

Legend

- Main Control

- Audible Alarm

- Smoke Detector

- Contact

- Keypad

M

A

S

C

K

Bedroom 1Bedroom 2

Bedroom 3 Living Room

Kitchen / Dining

TYPICAL BURGLARY INSTALLATION LAYOUT

M

A

K

Bedroom 1Bedroom 2

Bedroom 3 Living Room

Kitchen / Dining

TYPICAL FIRE INSTALLATION LAYOUT

M

A

K

C

CCCCC

S

SS

S

Basement

First Floor

All perimeter openings below 18" should be provided with protection.

A Smoke Detector shall be located in each sleeping area and between

the sleeping areas and the main living area.

Early warning fire detection is best achieved by the installation of fire

detection equipment in the location shown above.

In homes basements or multiple levels at least one smoke detector

shall be on each level.

WWW.DIYALARMFORUM.COM

M1EZ8 Installation and Programming

Page 8 [Effective w/Firmware 4.3.6]

NOTE: Refer to the section ‘Data Bus E.O.L. Termination’ for information on multiple homerun cables. NEVER SPLICE OR

CONNECT WIRE WITH CONTROL POWER ON. Minimum cabling should be four conductor 22 or 24 gauge. Maximum resistance per wire is

25 Ohms. Device placement beyond 1000' is not recommended.

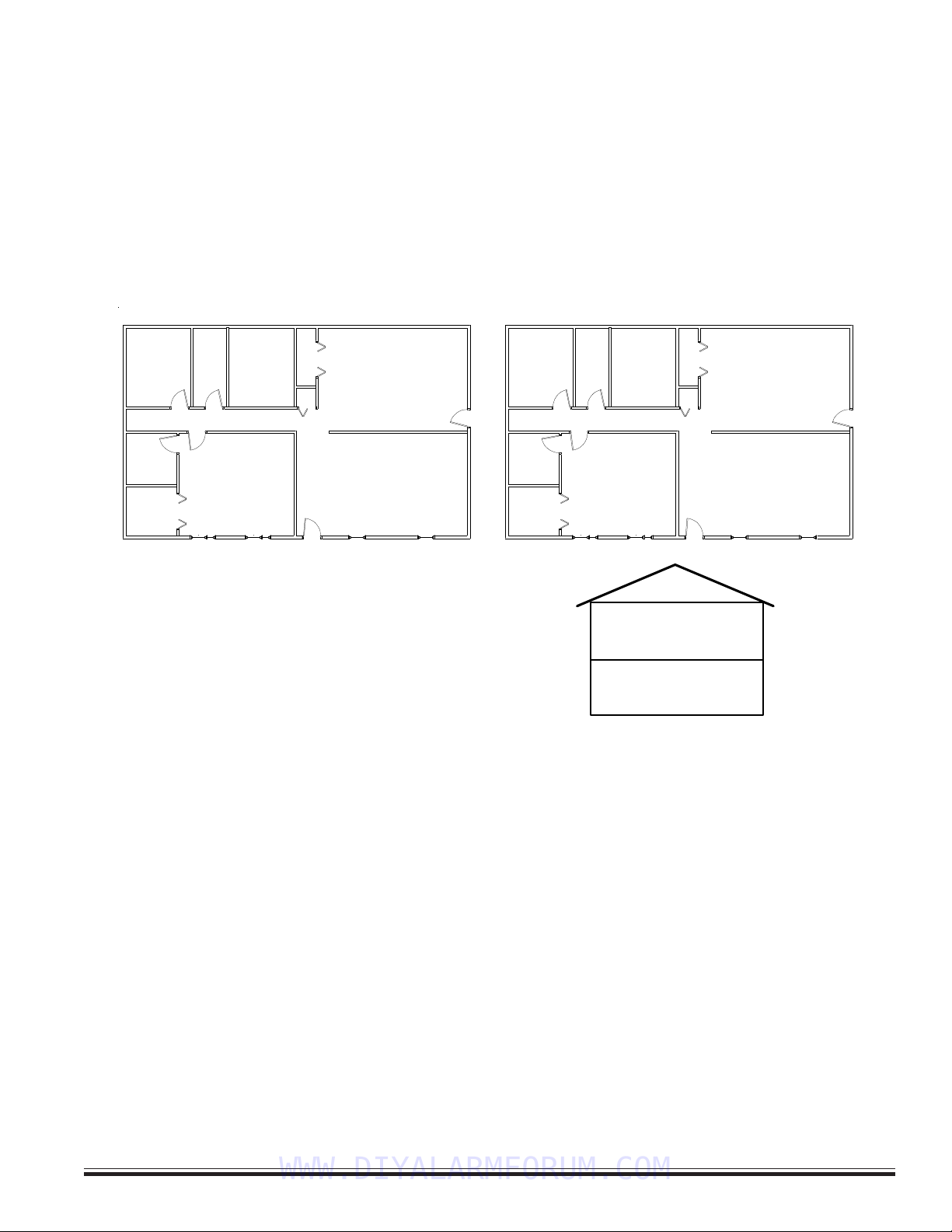

1.4 Control Wiring

Zone Inputs (1 thru 8 on main board, 17 thru 208 via expanders)

Zones Z1 thru Z8 are on the main board, others are in groups of 16, starting with Z17. Each 2 zones share a common

negative terminal. A zone may be programming for EOL resistor supervision (Default), or normally closed/normally open

without a resistor. In addition, Burglar and Keyswitch zones may be programmed for EOL with Security Alert on Short, or EOL

with Security Alert on Open/Short, also referred to as a Four (4) State Zone (firmware 4.3.5 or later). If EOL resistors are used,

they should be placed at the furthest most remote end of the detection device wiring. EOL zones permit a combination of

N.C. (normally closed) or N.O. (normally open) devices. Using voltage meter probes across the zone and com terminals, a

non-violated EOL zone will measures approx. 7.0 VDC. An open circuit will be approx. 13.8 VDC. A shorted circuit will be

0 VDC. The Keypad also provides the ability “Menu 8 “System Diagnostics” to view zone voltage.

ELK-M1KP

1

See Note about

Data Bus

Termination

6

BLACK

WHITE

GREEN

RED

Keypad

Wiring

Assembly

Data Bus Cable

CAT5 or CAT6 Recommended

Optional programmable Zone Input from Keypad

Hookup Diagram for Keypad

Splice 6 Pin Keypad Wiring Assembly to the Data Bus cable using ELK-900-2 "B" Connectors.

BROWN

Optional programmable Output from Keypad

Keypad 1

The optional Zone Input # or Output # is

determined by the Keypad Address.

Load (50mA max)

I.E. LED, Relay

-

+

To BLACK (Neg) Wire

To BROW N W i r e

N.C. N. O.

2200

Ohm

EOL

To BLACK (Neg) Wire

BLUE

To B LUE W i r e

NOTE: The first batch of M1KP Keypads provided a switched

negative (pull to ground) output. Connect per diagram above.

These units have the letter "E" at the end of the ID number on the

lower back side of the board. EG: PC096EBoards with a letter

"F" or later provide the output as a switched positive.

Load (50mA max)

i.e. Relay, LED

-

+

To Red (Pos) Wire

To Brown Wire

KP Zone Output

Address # #

1 193 193

2 194 194

3 195 195

4 196 196

5 197 197

6 198 198

7 199 199

8 200 200

KP Zone Output

Address # #

9 201 201

10 202 202

11 203 203

12 204 204

13 205 205

14 206 206

15 207 207

16 208 208

Optional Four (4) State Zone Wiring (2 series resistors w/ N.C. contacts)

Zone

Input

Neg.

N.C. Alarm

Contacts

2200 Ohm

EOL Resistor

2200 Ohm

EOL Resistor

N.C. Tamper

Contacts

Pos.

Neg.

Fig 2: Powered PIR, Glassbreak, etc. with Tamper

N.C. N.O.

Contact

2200

Ohm

EOL

Zone Input

Neg.

Tamper Contact

N.C.

Alarm

Contact

Diagnostic Table

Short ~

2.2k Ohms

4.4k Ohms

Open ~

0 - 3.9 Volts

4.0 - 7.3 Volts

7.4 - 11 Volts

11.1 - 13.8 Volts

Zone

Resistance

Approx. Zone

Voltage Reading

Alarm

-

Alarm

Alarm

Armed

Sec. Alert/Tamper

Ready

Not Ready

Sec. Alert/Tamper

Disarmed

Condition When:

0 - 72

73 - 159

160 - 220

221 - 255

A to D

Value

Fig 1: N.C. Alarm Contact

(Unpowered) with N.C. Tamper

Program Zone for EOL Wiring

Type 4 - Supervisory on Open

This feature

requires Firmware

2.3.5 or later.

2200 Ohm

EOL

Traditional Three (3) State Zone Wiring (1 series resistor)

Wire in Series with zone

input or use another zone.

Neg.

N.C. Alarm

Contacts

2200 Ohm

EOL Resistor

N.C. Tamper

Contacts

Pos.

Neg.

Powered Motion, PIR, Glassbreak, etc.

N.O.

Contact

2200

Ohm

EOL

Zone Input

Neg.

N.C.

Alarm

Contact

Diagostic Table

Short ~

2.2k Ohms

Open ~

0 - 3.9 Volts

4.0 - 8.8 Volts

8.9 - 13.8 Volts

Zone

Resistance

Approx. Range

of Zone Voltage

Alarm

-

Alarm

Armed

Not Ready

Ready

Not Ready

Disarmed

Condition When:

0 - 72

73 - 170

171 - 255

A to D

Value

Zone

Input

Alarm Contact

WWW.DIYALARMFORUM.COM

M1EZ8 Installation and Programming Page 9

[Effective w/Firmware 4.3.6]

Two-Wire Smoke Zones (Zone 8)

To enable the use of two-wire smoke detectors on Zone 8, move Jumper JP1 to the 2 wire smoke position. Go to the installer

programming mode, Menu 05 - Zone Definitions, and program Zone 8 as a Fire zone (Def=10). Program the Wire Type as a 6.

NOTE Use only compatible two-wire detectors as listed on the front label of the control. Do not mix brands. The

maximum number of detectors is also listed on the front label. When jumper JP1 is set for two-wire operation, a 680

Ohm EOL resistor (furnished in the hardware pack) must be used instead of the 2,200 Ohm. Maximum wire resistance

must not exceed 60 Ohms.

Switched Power Connection (+VSMK)

Four-wire smoke detector and other devices that require a temporary power disruption in order to reset or unlatch from the

alarm state (i.e. smoke detectors, etc.) should be connected to the +VSMK 12 Volt DC switched power terminal. When a

smoke reset is performed, the operating voltage to these devices is momentarily interrupted.

Auxiliary Power Connections (+VAUX)

Motion detectors, glass breaks, etc. and other devices requiring unswitched 24-hour power should be connected to one of the

auxiliary terminals, +VAUX. All negative terminals on the terminal strip are at the same reference and may be used whenever

a common (circuit ground) negative is required. Use caution when wiring the control to distribute the load devices among the

supply and the negative terminals evenly. NOTE: Circuit ground refers to any negative terminal connection on this control.

This does not refer to earth ground or to the common terminal of the relay output.. These are not at the same voltage

potential and should not be wired so that they are electrically connected to a negative.

PTC (Positive Temperature Coefficient) Circuit Breakers

The +VAUX Auxiliary power and J16 power output terminals are protected against shorts and overloads by a 1.25A PTC. A PTC

is a solid state, auto-restoring type of circuit breaker. The +VSMK Switched (Smoke) power output is protected by a 1.1A PTC.

The +12VKP Keypad power output is protected by a 1.25A PTC. The alarm output is protected by a 1.25A PTC. NOTE:

Sometimes it may be necessary to remove power (unplug the outputs) for approx. 20 seconds after a short, to allow the

PTC to reset. Even if the short is no longer present, the remaining residual current draw may be so high that the PTC

cannot determine that the short is gone. If the PTC re-trips, check the field wiring and repair.

Transformer Primary Power Input (AC)

The control is powered by a 16.5 VAC, 40 min. VA, UL Listed Class II (power limited) transformer (ELK-TRG1640). The

specified sized and rated transformer must be used to operate this control. The transformer must be connected to a 120 VAC,

24-hour outlet not controlled by a switch other than an approved overcurrent protection device.

Connect the transformer to the AC Terminals using 16 to 18 gauge minimun wire. Do not exceed 50 feet between the

transformer and the control or run the AC power in a multiconductor with other system circuits. Leave the transformer

unplugged as well as the standby battery until all other connections have been made.

Standby Battery Connection

Connect the BLACK wire to the Neg (-) terminal on the battery, the connect the RED wire to the Pos (+) terminal on the battery.

The control is designed to operate with and recharge a 12 volt, sealed lead acid battery from 5Ah up to 18 Ah for backup of the

primary power supply. The control maintains a float charge for the battery of 13.8 VDC at 100 mA. This is in addition to the

continuous output of 1.5 Amps that the power supply maintains (see maximum current drains for UL Listed Systems).

CAUTION: Do not reverse the battery leads! The control has special circuitry which helps protect it from battery reversal

damage for short durations. However, prolonged reversal of the battery leads may cause permanent damage. A reverse

battery warning LED is located to the left of the power On/Off switch. If this light is ON, turn the power off immediately

and correct the battery lead connections.

STATUS

UL Listed Transformer,

Class II, 16.5VAC, 45VA.

i.e ELK-TRG1640

Do not connect to a

switched outlet.

POWER

Sealed Lead Acid Battery

12Volt - 5Ah min. (ELK-1250)

NOTE: See UL requirements for

standby times and battery sizes.

The control is capable of

charging up to an 18Ah battery.

Test battery regularly with

ELK-BLT Battery Life Tester.

Replace every 3-5 years

BATTERY

RED BLK 16V XFMR

AC AC

Status LED:1 blink = Normal Operation.

2 fast blinks = Bootloader mode.

4 fast blinks = Initializing EEPROM memory.

5 fast blinks = Memory/Operation overflow.

Power LED is ON when AC Voltage is present.

12V Battery

WWW.DIYALARMFORUM.COM

M1EZ8 Installation and Programming

Page 10 [Effective w/Firmware 4.3.6]

AC Failure, Low Battery, and Automatic Low Voltage Shutdown

During an AC power failure the battery automatically takes over and AC Fail trouble annunciates at the keypad. The

communicator can be programmed to report AC Fail to the Central Station after a time delay (see Menu 12, System Option 01).

If the battery voltage falls below 11.2 VDC a Low Battery Trouble condition will occur. The communicator can be programmed

to report Low Battery to the Central Station. The battery will continue to run the control until its voltage reaches 10.5 VDC, at

which time the control will disconnect and shut down to prevent a false alarm and damage to the battery. The AC Fail trouble

display will clear if the AC restores. However, the Low Battery Trouble requires a manual or automatic battery load test before

it will clear. An automatic battery load test is performed every 24 hours. See Section 2.2 for powering up the control.

Telephone Line Connection (R1,T1,T,R)

The telephone interface is connected by the use of an approved RJ-31X interconnect jack. This device allows the subscriber

to disconnect the control/communicator from the public switched telephone network in the event of a malfunction. The control

is equipped with line seizure so that the premises telephone service is interrupted during communication to the central

station. Connection to the approved jack is done with a RJSET cord which connects the control terminals to the RJ31X jack.

HELPFUL HINT: The telephone cord can be supervised back to the RJ31X block or Telco demarcation block by installation of

a EOL resistor across the Orange and Blue wires (terminals 2 and 7 on the RJ31X jack). Back inside the control, connect the

Orange and Blue leads from the RJ cord to any 24hr Burglar zone input.

Outputs

There are 12 outputs on the main board. In programming these are numbered Out2, Out3, and Out 7 thru 16. The total

outputs may be expanded utilizing output expander boards connected to the RS-485 4-wire Keypad data bus. The Alarm

Output (Out 2) trips when any alarm is activated. All others must be enabled through the RP Rules Programming and can be

triggered by multiple conditions “events”. Do not exceed the current limits on voltage only outputs.

Output 2 is a traditional Alarm output. It is factory set to produce alarm siren sounds into standard 8 Ohm speakers (never go

below a total connected load of 4 Ohms). It can be alternately programmed to produce voltage only (12VDC) for driving self-

contained sirens or siren driver boards

Output 3 is a Single Pole Double Throw Relay with form “C” contacts (Com, N/O, and N/C).

Outputs 7, 8, 9, 10, 11, 12, 13, 14, 15, and 16 are low current, positive (+) voltage only, for driving LEDs, relays, etc. Outputs 4,

5, and 6 ARE NOT available from the main board. They can only be accessed with a data bus Output expander set to

address 1. This expander will replicate all the main board outputs, including outputs 4, 5, and 6.

Earth Grounding

Tests and studies have determined that the best results against lightning and transients are obtained by isolating the control

from ground. Do NOT connect any of the terminals, especially the Neg. terminals to earth ground. However, ancilliary devices

such as the ELK-950 Surge Protector on the incoming Telephone circuit are still recommended.

Keypad & Expanders on the RS-485 Data Bus (+12VKP, Data A, Data B, Neg)

Keypads and data bus expander devices connect to the four terminals marked +VKP, Data A, Data B, and Neg. The keypad

plug-in wire harness color code is: Red +VKP, Green Data A, White Data B, and Black (-) Neg. The +12VKP power terminal is

protected by an auto reset PTC device. In the event of a short circuit or malfunction, power will be removed from all devices

until the problem is resolved.

Using Output 7 (low current) with a sensitive relay to switch 24V AC to a Door Strike

24V AC

Transformer

+-

Door

Strike

ELK-924

POS

NEG

-T+T

N/OCOMN/C

D3

24V OPEN

N/OCOMN/C

+12V

NEG

16

15

14

13

12

11

10

9

8

7

J16

OUTPUTS

Programmable Outputs (J16) OUT 7 - 16 are +12V switched

positive general purpose outputs rated at 50mA.

+12V Red

Black

White

Green

Brown

Blue

Yellow

Violet

Pink

Tan

Orange

Grey

+VAUX

NEG

OUT 16

OUT 15

OUT 14

OUT 13

OUT 12

OUT 11

OUT 10

OUT 9

OUT 8

OUT 7

WWW.DIYALARMFORUM.COM

M1EZ8 Installation and Programming Page 11

[Effective w/Firmware 4.3.6]

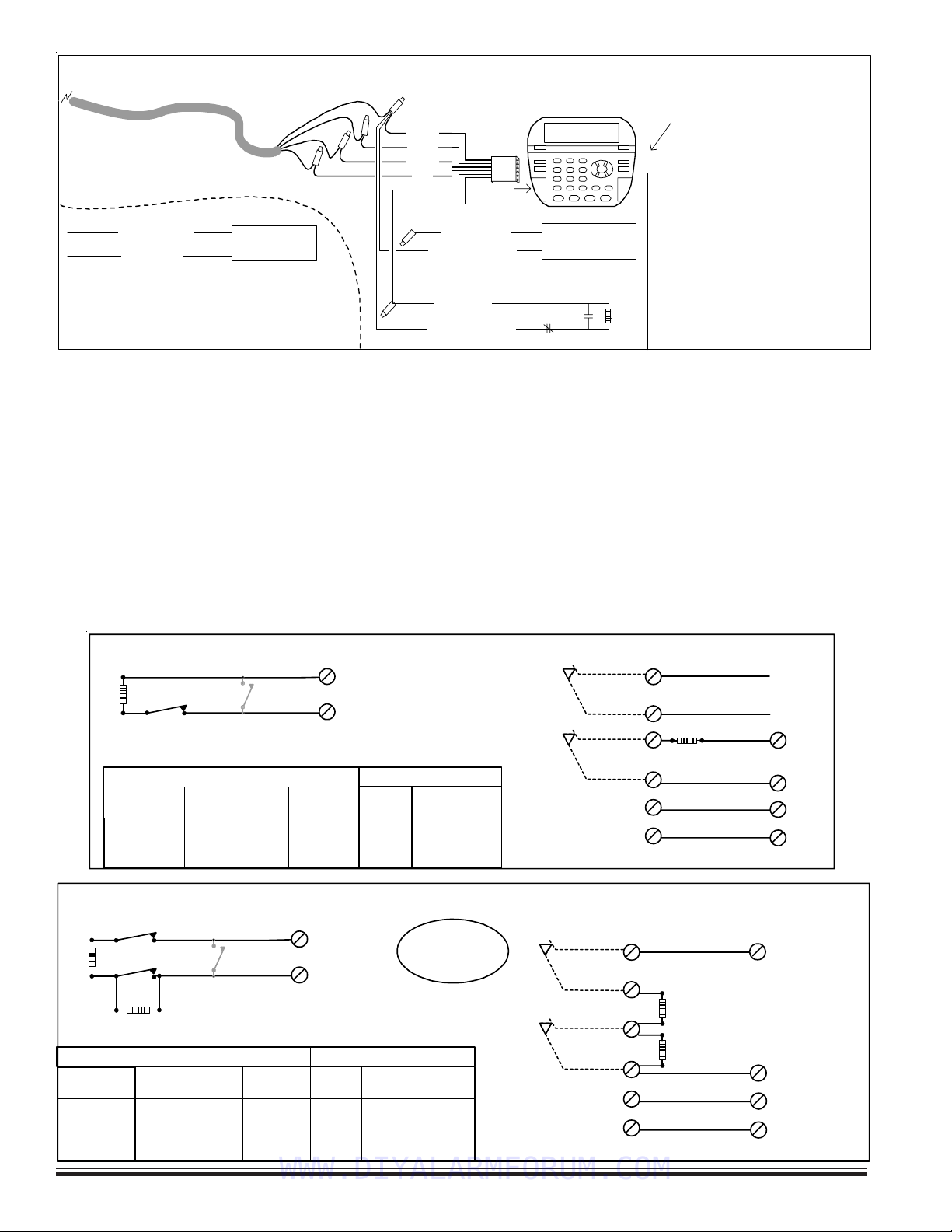

Data Bus E.O.L. Termination - VERY IMPORTANT!

The control features a true RS-485 “differential” data bus operating at 38,400 bits per second. This is relatively high speed by

industry standards and ensures fast, accurate communications. With this speed, EOL data bus terminating resistors are

required to eliminate the possibility of reflection errors caused by varying cable lengths. Every data bus device; keypad, zone

expander, etc. and the control board has a built-in bus terminating resistor (120 Ohm) which is installed (activated) via a 2 pin

header/jumper (2 Gold Pins). The hardware pack includes two black shorting caps. When one of the shorting caps is placed

on the two gold pins, it installs (activates) the 120 Ohm terminating resistor across Data Lines A & B. Terminating resistors

are marked JP2 on the keypads and JP1 on the expanders. From the factory, no terminating resistors are installed (activated).

WARNING! The RS-485 Data Bus must NEVER have more than 2 terminating resistors header/jumpers installed.

Ideally, there should be no more than 2 home run cables (4 wire) with daisy chained devices along each. The last device on each cable

MUST have a terminating resistor installed (activated) via the gold 2 pin header/jumpers marked JP2 on keypads, JP1 on expanders. Place a

black shorting cap (see hardware pack) onto the 2 gold pins to install a 120 Ohm resistor across data lines A & B. If there is only 1 data bus

cable place a shorting cap on JP3 of Main Board. See alternate hookups below.

For those that prefer to home run wires, use 6 or 8 conductor (CAT5 is ideal) cable. At each device, make a three way splice of the data A, the

device A wire (terminal), and a return data A1 wire (using one of the extra wires). At the control, make a two way splice of the data A1 return

wire (series connection) to the outgoing data A wire of the next cable. Repeat for the data B wire. Remember to install a terminating jumper on

the last wired device and the control JP3 ONLY! Electrically the data wires are now in series. Connect the POS (+) and Neg (-) power wires of

each device directly to the M1’s +VKP and Neg terminals. DO NOT SERIES THE POWER WIRES as this will cause unnecessary voltage loss.

The ELK-M1DBH † Data Bus Hub accepts CAT5 or CAT6 cable with RJ45 plugs on the ends and does all the work of series connecting the

DATA lines A & B. Terminate at the hub using the included RJ45 Terminating Plug in the first unused jack.

+VKP

DATA B

DATA A

NEG

EGND

ELK-M1KP

BLACK

WHITE

GREEN

RS-485 Data Bus (Max. length is 4000 ft.

Max. bus devices vary by control.)

RS-485 DATA BUS

RED

ELK-M1XIN

ELK-M1XOV

Jumper

Terminate

these two

devices.

DO NOT Jumper

Terminate these devices.

Keypad 1

ELK-M1KP

Keypad 2

ELK-M1KP

Keypad 3

Daisy Chain Connection of Data Bus Devices Using Two (2) Home Run Cables

Install Teminating Jumper

Cap on this last device

AND on the control JP3.

6conductorcables

+VKP

DATA A

DATA B

NEG

DATA

A1 A

B1 B

DATA

A1 A

B1 B

WHITE

GREEN

BLACK

RED

A

-

+

B

SPARE

PAIR

See Keypad Diagram for connection

of Optional Output and Zone Input

WHITE

GREEN

BLACK (-)

RED +12

BLUE

BROWN

6

Conductor

Cable

Keypad

DATA

A1

B1

For future

devices

A1

B1

Connect each device to the 6

conductor cable as shown.

Diagram for Daisy Chain Connection of Data Bus Devices Using 3 or More Home Run Cables.

NOTE: The power wires are parallel

connected to the +VKP & Neg terminals.

RS-485 DATA BUS

Keypad

Keypad

Keypad

ELK-M1DBH Data Bus Hub †

Mount M1DBH inside control. Connect it to the M1

Data Bus terminals using a 4 conductor cable.

J2 J4 J6 J8

J1 J3 J5 J7 J9

RJ45 Terminating Plug Insert in first unused jack and terminate the

control at JP3. DO NOT TERMINATE AT ANY OF THE DEVICES!

CAT5 Cables

Daisy Chain Connection using the ELK-M1DBH and CAT5 Cables.

RS-485 DATA BUS

8 - Brn/Wht

7 - Wht/Brn

6 - Org/Wht

5 - Wht/Blue

4 - Blue/Wht

3 - Wht/Org

2 - Grn/Wht

1 - Wht/Grn

RED +12V

BLACK (-)

GREEN (A)

WHITE (B)

BROWN

Pin1

RJ45 Plug

A1Grn/Wht

AOrg/Wht

-Wht/Brn

+Brn/Wht

BWht/Org

B1Wht/Grn

Spare

Spare

COLOR CODE for CAT5 or CAT6 Data Bus Cable

to RJ45 Plugs for ELK-M1DBH Data Bus Hub.

Pin1

Front

view

Optional programmable Zone Input from Keypad

Optional programmable Output from Keypad

Load (50mA max)

I.E. LED, Relay

-

+

To BLACK (Neg) Wire

To BROWN Wire

N.C

.

N.O

.

2200

Ohm

EOL

To BLACK (Neg) Wire

To BLUE Wire

BLUE

Keypad

Keypad

CAT5

or

CAT6

Cable

† Not evaluated by UL †† Not for use in UL Listed Installations

WWW.DIYALARMFORUM.COM

M1EZ8 Installation and Programming

Page 12 [Effective w/Firmware 4.3.6]

Setting the Data Bus Address and Enrolling Device(s) into the System

Keypads and expander devices communicate over the RS-485 4-wire data bus. Each device must have a unique address

setting (from 1 to 16) within it's device type. Keypads are TYPE 1, input (zone) expanders TYPE 2, output expanders TYPE 3, etc.

The purpose of device types is so that the address numbers can be re-used in each different device type. It’s OK to have a

Keypad, Zone Expander, and Output Expander all set to address 2 and on the same data bus since each device is a different

device type. It is NOT OK to have duplications of addresses within the same device type. I.E. Multiple keypads on the same

control cannot be set to 'like' addresses.

ADDRESS: From the factory all keypads are set to address 1. Valid addresses are 1 to 16. The first keypad on the system

(Keypad 1) is automatically enrolled upon power up. Each additional keypad must be assigned a unique address and then

manually enrolled from “Menu 1 - Bus Module Enrollment”. (See Menu 01, for complete instructions on Bus Module Enrollment)

1. Press and hold the " * " key, followed by the F5 key . HOLD BOTH keys pressed for 5-10 seconds or until the LCD displays:

Exit when done. F1 Set Addr. (This is Keypad setup mode)

NOTE: An alternate method is to remove power from the keypad and then power up while holding any key pressed.

2. Press the F1 key to display the current address setting.

3. Set the desired address (from 1 to 16) by using the Up or Down arrow keys.

4. Press the Exit key twice when done.

12345678901234567890123456

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

12345678901234567890123456

Auth. Required

Enter Valid Pin

12345678901234567890123456

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

12345678901234567890123456

01-Bus Module

Enrollment

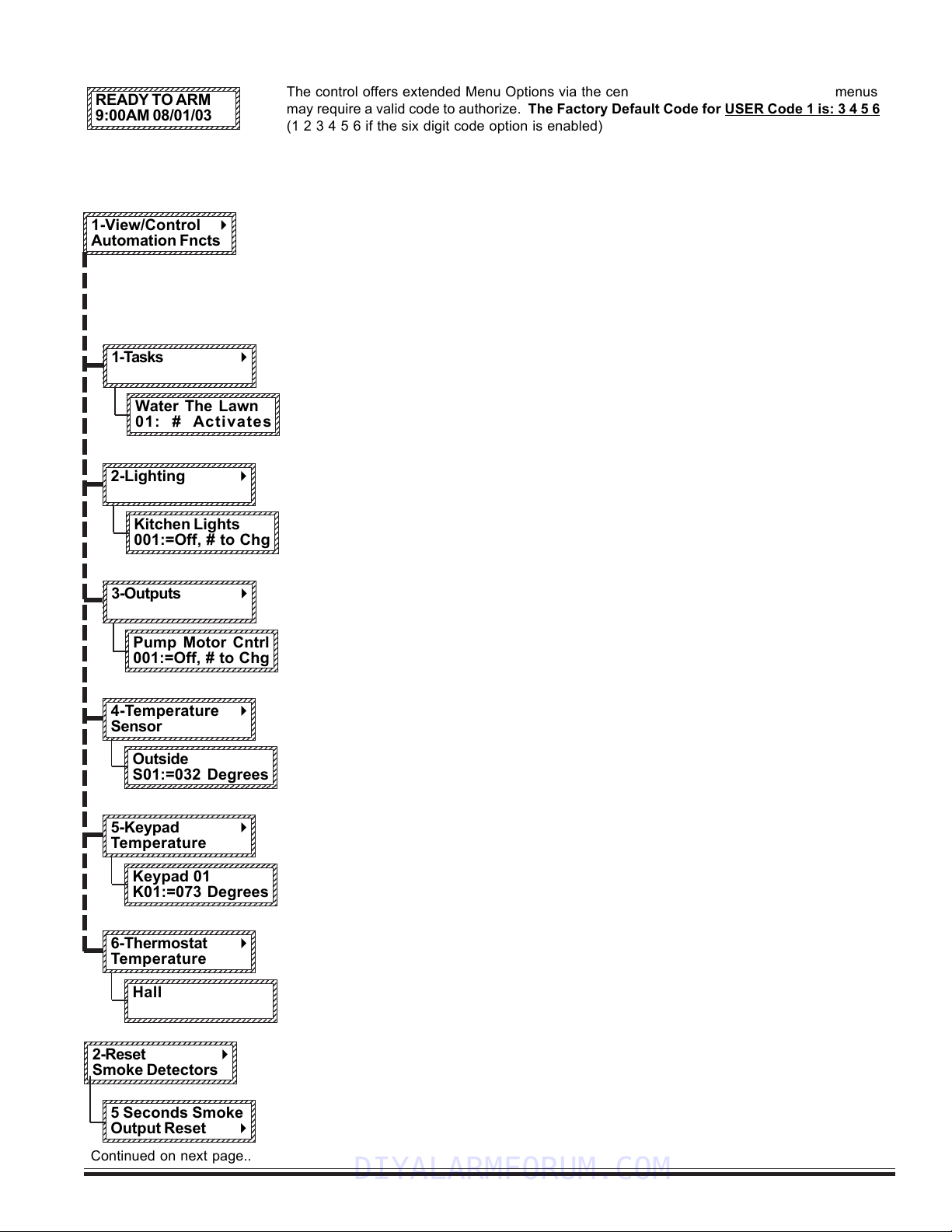

ENROLLING:

1. Press the ELK key, then 9 (or scroll up) to display 9 - Installation Programming. Press the RIGHT

arrow key to select this menu. The Installer Program Code must be entered to access this menu.

2. Enter the Installer Program Code. (The default code is 172839)

3. The first Installer Programming menu displayed will be "Bus Module Enrollment"

4. Press the RIGHT arrow key to select this menu. "Enrolling Bus Modules" will display

5. After a few seconds the display will show the total Bus Modules that are enrolled. To view the

enrolled devices and/or remove a device press the RIGHT arrow key next to the word Edit.

6. Press the * or Exit keys to exit Installer Programming.

12345678901234567890123456

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

12345678901234567890123456

XX Bus Modules

Enrolled, Edit rr

rr

r

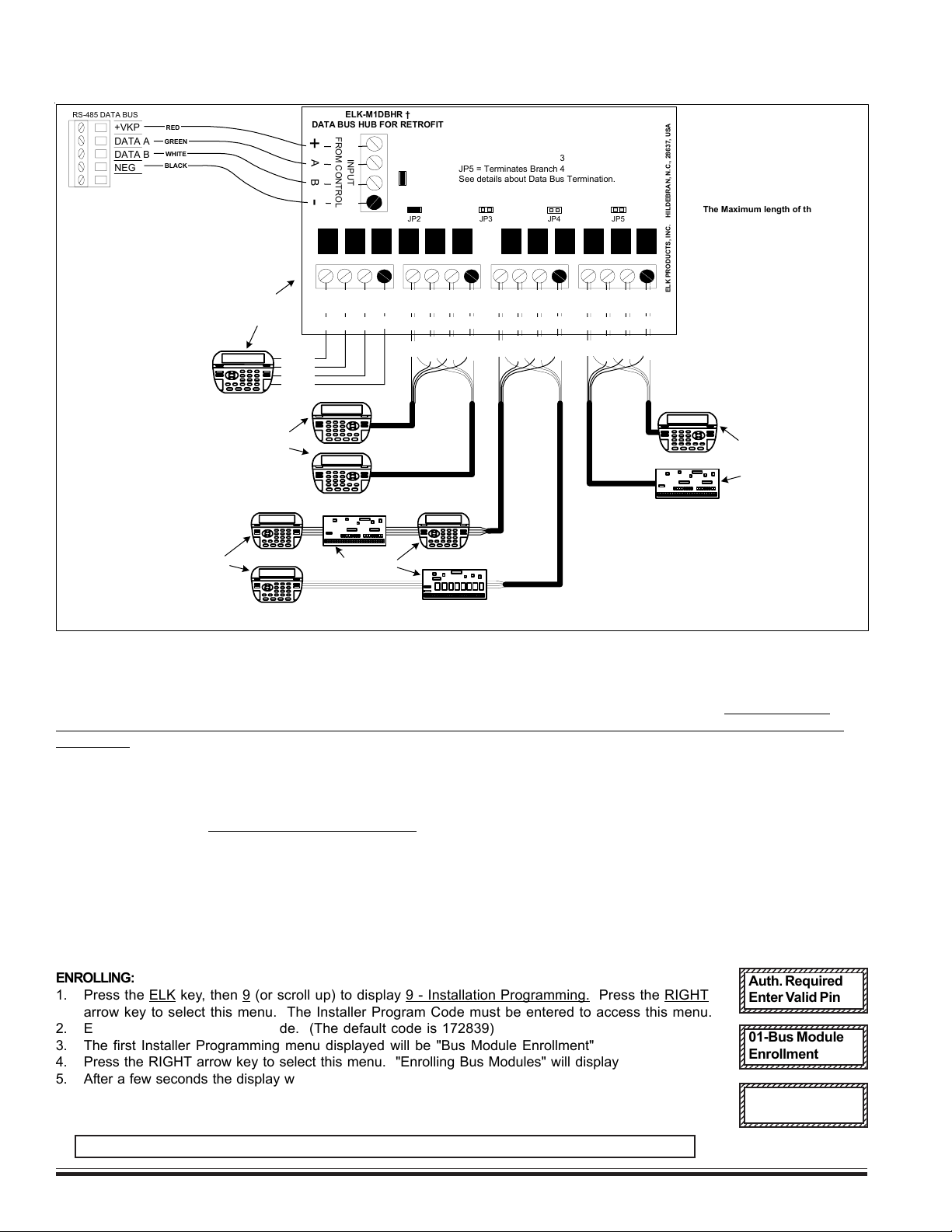

The ELK-M1DBHR † "Active" Data Bus Hub Retrofit splits the Controls' main RS-485 Data Bus into 4 managed RS-485 branches. Each branch

can have 2 parallel home run cables for a total of 8 home runs. The last (end of line) device on each home run should be jumper terminated to

insure proper operation and supervision.

JP1

Terminating Jumpers (JP1 - JP5)

JP1 = Terminates Input from Control

JP2 = Terminates Branch 1

JP3 = Terminates Branch 2

JP4 = Terminates Branch 3

JP5 = Terminates Branch 4

See details about Data Bus Termination.

ELK-M1DBHR †

DATA BUS HUB FOR RETROFIT

ELK PRODUCTS, INC. HILDEBRAN, N.C., 28637, USA

JP2 JP3 JP4 JP5

+VKP

DATA B

DATA A

NEG

RS-485 DATA BUS

BLACK

RED

GREEN

WHITE

AB-

+

INPUT

FROM CONTROL

The Maximum length of the

RS-485 Data Bus or any single

Branch is 4000 ft.

Max. devices varies by product.

+VKP protected with 1.25A PTC

Mount M1DBHR inside control.

Connect it to the Data Bus terminals

using a 4 conductor cable.

RED

GREEN

WHITE

BLACK

A

+B-

DATA BUS

BRANCH 1

RED

GREEN

WHITE

BLACK

Keypad

A

+B-

DATA BUS

BRANCH 2

Keypad

RED

GREEN

WHITE

BLACK

Keypad

Single Keypad /Bus Device:

If only one (1) Keypad or Bus Device

is connected to a branch (# 1 in this

example), place terminating jumper

on the Keypad/Bus Device AND on

JP2 of the M1DBHR.

Two Keypad /Bus Devices:

If two (2) Keypad/Bus Devices are connected to

a branch (#2 in this example), place terminating

jumper on both Keypads/Device and REMOVE

jumper JP3 on the M1DBHR.

Multiple Keypads/Bus Devices

(Series Connected):

If more than two (2) Keypad/Bus

Devices are connected to a

branch (#3 in this example), they

MUST be series connected on no

more than 2 homerun wires.

Place terminating jumpers on

LAST device connected to each

homerun. REMOVE jumper JP4

on the M1DBHR.

ELK-M1XIN

ELK-M1XOV

Jumper

Terminate

these two

devices.

DO NOT Jumper Terminate

these devices.

ELK-M1KP

Keypad

KeypadKeypad

RED

GREEN

WHITE

BLACK

A

+B-

DATA BUS

BRANCH 3

A

+B-

DATA BUS

BRANCH 4

ELK-M1XIN

Jumper

Terminate

these two

devices.

One Keypad and one

Zone Expander:

When two (2) Bus

Devices are connected

to a branch (#4 in this

example), place

terminating jumper on

both Bus Devices and

REMOVE jumper JP3

on the M1DBHR.

Jumper

Terminate

these two

devices.

Keypad

JumperTerminate

this device AND JP2

on the M1DBHR.

DO NOT Jumper JP3. DO NOT

Jumper JP5

DO NOT Jumper JP4.

This diagram illustrates the M1DBHR Hub as a single

branch on a Control. Terminate JP3 on Control and JP1

on the M1DBHR. If a second hub is wired to the Control

terminate JP1 on the hubs but DO NOT terminate JP3 on

Control. NEVER place more than two (2) terminating

jumpers on any branch of the RS-485 Data Bus!

Diagram for Home run wiring using M1DBHR Active Data Bus Hub

† Not evaluated by UL †† Not for use in UL Listed Installations

WWW.DIYALARMFORUM.COM

M1EZ8 Installation and Programming Page 13

[Effective w/Firmware 4.3.6]

2.1 Introduction

For best operation during bench testing, all zones should be terminated with end of line resistors and the correct transformer

and battery should be connected to the unit. The control comes with factory default programming, allowing it to be bench

tested prior to installation. The factory default code for user 1 is 3456. This code is authorized to operate all user related

features of the system. The control is designed to accommodate the grouping of specific zones into partitions called areas

and by default, all zones are assigned to area #1. This is the most common mode in which the system operates. This section

of the manual gives an overview of powering up and basic keypad functioning.

2.2 Powering Up (One Keypad)

After all other connections have been made and checked thoroughly, the controls AC transformer and battery may be

connected. Upon power up the control will perform self-diagnostics and auto-enroll the first keypad (Keypad Address #1). Any

additional keypads or expanders must be manually enrolled using Installer Level Programming. See “Menu 01 - Bus Module

Enrollment”.

NOTE: It is very important to make certain that every keypad, input expander, output expander, or any other data bus

device be assigned a unique data bus address within its type. See “MENU 01 - Bus Module Enrollment” for instructions

on setting keypad and expander addresses.

2.3 User Codes and Authorities

The control has 99 user passcodes plus one installer passcode. Each user code may be assigned specific authorities as to

what it is allowed to do. The authorities are assigned from the Installer level programming, however the code numbers and

user name is assigned from the keypad user menu 6 - Change User Codes. Only a Master authority level code or the

Installer code is allowed to access keypad user menu 6. The User’s Guide contains a description of panel

operations accessible to the user codes. Control operations accessed by the installer passcode are slightly different.

The Factory Default Code for User Code 1 is: 3 4 5 6 (Master Code)

(If the six digit code option is enabled, User Code 1 default will then be: 1 2 3 4 5 6)

The user code may be used for functions in a specific area or system-wide. Some options may be performed at any time,

even while the control is fully or partially armed. The menu system is designed to be next-step-oriented. After a brief

explanation of the options, the user should be able to begin operating the system immediately. For purposes of discussion,

the installer and the end consumer are both considered users, but have different capabilities.

2.4 Installer Program Code and Authorities

The installer code can access all the keypad user menus, including of course menu 9 - Installation Programming. The

Installer code also has limited arm/disarm privileges. It may be used to arm any area and may be used to disarm any area,

so long as that area was armed specifically by the installer code. The Installer code cannot disarm if an area was armed by

any user code. The Installer code may be used to silence 24hr alarms or a Burglary alarm in an area that was armed by the

installer or in an area that is not armed. The installer code may also be used to silence a trouble condition in a disarmed

area. See User’s Guide for a full description of arming and disarming procedures.

The Factory Default Installer Program Code is: 1 7 2 8 3 9

Section 2 - Operating the System

WWW.DIYALARMFORUM.COM

M1EZ8 Installation and Programming

Page 14 [Effective w/Firmware 4.3.6]

Ready Light - This light is ON when all burglar zones are secure and the system is OK for arming. If this light is OFF, one or more zones are

violated (not secure). For maximum security, all zones should be secured before the system is armed.

If FLASHING, one or more force-armable zones are violated. Force arming temporarily excludes violated zone(s) from the system. However, if

a force armed zone becomes secure while the system is armed, it will automatically restore to service. This is handy for a garage door. The

system may be armed with the door up, but once the car is backed out and the door is closed, it will become secured.

Armed Light- This light will be ON when the system is armed. The mode of arm will be indicated by the LCD display and the Exit or Stay

lighted pushbuttons. This light will be OFF when the system is disarmed.

Exit Key - This lighted key may be programmed for single or double press arming to the AWAY (not occupied) mode. If the Exit light is ON the

system is armed and all perimeter sensors and interior motions are active. The Away key may be pressed during the exit delay time t to

convert from Away mode to Away Vacation mode. The Away Vacation mode is primarily for use with the Whenever/And/Then Rules program-

ming of Elk-RP to invoke long term energy savings.

Stay Key - This lighted key may be programmed for single or double press arming to the STAY (occupied) mode. If the Stay light is ON the

system is armed and all interior zones are excluded (bypassed). Only perimeter doors and windows are active in the Stay mode. This key

may also be programmed to change to other Stay modes such as: Stay Instant, Stay Night, and Stay Night Instant. Since interior zones are

automatically excluded once the Stay mode is activated, the M1 allows this key to Stay arm even while one or more interior zones are

violated, provided they are programmed for “force arming”. The Stay Night mode re-activates any interior night zones. To prevent a false

alarm the control will not allow change to the Stay Night mode when a interior night zone is violated unless it is programmed for “Force arm”.

Chime Key - Chime produces an audible tone alert whenever certain doors, windows, or other selected zones are violated. There are two

selections: Tone only and Off. Whenever Chime in On the Chime key will be illuminated. In the programming mode the Chime key also

functions as an insert character key for text programming.

Bypass Key - Pressing this key followed by a zone number and the bypass key again will exclude or bypass the selected zone. This

key may also be used to delete a character during text programming. When the Bypass key is lit, one or more zones are bypassed.

* Key - This key serves as a clear or reset key. If an error is made while entering digits, pressing this key clears the error. Three presses is

a master clear.

# Key - This key is currently a duplicate of the Bypass key.

Numerical Keys - These keys are used for entry of passcodes, programming, etc. Keys 2 - 9 also have an assigned alpha character

which are used for entering text.

Arrow Keys - The ELK and arrow keys have powerful functionality used for both normal operation and programming. Pressing the ELK

key displays relative information according to each application. The arrow keys allow scrolling through all available options. The user can

activate or select the displayed option by pressing the right arrow key. Once an option has been selected, the user may be prompted for

a passcode. Additional sub-menu options may appear to assist. The user may return to the status screen by pressing the * key.

2.5 Keypad Overview

WWW.DIYALARMFORUM.COM

M1EZ8 Installation and Programming Page 15

[Effective w/Firmware 4.3.6]

Access to menus 1 to 5 can be restricted via programming to only Users that have “User Code Option 8” set. Menus 6, 7, and

8 required a Master or Installer Code. Menu 9 requires the Installer Code. Press ELK to begin, then press the UP or DOWN

arrow key to select a menu. Enter a code if prompted. To select a menu press the RIGHT arrow key.

Keypad Menus

Allows viewing or controlling of the automation functions such as Tasks, Lighting, Outputs,

Temperature Sensor, Keypad Temperature, and Thermostats. Press the RIGHT arrow key to

select, then choose the desired function using the UP or DOWN arrow keys.

NOTE: The automation functions must be assigned and named using the ELK-RP software.

In most cases they cannot do anything unless they have been written into one of the

“Whenever/And/Then” automation rules.

Tasks are like 1 button macros, performing multiple jobs with one push. To activate a task

press the RIGHT arrow key and press UP or DOWN to scroll through the list of available tasks.

To jump directly to a particular task, enter it’s two digit number. Once the task is displayed, all

it takes to activate it is to press the # key. A rule to use the “Water the Lawn” task might be:

WHENEVER “Water the Lawn” IS ACTIVATED THEN TURN ON Valve 19 FOR 5 MINUTES, etc.

Lighting allows the individual control of lights and/or appliances which have been assigned

through the ELK-RP software. Press the RIGHT arrow key to select Lighting, then press the

UP or DOWN arrow keys to scroll through the list. If you know the three digit number, you may

enter it to jump directly to that Lighting/Appliance. The current state of the unit will be

displayed. Press the # key to toggle (change) the unit from on > off or from off > on.

Outputs might be relays or voltages used to actuate something like a motor, fan, pump, etc.

Outputs can be turned on or turned off from this menu. Press the RIGHT arrow key to select

Outputs, then press the UP or DOWN arrow keys to scroll through the list. If you know the

three digit number, you may enter it to jump directly to that Output. The current state of the

output will display. Press the # key to toggle (change) the output from on > off or from off > on.

Remote “Zone” Temperature Sensors can be read from this menu. Press the RIGHT arrow

key to select this menu, then press the UP or DOWN arrow keys to scroll through the list of

available sensors. To jump directly to a particular sensor enter it’s two digit number. The

current temperature will be displayed. Press the * key to exit.

Keypad Temperature Sensors can be read from this menu. Press the RIGHT arrow key to

select this menu, then press the UP or DOWN arrow keys to scroll through the list of available

keypads. To jump directly to a particular keypad enter it’s two digit number. The current

temperature at the keypad will be displayed. Press the * key to exit.

Thermostats can be read from this menu. Press the RIGHT arrow key to select this menu,

then press the UP or DOWN arrow keys to scroll through the list of available thermostats. To

jump directly to a particular thermostat enter it’s two digit number. The current temperature at

the thermostat will be displayed. Press the * key to exit.

Used for resetting latched smoke detectors after a fire alarm activation..

Press the RIGHT arrow key to actuate the Reset Smoke Detector feature. This causes the

power to smoke detectors to be removed for 5 seconds. During this time all fire zones will be

ignored to keep an accidental alarm from occurring.

1234567890123456789012345678901

1

23456789012345678901234567890

1

1

23456789012345678901234567890

1

1

23456789012345678901234567890

1

1

23456789012345678901234567890

1

1

23456789012345678901234567890

1

1

23456789012345678901234567890

1

1

23456789012345678901234567890

1

1

23456789012345678901234567890

1

1234567890123456789012345678901

1-View/Control r

Automation Fncts

123456789012345678901234567890

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

123456789012345678901234567890

2-Reset r

Smoke Detectors

123456789012345678901234567890

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

123456789012345678901234567890

READY TO ARM

9:00AM 08/01/03

Continued on next page..

123456789012345678901234567890

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

123456789012345678901234567890

3-Outputs r

1234567890123456789012345678901

1

23456789012345678901234567890

1

1

23456789012345678901234567890

1

1

23456789012345678901234567890

1

1

23456789012345678901234567890

1

1

23456789012345678901234567890

1

1

23456789012345678901234567890

1

1

23456789012345678901234567890

1

1234567890123456789012345678901

Pump Motor Cntrl

001:=Off, # to Chg

123456789012345678901234567890

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

123456789012345678901234567890

2-Lighting r

123456789012345678901234567890

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

123456789012345678901234567890

1-Tasks r

123456789012345678901234567890

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

123456789012345678901234567890

Water The Lawn

01: # Activates

123456789012345678901234567890

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

123456789012345678901234567890

Kitchen Lights

001:=Off, # to Chg

123456789012345678901234567890

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

123456789012345678901234567890

5 Seconds Smoke

Output Reset r

The control offers extended Menu Options via the center navigation “ELK” key. Some menus

may require a valid code to authorize. The Factory Default Code for USER Code 1 is: 3 4 5 6

(1 2 3 4 5 6 if the six digit code option is enabled)

123456789012345678901234567890

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

123456789012345678901234567890

4-Temperature r

Sensor

1234567890123456789012345678901

1

23456789012345678901234567890

1

1

23456789012345678901234567890

1

1

23456789012345678901234567890

1

1

23456789012345678901234567890

1

1

23456789012345678901234567890

1

1

23456789012345678901234567890

1

1

23456789012345678901234567890

1

1234567890123456789012345678901

Outside

S01:=032 Degrees

123456789012345678901234567890

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

123456789012345678901234567890

5-Keypad r

Temperature

1234567890123456789012345678901

1

23456789012345678901234567890

1

1

23456789012345678901234567890

1

1

23456789012345678901234567890

1

1

23456789012345678901234567890

1

1

23456789012345678901234567890

1

1

23456789012345678901234567890

1

1

23456789012345678901234567890

1

1234567890123456789012345678901

Keypad 01

K01:=073 Degrees

123456789012345678901234567890

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

123456789012345678901234567890

6-Thermostat r

Temperature

1234567890123456789012345678901

1

23456789012345678901234567890

1

1

23456789012345678901234567890

1

1

23456789012345678901234567890

1

1

23456789012345678901234567890

1

1

23456789012345678901234567890

1

1

23456789012345678901234567890

1

1

23456789012345678901234567890

1

1234567890123456789012345678901

Hallway

T01:=072 Degrees

WWW.DIYALARMFORUM.COM

M1EZ8 Installation and Programming

Page 16 [Effective w/Firmware 4.3.6]

123456789012345678901234567890

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

123456789012345678901234567890

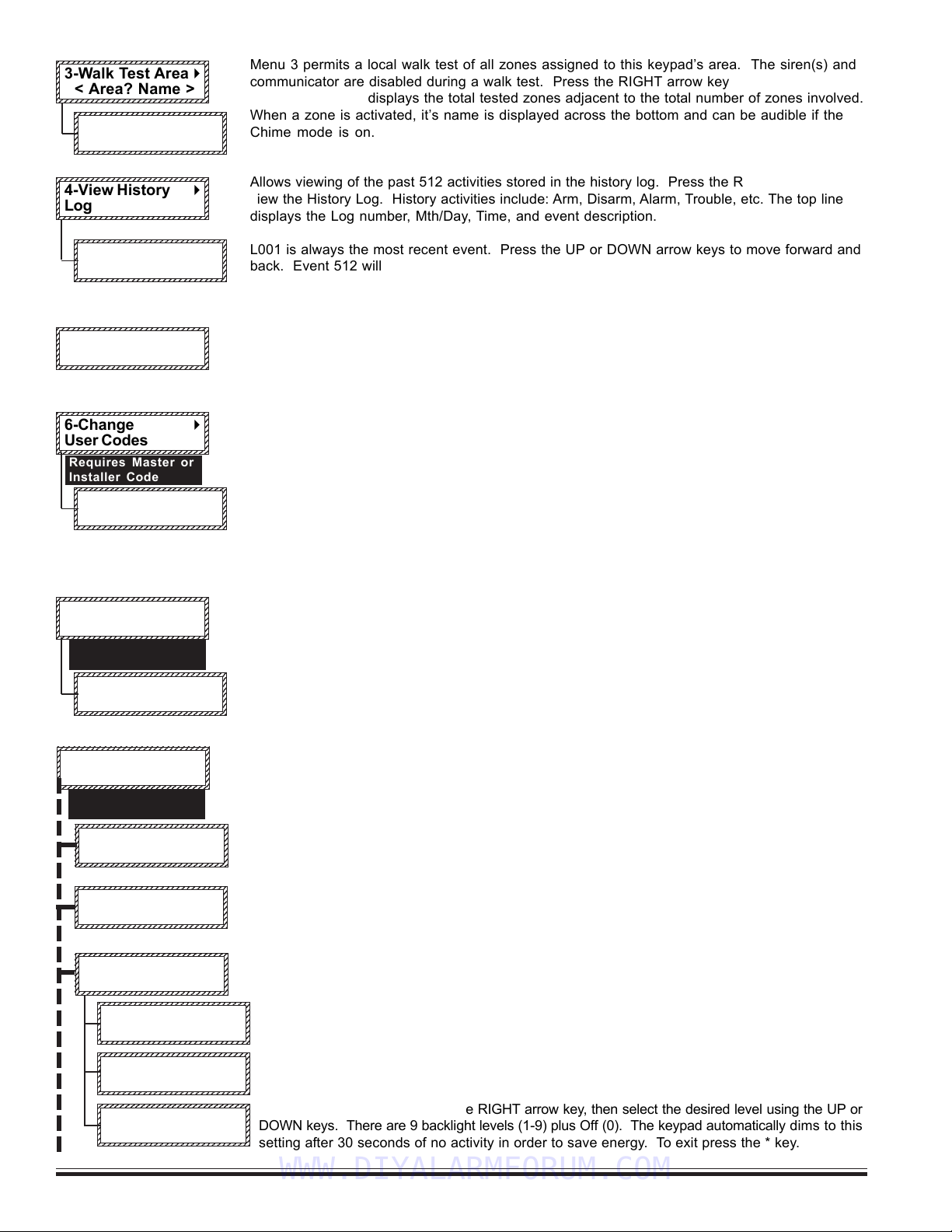

3-Walk Test Area r

< Area? Name >

123456789012345678901234567890

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

123456789012345678901234567890

4-View History r

Log

123456789012345678901234567890

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

1

2345678901234567890123456789

0

123456789012345678901234567890

6-Change r

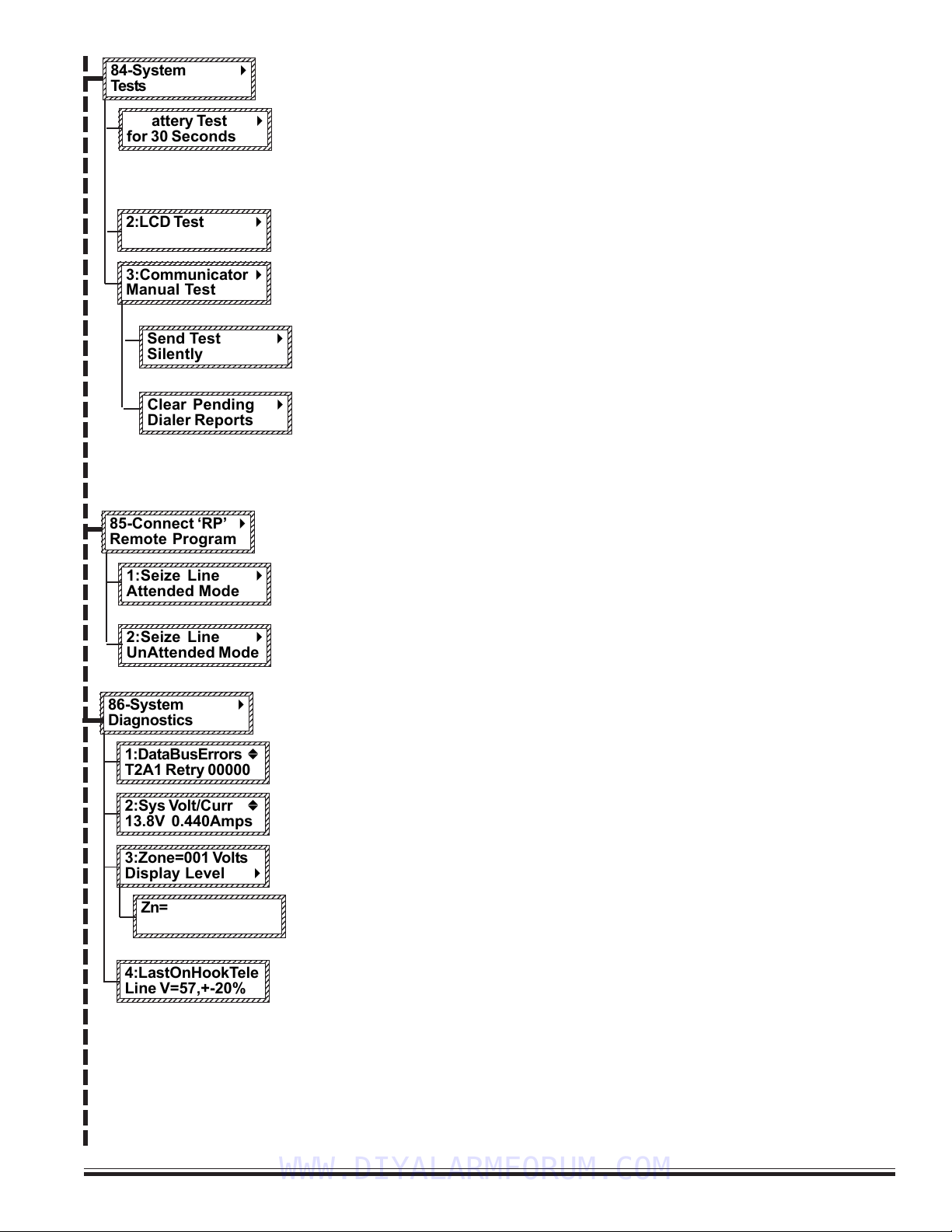

User Codes