Page 2

EZWSR*1D, *2D LZWSR*1D, *2D

1000004729 (Rev. C - 08/21)

WATER COOLER PREPARATION

1. Remove lower front panel of watercooler by removing the four (4) screws from the bottom

of cooler. (See Fig. 1) NOTE: For Bi-Level Models the Bottle Filling Unit can be mounted

to the higher or lower unit. Both lower front panels and basin assemblies will need to be

removed.

1a. For units with model no’s. ending with 1, 1A, 2 or 3 these units will need to be

removed from the wall in order to remove the basin assembly(s).

2. Power OFF circuit that the water cooler is connected to by switching the circuit

breaker to the “OFF” position or by removing the fuse to the circuit. Remove the

water cooler plug from the outlet and shut o water supply.

3. Remove Basin Assembly by loosening four (4) screws two on each side of cooler as

shown in Fig. 8. Disconnect water line “A” from bubbler at the evaporator tank (See Fig.

6). NOTE: When disconnecting water lines use a container to catch any water running

out of the lines. Disconnect basin assembly from drain trap. Lift basin assembly straight

up to remove, and disconnect two wires from push bar switches. (Note: This will allow

easier assembly of water lter to unit and pressurization of the unit.)

4. For units referenced in step “1a”. Remove Basin Assembly by loosening four (4) screws

two on each side of cooler as shown in Fig. 8. Remove 2 screws from top back of unit to

remove the “L” bracket. Remove 1 screw from left side of cross brace in front of unit that

retains the drain support. Disconnect water line “A” from regulator at the evaporator tank

(See Fig. 6B). NOTE: When disconnecting water lines use a container to catch any water

running out of the lines. Disconnect basin assembly from drain trap. Lift basin assembly

straight up to remove, and disconnect two wires from push bar switches. (Note: This will

allow easier assembly of water lter to unit and pressurization of the unit.)

EWF3000 WATERSENTRY PLUS FILTER INSTALLATION

NOTICE: Do not use with water that is microbiologically unsafe or of unknown quality

without adequate disinfection before or after the system.

1. These lter kits must be installed in compliance with all state and local laws and

regulations governing the installation and use of this product. Maximum inlet water

temperature 100°F (38°C).

2. See lter instructions for lter assembly. Insert 3/8” elbow tting into the inlet side of

lter head, insert 1/4” poly tube or 1/4” x 90° elbow into outlet side of lter head prior to

mounting the lter head assembly into the cooler.

3. Mount lter head as shown in Fig. 9, using the lter mounting bracket and screws

supplied. For Bi-Level units the lter must be mounted to the L.H. non-refrigerated unit at

the same location as shown in Fig. 9.

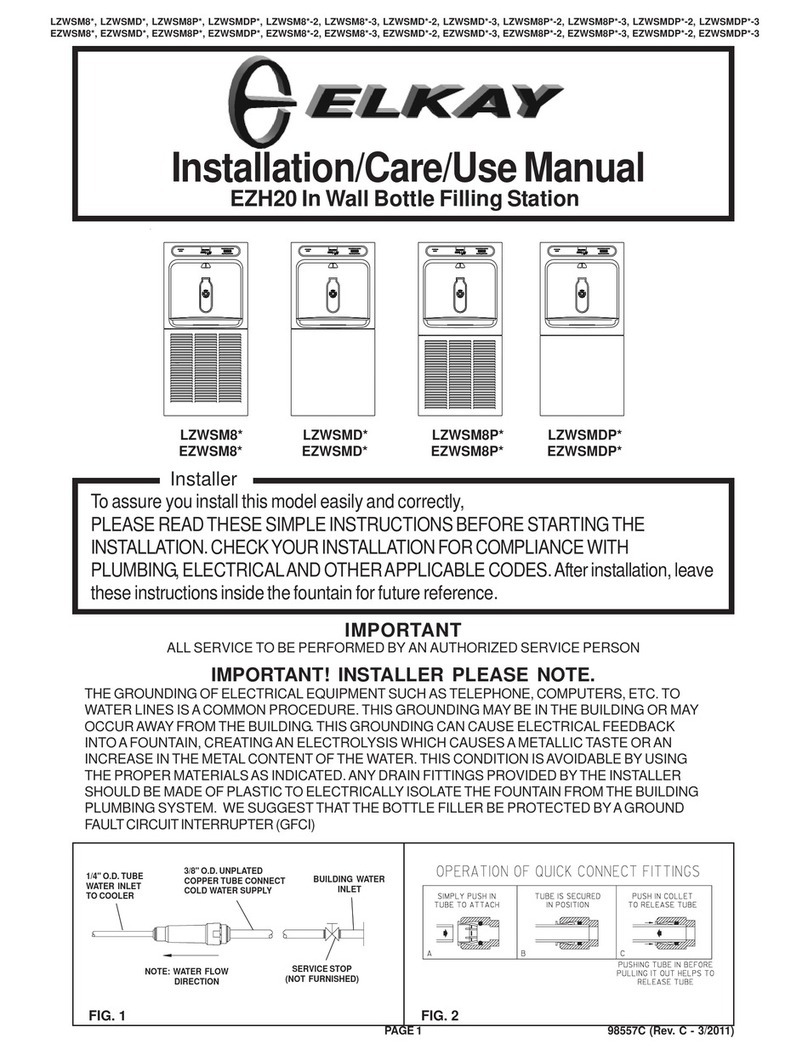

Fig. 1

LOWER COVER SCREWS

PRESSURIZATION OF WATER SYSTEM

NOTE: This procedure MUST be performed on ALL SINGLE EZ WATER COOLERS or the bottle lling unit WILL NOT perform properly!

1. Remove water inlet (B) and outlet (C) from solenoid valve (See Fig. 6 or 6B). NOTE: When disconnecting water lines use a container to catch

any water running out of the lines.

2. CAUTION: If supply pressure will ever exceed 100 psi, install a pressure regulator to limit the inlet pressure to the lter to 100 psi or

below. DO NOT ATTACH HOT WATER LINE TO FILTER. To make connections on the lter head, loosen locknut. Push the tube end past both

o-rings to a positive stop in the lter head recess - approx. 1”, locknut may have to be backed out a little more. Screw the locknut hand tight to

seal (See Fig. 10). Ends of tubing must be cut square and free of burrs and sharp ends that could cut or nick the o-rings.

3. Connect the outlet of the lter to the inlet of the evaporator using the 1/4” O.D. poly tubing and 1/4” union supplied (See Fig. 7 or 7B).

4. Cut a 12” long piece of poly tube (be sure to insulate poly tube with supplied insulation tubing) and insert one end into the outlet side of the

evaporator “D” (See Fig. 7 or 7B), connect Tee to other end of tube.

5. Cut a 12” long piece of poly tube (be sure to insulate poly tube with supplied insulation tubing) and insert into the Tee and the other end into the

inlet side of the solenoid valve “E” (See g. 7 or 7B).

Bi-Level MODIFICATION OF WATER SYSTEM

NOTE: Bi-Level water systems are already plumbed for pressurization.

STANDARD Bi-Level MODELS

Follow instruction 2 thru 4 under “Pressurization of water system” to attach lter to water system. The non-refrigerated side must be removed from the wall

in order to remove the basin assy. and install the lter head assy.

1. Remove the Bi-Level Cover Plate from the right hand side of the non-refrigerated unit in order to access the rear Basin Assy. screw.

2. Cut poly tube “H” between the existing tee and the solenoid valve of the L.H. unit (See Fig. 6A or 6C).

3. Insert supplied Tee in water line “H” where it was just cut (See Fig. 7A or 7C).

Bi-Level Versatile MODELS

Follow instruction 2 thru 4 under “Pressurization of water system” to attach lter to water system. The non refrigerated side must be removed from the wall

in order to remove the basin assy. and install the lter head assy.

1. Remove the Bi-Level Cover Plate from the left hand side of the refrigerated unit in order to access the rear Basin Assy. screw (See Fig 8).

2. Cut poly tube “H” approximately 3” from the left side of the existing tee.

3. Insert supplied tee in water line “H” where it was just cut.