Ellard CITY1-EVO User manual

ENGLISH

- 15 -

INDEX

1 - IMPORTANT REMARKS .........................................................................................................................................

2 - DISPOSAL...............................................................................................................................................................

3 - EU DECLARATION OF CONFORMITY....................................................................................................................

4 - TECHNICAL SPECIFICATIONS ................................................................................................................................

5 - DESCRIPTION OF THE CONTROL UNIT .................................................................................................................

5.1 - ELECTRIC CONNECTIONS ................................................................................................................................

5.2 - PLUG IN RECEIVER..........................................................................................................................................

6 - CONTROL PANEL ..................................................................................................................................................

6.1 - USE OF DOWN MENU AND UP KEYS FOR PROGRAMMING ............................................................................

7 - QUICK CONFIGURATION......................................................................................................................................

8 - LOADING DEFAULT PARAMETERS.......................................................................................................................

9 - SELF-LEARNING OF WORKING TIMES.................................................................................................................

10 - EMERGENCY DEAD MAN OPERATION..............................................................................................................

11 - PROGRAMMING THE CONTROL UNIT...............................................................................................................

12 - OPERATION DEFECTS .........................................................................................................................................

mATTENTION

THIS QUICK GUIDE IS ONLY USED TO START THE AUTOMATION IN ITS

BASIC CONFIGURATION. THE FULL MANUAL IS AVAILABLE ON THE V2

WEBSITE (www.v2home.com)

16

16

16

17

17

18

18

20

20

21

21

21

23

23

28

ENGLISH

- 16 -

1 - IMPORTANT REMARKS

For any installation problem please contact our Customer Service

at the number +39-0172.812411 operating Monday to Friday

from 8:30 to 12:30 and from 14:00 to 18:00.

V2 has the right to modify the product without previous

notice; it also declines any responsibility to damage or

injury to people or things caused by improper use or wrong

installation.

mPlease read this instruction manual very carefully

before installing and programming your control unit.

• This instruction manual is only for qualified technicians, who

specialize in installations and automations.

• The contents of this instruction manual do not concern the end

user.

• Every programming and/or every maintenance service should

be done only by qualified technicians.

AUTOMATION MUST BE IMPLEMENTED IN COMPLIANCE

WITH THE EUROPEAN REGULATIONS IN FORCE:

EN 60204-1 (Machinery safety. electrical equipment of

machines, part 1: general rules)

EN 12445 (Safe use of automated locking devices,

test methods)

EN 12453 (Safe use of automated locking devices,

requirements)

• The installer must provide for a device (es. magnetotermical

switch) ensuring the omnipolar sectioning of the equipment

from the power supply. The standards require a separation of

the contacts of at least 3 mm in each pole (EN 60335-1).

• After making connections on the terminal board, use one

hose clamp to fix dangerous voltage wires near the terminal

board and another hose clamp to fix safety low voltage wires

used for accessories connection; this way, in case of accidental

detachment of a conducting wire, dangerous voltage parts will

not come into contact with safety low voltage ones.

• The plastic case has an IP55 insulation; to connect flexible or

rigid pipes, use pipefittings having the same insulation level.

• Installation requires mechanical and electrical skills, therefore it

shall be carried out by qualified personnel only, who can issue

the Compliance Certificate concerning the whole installation

(EEC Machine Directive 89/392, Annex IIA).

• The automated vehicular gates shall comply with the following

rules: EN 12453, EN 12445, EN 12978 as well as any local rule

in force.

• Also the automation upstream electric system shall comply with

the laws and rules in force and be carried out workmanlike.

• The door thrust force adjustment shall be measured by means

of a proper tool and adjusted according to the max. limits,

which EN 12453 allows.

• We recommend to make use of an emergency button, to be

installed by the automation (connected to the control unit

STOP input) so that the gate may be immediately stopped in

case of danger.

• Always remember to connect the earth according to current

standards (EN 60335-1, EN 60204-1).

2 - DISPOSAL

As for the installation operations, even at the end of this product’s

life span, the dismantling operations must be carried out by

qualified experts.

This product is made up of various types of materials: some can

be recycled while others need to be disposed of.

Find out about the recycling or disposal systems envisaged by your

local regulations for this product category.

Important! – Parts of the product could contain pollutants or

hazardous substances which, if released into the environment,

could cause harmful effects to the environment itself as well as to

human health.

As indicated by the symbol opposite, throwing away this product

as domestic waste is strictly forbidden. So dispose of it as

differentiated waste, in accordance with your local regulations,

or return the product to the retailer when you purchase a new

equivalent product.

Important! – the local applicable regulations may envisage heavy

sanctions in the event of illegal disposal of this product.

3 - EU DECLARATION OF CONFORMITY

V2 S.p.A. hereby declare that CITY1-EVO products conform to the

essential requirements established in the following directives:

• 2014/30/UE (EMC Directive)

• 2014/35/UE (Low Voltage Directive)

• ROHS2 2011/65/CE

Racconigi, 01/06/2015

V2 S.p.A. legal representative.

Giuseppe Pezzetto

ENGLISH

- 17 -

4 - TECHNICAL SPECIFICATIONS 5 - DESCRIPTION OF THE CONTROL

UNIT

The digital control unit CITY1-EVO is an innovative V2 product

that guarantees a safe and reliable automation of leaf swing or

sliding gates.

CITY1-EVO is provided with a display that, not only makes

programming simple, but also allows a continuous monitoring of

the input statuses; in addition, thanks to a menu structure, the

working schedule and the operation logic can be set easily.

In compliance with the European standards concerning electrical

safety and electromagnetic compatibility (EN 60335-1,

EN 50081-1 and EN 50082-1) it has been equipped with the low

voltage circuit total electric insulation (motors included) from the

network voltage.

Other characteristics:

• Automatic control for the null current relay switch

• Allows to control ENCODER-equipped 230V motors

• Power adjustment with independent wave shutting on both

the two motors

• Obstacle detection by means of monitoring start condenser

voltage

• Automatic learning of the operation time

• Operation by means of mechanical ends of stroke connected to

the gearcase or connected in series to the motor

• Tests for safety devices (photocells, safety edges and triacs)

before each opening (as required by the referred regulations)

• Deactivation of safety inputs through the configuration menu:

no jumper is required for terminals concerning safety devices

that have not been installed, yet. You will only need to disable

this function from its relevant menu

• Control unit programming can be locked through the optional

CL1+ key

• ADI 2.0 connector for the advanced management of the ADI

devices.

• USB connector to connect the control unit to a PC and manage

through software the programming of the unit, the firmware

updates and the operation diagnostics.

• Connector for the LOW ENERGY module that allows saving

electrical energy: when the gate is standing the LOW ENERGY

module deactivates the display, the photocells and all the

devices power supplied by a terminal box.

To activate the operation of the module, it is necessary to

activate the ENERGY SAVING function (parameter EnSA = Si).

CITY1-EVO

Power supply 230V / 50Hz

Max motors load 2 x 700W

Duty clcle 40%

Consumption in stand-by

(with LOW ENERGY module installed)

0,45 W

Max accessories load 24V 10W

Protection fuse 5A

Weight 1600 g

Dimensions 295 x 230 x 100 mm

Working temperature -20 ÷ +60°C

Protection IP55

CITY1-EVO-120V

Power supply 120V / 60Hz

Max motors load 2 x 500W

Duty clcle 30%

Consumption in stand-by

(with LOW ENERGY module installed)

0,45 W

Max accessories load 24V 10W

Protection fuse 8A

Weight 1600 g

Dimensions 295 x 230 x 100 mm

Working temperature -20 ÷ +60°C

Protection IP55

ENGLISH

- 18 -

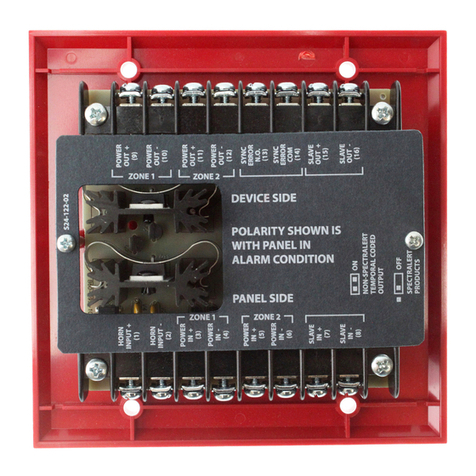

L1 Antenna

L2 Antenna shielding

L3 START - Opening control for the connection of

control devices with N.O. contact

L4 START P. - Opening controls for pedestrian access for

the connection of control devices with N.O. contact

L5 STOP - Stop command. N.C. contact

L6 Common (-)

L7 FOT1 - Photocells type 1. N.C. contact

L8 FOT2 - Photocells type 2. N.C. contact

L9 COS1 - Safety edges type 1. N.C. contact

L10 COS2 - Safety edges type 2. N.C. contact

L11 Common (-)

H1 - H2 Flashing light 230 / 120 Vac - 40W

H3 Motor M2 (OPENING)

H4 Motor M2 (COMMON)

H5 Motor M2 (CLOSING)

H6 Motor M1 (OPENING)

H7 Motor M1 (COMMON)

H8 Motor M1 (CLOSING)

LPower phase 230V / 120V

NNeutral 230V / 120V

Z1 Power output 24 Vac for photocells and other

accessories

Z2 Common for accessories power supply

Z3 Photocell/optical edge TX power supply for

functional test

Z4 - Z5 Lock 12V

Z5 - Z6 Low voltage light (12Vdc - 3W)

RM MR receiving modules

ADI 2.0 ADI 2.0 interface

USB USB connector

OVERLOAD It shows that there is an overload on accessories

power supply

MAINS It shows that the control unit is power supplied

F1 5 A (230V versions)

8 A (120V versions)

J1 - J2 - J3 Connectors for the LOW ENERGY module

REFER TO THE COMPLETE MANUAL TO CONFIGURE THESE

DEVICES

E1 FCA1 - Open limit switch

motor M1 Encoder

motor M2

E2 FCC1 - Close limit switch

motor M1

E3 FCA2 - Open limit switch

motor M2 Encoder

motor M1

E4 FCC2 - Close limit switch

motor M2

E5 Common (-)

5.1 - ELECTRIC CONNECTIONS

mWARNING: The installation of the unit, safety

devices and accessories must be carried out when the

power supply is disconnected

BEFORE PROCEEDING WITH THE ELECTRICAL

CONNECTIONS, READ CAREFULLY THE CHAPTERS

DEDICATED TO THE INDIVIDUAL DEVICES AVAILABLE IN

THE PAGES THAT FOLLOW.

5.2 - PLUG IN RECEIVER

CITY1-EVO is suitable for plugging in a Personal Pass MR receiver.

mWARNING: Pay attention to the way you connect the

removable modules.

MR1 module receiver is provided with 4 channels and each of

them is suitable for a command of CITY1-EVO control unit::

• CHANNEL 1 gSTART

• CHANNEL 2 gPEDESTRIAN START

• CHANNEL 3 gSTOP

• CHANNEL 4 gCOURTESY LIGHT

The transmitter codes can be stored in two ways:

1. By pressing the P1 button on the MR receiver (read the

instructions supplied with the receiver)

2. Using WINPPCL software: to run the program you need to

connect a PC to the control unit. The connection can be made

via USB using a standard USB cable.

ENGLISH

- 19 -

ANT

START

STOP

START P.

COM

FOT1

FOT2

COS1

COS2

COM

FCA1

FCC1

FCA2

FCC2

COM

+24VAC

COM (-)

+24VAC (TEST)

NEUTRAL

PHASE

LOCK

WARNING LIGHT

FLASHING LIGHT

ANT-

E1

OVERLOAD

RM

DOWN MENU UP

MAINS

J1 J2

J3

F1

E2 E3 E4 E5 Z1 Z2 Z3 Z4 Z5 Z6 H1 H2 H3 H4 H5 H6 H7 H8 N L

OPEN

COM

CLOSE

M2

OPEN

COM

CLOSE

M1

L1 L2 L3 L4 L5 L6 L7 L8 L9 L10 L11

mATTENTION: jumpers J1 and J2 must be removed

only to allow connection of the LOW ENERGY

optional module. Insert the module only after having

disconnected the power supply unit.

ENGLISH

- 20 -

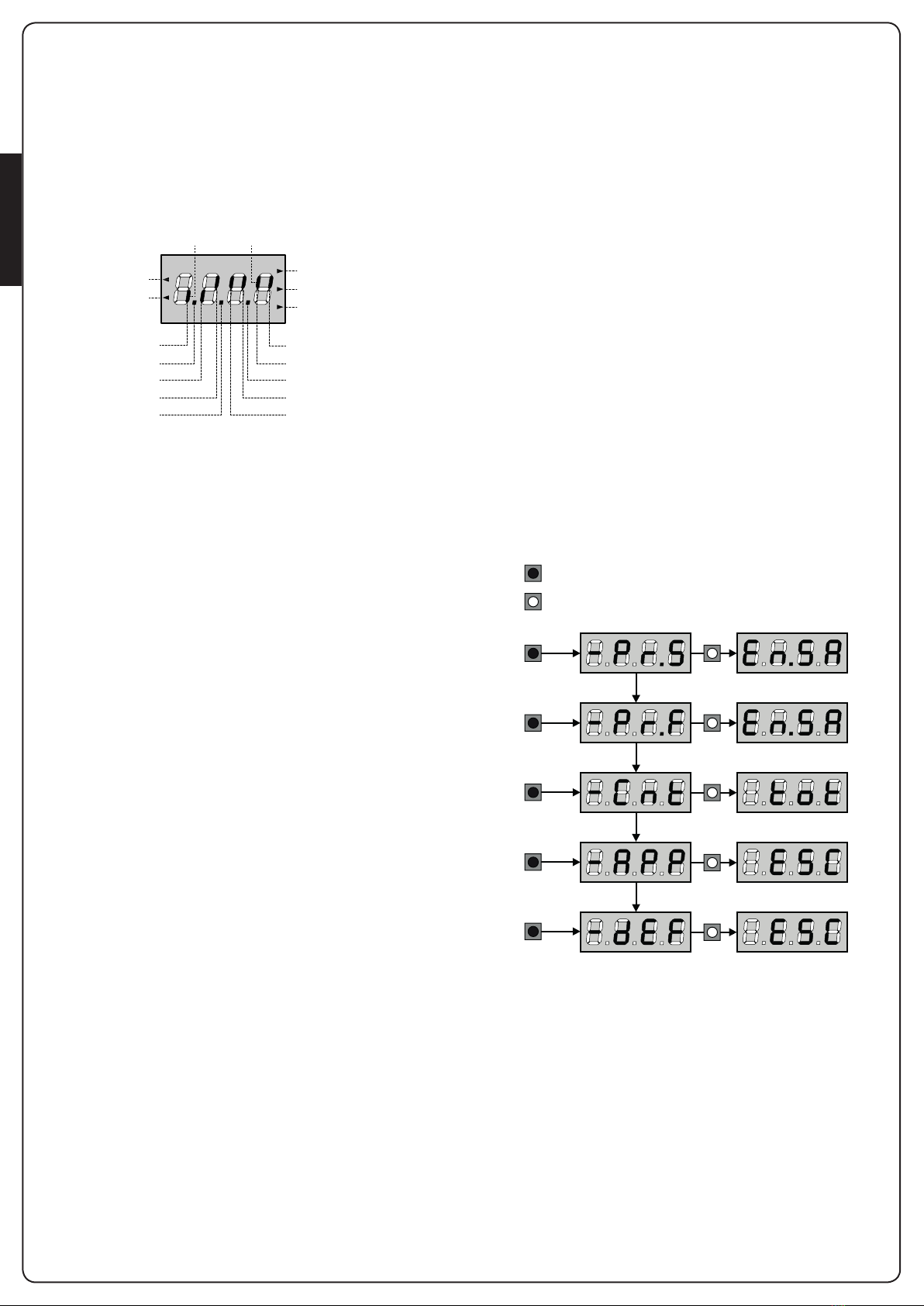

6 - CONTROL PANEL

When power is on, the control unit checks that display correctly

operates by switching on all segments for 1.5 sec. 8.8.8.8.

Then you can see the ID of the control unit (Evo1) and the version

of the firmware (Pr 1.0).

Panel will be viewed upon completion of this test.

The control panel represents the physical status of the terminal

board contacts and of the program mode keys: if the upper

vertical segment is on, the contact is closed; if the lower vertical

segment is on, the contact is open (the above picture shows

an instance where the inputs START, START P, FOTO 1, FOTO 2,

COSTA 1, COSTA 2 and STOP have all been correctly connected).

Points being among display digits show the status of

programming push-buttons: as soon as a push-button is pressed,

its relevant point turns on.

NOTE: the “points” among the numbers, are used also to signal

the state of the remote safety devices controlled through the ADI

module.

The arrows on the display left side show the status of the ends

of stroke. As for a one door-gate, arrows turn on when its end

of stroke shows that the gate is completely closed or completely

open.

As for a two-door gate, arrows turn on when both the ends

of stroke show that both the doors are completely closed or

completely open; the arrow will blink in case only one door

reaches its end of stroke.

mWARNING: these functions have not been activated

in case of ends of stroke being connected in series to the

motor.

The arrows on the display right side show the gate status:

• The highest arrow turns on when the gate is into its opening

phase. If it blinks, it means that the opening has been caused

by a safety device (border or obstacle detector).

• The central arrow shows that the gate is on pause. If it blinks, it

means that the time countdown for the automatic closing has

been activated.

• The lowest arrow blinks when the gate is into its closing phase.

If it blinks, it means that the closing has been caused by a

safety device (border or obstacle detector).

6.1 - USE OF DOWN MENU AND UP KEYS FOR

PROGRAMMING

Control unit time and function programming is made within a

special configuration menu, to which you can access and where

you can shift through DOWN, MENU and UP keys placed under

the display.

mCAUTION: Except in the configuration menu, pressing

the UP key activates a START command and pressing the

DOWN key activates a START PEDESTRIAN command.

Hold down the MENU key to scroll through the 5 main menus:

-Pr.S BASE PROGRAMMING (SHORT MENU): only the useful

parameters for a base programming are displayed.

-Pr.F ADVANCED PROGRAMMING (FULL MENU) *: all

parameters of the programming menu are displayed.

-Cnt COUNTERS *

-APP SELF-LEARNING OF WORKING TIMES

-dEF LOAD DEFAULT PARAMETERS

To enter one of the 5 main menus, just release the MENU key

when the menu you want appears on the display.

To move through the 5 main menus, press the UP and DOWN keys

to scroll through the various items. Press the MENU key to display

the current value of the selected item and change it if needed.

OPENING IN PROGRESS

CLOSED CONTACTOPEN CONTACT

CLOSING

LIMIT SWITCH

OPENING

LIMIT SWITCH

PAUSE (GATE OPENED)

CLOSING IN PROGRESS

EDGE 2

EDGE 1

UP

PHOTOCELL 2

PHOTOCELL 1

START

DOWN

PEDESTRIAN START

STOP

MENU

MENU

3”

3”

MENU

6”

3”

3”

3”

MENU

9”

MENU

12”

MENU

15”

* download the full manual from the website www.v2home.com

ENGLISH

- 21 -

7 - QUICK CONFIGURATION

This paragraph concerns a quick procedure to set the control unit

and set it at work immediately.

We recommend following these instructions, in order to

check quickly the correct operation of control unit, motor and

accessories, and then changing the configuration in case of any

non-satisfactory parameter.

1. Call up the default configuration (chapter 8).

NOTE: The DEFAULT configuration includes a photocell

connected to the FOT2 input.

mWARNING: If you load the AntE DEFAULT and the

installation only requires one door, set the opening time

t.AP2 to zero.

2. Set parameters StoP, Fot1, Fot2, CoS1, CoS2 according

to the safety devices installed on the gate

3. Check that the connection of the motors is correct:

a. Feed the unit and activate the automation with a START

order: the motors must move in opening in the correct order

b. If the direction of the movement is wrong, invert the

opening/closing motor cables that move in reverse

c. If the opening order of the doors is not correct, invert the

connections of the two motors

4. Start the self-learning cycle (chapter 9)

5. Check that the automation work properly and if necessary

modify the configuration of the desired parameters

8 - LOADING OF DEFAULT

PARAMETERS

If necessary, it is possible to restore all the parameters to their

standard or default value (see table at the end)

mWARNING: This procedure causes the loss of all the

customized parameters.

1. Press and hold down the MENU key until the -dEF appears

on the display

2. Release the MENU key: the display will show ESC (press the

MENU key only if you want to leave this menu)

3. - If the unit controls a door, press the UP key: the display

shows AntE

- If the unit controls another type of automation press the

DOWN key: the display shows SCor

4. Press the MENU key: no will appear on the display.

5. Press the DOWN key: Si will appear on the display.

6. Press the MENU key: All of the parameters are returned to their

default values (chapter 11) and the display shows the control

panel

9 - SELF-LEARNING OF WORKING

TIMES

This menu allows the automatic learning of the times necessary to

open and close the gate. The encoder positions are also saved, if

enabled.

Place the doors, or door, at half run and proceed with the

following points:

NOTE: if the gate has only one door, the opening time of motor 2

must be set at 0 (t.AP2 = 0)

1. Press and hold down the MENU key until the -APP appears

on the display

2. Release the MENU key: the display will show ESC (press the

MENU key only if you want to leave this menu)

3. Press the DOWN key: t.LAv will appear on the display

4. Press the MENU key to start the self-learning cycle for the work

cycle times.

CAUTION: This procedure varies based on the number of gate

panels and travel control devices installed (refer to the tables

outlined on the following pages).

ENGLISH

- 22 -

2 MOTORS

(LIMIT SWITCHES OR SENSOR OF OBSTACLES IS ENABLED)

1. Door 1 is opened for a few

seconds

2. Door 2 is closed until the limit

switches comes into action, or

the sensor of obstacles detects

that the door is locked

3. Door 1 is closed until the limit

switches comes into action, or

the sensor of obstacles detects

that the door is locked

4. An opening manoeuvre for

each door is carried out, the

operation ends when the limit

switches comes into action, or

the sensor of obstacles detects

that the door is locked

5. A closing manoeuvre for

each door is carried out, the

operation ends when the limit

switches comes into action, or

the sensor of obstacles detects

that the door is locked

6. The detected parameters are stored and the unit is ready for

use

2 MOTORS

(NO LIMIT SWITCHES AND SENSOR OF OBSTACLES IS

DISABLED)

ATTENTION: in this case the limits of the run must be signalled

with a START order

1. Door 1 is opened for a few

seconds

2. Door 2 is closed until the unit

receives a START order

3. Door 1 is closed until the unit

receives a START order

4. An opening manoeuvre is

carried out for each door, the

operation ends when the unit

receives a START order (the first

START stops door 1, the second

START stops door 2)

5. A closing manoeuvre is

carried out for each door, the

operation ends when the unit

receives a START order (the first

START stops door 2, the second

START stops door 1)

6. The detected parameters are stored and the unit is ready for

use

1 MOTOR

(LIMIT SWITCHES OR SENSOR OF OBSTACLES IS ENABLED)

1. The door is closed until the limit

switches comes into action, or

the sensor of obstacles detects

that the door is locked

2. An opening manoeuvre is

carried out, the operation ends

when the limit switches comes

into action, or the sensor of

obstacles detects that the door

is locked

3. A closing manoeuvre is carried

out, the operation ends when

the limit switches comes

into action, or the sensor of

obstacles detects that the door

is locked

4. The detected parameters are stored and the unit is ready for

use

1 MOTOR

(NO LIMIT SWITCHES AND SENSOR OF OBSTACLES IS

DISABLED)

ATTENTION: in this case the limits of the run must be signalled

with a START order

1. The door is closed until the unit

receives a START order

2. An opening manoeuvre is

carried out, the operation ends

when the unit receives a START

order

3. A closing manoeuvre is carried

out, the operation ends when

the unit receives a START order

4. The detected parameters are stored and the unit is ready for

use

ENGLISH

- 23 -

11 - CONTROL UNIT

CONFIGURATION

Control unit time and function programming is made within a

special configuration menu, to which you can access and where

you can shift through DOWN, MENU and UP keys placed under

the display.

The configuration menu consists in a list of configurable items;

the display shows the selected item.

• By pressing DOWN, you will pass to the next item

• By pressing UP, you will return to the previous item

• By pressing MENU, you can view the current value of selected

item and possibly change it.

Based on the requirements of the installation, it is possible to

activate the SHORT or FULL programming menu.

The SHORT menu consists only of parameters useful for a

programming base, while the FULL menu consists of all the

parameters of the programming menu (the parameters present

only in the FULL menu are shown in the table).

To activate the SHORT programming menu hold the MENU key

until the display shows -Pr.S; by releasing the key, the unit

displays the first parameter of the En.SA menu.

To activate the FULL programming menu *hold the MENU key

until the display shows -Pr.F; by releasing the key, the unit

displays the first parameter of the En.SA menu.

The last menu item (FinE) allows storing the carried out changes

and going back to the control unit normal operation.

You must exit from programming mode through this menu item if

you do not want to lose your configuration.

mWARNING: in case no operation is carried out for

more than one minute, the control unit exits from the

programming mode without saving any of your setups and

changes, which will get lost.

NOTE: By holding pressed the UP key the programming menu

parameters scroll fast backwards until item En.SA is displayed.

By pressing key DOWN the programming menu parameters scroll

fast forward until item FinE is displayed.

MENU

3”

3”

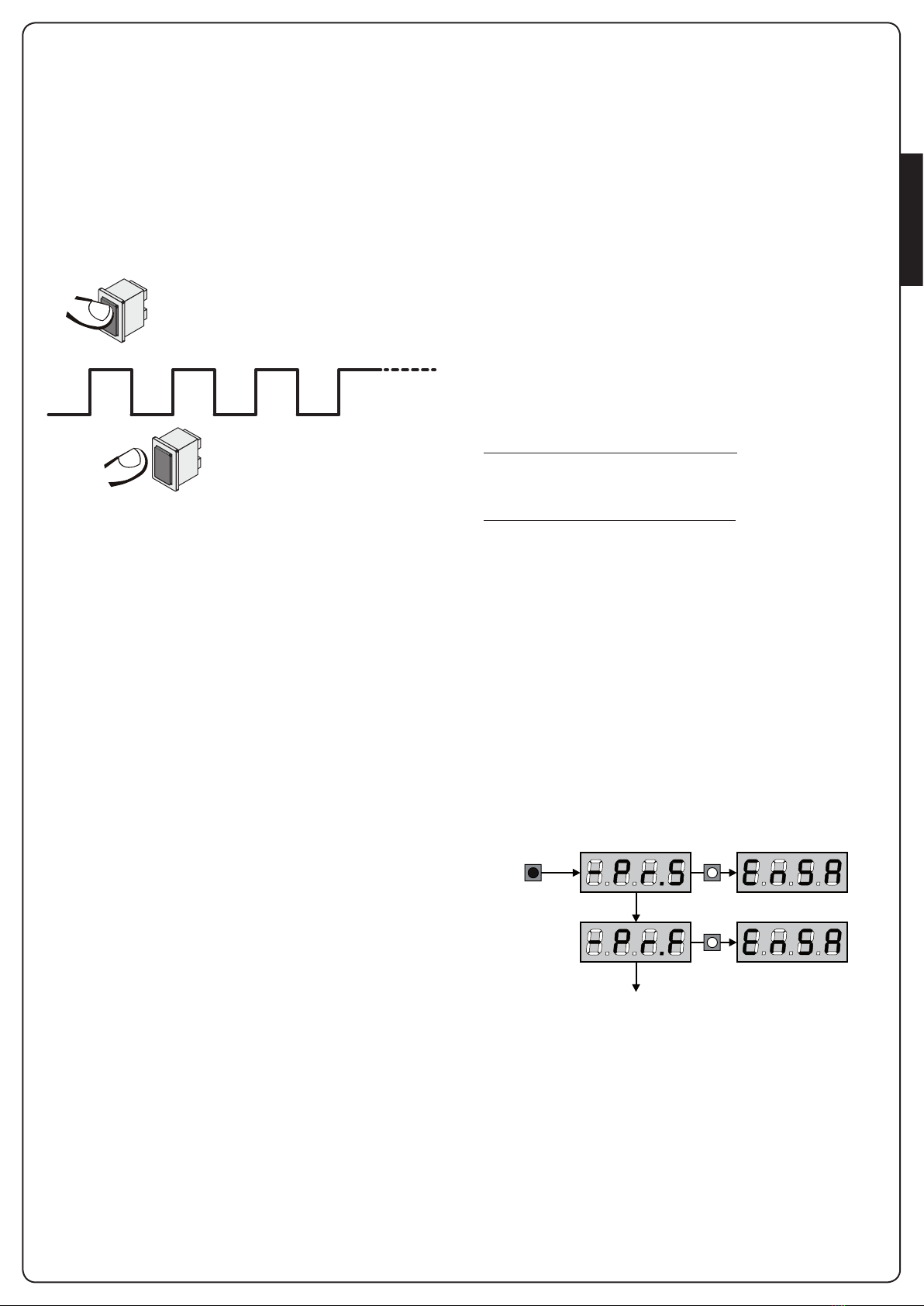

10 - EMERGENCY DEAD MAN

OPERATION

This operational mode can be used to move the gate in DEAD

MAN mode in particular cases, such as installation/maintenance or

in the case of malfunctioning of photocell, edge, limit switches or

encoder.

To activate the function the START command must be pressed

3 times (presses must last at least 1 second; the pause between

commands must last at least 1 second).

1” 1” 1” T

>1” >1” >1”

The fourth START command activates the gate in MAN PRESENT

mode. To move the gate keep the START command pressed for

the duration of the operation (time T).

The function will automatically turn off after 10 seconds of

inactivity of the gate.

NOTE: if the Strt parameter is set as StAn, the Start

command (from the terminal block or remote control) moves the

gate in the open and closed directions alternatively (unlike the

normal DEAD MAN mode).

* download the full manual from the website www.v2home.com

ENGLISH

- 24 -

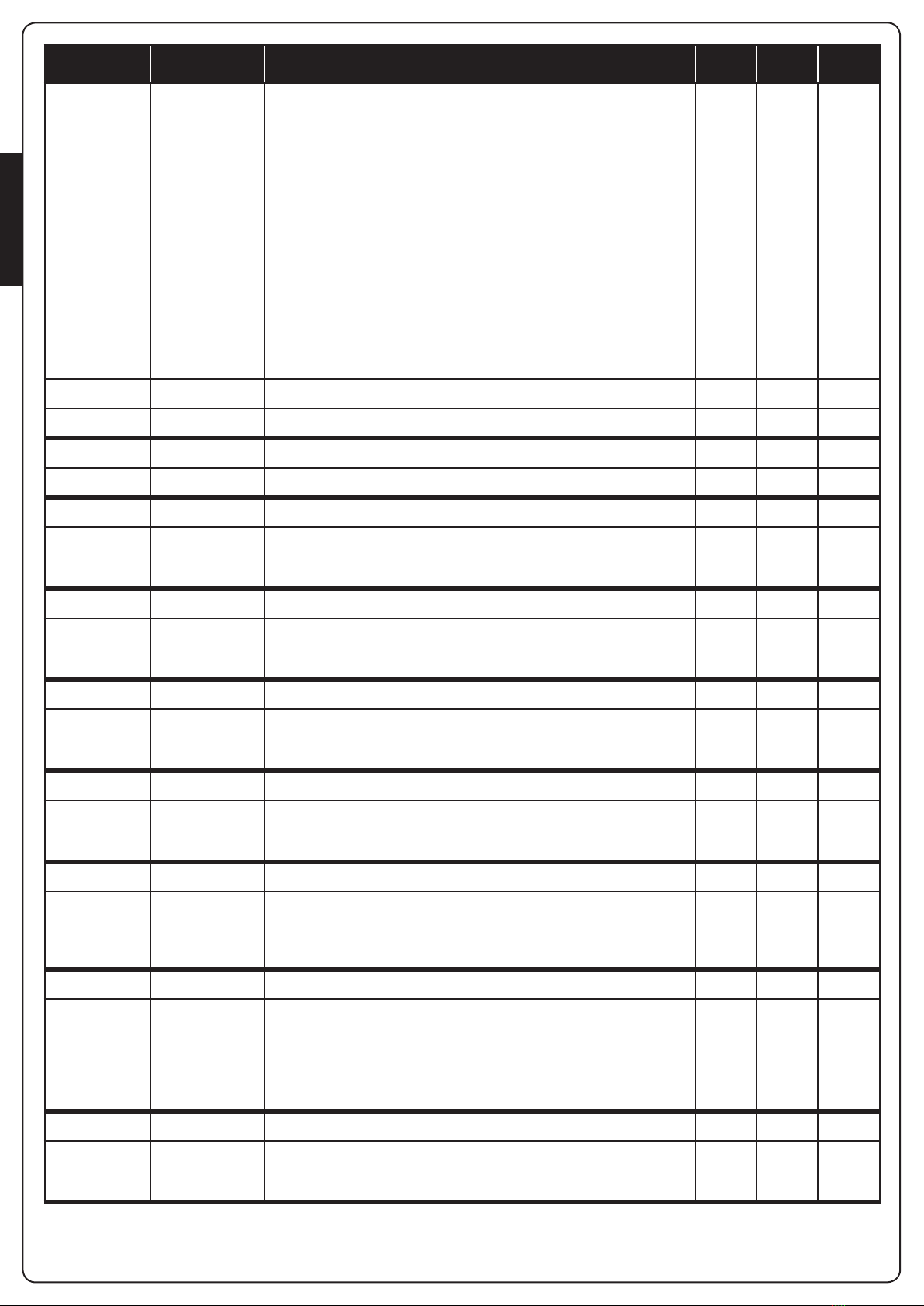

PARAMETER VALUE DESCRIPTION AntE SCor MEMO

En.SA ENERGY SAVING function

When the function is active and the LOW ENERGY module is installed,

the control unit deactivates the display, the photocells, and all the

devices powered by a terminal box under determined conditions.

NOTE: If the LOW ENERGY module is not installed, the control unit

deactivates only the display.

The control unit activates the ENERGY SAVING mode under the

following conditions:

• 30 seconds after completion of an operational cycle

• 30 seconds after an opening (if automatic closure is not enabled)

• 30 seconds after exiting the programming menu

The control unit exits from the ENERGY SAVING mode in these cases:

• If an operational cycle is activated

• If one of the keys on the control unit are pressed

no no

no Function deactivated

Si Function activated

t.AP1 Leaf 1 opening time 20.0” 22.5”

0.0”-5’00 Adjustable time from 0 seconds to 5 minutes

t.AP2 Leaf 2 opening time 20.0” 0.0”

0.0”-5’00 Adjustable time from 0 seconds to 5 minutes.

WARNING: if motor M2 is not connected, this time must be set to

zero

t.Ch1 Leaf 1 closing time 21.0” 23.5”

0.0”-5’00 Adjustable time from 0 seconds to 5 minutes.

NOTE: To avoid that the door does not close completely, we

recommend to setup a longer time than t.AP1 opening time.

t.Ch2 Leaf 2 closing time 21.0” 0.0”

0.0”-5’00 Adjustable time from 0 seconds to 2 minutes

NOTE: To avoid that the door does not close completely, we

recommend to setup a longer time than t.AP2 opening time

t.APP Partial opening time (pedestrian access) 6.0” 6.0”

0.0” - 2’00 When the control unit receives a Start Pedestrian command, it

will open leaf 1 only, for a shorter time.

Max allowed time to be setup is t.AP1

t.ChP Partial closing time (pedestrian access) 7.0” 7.0”

0.0” - 2’00 When the control unit receives a Start Pedestrian command, it will use

this time to close the gate. Max allowed time to be setup is t.Ch1.

NOTE: To avoid that the door does not close completely, we

recommend to setup a longer time than t.APP opening time

r.AP Opening door delay 1.0” 0.0”

0.0” - 1’00 During the opening phase, leaf 1 must start moving before leaf 2, to

avoid that both doors may collide.

Leaf 2 opening will be delayed for the setup time.

NOTE: If you set the opening door delay to zero, the control board

does not execute the control of the correct leaves closing order

r.Ch Closing door delay 3.0” 0.0”

0.0” - 1’00 During the closing phase, leaf 1 must start moving after leaf 2, to

avoid that both doors may collide.

Leaf 1 closing will be delayed for the setup time

ENGLISH

- 25 -

PARAMETER VALUE DESCRIPTION AntE SCor MEMO

Pot1 Motor M1 power 60 60

30 - 100 The displayed value is the percentage of max. motor power.

mWARNING: In case an hydraulic motor is used, set value

100

Pot2 Motor M2 power 60 60

30 - 100 The displayed value is the percentage of max. motor power.

mWARNING: In case an hydraulic motor is used, set value

100

rA.AP Slow down in opening 25 15

no Function deactivated

1 - 50 This menu allows regulating the percentage of the ride/drive that is

carried out at reduced speed during the last opening stretch

rA.Ch Slow down in closing 25 15

no Function deactivated

1 - 50 This menu allows regulating the percentage of the ride/drive that is

carried out at reduced speed during the last closing stretch

St.AP Start command during the opening phase

This menu allows fixing the control unit conduct in case it receives a

Start command during the opening phase

PAUS PAUS

PAUS The gate stops and goes to pause

ChiU The gate immediately starts closing

no The gate go on with the opening phase (command is ignored)

St.Ch Start command during the closing phase

This menu allows fixing the control unit conduct in case it receives a

Start command during the closing phase

StoP StoP

StoP The gate stops and its cycle is considered as finished

APEr The gate opens again

St.PA Start command during the pause

This menu allows fixing the control unit conduct in case it receives a

Start command when the gate is open during its pause phase

ChiU ChiU

ChiU The gate starts closing

no Command is ignored

PAUS The pause time is reset (Ch.AU)

SPAP Pedestrian Start during the partial opening phase

This menu allows fixing the control unit conduct in case it receives a

Pedestrian Start command during the partial opening phase.

mWARNING: a Start command in any phase of partial

opening will cause the total opening; the Start Pedestrian

command is always ignored during a total opening.

PAUS PAUS

PAUS The gate stops and goes to pause

ChiU The gate immediately starts closing

no The gate goes on with the opening phase (command is ignored)

ENGLISH

- 26 -

PARAMETER VALUE DESCRIPTION AntE SCor MEMO

Ch.AU Automatic closing no no

no Function deactivated

0.5” - 20.0’ The gate closes after the setup time

StoP Stop Input no no

no The input STOP is not available

ProS The input STOP stops the gate: pressing the command START the gate

continues the motion

invE The command STOP stops the gate: at the next START the gate starts

moving in the opposite direction

Fot1 Photocell 1 input

This menu allows enabling the input for type 1 photocells, that is to

say, photocells active both during the opening and closing phase

no no

no Input disabled

APCh Input enabled

Fot2 Photocell 2 input

This menu allows enabling the input for type 2 photocells, that is to

say, photocells non active during the opening phase

CFCh CFCh

CFCh Input enabled even at standstill gate too

Ch Input enabled for the closing phase only

mWARNING: If the photocell is damaged the gate is opened

anyway.

Before closing the test of the photocell (if enabled) will detect

the fault and prevent the gate from closing.

no Input disabled

CoS1 Safety edge 1 input

This menu allows enabling the input for type 1 safety edge, that is to

say, fixed edges

no no

no Input disabled

APCh Input enabled in opening and closure

AP Input enabled during the opening and disabled during the closure

CoS2 Safety edge 2 input

This menu allows enabling the input for type 2 safety edge, that is to

say mobile edges

no no

no Input disabled

APCh Input enabled in opening and closure

Ch Input enabled during the closing and disabled during the opening

This manual suits for next models

1

Table of contents

Popular Control Unit manuals by other brands

Spirax Sarco

Spirax Sarco TD3-3 Installation and maintenance instructions

Minarik

Minarik SL-15U user manual

Whelen Engineering Company

Whelen Engineering Company 295HFSA6 installation guide

CALEFFI

CALEFFI PLUMBVENT NA502640A instructions

vistaCNC

vistaCNC iMachIII P4-S manual

laerdal

laerdal Q-CPR Directions for use