Elmi DOS-20S User manual

ISO 9001:2008

User’s manual

Shaker DOS-20S

Dear users!

DOS-20S shaker is a simple and reliable device. We ask you to consider a

technical requirement for exploitation to provide the use of the equipment without

problems for a long period of time.

General information

DOS-20S is designed to perform the mixing up of components in different kind of

test tubes, laboratory dishes with flat bottom, flasks, Petri dishes, etc. The control

panel of the device contains indicators of the speed and time of rotation of the

platform. This device is fully controlled by the microprocessor system with memory,

independent from the source of energy. When the shaker is not used for more than

15 minutes it automatically goes to the ''SLEEP'' mode and turns off.

Technical specifications

Size of working space of platform: 168 x 168 mm

Amplitude of platform rotation: 20 mm

Type of rotation: orbital

Time controller: from 1 min to 9 hours and the ''HOLD'' mode

Speed of rotation RPM: from 20 to 300

Environmental temperature, ºC From +10 to + 45

Relative moisture of atmosphere

(at the temperature of 20 ºC) no more than 80 %

Voltage and frequency 100-240V; 50-60Hz

The recommended pulley block: DC in 24V 1 A

Power (at maximum speed): no more than 24 W

Size of the device (length x width xheight) mm 205x170x70

Weight, kg 1.6

Certificate of approval

Shaker DOS-20S N has been inspected for thetechnical

conditions and it meets all regulations necessary for such class ofdevice.

Quality control person (name) (signature)

Date of manufacture

Place for stamp.

Certificate of sale

Organization

Address

Phone

Vendor

(name) (signature)

Date of sale

Delivery package

Item Quantity

Shaker........................................................................................................................... 1

Power supply................................................................................................................1

Magnetic clips ..............................................................................................................3

User manual.................................................................................................................1

Packaging.....................................................................................................................1

Manufacturer’s address.

21-133 Aizkraukles Str., Riga LV-1006

Tel: (+371) 6755 8743

Tel: (+371) 6755 1934

E-mail: info@elmi-tech.com

WWW: www.elmi-tech.com

Disinfection and cleaning

Before you start disinfection or cleaning make sure the power adapter is

unplugged. It is recommended to perform cleaning with water and universal

washing liquids. Afterwards the machine should be carefully dried.

Warranty statements

•

Warranty applies to 24-month period from the date of purchasing.

•

Malfunctions arisen through the fault of manufacturer in this period, are

removed free of charge.

•

Guaranty is not valid in the following cases:

-

If the serial number label of the manufacturer is damaged.

-

If damages appear as a result of the incorrect operation, transportation or

storage.

•

These documents are necessary if applying for warrantyrepair:

-

User manual with serial number of the machine.

-

Officially signed report, describing the reasons and conditions of

equipment malfunction.

•

Warranty repair could be performed only if the equipment is delivered

in the original manufacturers packaging or equally safe packaging.

Therefore, please keep the transportation packaging after unpacking the

device.

•

If the above warranty requirements are disturbed, repair charges are applied

to the consumer.

For all further questions concerning exploitation and maintenance please

Contact manufacturer or product vendor.

Transportation and storage

To ensure safety during the transportation, transported equipment should be

packed in the original manufacturers’ packaging or similar packaging

substitute.

Equipment can be transported by any kind of closed transport so that

equipment is tightly fixed, and transportation runs accordingly to regulations

applied to this way of transport. Equipment should be stored in original

manufacturers packaging in dry room with humidity not more than 80% and

temperature range from +10 C up to +45 C.

It is not recommended to store the equipment more than 36 month.

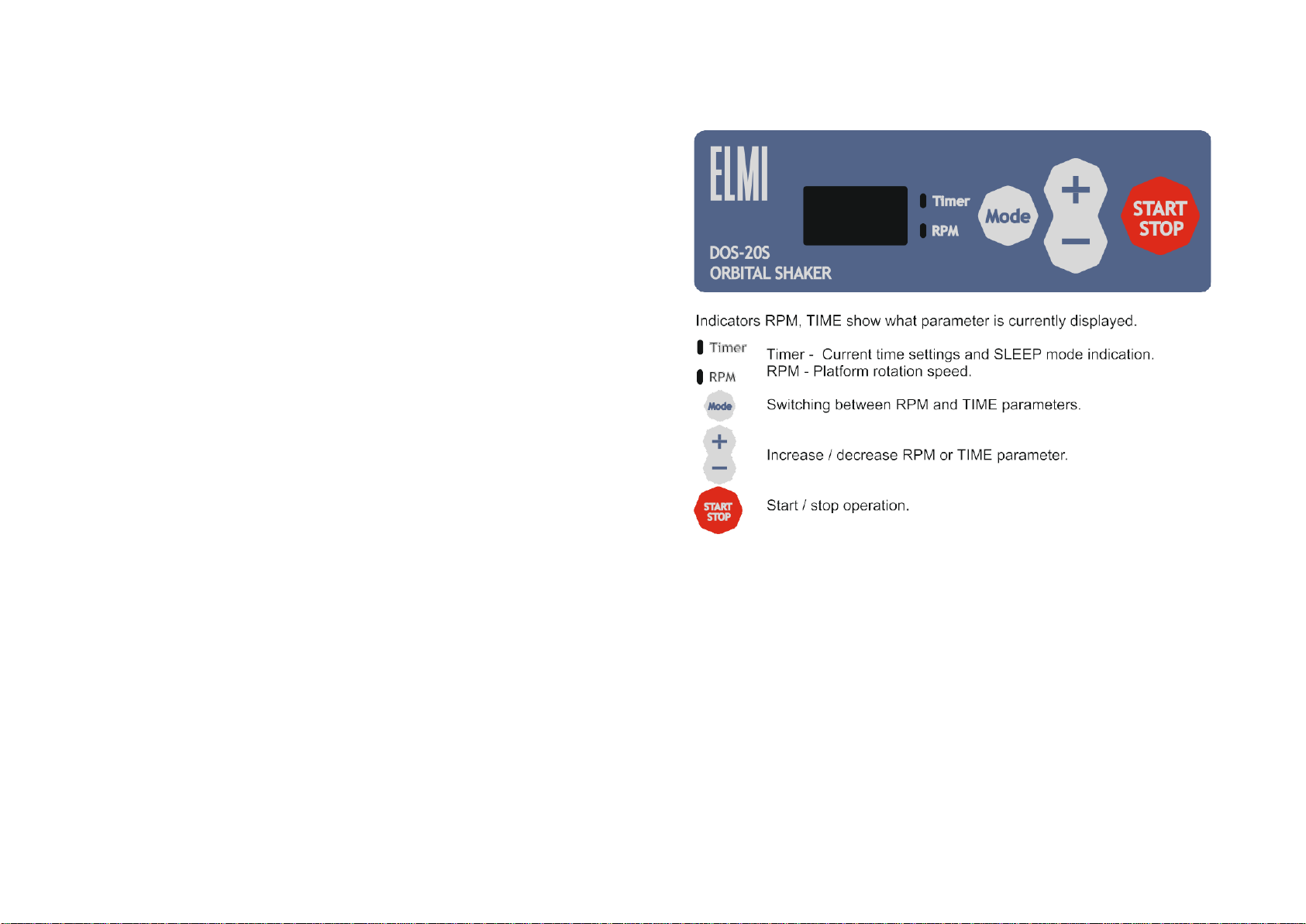

Controls description

The control panel of the shaker consists of the following elements:

Setting regimes of operation

The operation regime is set by adjusting two parameters:

RPM - Platform rotation speed.

TIME –Platform rotation time, timer turn off.

Choose the desired parameter buy pressing mode button. The light indicator will

show which parameter is selected.

Set the desired parameter value.

If the time parameter is less than 1 minute, the timer automatically switches off and

the display will show OFF message.

Launch the operation with start / stop button. If you wish to end the operation before

the estimated time runs out press the start / stop button again.

All the TIME and RPM parameter settings are stored in the power independent

memory.

Unpacking and setting up

Before turning the machine on, please take a look at the adapter. Ensure that the

wire and the body of adapter are not damaged. In case of external damage of the

adapter, do not plug it in the machine without the supervision ofspecialist!

1)

Plug the adapter into the outlet. The indicators on the control panel will turn on.

2)

Set up the desired operation regime: rotation time andspeed.

3)

Press the start button. The platform will start to move. When the desired time will

run out, the shaker stops and gives the sound signal.

4)

During rotation on the display time counts down in minutes and when the last

minute is left the shaker starts the countdown in seconds.

5)

When the shaker is operating the time parameters cannot be changed. By

pressing the control buttons shortly, the indicators will show the set time

period.

6)

The rotation speed can be changed during the rotation of platform by pressing

the control buttons.

7)

The shaker automatically protects itself from the overloading. If during the

operation the platform is overloaded or there is an other obstacle, the platform halts

and attempts to start again until the obstacle isremoved.

8)

The shaker has a power consumption “SLEEP” mode. The shaker enters sleep

mode if it is not operated and the user does not press any button for more than 15

minutes. By pressing any button machine goes back to normalmode.

9)

The machine is plugged into the power socket and it is not necessary to pull out

the adapter from the outlet. But if the machine is not used for a long period of time it

is recommended to unplug the adapter.

Safety features

It is prohibited to:

•

Plug the device to a power outlet configuration different from the power

adapters’ plug configuration.

•

Plug the power adapter in to the outlet if the adapter isdamaged.

•

Work with aggressive media while the flask is not closed tight.

•

Move the device while working.

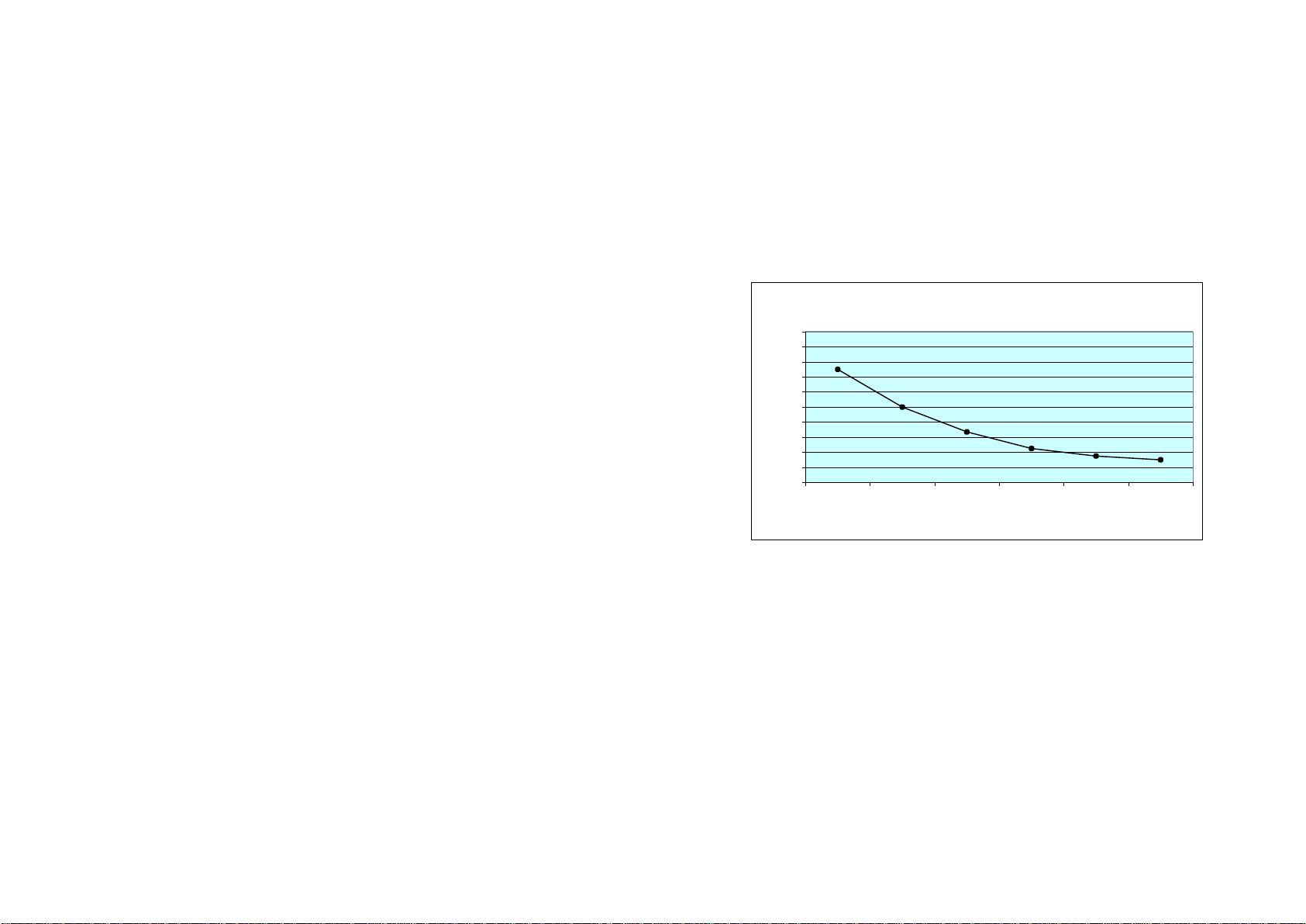

Load (kg) depending on speed (rpm)

2

1,8

1,6

1,4

1,2

kg

1

0,8

0,6

0,4

0,2

0

60

80

100

150

200

250

rpm

This manual suits for next models

1