fire and if it looks to be fading, add some more charcoal. You will soon have steam

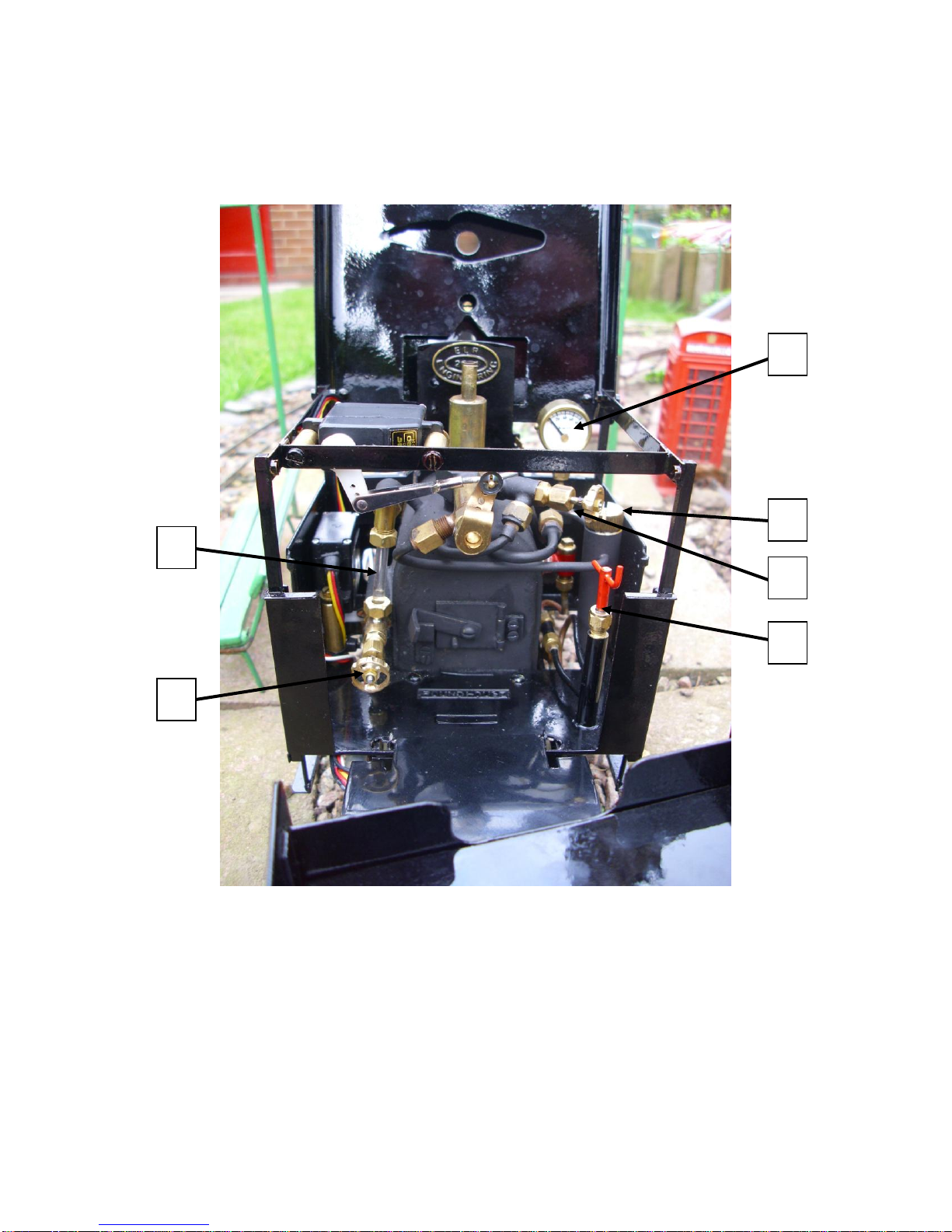

pressure. Once the pressure gauge (5) reaches over 30psi (pounds per square inch), you

can then open the locomotive’s own steam blower (6) and remove the battery blower

from the chimney at the same time.

Charybdis will now be able to draw its fire harder and therefore generate more heat from

the charcoal. You will be able to see the fire increase in intensity and hear the increased

draw from the locomotive’s steam blower: if you cant, open the blower a little more.

At this stage, you can add some steam coal: a little at first and again, shut the firebox

door between each shovelful. This allows the coal to start to burn (too much at once

could put the fire out). You should soon be able to see the fire building up nicely. When

the locomotive has reached its full working pressure, you will be able to move it under its

own steam.

Move the reverser (2) into forward gear (push it forward) and then open the regulator (8).

Some priming is expected (identified by water escaping from the chimney). This is

normal and will soon clear. Following priming, the locomotive is ready to start running.

When running the locomotive, it is important to keep a draft to draw the fire. Without one

the fire will go out. When the loco is stationary, it should become automatic to open the

blower valve: doing this will create the draft of steam required to draw the fire. Shortly

before you open the regulator to move the locomotive, you may shut the blower valve.

Once the locomotive is moving, its own exhaust creates the necessary draft to draw the

fire.

By this stage, you will need to add more coal to your fire, with the aim of producing a

nice, deep orange glow. Remember to shut the door in between shovelfuls in an attempt

to keep in as much heat as possible.

The water bypass valve (1) can now be closed. This pumps water from the saddle tank

into the boiler while the loco is running and therefore maintains a steady level of water in

the gauge glass (3). Setting the water bypass value so it pumps water at the optimum rate

is something that is learnt as you run your locomotive. If the gauge glass fills completely,

you will be able to hear the loco prime, as the boiler is full of water. At this point you

open the water bypass valve. This stops water being pumped into the boiler for the

moment. Only begin to close it again when the gauge glass indicates that the water level

has dropped to a more sensible level. Keeping plenty of water in boiler is very important

and this is why the top-up bottle is included. If the water level drops too low, i.e. it falls

out the bottom of the gauge glass, attach the top-up bottle to the water top-up valve in the

cab (9) and add water to the boiler using the bottle.

Operators should aspire to run their locomotive efficiently, eventually achieving between

10 –15 minutes running time between firings, while remembering to keep the saddle tank

topped up with water.

N.B If you intend running your locomotive for extended periods, the lubricator will

require oil after about an hour (please note, it will be hot! ). You will also need to keep

the water pump ram and its cam (between the locomotive frames) well oiled.