ELR Engeineering NGG16 Garratt User manual

Coal fired steam locomotive

NGG16 Garratt

Owners Manual

Contents

Controls

Locomotive running tools

Running in

Preparing to run your locomotive

Running your locomotive

Once you have finished your running session

Maintenance / troubleshooting

Precautionary instructions

The NGG16 Garratt locomotive operates just like its full-sized counterpart by using coal

to produce steam under pressure. Therefore, parts of the locomotive will become very

hot. Provided the locomotive is operated with adequate care and attention, no problems

should arise. The model is intended for outdoor use and should only be used in well-

ventilated areas.

The model is unsuitable for children unless they are carefully supervised at all times: The

locomotive is not a toy.

Whilst the locomotive is in steam, an exhaust will be emitted through the chimney that

includes hot steam, ash and sparks. Therefore, any operator or bystander must not lean

over the locomotive while it is running.

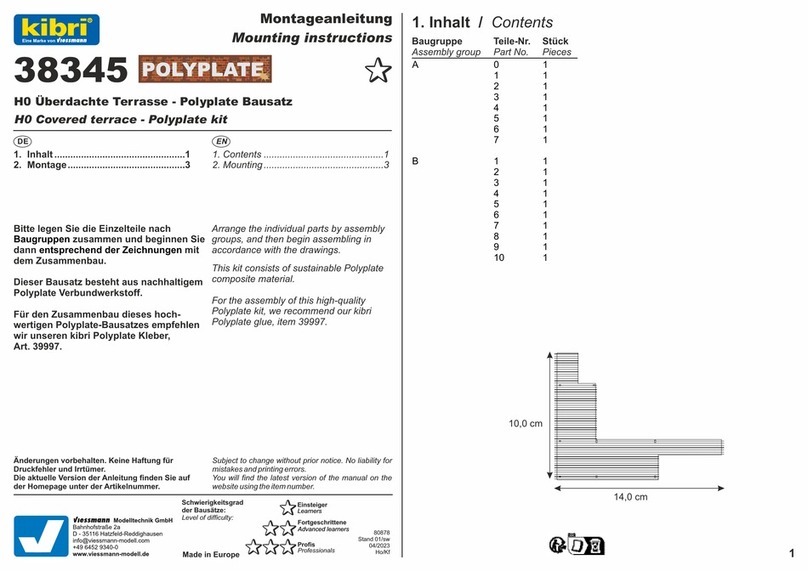

Controls

1. Water gauge glass

2. Water gauge glass blow-down valve

3. Pressure gauge

4. Lubricator

5. Blower valve

6. Water bypass control

1

2

3

4

5

6

Locomotive running tools

The following tools are supplied with your new locomotive:

Battery blower

Firing shovel and pricker

Flu brush

Water top-up bottle

Bottle of steam oil

Bag of coal

Preparing your locomotive

Your locomotive must be fully prepared before every running session in accordance with

the operational guidelines below.

Use light motion oil to lubricate the valve gear. Make sure to include all moving parts.

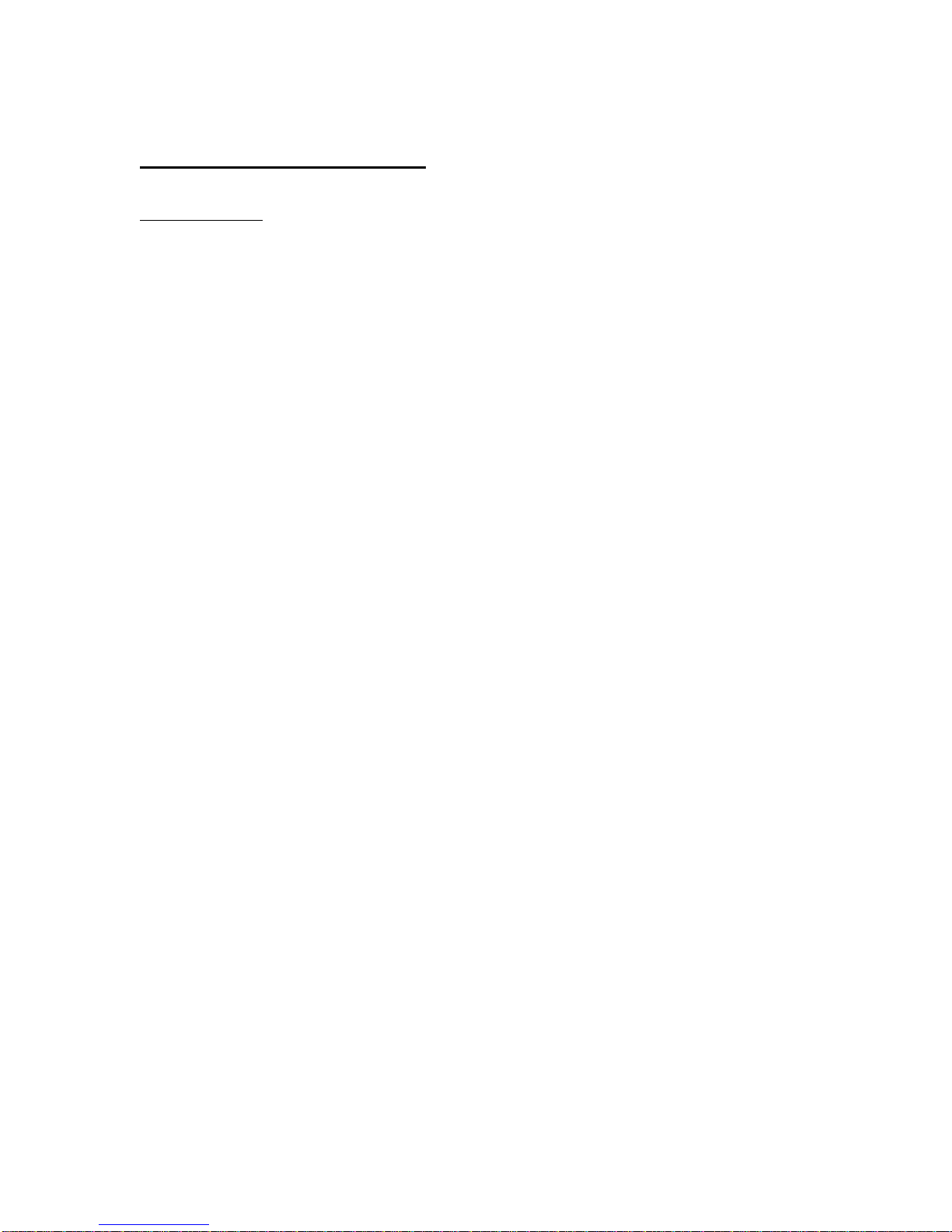

The water axle pump ram, located just above the front axle, together with its joint to the

eccentric arm are both easy to miss, yet require routine lubrication. Also, there are parts

of the eccentric located on the rear axle that will benefit from frequent lubrication.

Remove the front tank to access the axle pump. It is recommended that this is done first,

before the tank is filled with water.

Fill the boiler with water using the top-up bottle or if the boiler is completely empty

remove a safety valve and fill the boiler. Distilled water is preferred if available. Place

the end of the flexible pipe from the bottle into the water top-up valve, which is located

under the dome. Fill until the water reading is slightly over the top of the gauge glass.

Next, fill up the front tank with water. To do this, remove the tank cap located in the

middle of the tank.

N.B. If distilled water is not available: clean soft tap water, filtered rainwater or filtered water from a

dehumidifier may also be used.

Next, unscrew the top of the lubricator and also unscrew the drain of the lubricator.

Allow any water to drain then, as oil starts to appear, retighten the lubricator drain screw

(finger tighten only). Top up the lubricator with steam oil until full and then screw the top

on again (finger tight).

Shortly before you’re ready to light the locomotive, fill the firebox level to the door with

unlit paraffin soaked charcoal.

Your locomotive is now ready to be steamed.

Operating your locomotive

Raising steam

When you are ready to light your locomotive, place the battery blower into the chimney

and turn it on. Then prepare a shovel of lit paraffin-soaked charcoal and shovel this into

the firebox to light the fire.

Soon after, shovel three or four more loads onto the fire and shut the firebox door. After a

couple of minutes or so put another three or four loads into the firebox, as to create a nice

even spread and again shut the door. It is important to keep the firebox door shut as much

as possible as the most heat is lost here because the electric blower is pulling cold air

across the fire.

Keep an eye on your fire and if it looks to be fading, add some more charcoal.

With practice, you will gain a working knowledge of how your locomotive’s fire behaves during the

warming up period.

You will soon have steam pressure and once the pressure gauge reaches 40psi (pounds

per square inch) or above, you can then open the locomotive’s own steam blower and

remove the battery blower from the chimney at the same time.

The locomotive will now be able to draw its fire harder and therefore generate more heat

from the charcoal. You will be able to see the fire increase in intensity and hear the

increased draw from the locomotive’s steam blower: if you can’t, open the blower a little

more to increase the air flow through the fire.

At this stage, you can add some steam coal: a little at first and again, shut the firebox

door between each shovelful. This allows the coal to start to burn (too much at once

could choke the fire and put it out). You should be aiming for an even spread of coal

across the firebox, giving an even glow.

It is recommended that you practice opening and closing the firebox with the fire pricker whilst the engine

is cold. This will make your shovelling technique more efficient when the locomotive is in steam.

When the locomotive has reached the full working pressure of 70psi, you will be able to

move it under its own steam.

Running the locomotive

Turn on the radio transmitter and then the locomotive.

Move the reverser into the desired gear by moving the right hand stick left or right and

then open the regulator by moving the left hand stick up. Some priming is to be expected

(identified by water escaping from the chimney). This is normal and will soon clear.

Following priming, the locomotive is ready to start running.

When operating the locomotive, it is important to keep a draft to draw the fire.

Without one the fire will go out.

When the loco is stationary the blower valve should be open: doing this will create the

draft of steam required to draw the fire.

Teach yourself to automatically open the blower whenever the locomotive is stationary.

Shortly before you open the regulator to move the locomotive, you may shut the blower

valve. Once the locomotive is moving, the exhaust from the cylinders creates the

necessary draft to draw the fire.

By this stage, you will need to add more coal to your fire, with the aim of producing a

nice, deep orange glow. Remember to shut the door in between shovelfuls in an attempt

to keep in as much heat as possible.

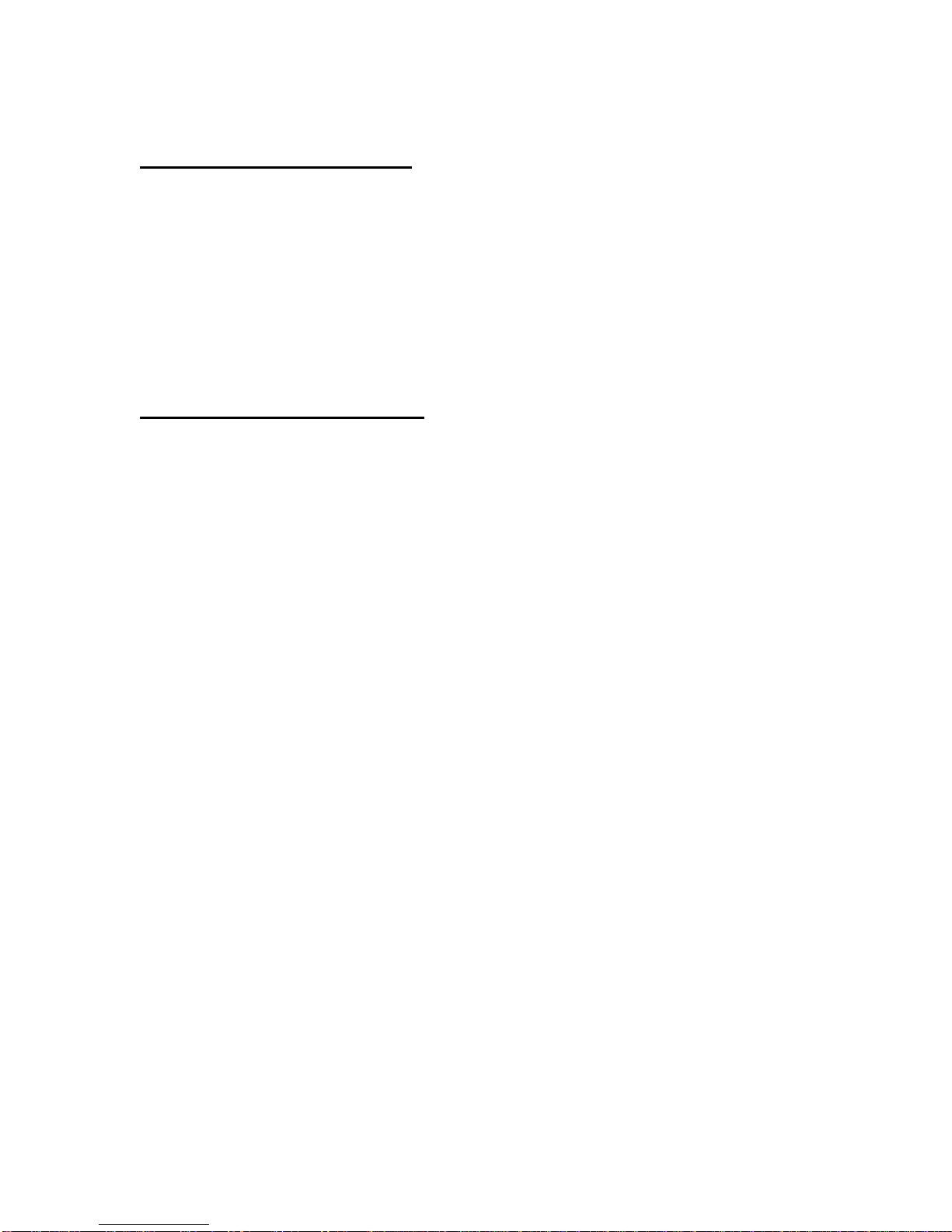

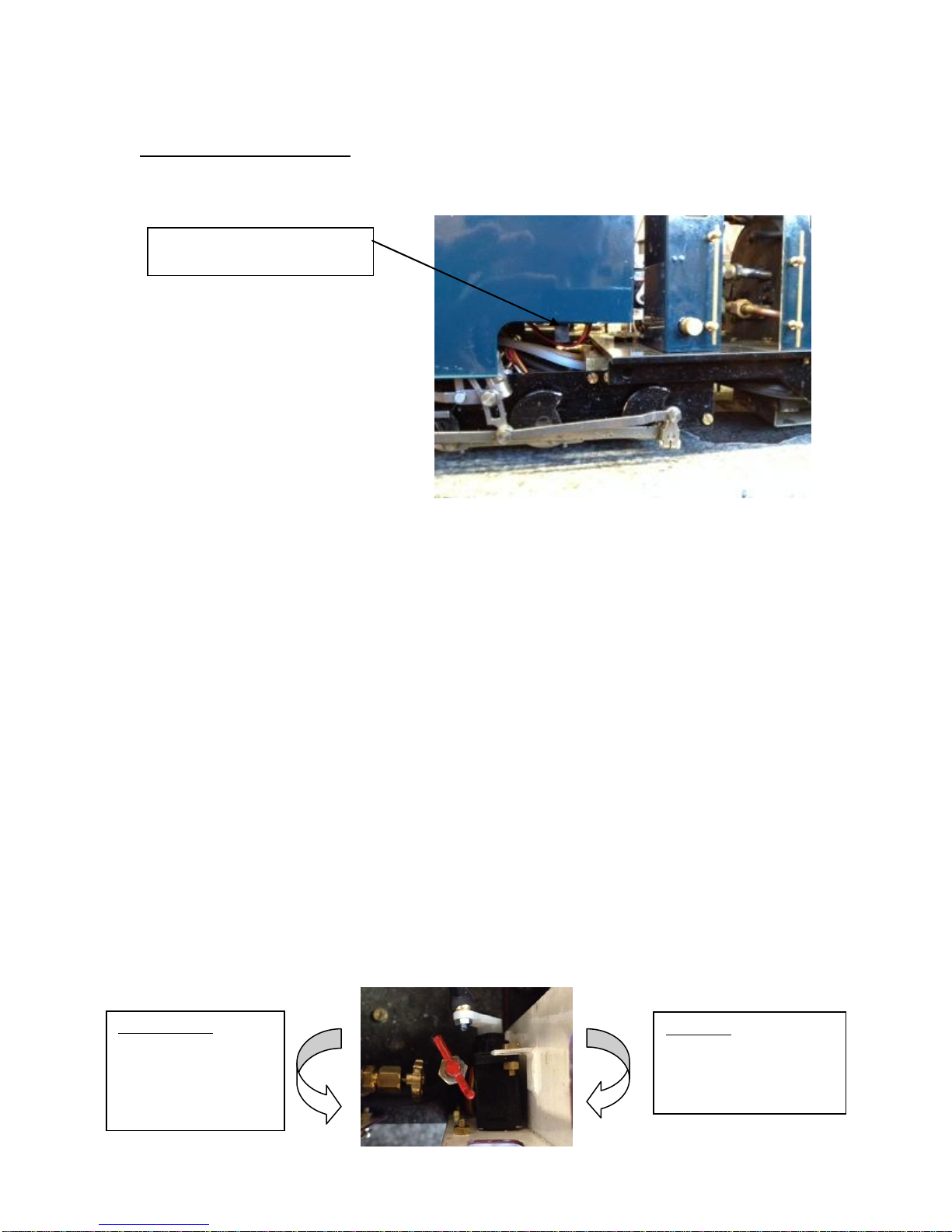

The water axle pump should be turned on using the bypass valve in the cab.

The switch is located under the

rear tank on the right hand side.

Anti-clockwise

Axle pump is turned

OFF and is not pumping

Water into the boiler.

Clockwise

Axle pump is turned ON

and is pumping water into

the boiler.

The bypass valve controls the axle pump, which pumps water from the tank into the

boiler while the loco is running and therefore maintains a steady level of water in the

gauge glass. Setting the water bypass valve so it pumps water at the optimum rate is

something that is learnt over time as you become familiar with your locomotive. If the

gauge glass fills completely, you will be able to hear the loco prime, as the boiler is full

of water. At this point you should turn off the axle pump by opening the bypass valve.

This stops water being pumped into the boiler for the moment. Only begin to close it

again when the gauge glass indicates that the water level has dropped to a more sensible

level. Keeping plenty of water in boiler is very important and this is why the top-up bottle

is included. If the water level drops too low, i.e. it falls to the very bottom of the gauge

glass, attach the top-up bottle to the water top-up valve in the cab and add water to the

boiler using the bottle.

Operators should aspire to run their locomotive efficiently, eventually achieving between

10 –15 minutes running time between firings, while remembering to keep the tank

topped up with water.

N.B If you intend running your locomotive for extended periods, the lubricator will require oil after about

an hour (please note, it will be hot! ). You will also need to keep the water pump ram and its cam (between

the locomotive frames) well oiled.

Once you have finished your running session

Once you have finished running your locomotive, it needs to be ‘disposed of’ responsibly

–just like the real thing!

Firstly, ensure that the blower valve and regulator are closed and allow the locomotive to

cool slightly. Next, drop the remnants of your fire. The NGG16’s ash pan makes this

easy. Behind the ash pan (located under the firebox) is a movable hook and bar. Just push

the hook to one side out away from the bar (which is attached to the ash pan), the whole

ash pan and grate will fall out with guidance and allow complete and easy removal of the

remaining fire and ash. Beware: this may still be hot so please take extreme caution when

removing the ash pan. Once the fire has been removed and the grate has cooled, locate

the ashpan back into the firebox with the two locating pins and push the hook back

around the bar.

It is vital that the boilers flue tubes and smokebox are cleared at the end of every run.

Access to the smokebox door on the NGG16 is gained by lifting the front tank off its

locating pins.

It is strongly recommended that a cloth is draped over the exposed front chassis at this

point so that ash cannot get into the valve gear and axle pump.

On front of the smoke-box, completely unscrew the centre dart and remove the smoke-

box door. You will probably be able to see an accumulation of ash built up inside the

smoke-box (the amount depends upon the length of your run). Next, brush out as much of

the ash as possible using a small paintbrush. A gentle blow down the chimney will

remove the remainder.

Removing the smoke-box ash will reveal the boiler tubes. Using the flu brush provided,

clean out the seven tubes that are accessable. These can get blocked with bits of coal and

ash, limiting the boiler’s steaming capability. Don’t worry if it is difficult to push the

brush through, keep trying: dipping the end of the brush in paraffin is helpful.

Reattach the smoke-box door using the screw dart you removed earlier. Tighten until

finger tight.

You can now clean your locomotive, removing unwanted ash and dirt. We have found

that a soft paintbrush can be very effective for removing fresh ash that has covered some

of the bodywork.

Maintenance / troubleshooting

To keep your locomotive running well, you must keep all moving parts well oiled. It is

worth being aware that well-oiled valve gear can very easily attract ash onto itself. This

ash is abrasive and its presence can increase wear on the valve gear. To keep this wear at

a minimum, we suggest using an old toothbrush to remove ash out of the valve gear.

As is the case for many new locomotives, the seals at certain joints may take time to ‘bed

in’. This can soon be overcome by a gentle tightening of the seal.

If the axle pump is failing to pump enough water into the boiler, there are usually two

reasons for this. The most likely of which is that small particles of dirt have blocked the

pump. This dirt can be removed by opening the bypass valve in order to allow the water

system to unblock itself after a moment of running. The second reason for a lack of water

is that water may be leaking out of the gland and avoiding the pump. Check the gland

over the ram is finger tight. If you are still having trouble, you can disconnect the rubber

tube underneath the loco. This pipe runs between the centre driving wheels and supplies

water to the pump. Put the end of your water top-up bottle onto the pipe and pump water

around the system, this pushes out any dirt. Once done reconnect the rubber tube and test

the locomotive.

Remember; practice makes perfect!

We hope that you find great enjoyment in your NGG16 Garratt.

Table of contents

Other ELR Engeineering Toy manuals