Technical Information

8 I elson BUSHPEX Crimp-On V3.0 Apr 2023

Pipe & Fitting Protection and Care during Handling and Installation

BUSHPEX pipe and Crimp-on fittings must be protected from damage through all stages of the process from

transport to storage and installation in accordance with AS/NZS3500. Provision for pipe and fitting protection

therefore includes but is not limited to the following:

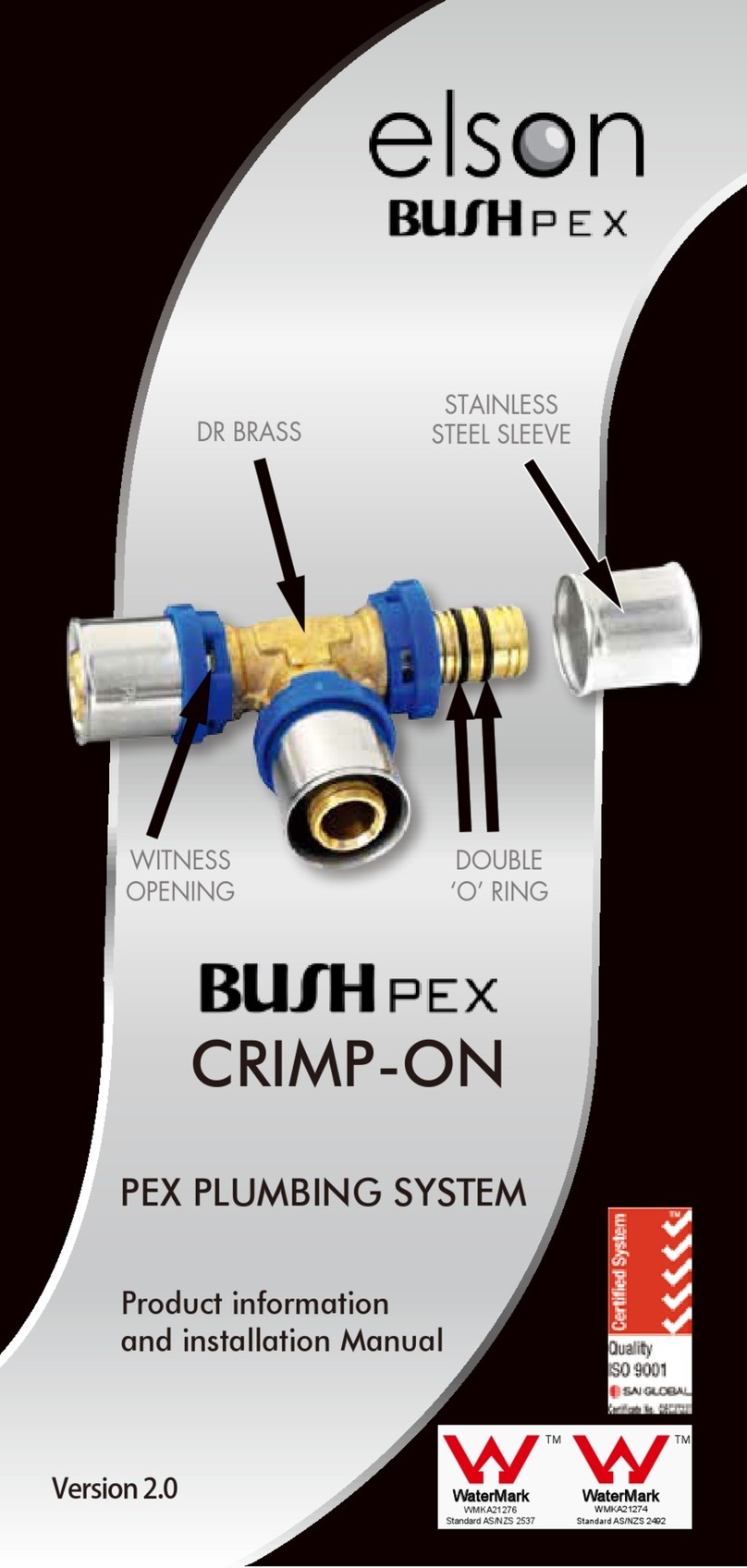

• Care must be taken to keep the pipe and fittings free of grit, dirt, dust and any foreign matter. All blue

retaining rings must be securely seated onto the fitting along with the stainless steel crimp sleeve and dual

“O” rings.

• Pipe must be protected from physical damage. Including cuts, abrasions, dents, kinks, tears, holes, etc.

• Pipes, either black, red, green or lilac, are not to be installed in direct sunlight.

• Pipe must be protected from long term or permanent U.V. exposure, by way of lagging, enclosing in a

conduit etc.

• Pipe and fittings must be protected from excessive heat or burning, chemical / solvent attack, animal or

rodent attack, machinery damage, other external threats, etc.

• Pipe must never be installed where it could be exposed to a naked flame. PE-Xa Pipe has the potential to

ignite and continue to burn after the source of the flame is extinguished. In accordance with AS/NZS3500, all

plastic pipe for water supply must be protected from excessive ambient heat.

• Chemical or corrosive environments.

- Pipe must be protected.

- Fittings must be wrapped and protected. This includes all underground installations for all fittings.

• Pipe support and clipping, both vertically and horizontally is required to ensure conformance for vibration,

excessive tension, torsion or compressive stresses on fittings and pipe. Refer to Pipe Specification Chart for

spacing.

• Pipe penetrations through timber and steel frames and concrete sections must conform and may require

protection using grommets, fire collars, sleeving or wrapping. Holes, notches and cut-outs must be

accurately drilled “in-line” to allow movement for expansion and contraction of the pipe and fittings so joints

are not exposed to excessive stress. Refer to Pipe Specification Chart for timber frame cut-out limitations.

• Pipe expansion and contraction needs to be accommodated during installation to allow for movement

due to thermal Linear Expansion. Failure to do so may exceed the torsional pull-out allowances on fittings

resulting in leakage. Refer to the Pipe Specification Chart for the Thermal Expansion Co-efficient.

• BUSHPEX pipe is flexible but requires care when bending to avoid kinks or other permanent deformation

that may restrict flow or put undue pressure on joints. If the pipe is kinked or damaged in any way it must

be cut-out and replaced. BUSHPEX Crimp-On elbows are recommended for tight bends. Refer to the Pipe

Specification Chart for minimum bending radius and tools for bending.