Elson CBi Release note

CB Heat Interface Unit Manual

Wall Mounted Heat Interface Units for

Community Heating Systems

Installation & Servicing Instructions

IMPORTANT

Please read & understand these instructions along with the instructions for the heating

controller, unvented cylinder / thermal store before commencing installation.

Please leave this manual with the user for future reference.

Page 2

INTRODUCTION..................................................................3

GENERAL REQUIREMENTS..............................................3

PRODUCT SPECIFICATION...............................................3

PRODUCT FEATURES........................................................4

DIMENSIONS AND WEIGHT............................................12

INSTALLATION ................................................................13

WIRING..............................................................................16

WIRING DIAGRAMS.........................................................17

HYDRAULIC DIAGRAMS..................................................21

HYDRAULIC DIAGRAMS LEGEND..................................26

CONTROL STRATEGY......................................................27

MAJOR COMPONENTS...................................................29

COMMISSIONING.............................................................36

SERVICE............................................................................37

FAULT FINDING.................................................................38

SPARES..............................................................................39

SALES AND SUPPORT.....................................................44

CONTENTS

Page 3

The heating and hot water to your home are provided

by the CB heat interface unit and unvented cylinder or

thermal store package.

Heat is supplied to the CB heat interface unit from the

central boiler(s) installed elsewhere in the building. The

central boiler will provide heat to your CB unit for your

central heating and domestic hot water.

The CB heat interface unit is a heat only unit and works in

conjunction with an indirect domestic hot water cylinder or

thermal store to provide hot water to your taps. As such

you must read these instructions in conjunction with those

for the cylinder / thermal store.

The CB heat interface unit can be fitted within a cylinder

frame. The cylinder frame arrangement permits the

cylinder / thermal store to sit above a washing machine

or shelves for storage. This space saving design is

particularly advantageous for apartments with open plan

living areas, as this allows the washing machine to be

positioned in the airing cupboard (not detailed in these

instructions).

Alternatively the CB heat interface unit is suitable for wall

mounting and can be supplied with a first fix rail for ease

of installation. For wall mounted versions an optional set of

casings is available on request.

The CB unit is supplied complete with all the necessary

safety and control devices needed to allow connection

to the community heating system and the apartment’s

central heating system.

The CB heat interface unit can provide space heating via a

radiator or underfloor heating system.

This appliance complies with the requirements of the CE

marking directive.

The following instructions are offered as a guide to

installation which must be carried out by a competent

plumbing and electrical installer in accordance with

Building, Electrical and Water Regulations.

NOTE: Prior to installation, the unit should be stored in an

area free from excessive dampness or humidity.

IMPORTANT:

THIS APPLIANCE CAN BE USED BY CHILDREN

AGED FROM 8 YEARS AND ABOVE AND

PERSONS WITH REDUCED PHYSICAL SENSORY

OR MENTAL CAPABILITIES OR LACK OF

EXPERIENCE AND KNOWLEDGE IF THEY HAVE

BEEN GIVEN SUPERVISORY OR INSTRUCTION

CONCERNING USE OF THE APPLIANCE IN A

SAFE WAY AND UNDERSTAND THE HAZARDS

INVOLVED. CHILDREN SHALL NOT PLAY

WITH THE APPLIANCE. CLEANING AND USER

MAINTENANCE SHALL NOT BE MADE BY

CHILDREN WITHOUT SUPERVISION.

INTRODUCTION

GENERAL REQUIREMENTS

Maximum Working Pressure:

Primary Side (Community / District Heating): 10 bar g

Secondary Side (Apartment Heating): 3 bar g

Maximum Working Temperature:

Primary Side (Community / District Heating): 90 deg C

Secondary Side (Apartment Heating): 85 deg C

Primary Side Pressure drop 30 kPa

As previously stated, the CB heat interface unit is a versatile

unit suitable for wall mounting or fitting within a purpose

made frame.

The CB heat interface unit includes the following

components:

- an apartment central heating pump,

- pump isolation valves,

- steel central heating manifold with built-in central

heating bypass,

- standard S plan or S plan plus control system

- either 2 or 3 No. two port motorized zone valves,

- an 8 litre sealed system expansion vessel,

- central heating pressure relief valve with tundish,

- Automatic air vent with anti-suction valve and shut

off valve for ease of maintenance,

- brazed stainless steel plate heat-exchanger to provide a

pressure break between the community (district) heating

system and the apartment’s central heating system,

- provision for a heat meter in the apartment’s system,

- community (district) heating 2-port pressure independent

balancing and control valve,

- district heating in-line strainer,

- all mounted on a powder coated steel back plate.

Filling Loop and Pressure Gauge

The system filling loop and associated pressure gauge

are supplied as part of the cylinder / thermal store primary

pipework kit, as these need to be installed adjacent to both

the central heating system and cold water mains pipework.

Where the cylinder / thermal store is supplied by a third party,

these components will be deemed outside the Elson scope of

supply / responsibility.

PRODUCT SPECIFICATION

Safety Valve

WATER MAY DRIP FROM THE DISCHARGE PIPE

OF THE PRESSURE RELIEF VALVE. THE TUNDISH

PROVIDED ALLOWS THE DISCHARGE PIPE TO

ALWAYS BE OPEN TO THE ATMOSPHERE. AS PART

OF THE MAINTENANCE REGIME FOR THE PRODUCT

REGULARLY OPERATE THE SAFETY VALVE TO ENSURE

IT IS NOT BLOCKED.

PRODUCT FEATURES

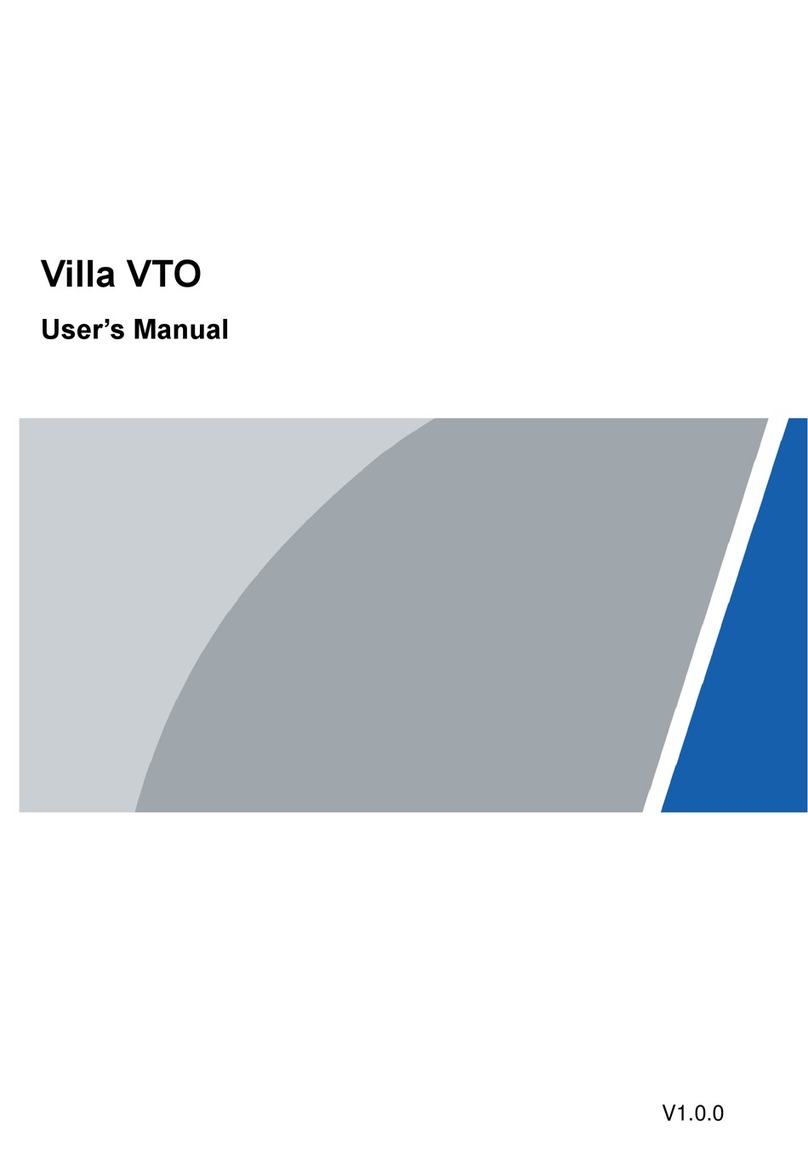

Fig 1 Product Features and Components for the CB-1Z (Single Heating Zone)

1

2

3

4

5

6

7

8

9

10

11

12

13 14

15

16

17

18

19

20

21

22

23

24

25

2627

2829

30

31

32

Page 4

(1) First fix rail bracket

(2) 4 No. Fixing holes for first fix rail (7mm)

(3) Earth stud (M4)

(4) Wiring Centre

(5) HIU mounting studs (M6) x 2 on 1st fix rail

(6) 8 litre expansion vessel with 3/8”bsp system connection

(7) Expansion vessel pipe

(8) 15mm central heating system safety valve 3 bar g

(9) 3/8” automatic air vent complete with shut off valve and anti-suction valve

(10) 15mm x 22mm compression tundish

(11) Brazed stainless steel plate heat exchanger with EPP moulded insulation cover

(12) Expansion vessel support bracket

(13) Plate heat exchanger support rail

(14) Plate heat exchanger support bracket

(15) Unit drain valves (Primary and secondary circuits)

(16) Wall mounting bottom fixing holes (3 No.)

(17) Frame fixing slots

(18) Apartment heating zone drain valve

(19) Volume flow meter (for heat meter) stool piece 3/4”bsp x 110mm centres EN1434

(20) Apartment heating 2 port zone valve

(21) Common central heating return drain valve

(22) Position of 1/2”bsp heat meter flow sensor pocket (supplied by heat meter company)

(23) Elson central heating system manifold

(24) Pump isolation unions

(25 Central heating pump

(26) HWS primary 2 port zone valve

(27) HWS primary flow connection - 3/4”bsp male

(28) Central heating flow (zone 1) connection - 3/4”bsp male

(29) Common central heating return connection - 3/4”bsp male

(30) HWS primary return connection - 3/4”bsp male

(31) Community (district) heating return - 3/4”bsp male

(32) Community (district) heating flow - 3/4”bsp male

PRODUCT FEATURES

Page 5

PRODUCT FEATURES

Fig 2 Product Features and Components for the CB-1Z-DC (Single Heating Zone with District Control Valve)

1

2

3

4

5

6

7

8

9

10

11

12

13

14 15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

3132

3334

35

36

37

Page 6

(1) First fix rail bracket

(2) 4 No. Fixing holes for first fix rail (7mm)

(3) Earth stud (M4)

(4) Wiring Centre

(5) HIU mounting studs (M6) x 2 on first fix rail

(6) 8 litre expansion vessel with 3/8”bsp system connection

(7) Expansion vessel pipe

(8) 15mm central heating system safety valve 3 bar g

(9) 3/8” automatic air vent complete with shut off valve and anti-suction valve

(10) 15mm x 22mm compression tundish

(11) 3/4”bsp male Y strainer

(12) Brazed stainless steel plate heat exchanger with EPP moulded insulation cover

(13) Expansion vessel support bracket

(14) Plate heat exchanger support rail

(15) Plate heat exchanger support bracket

(16) Test point (red) to measure the pressure drop across the district control valve

(17) Unit drain valves (Primary and secondary circuits)

(18) Wall mounting bottom fixing holes (3 No.)

(19) Frame fixing slots

(20) Apartment heating zone drain valve

(21) Volume flow meter (for heat meter) stool piece 3/4”bsp x 110mm centres EN1434

(22) DN 15 Frese Optima Compact pressure independent balancing and control valve

(23) 230V on/off thermo actuator

(24) Apartment heating 2 port zone valve

(25) Common central heating return drain valve

(26) Position of 1/2”bsp heat meter flow sensor pocket (supplied by heat meter company)

(27) Test point (blue) to measure the pressure drop across the district control valve

(28) Elson central heating system manifold

(29) Pump isolation unions

(30) Central heating pump

(31) HWS primary 2 port zone valve

(32) HWS primary flow connection - 3/4”bsp male

(33) Central heating flow (zone 1) connection - 3/4”bsp male

(34) Common central heating return connection - 3/4”bsp male

(35) HWS primary return connection - 3/4”bsp male

(36) Community (district) heating return - 3/4”bsp male

(37) Community (district) heating flow - 3/4”bsp male

PRODUCT FEATURES

Page 7

PRODUCT FEATURES

Fig 3 Product Features and Components for the CB-2Z (Two Heating Zones)

1

2

3

4

5

6

7

8

9

10

11

12

13 14

15

16

17

18

19

20

21

22

23

24

25

2627

29

30

31

32

33 28

Page 8

(1) First fix rail bracket

(2) 4 No. Fixing holes for first fix rail (7mm)

(3) Earth stud (M4)

(4) Wiring Centre

(5) HIU mounting studs (M6) x 2 on 1st fix rail

(6) 8 litre expansion vessel with 3/8”bsp system connection

(7) Expansion vessel pipe

(8) 15mm central heating system safety valve 3 bar g

(9) 3/8” automatic air vent complete with shut off valve and anti-suction valve

(10) 15mm x 22mm compression tundish

(11) Brazed stainless steel plate heat exchanger with EPP moulded insulation cover

(12) Expansion vessel support bracket

(13) Plate heat exchanger support rail

(14) Plate heat exchanger support bracket

(15) Unit drain valves (primary and secondary circuits)

(16) Wall mounting bottom fixing holes (3 No.)

(17) Frame fixing slots

(18) Apartment heating zones drain valve

(19) Volume flow meter (for heat meter) stool piece 3/4”bsp x 110mm centres EN1434

(20) Apartment heating 2 port zone valves

(21) Common central heating return drain valve

(22) Position of 1/2”bsp heat meter flow sensor pocket (supplied by heat meter company)

(23) Elson central heating system manifold

(24) Pump isolation unions

(25) Central heating pump

(26) HWS primary 2 port zone valve

(27) HWS primary flow connection - 3/4”bsp male

(28) Central heating flow (zone 2) connection - 3/4”bsp male

(29) Central heating flow (zone 1) connection - 3/4”bsp male

(30) Common central heating return connection - 3/4”bsp male

(31) HWS primary return connection - 3/4”bsp male

(32) Community (district) heating return - 3/4”bsp male

(33) Community (district) heating flow - 3/4”bsp male

PRODUCT FEATURES

Page 9

PRODUCT FEATURES

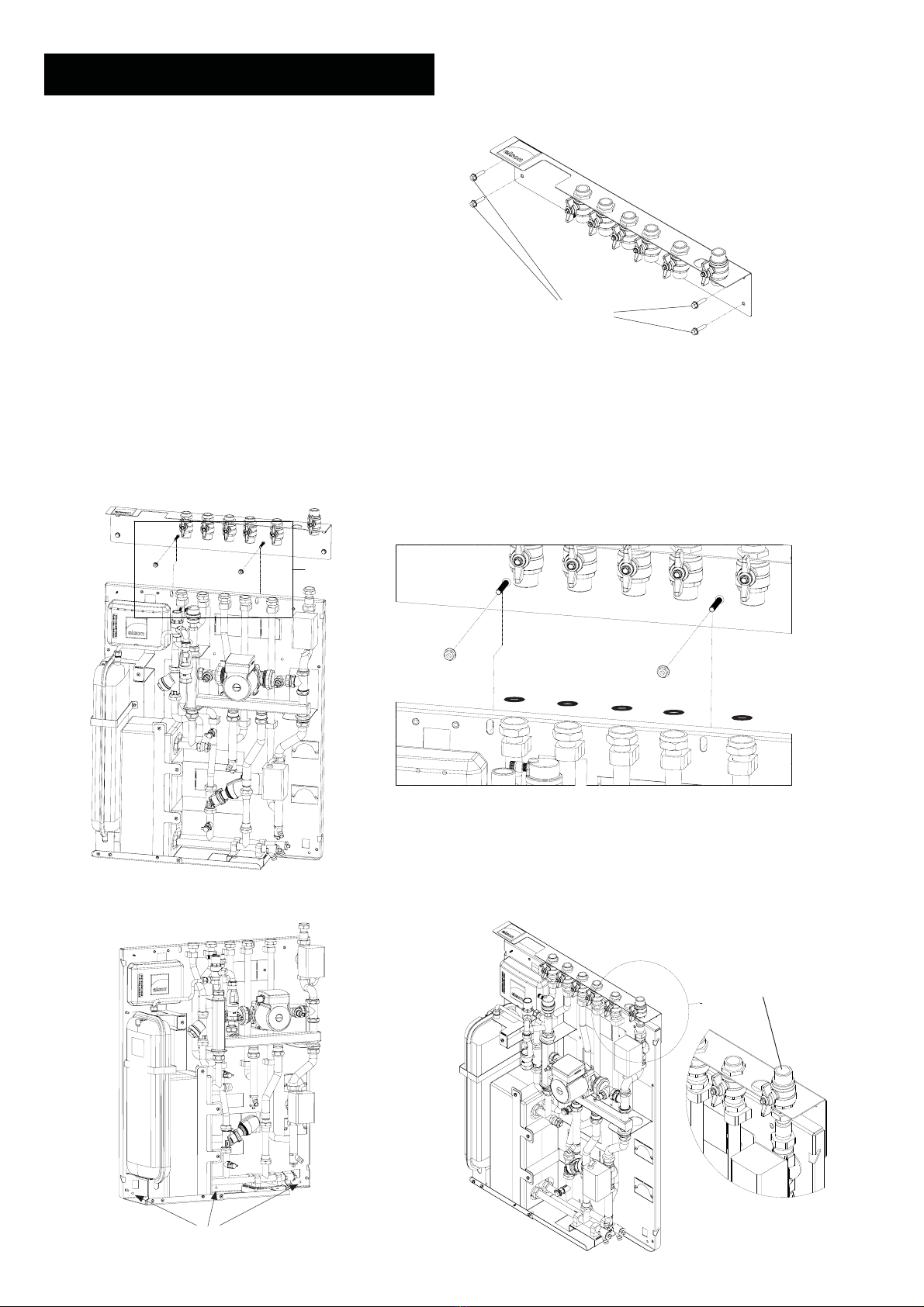

Fig 4 Product Features and Components for the CB-2Z-DC (Two Heating Zones with District Control Valve)

1

2

3

4

5

6

7

8

9

10

11

12

13

14 15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

3132

34

35

36

37

38 33

Page 10

(1) First fix rail bracket

(2) 4 No. Fixing holes for first fix rail (7mm)

(3) Earth stud (M4)

(4) Wiring Centre

(5) HIU mounting studs (M6) x 2 on first fix rail

(6) 8 litre expansion vessel with 3/8”bsp system connection

(7) Expansion vessel pipe

(8) 15mm central heating system safety valve 3 bar g

(9) 3/8” automatic air vent complete with shut off valve and anti-suction valve

(10) 15mm x 22mm compression tundish

(11) 3/4”bsp male Y strainer

(12) Brazed stainless steel plate heat exchanger with EPP moulded insulation cover

(13) Expansion vessel support bracket

(14) Plate heat exchanger support rail

(15) Plate heat exchanger support bracket

(16) Test point (red) to measure the pressure drop across the district control valve

(17) Unit drain valves (primary and secondary circuits)

(18) Wall mounting bottom fixing holes (3 No.)

(19) Frame fixing slots

(20) Apartment heating zones drain valve

(21) Volume flow meter (for heat meter) stool piece 3/4”bsp x 110mm centres EN1434

(22) DN 15 Frese Optima Compact pressure independent balancing and control valve

(23) 230V on/off thermo actuator

(24) Apartment heating 2 port zone valves

(25) Common central heating return drain valve

(26) Position of 1/2”bsp heat meter flow sensor pocket (supplied by heat meter company)

(27) Test point (blue) to measure the pressure drop across the district control valve

(28) Elson central heating system manifold

(29) Pump isolation unions

(30) Central heating pump

(31) HWS primary 2 port zone valve

(32) HWS primary flow connection - 3/4”bsp male

(33) Central heating flow (zone 2) connection - 3/4”bsp male

(34) Central heating flow (zone 1) connection - 3/4”bsp male

(35) Common central heating return connection - 3/4”bsp male

(36) HWS primary return connection - 3/4”bsp male

(37) Community (district) heating return - 3/4”bsp male

(38) Community (district) heating flow - 3/4”bsp male

PRODUCT FEATURES

Page 11

Page 12

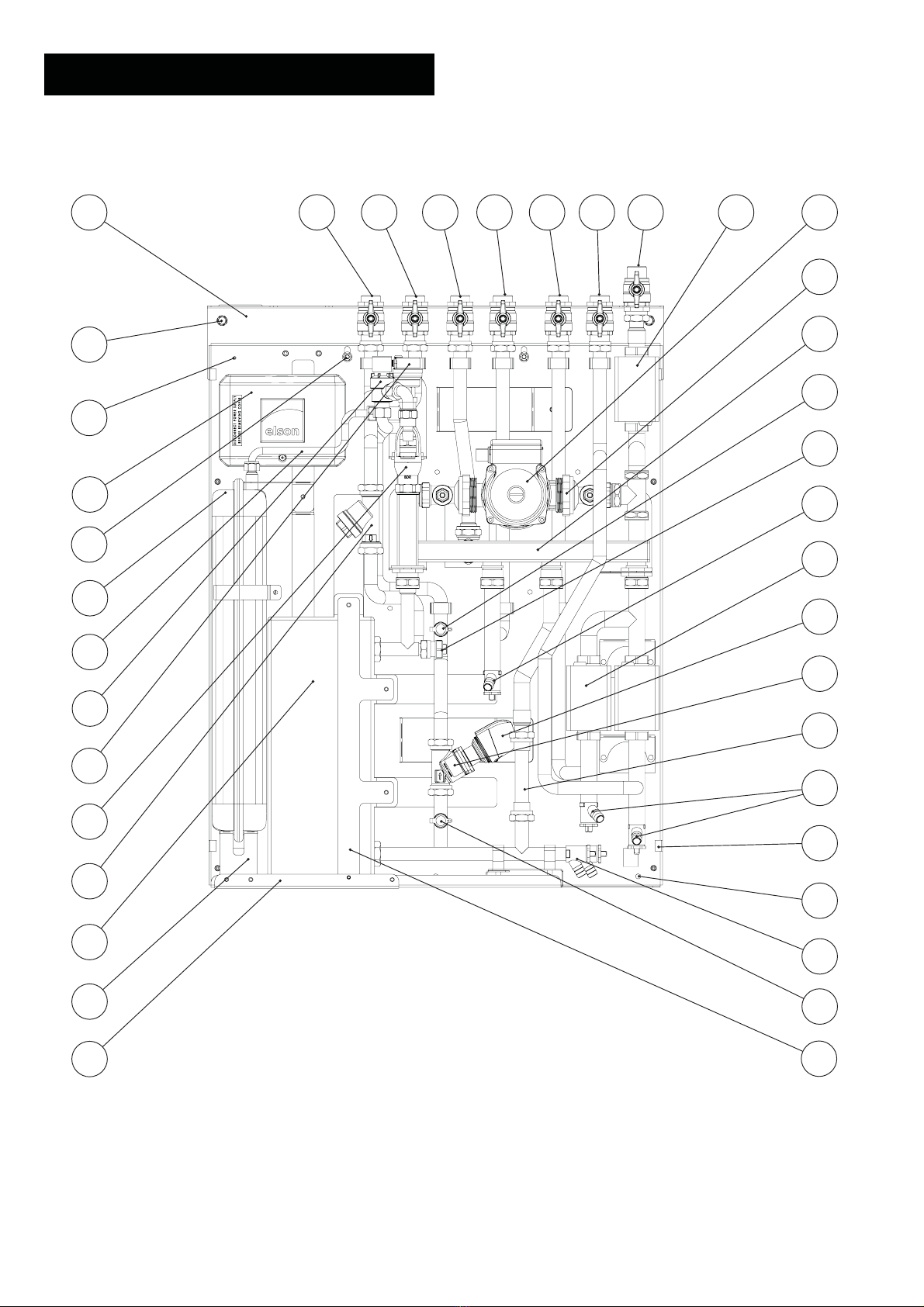

DIMENSIONS AND WEIGHT

Fig 5 CB-1Z and CB-1Z-DC Heat Interface Unit - 1 Heating Zone

Fig 6 CB-2Z and CB-2Z-DC Heat Interface Unit - 2 Heating Zones

(1) Community (district) heating flow - 3/4”bsp male

(2) Community (district) heating return - 3/4”bsp male

(3) HWS primary return connection - 3/4”bsp male

(4) Common central heating return connection - 3/4”bsp male

(5) Central heating flow (zone 1) connection - 3/4”bsp male

(6) Central heating flow (zone 2) connection - 3/4”bsp male

(7) HWS primary flow connection - 3/4”bsp male

(1) Community (district) heating flow - 3/4”bsp male

(2) Community (district) heating return - 3/4”bsp male

(3) HWS primary return connection - 3/4”bsp male

(4) Common central heating return connection - 3/4”bsp male

(5) Central heating flow (zone 1) connection - 3/4”bsp male

(6) N/A

(7) HWS primary flow connection - 3/4”bsp male

Unit Dry Weight (kg)

6 valve 1st fix rail 2.5

CB-1Z 25.0

CB-1Z-DC 26.0

Unit Dry Weight (kg)

7 valve 1st fix rail 2.8

CB-2Z 27.0

CB-2Z-DC 28.0

CB-1Z-DC unit detailed.

CB-2Z-DC unit detailed.

Note: All dimensions are for reference only.

Page 13

INSTALLATION

Access

The CB unit must be vertically mounted, either on a

supporting wall or within the cylinder frame provided for the

frame mounted variant. Although location is not critical, the

following points should be considered:

• Avoid siting where extreme cold temperatures will

be experienced. All exposed pipe work should be

insulated.

• The discharge pipework from the safety valves

must have minimum fall of 1:200 from the unit and

terminate in a safe and visible position.

• Access to associated controls and components

must be available to provide for the servicing and

maintenance of the system. Please refer to Fig 7 and

Fig 8 for minimum clearance requirements.

• Ensure the first fix rail is installed horizontally, check using

a spirit level.

Fig 8 Minimum Clearances

Please note that the clearance dimension detailed

above are for guidance. In installations where

available space to site the unit is less than these

recommendations please seek advice from Elson

Technical on 0844 335 8819.

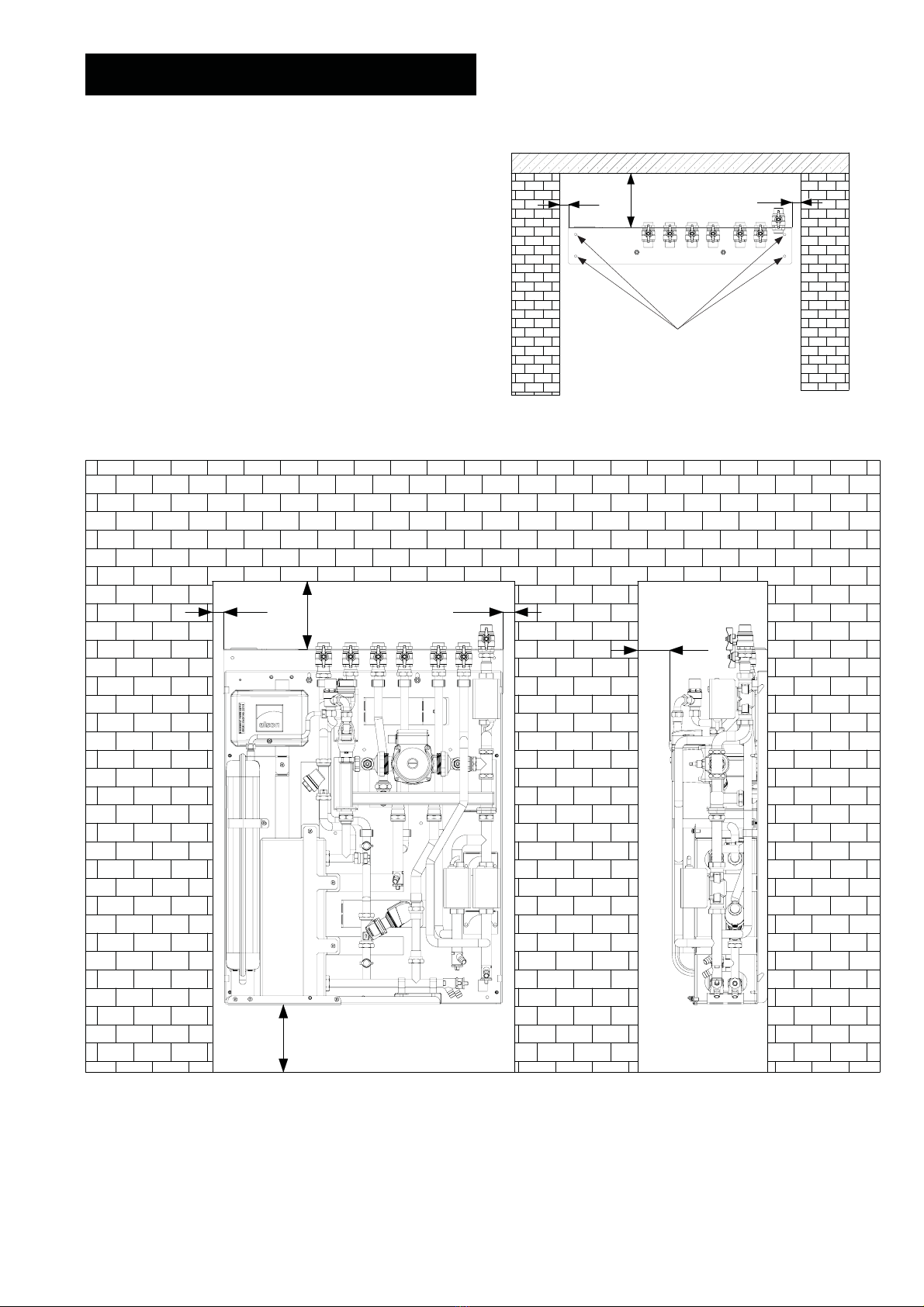

Fig 7 Fitting the first fix rail

Note: CB-2Z-DC detailed.

Note: 7 valve rail detailed.

Fixing points

Page 14

INSTALLATION

$

'(7$,/$

Fig 10. CB Heat Interface Unit - Mounting on the 1st fix rail

Fig 11 CB Heat Interface Unit - Bottom Support Fixing

Points

Bottom Fixing Points

Wall Fixing

The CB unit can be supplied with a first fix rail for ease of

installation. The rail allows the plumber to pipe up and test

the pipework to and from the heat interface unit without

the need to have the heat interface unit on site.

• Ensure that the access requirements detailed in

Fig 7 and Fig 8 have been met.

• Ensure the surface to be used will sustain the weight

of the unit when full of water.

• Fix the 1st fix rail to the wall using suitable fixings and

ensure the rail is level (Fig. 9).

• Slide the two studs provided on the 1st fix rail through

the slotted holes in the CB unit back plate and secure

loosely with the M6 nuts provided (Fig 10).

• Insert the washers supplied onto the tops of the pipe

faces on the CB unit and slide the CB unit upwards

until the washers come in contact with the isolation

valves on the 1st fix rail and tighten nuts.

• Mark out and drill the bottom fixing points and use

suitable fixings for the mounting surface (see Fig 11).

CB-1Z-DC Single heating zone unit detailed.

$

'(7$,/$

Fig 12 CB Heat Interface Unit - 1st fix rail isolation

valves IMPORTANT

Ensure the HWS primary

flow isolation valve is above

the rail bracket. All other

isolation valves should be

below the rail

Fig 9. First fix rail mounting details

Suitable

fixings

(not supplied)

CB-1Z-DC Single heating zone unit detailed.

INSTALLATION

TRVs, Room Thermostats and Automatic Bypass:

The room thermostat should be installed in the coldest

room in the house where the only heat source is a radiator

without TRV. The radiator should be fitted with lock

shield valves to avoid it being inadvertently isolated. It will

then act as a system bypass and heat dissipater for the

system.

Access for Servicing:

When installing the equipment within a confined space

/ cupboard consideration should be given to future

servicing and maintenance of the CB unit. Therefore

adequate access should be given to pumps, valves and

accessories. Please see Fig 7 and Fig 8.

System Filling:

The heating system filling loop is intended for temporary

connection to the system only. When this is not in use for

filling / topping up, the filling loop must be disconnected in

accordance with local water bylaws.

System Venting:

Automatic air vents should be used where practicable at

system high points.

In the case of pipework at high level which is not

accessible (i.e. on district systems within apartments and

similar) a line size automatic separator should be fitted.

Pipe Jointing and Cleaning:

All joints which are to be soldered should be made using a

flux that is sparingly applied and any residue to be flushed

out of the system before commissioning using a chemical

cleanser if necessary. All as per British Gas specification

for domestic wet central heating systems.

Pipework Insulation:

Elson system packages are supplied without pipe

insulation to allow the installer to ensure all joints are still

sound after installation. It is recommended that these

pipes are insulated.

District heating flow and return pipes should be insulated

to avoid stray heat losses in the apartment.

All pipes in unheated areas must be insulated in

accordance with local and national regulations.

Flushing bypass arrangement:

It is recommended that a flushing bypass arrangement is

installed to allow the CB heat interface unit to be isolated

from the district heating system during flushing and filling

of the distribution network.

District heating piping arrangement:

Where the CB unit is fitted with a two port on/off district

heating control valve, all branches within the distribution

pipework should be fitted with a reduced flow bypass

valve to ensure water flows through these pipes at all

times. It is recommended that this valve is sized and set to

pass 5% of the design flow rate for each branch. Details

of this arrangement are shown in Fig 24.

Two channel programmable room thermostat:

The CB heat interface unit can be supplied with a Danfoss

TP9000 2 channel controller (available as an accessory).

The controller has an in built room thermostat to control

one heating zone and also comes with a separate room

sensor should you wish to install the controller in a

cupboard or the kitchen for example.

On systems where there are two heating zones, an

additional programmable room thermostat, such as the

TP5000 is required (available as an accessory).

Treatment of water in the central heating system

All re-circulatory water systems will be subject to corrosion

unless they are flushed and an appropriate water

treatment is applied. To prevent this, follow the guidelines

given in BS 7593 ‘Treatment of Water in Domestic Hot

Water Central Heating Systems’ and the treatment

manufacturer’s instructions.

Treatment must involve the use of a proprietary cleanser,

such as Sentinel X300 or X400, or Fernox F3 and an

inhibitor such as Sentinel X100 or Fernox MB-1.

Full instructions are supplied with the products. For further

information contact Sentinel or Fernox.

Failure to flush and add inhibitor to the system will

invalidate the appliance warranty.

It is important to check the inhibitor concentration after

installation, system modification and at every service in

accordance with the inhibitor manufacturer’s instructions.

(Test kits are available from inhibitor stockists.)

For information or advice regarding any of the above

contact Technical Enquiries 0844 335 8819.

Earth Bonding

Ensure the installation is earth bonded in accordance with

BS EN 7671:2008.

Page 15

WIRING

Wiring

The CB heat interface unit is fitted with a pre-wired wiring

centre for ease of installation. There is an additional entry

point available on the right hand side of the wiring centre for

the mains cable and the cylinder / thermal store thermostat

cable. This is detailed in Fig 13.

Electrical isolation

The power supply to the CB unit should come via a double

poled isolation switched fused spur with contact separation

of at least 3mm fused at 3 Amps.

Cable entry point Cable bar clamp Clamp fixing points

Fig 13 Wiring centre

Fig 14 District Heating flow pipe thermostat

When the district heating system has a set back

temperature regime a district heating flow pipe thermostat

can be supplied to prevent the thermal store from being

charged during the set back temperature periods.

Main district flow pipe

Spring clip

District flow pipe

thermostat

3 core cable

IMPORTANT

The pipe thermostat must be fitted to the main flow pipe prior

to the flow pipe leg entering the apartment. This will ensure

the thermostat witnesses the temperature within the district

heating flow at all times.

The thermostat is set around a mean temperature of

70 deg C and wired across terminals 1 and 3 to make

contact on temperature rise. Thus allowing the cylinder to be

charged during district heating boost periods.

Fig 15 Fitting the thermostat to the flow pipe

ALL WIRING MUST BE IN ACCORDANCE WITH IEE &

BUILDING REGULATIONS.

A switch (having contact separation of at least 3mm in all

poles) must be incorporated in the fixed wiring as a means of

disconnecting the mains supply.

The heating system must be appropriately fused. A fuse

rated at no more than 3 amps should be installed.

Earth terminals, where provided, are for earth continuity

purposes only. All earth conductors inside the programmer

and room thermostat must be appropriately sleeved.

The zone valves are Class I devices and must be

connected to a suitable earth.

The unit should be earthed throughout and cross bonded.

Page 16

IMPORTANT

Please note that the blue neutral

wire MUST be identified with a

brown sleeve to indicate that it is

used as a live cable.

WIRING DIAGRAM

4

6

Not Used

3

10

2

4

10

2

71

2

3

4

5

6

7

8

9

10

1

6

8

Mains supply

Fused @ 3amp

240 volt (by

others)

N

L

Brown

Blue

Grey

Orange

Green/Yellow

V4043H1056

Zone valve

Hot water

Brown

Blue

Grey

Orange

Green/Yellow

V4043H1056

Zone valve

Central heating

Zone 1

L

N

1

3

4

Programmer

TP9000MA

3

2

1

E

Not Used

HTG

HWS

11

12

13

14

15

16

N N N

N

N

N

N

Wiring

Centre

Green/Yellow

Orange

Grey

Blue

Brown

73

1

8

2

5

6

Room

Sensor

11 L

E

N

District Valve

11

E

N

Pump

L

N

N

Coral Aquanox

Thermostat

District Flow

Temperature

Thermostat

##

## Note:

Remove link when

district heating flow

thermostat is fitted.

Fig 16 Wiring diagram for CB-1Z and CB-1Z-DC heat interface unit with 1 heating zone, an Elson Coral Aquanox thermal store and a district

flow temperature thermostat

Page 17

WIRING DIAGRAM

4

6

Not Used

3

10

2

4

10

2

71

2

3

4

5

6

7

8

9

10

1

6

8

15

11

N

2

3

Mains supply

Fused @ 3amp

240 volt (by

others)

N

L

TP5000M Si

Programmable

Room thermostat

Zone 2

Brown

Blue

Grey

Orange

Green/Yellow

V4043H1056

Zone valve

Hot water

Brown

Blue

Grey

Orange

Green/Yellow

V4043H1056

Zone valve

Central heating

Zone 1

L

N

1

3

4

Programmer

TP9000MA

3

2

1

Coral Aquanox

Thermostat

E

Not Used

L

E

N

District Valve

11

E

N

Pump

L

HTG

HWS

11

12

13

14

15

16

N N N

N

N

N

N

N

N

N

Wiring

Centre

Green/Yellow

Orange

Grey

Blue

Brown

10

3

15

Brown

Blue

Grey

Orange

Green/Yellow

V4043H1056

Zone valve

Central heating

Zone 2

N

5

6

Room

Sensor

3

L

3

73

1District Flow

Temperature

Thermostat

8

2

##

## Note:

Remove link when

district heating flow

thermostat is fitted.

Fig 17 Wiring diagram for CB-2Z and CB-2Z-DC heat interface unit with 2 heating zones, an Elson Coral Aquanox thermal store and a district

flow temperature thermostat

Page 18

WIRING DIAGRAM

Fig 18 Wiring diagram for CB-1Z and CB-1Z-DC heat interface unit with 1 heating zone and a Megaflo eco unvented cylinder

4

6

Not Used

3

10

2

4

10

2

71

2

3

4

5

6

7

8

9

10

1

6

8

Mains supply

Fused @ 3amp

240 volt (by

others)

N

L

Brown

Blue

Grey

Orange

Green/Yellow

V4043H1056

Zone valve

Hot water

Brown

Blue

Grey

Orange

Green/Yellow

V4043H1056

Zone valve

Central heating

Zone 1

L

N

1

3

4

Programmer

TP9000MA

3

2

1

E

Not Used

HTG

HWS

11

12

13

14

15

16

N N N

N

N

N

N

Wiring

Centre

Green/Yellow

Orange

Grey

Blue

Brown

5

6

Room

Sensor

11 L

E

N

District Valve

11

E

N

Pump

L

N

N

Megaflo cylinder

Thermostat

##

## Note:

Remove link when

district heating flow

thermostat is fitted.

Page 19

WIRING DIAGRAM

4

6

Not Used

3

10

2

4

10

2

71

2

3

4

5

6

7

8

9

10

1

6

8

15

11

N

2

3

Mains supply

Fused @ 3amp

240 volt (by

others)

N

L

TP5000M Si

Programmable

Room thermostat

Zone 2

Brown

Blue

Grey

Orange

Green/Yellow

V4043H1056

Zone valve

Hot water

Brown

Blue

Grey

Orange

Green/Yellow

V4043H1056

Zone valve

Central heating

Zone 1

L

N

1

3

4

Programmer

TP9000MA

3

2

1

Megaflo cylinder

Thermostat

E

Not Used

L

E

N

District Valve

11

E

N

Pump

L

HTG

HWS

11

12

13

14

15

16

N N N

N

N

N

N

N

N

N

Wiring

Centre

Green/Yellow

Orange

Grey

Blue

Brown

10

3

15

Brown

Blue

Grey

Orange

Green/Yellow

V4043H1056

Zone valve

Central heating

Zone 2

N

5

6

Room

Sensor

3

L

3

##

## Note:

Remove link when

district heating flow

thermostat is fitted.

Fig 19 Wiring diagram for CB-2Z and CB-2Z-DC heat interface unit with 2 heating zones and a Megaflo eco unvented cylinder

Page 20

This manual suits for next models

1

Table of contents