Elta Select Skyflow SSMF Series User manual

t: 01384 275800

f: 01384 275810

visit: eltaselect.com

Skyflow SSMF

Installation and Maintenance Instructions

THESE INSTRUCTIONS MUST BE READ FULLY BEFORE COMMENCING INSTALLATION.

CONTENTS

PAGE NO.

Electrical Data 2

Dimensional Data 3

Installation Instructions 4

General 4

Installation 4

Start Up 4

Fan Maintenance 4

Guarantee 5

Wiring Diagrams 6

SSMF Inst Issue C: 28-08-13

Tel: 01384 275800 Fax: 01384 275810 Email: [email protected] Visit: eltaselect.com Twitter: @eltaselect & @eltafans 2

Elta Fans Limited has a policy of continuous product development and improvement and therefore reserves the right to supply products which may differ from those illustrated and described in this publication.

Confirmation of dimensions and data will be supplied on request.

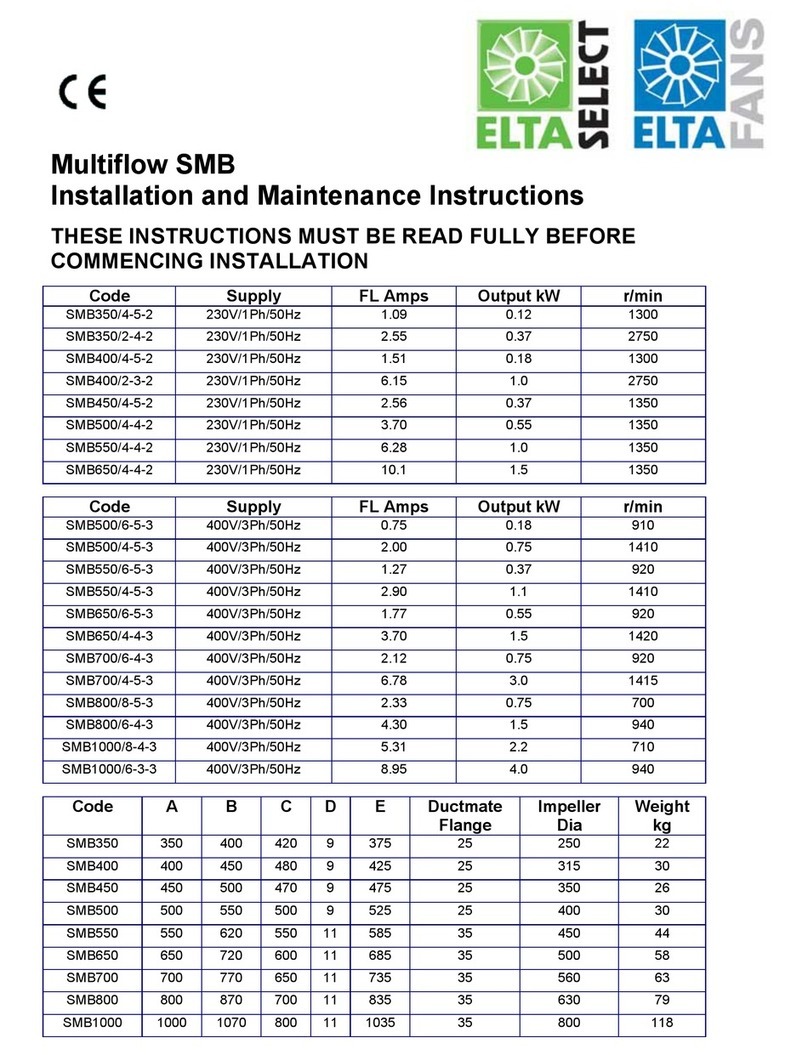

Skyflow SSMF AC

SSMF Inst Issue C: 28-08-13

Product

Code Supply FLC

Amps

Output

kW

Speed

r/min

Wiring

Diagram No.

SSMF315/6-5-2 230V/1Ph/50Hz 1.05 0.12 935 152-500

SSMF315/4-5-2 230V/1Ph/50Hz 1.80 0.25 1395 152-500

SSMF350/6-5-2 230V/1Ph/50Hz 1.05 0.12 885 152-500

SSMF350/4-4-2 230V/1Ph/50Hz 1.80 0.25 1300 152-500

SSMF400/6-5-2 230V/1Ph/50Hz 1.05 0.12 820 152-500

SSMF400/4-5-2 230V/1Ph/50Hz 3.60 0.55 1330 152-500

SSMF450/6-5-2 230V/1Ph/50Hz 6.00 0.55 935 152-500

SSMF450/4-4-2 230V/1Ph/50Hz 4.90 0.75 1290 152-500

SSMF500/6-5-2 230V/1Ph/50Hz 6.00 0.55 890 152-500

SSMF560/6-3-2 230V/1Ph/50Hz 6.00 0.55 875 152-500

Electrical Data

Product

Code Supply FLC

Amps

Output

kW

Speed

r/min

Wiring

Diagram No.

SSMF315/6-5-3 400V/3Ph/50Hz 0.68 0.18 955 152-608

SSMF315/4-5-3 400V/3Ph/50Hz 1.40 0.37 1415 152-608

SSMF350/6-5-3 400V/3Ph/50Hz 0.68 0.18 920 152-608

SSMF350/4-5-3 400V/3Ph/50Hz 1.40 0.37 1330 152-608

SSMF400/6-5-3 400V/3Ph/50Hz 0.68 0.18 855 152-608

SSMF400/4-5-3 400V/3Ph/50Hz 2.00 0.75 1460 152-608

SSMF450/6-5-3 400V/3Ph/50Hz 0.94 0.25 910 152-608

SSMF450/4-4-3 400V/3Ph/50Hz 2.00 0.75 1380 152-608

SSMF500/6-5-3 400V/3Ph/50Hz 2.00 0.55 920 152-608

SSMF500/4-4-3 400V/3Ph/50Hz 4.30 1.5 1390 152-608

SSMF560/6-3-3 400V/3Ph/50Hz 2.00 0.55 910 152-608

SSMF560/4-2-3 400V/3Ph/50Hz 4.30 1.5 1390 152-608

SSMF560/4-4-3 400V/3Ph/50Hz 6.78 3.0 1435 152-608

SSMF630/6-3-3 400V/3Ph/50Hz 5.36 2.2 965 152-601

Tel: 01384 275800 Fax: 01384 275810 Email: [email protected] Visit: eltaselect.com Twitter: @eltaselect & @eltafans 3

Elta Fans Limited has a policy of continuous product development and improvement and therefore reserves the right to supply products which may differ from those illustrated and described in this publication.

Confirmation of dimensions and data will be supplied on request.

Skyflow SSMF AC

SSMF Inst Issue C: 28-08-13

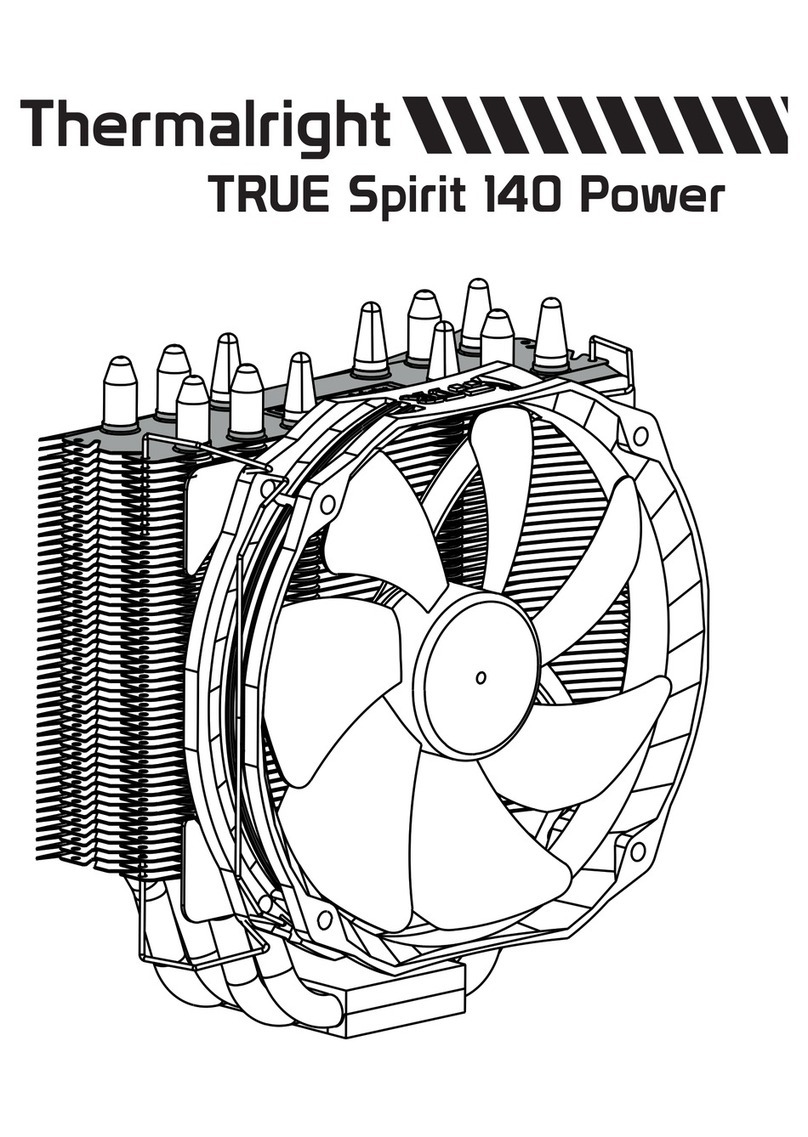

Dimensional Data

MIXED FLOW FAN

FOR ROOF THICKNESS

OF 50-75mm

STANDARD PURLIN

BOX IS SUITABLE

SECURE UNIT TO HARDWOOD

SILL WITH M10 COACH BOLTS

(NOT SUPPLIED BY ELTA FANS)

PURLIN BOX

PURLIN BOX SECURED TO TRIMMERS

WITH M10 LINDAPTERS

(NOT SUPPLIED BY ELTA FANS)

CURB MOUNTING UNIT

PURLIN MOUNTING UNIT

K CTS

J TYP CTS

H TYP CTS

G BETWEEN TRIMMERS

50

C

E SQ.

B SQ. INSIDE

A SQUARE

D

F HEIGHT

K CTS

M OUTSIDE 150

L SQUARE

75

50

Product

Code A B C D E F G H J K L M Weight

Kg

SSMF31 710 684 325 85 610 240 636 250 750 500 460 610 20

SSMF35 800 784 445 90 730 250 756 300 870 600 550 700 25

SSMF40 800 784 445 90 730 250 756 300 870 600 550 700 27

SSMF45 960 934 510 100 860 250 886 350 1000 745 700 850 40

SSMF50 960 934 510 100 860 250 886 350 1000 745 700 850 42

SSMF56 1230 1054 590 105 1000 250 1026 435 1140 870 830 980 82

SSMF63 1230 1054 590 105 1000 250 1026 435 1140 870 830 980 90

Tel: 01384 275800 Fax: 01384 275810 Email: [email protected] Visit: eltaselect.com Twitter: @eltaselect & @eltafans 4

Elta Fans Limited has a policy of continuous product development and improvement and therefore reserves the right to supply products which may differ from those illustrated and described in this publication.

Confirmation of dimensions and data will be supplied on request.

Skyflow SSMF AC

SSMF Inst Issue C: 28-08-13

1.0 GENERAL

1.1 It is important these Installation and Maintenance Instructions are fully adhered to.

1.2 Full details of the unit supplied are shown on the product nameplate. If in doubt about any detail contact Elta Fans Ltd or its agents for

clarification.

1.3 All electrical installation must be carried out by suitably qualified and competent personnel in accordance with all current statutory

requirements.

1.4 These instructions cover only the Elta Fans Ltd product and do not include the supply or installation of any safety equipment that may

be required e.g. adequate guarding or protection from rotating parts and proper electrical isolation.

1.5 Any declarations made by Elta Fans Ltd about product installation and safety, are dependant on the fan equipment being used within

installations which themselves meet the requirements of the relevant Standards and Directives of your region.

1.6 The fan is designed for use in an ambient temperature of -20°C up to +70°C fixed speed, -20°C up to +50°C when used with a speed

controller and up to 95% relative humidity. The fan is not suitable for corrosive or explosive atmospheres.

1.7 The installer should provide easy access to the fan to facilitate future maintenance.

1.8 The installer should ensure the fan is adequately supported.

1.9 This product is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given supervision or instruction concerning use of the product by a person responsible

for their safety.

Children should be supervised to ensure that they do not play with the product.

1.10 At end-of-life, the unit must be disposed of in an environmentally friendly manner by suitably qualified and competent personnel in

accordance with the requirements of applicable Standards and Directives.

2.0 INSTALLATION

WARNING – The fan must be isolated from the power supply during installation and maintenance. The fan must be earthed in

accordance with the local regulations.

2.1 Upon receipt, the fan equipment should be visually inspected to check for any damage. Ensure that the impeller is free to rotate.

2.2 If there are any queries concerning the fan equipment, Elta Fans Ltd should be contacted prior to the installation.

2.3 The fan must be securely mounted in the desired position to suit the application. The fan can be mounted on flat or inclined roofs with a

maximum pitch angle of 35o .

2.4 Assembly: SSMF fans are supplied with the fan/motor fully assembled to the base/cowl.

DO NOT OVERTIGHTEN THE BOLTS AS THIS MAY DAMAGE THE BASE.

2.5 Backdraught shutters: Backdraught shutters for SSMF fans are supplied as an assembled unit and are fitted prior to roof unit

installation. The shutter assembly top flange locates onto the curb or purlin box top face.

2.6 Having fitted the shutter tray, it is necessary to make the connections to the motor terminal box before fitting the roof unit to the curb or

purlin box. Feed the supply cable through the grommet hole in the bottom flange of the shutter tray and make the connections to the

terminal box which is attached to the motor plate.

2.7 Curb mounting: Position the assembled roof unit onto the curb and secure to the timber sill with M10 coach bolts (not supplied by Elta

Fans), ensuring that fibre washers are positioned under each bolt head. It is advisable to drill pilot holes prior to fitting the bolts to prevent

splitting the timber curb.

DO NOT OVERTIGHTEN THE BOLTS AS THIS MAY DAMAGE THE BASE.

2.8 Purlin mounting:

• Purlin trimmers: - should be bolted to the vertical flange of the purlin member taking care to align with the roof opening.

• Purlin box: - position onto trimmers and fit M10 type ‘A’ short tail lindaptors (not supplied by Elta Fans) into holes in the bottom flanges.

Do not tighten nuts at this stage.

• Soaker sheets: - slip the soaker sheet over the purlin box and fix and seal to the roof sheeting. Align the purlin box with the soaker sheet

and tighten the lindaptor nuts.

• Position the roof unit into the purlin box and insert M10 bolts into the four corner holes and into the purlin box captive fixings ensuring

that fibre washers are positioned under the bolt heads.

DO NOT OVERTIGHTEN THE BOLTS AS THIS MAY DAMAGE THE BASE.

2.9 Check the details on the motor rating plate to ensure that the correct power supply (voltage, frequency and phase) is available.

An incorrect power supply will lead to permanent damage to the fan motor.

2.10 Refer to the appropriate wiring diagram. Ensure that all earth connections are made.

2.11 Means for electrical disconnection must be incorporated in the wiring installation in accordance with the relevant wiring and electrical

regulations.

2.12 Precaution must be taken to locate the exhaust discharge terminal so as to avoid the backflow of gases into the room from the open flue

of gas or other fuel burning appliances.

Installation Instructions

Tel: 01384 275800 Fax: 01384 275810 Email: [email protected] Visit: eltaselect.com Twitter: @eltaselect & @eltafans 5

Elta Fans Limited has a policy of continuous product development and improvement and therefore reserves the right to supply products which may differ from those illustrated and described in this publication.

Confirmation of dimensions and data will be supplied on request.

Skyflow SSMF AC

SSMF Inst Issue C: 28-08-13

3.0 START-UP

3.1 Before power is supplied to the unit, check that the wiring is correct as per the fan connection diagram.

3.2 At initial start-up, check that impeller rotation and airflow direction is correct.

3.3 Check that the motor amperage draw does not exceed the nameplate rating.

4.0 FAN MAINTENANCE

4.1 Inspection of the fan at least once every 12 months is recommended to ensure that the motor, fan blades, and supporting guards, are

clean. Any build up of dust and deposits on the blades or guards should be removed using a non-abrasive cleaner.

4.2 All fastenings should be checked for tightness. In addition, all rotating items should be checked.

4.3 Bearings are of the ‘sealed for life’ type and will not need a detailed inspection.

WARNING – This fan is fitted with an auto-reset thermal contact which switches the fan off in the event of a fault condition.

Once the motor cools down the fan may start unexpectedly.

Only a suitably qualified and competent person may carry out maintenance after the electrical supply has been isolated.

Installation Instructions

GUARANTEE

Elta Fans Ltd will, free of charge, within a period of 1 year from the date of dispatch from their works, repair or at its option replace

any goods which are proved to have defects as a result of defective materials or workmanship. The goods MUST be returned to Elta

Fans Ltd carriage paid for examination.

Tel: 01384 275800 Fax: 01384 275810 Email: [email protected] Visit: eltaselect.com Twitter: @eltaselect & @eltafans 6

Elta Fans Limited has a policy of continuous product development and improvement and therefore reserves the right to supply products which may differ from those illustrated and described in this publication.

Confirmation of dimensions and data will be supplied on request.

Skyflow SSMF AC

SSMF Inst Issue C: 28-08-13

Wiring Diagrams

TB (WHITE)

220 - 240V 1PH 50Hz SUPPLY

E (GREEN/YELLOW)

TB (WHITE)

Z2 (YELLOW)

BROWN

BLUE

U2 (BLACK)

U1 (RED)

Z1 (BLUE)

CAPACITOR

FAN TERMINAL

BOX

EL N

FIXED SPEED CONNECTION

GREEN/YELLOW

BROWN

BLUE

L/U1 N/U2

TBTB AUX

THERMAL CUT - OUT

CONNECT INTO

STARTER CONTROL

CIRCUIT

TB (WHITE)

E (GREEN/YELLOW)

TB (WHITE)

Z2 (YELLOW)

BROWN

BLUE

U2 (BLACK)

U1 (RED)

Z1 (BLUE)

CAPACITOR

FAN TERMINAL

BOX

GREEN/YELLOW

L/U1 N/U2

TBTB AUX

220 - 240V 1PH 50Hz SUPPLY

N

CONTROLLER

TERMINAL BOX

LE

GREEN/YELLOW

BLUE

BROWN

BLUE

BROWN

BROWN

VARIABLE SPEED CONNECTION CONTROLLER TYPE TC12, TC14, TC18, TC110, TC112

THERMAL CUT - OUT

CONNECT INTO

STARTER CONTROL

CIRCUIT

L NN AUX EL

TB (WHITE)

E (GREEN/YELLOW)

TB (WHITE)

Z2 (YELLOW)

BROWN

BLUE

U2 (BLACK)

U1 (RED)

Z1 (BLUE)

CAPACITOR

FAN TERMINAL

BOX

L/U1 N/U2

TBTB AUX

EU1TKTK L AUXU2N

BLUE

BROWN

GREEN/YELLOW

BROWN

BROWN

BLUE

VARIABLE SPEED CONNECTION CONTROLLER TYPE EL31TK, EL61TK

GREEN/YELLOW

220 - 240V 1PH 50Hz SUPPLY

N

CONTROLLER

TERMINAL BOX

LE

ALL WIRING AND CONTROL EQUIPMENT MUST COMPLY TO THE

LATEST IEE REGULATIONS, IN PARTICULAR PART 552-01-02/03

11/07/2013

MK-152-500 Issue: Saved Date:

D

152-500

Tel: 01384 275800 Fax: 01384 275810 Email: [email protected] Visit: eltaselect.com Twitter: @eltaselect & @eltafans 7

Elta Fans Limited has a policy of continuous product development and improvement and therefore reserves the right to supply products which may differ from those illustrated and described in this publication.

Confirmation of dimensions and data will be supplied on request.

Skyflow SSMF AC

SSMF Inst Issue C: 28-08-13

4 5 6 731 2 811109

L1/L U V WL3

L2/N

BROWN

BLACK

GREY

GREEN/YELLOW

BROWN

BLACK

GREY

GREEN/YELLOW

1 - 7 PRE WIRED

EL1

380 - 440V 3PH 50Hz SUPPLY

L2

10 RELAY COMMON

11 RELAY CONTACT

3PH - 3PH

IP55 INVERTER

ANALOG / DIGITAL

INPUT CONNECTIONS

VERIABLE SPEED CONNECTION CONTROLLER TYPE 3PH - 3PH IP55 INVERTER

L3

W1 (BLUE)

V1 (YELLOW)

U1 (RED)

N (BLACK)

TB (WHITE)

E (GREEN/YELLOW)

TB (WHITE)

FAN TERMINAL

BOX

THERMAL CUT-OUT

CONNECT INTO

STARTER CONTROL

CIRCUIT

U1V1W1TBTB

W1 (BLUE)

V1 (YELLOW)

U1 (RED)

N (BLACK)

TB (WHITE)

THERMAL CUT-OUT

CONNECT INTO

STARTER CONTROL

CIRCUIT

L1L2L3

E (GREEN/YELLOW)

TB (WHITE)

FAN TERMINAL

BOX

E

380 - 440V 3PH 50Hz SUPPLY

GREEN/YELLOW

GREY

BLACK

BROWN

FIXED SPEED CONNECTION

U1V1W1TBTB

VARIABLE SPEED CONNECTION CONTROLLER TYPE TC33, TC35, TC310

BROWN

BLACK

GREY

GREEN/YELLOW

CONTROLLER

TERMINAL BOX

L3L2L1 E

380 - 440V 3PH 50Hz SUPPLY

V WUL1 EL2 L3

TB TB W1 V1 U1

BROWN

BLACK

GREY

GREEN/YELLOW

FAN TERMINAL

BOX

TB (WHITE)

E (GREEN/YELLOW)

TB (WHITE)

N (BLACK)

U1 (RED)

V1 (YELLOW)

W1 (BLUE)

THERMAL CUT-OUT

CONNECT INTO

STARTER CONTROL

CIRCUIT

L1/L U V WL3

L2/N 4 5 6 731 2 811109

THERMAL CUT-OUT

CONNECT INTO

STARTER CONTROL

CIRCUIT

FAN TERMINAL

BOX

TB (WHITE)

E (GREEN/YELLOW)

TB (WHITE)

N (BLACK)

U1 (RED)

V1 (YELLOW)

W1 (BLUE)

L3

VERIABLE SPEED CONNECTION CONTROLLER TYPE 3PH - 3PH IP20 INVERTER

ANALOG / DIGITAL

INPUT CONNECTIONS

3PH - 3PH

IP20 INVERTER

10 RELAY COMMON

11 RELAY CONTACT

L2

380 - 440V 3PH 50Hz SUPPLY

L1 E

GREEN/YELLOW

GREY

BLACK

BROWN

GREEN/YELLOW

GREY

BLACK

BROWN

1: +24V OUTPUT

2: STOP/RUN DI1

3: FWD/REV DI2

4: ANALOG/PRESET DI3

5: +10V OUTPUT

6: ANALOG INPUT

7: 0V

TB TB W1 V1 U1

ALL WIRING AND CONTROL EQUIPMENT MUST COMPLY TO THE

LATEST IEE REGULATIONS, IN PARTICULAR PART 552-01-02/03

15/07/2013

MK-152-608 Issue: Saved Date:

C

Wiring Diagrams

152-608

Tel: 01384 275800 Fax: 01384 275810 Email: [email protected] Visit: eltaselect.com Twitter: @eltaselect & @eltafans 8

Elta Fans Limited has a policy of continuous product development and improvement and therefore reserves the right to supply products which may differ from those illustrated and described in this publication.

Confirmation of dimensions and data will be supplied on request.

Skyflow SSMF AC

SSMF Inst Issue C: 28-08-13

Wiring Diagrams

L1/L U V WL3

L2/N 4 5 6 731 2 811109

L3

3PH

Δ

CONNECTED FAN C/W INVERTER

ANALOG / DIGITAL

INPUT CONNECTIONS

3PH - 3PH

IP20 INVERTER

10 RELAY COMMON

11 RELAY CONTACT

L2

380 - 440V 3PH 50Hz SUPPLY

FAN TERMINAL

BOX

L1 E

1: +24V OUTPUT

2: STOP/RUN DI1

3: FWD/REV DI2

4: ANALOG/PRESET DI3

5: +10V OUTPUT

6: ANALOG INPUT

7: 0V

GREEN/YELLOW

GREY

BLACK

BROWN

W2 U2 V2

U1 W1V1

GREEN/YELLOW

GREY

BLACK

BROWN

BROWN

BLACK

GREY

GREEN/YELLOW

FAN TERMINAL

BOX

L2 EL3L1

380 - 440V 3PH 50Hz SUPPLY

FIXED SPEED

Δ

CONNECTION

W2 U2 V2

U1 W1V1

1 TO 7

PRE - WIRED 10 RELAY COMMON

11 RELAY CONTACT

L3

ANALOG / DIGITAL

INPUT CONNECTIONS

3PH - 3PH

IP55 INVERTER

L2

380 - 440V 3PH 50Hz SUPPLY

FAN TERMINAL

BOX

L1 E

GREEN/YELLOW

GREY

BLACK

BROWN

W2 U2 V2

U1 W1V1

GREEN/YELLOW

GREY

BLACK

BROWN

3PH

Δ

CONNECTED FAN C/W INVERTER

9 10 11

8

21 3 7654

L2/N L3 WVU

L1/L

GREY

BLACK

BROWN

GREEN/YELLOW

GREY

BLACK

BROWN

GREEN/YELLOW

FAN TERMINAL

BOX

W2 U2 V2

U1 W1V1

380 - 440V 3PH 50Hz SUPPLY

VARIABLE SPEED

Δ

CONNECTION CONTROLLER TYPE TC33, TC35, TC310

L1 L2 L3

E

CONTROLLER

TERMINAL BOX

W

EL3 U VL2L1

ALL WIRING AND CONTROL EQUIPMENT MUST COMPLY TO THE

LATEST IEE REGULATIONS, IN PARTICULAR PART 552-01-02/03

15/07/2013

MK-152-601 Issue: Saved Date:

B

152-601

EC Declaration of Conformity

Designation of Equipment:

Raptor, Compact, Powerplus, Revolution, Miniflow, Multiflow,

Viper, Jetflow, Jetstream, Hideaway, Singleflow, Quietflow,

Twinflow, Powerduct, Qube, Slim-Qube, Skyflow, Heritage,

Biflow, Zoo Fan, Ceiling Fan, SmokeVent, Pedestal, Window/

Wall, Ezifit

Type:

SPA, SDA, SCP, SCPA, SCD, SCPP, SPP, SLC, SAMF, SMB,

SMC, SMT, SCC, HIT, SJS, SH, SSD, SQS, SQSDCV,STD,

SQT, SQTDCV, SPD, SQU, SQU-HT, SSQU, SSR, SSF,

SSMF, SMF, SSDR, SSDRDCV, STDR, STDRDCV, SGE, SCH,

SCHT, SSFV, SSRV, SSC, SB, SDF, HCF, HPFA, HWFA, SRC,

SAX, SRE, SEIE, SEWE

Low Voltage Directive2006/95/EC

Electromagnetic Compatibility (EMC) Directive 2004/108/EC

Energy-Related Products (ErP) Directive 2009/125/EC

Herewith declare that the air movement equipment below, on

the basis of its design and construction as partly completed

machines brought onto the market is in compliance within rele-

vant health and safety requirements of the EC Directives stated

above. In the event that alterations are made to the machinery

without prior consent with the manufacturer, this declaration

becomes invalid.

EC Declaration of Incorporation

In accordance with the Machinery Directive 2006/42/EC

Designation of Equipment:

Raptor, Compact, Powerplus, Revolution, Miniflow, Multiflow,

Viper, Jetflow, Jetstream, Hideaway, Singleflow, Quietflow,

Twinflow, Powerduct, Qube, Slim-Qube, Skyflow, Heritage,

Biflow, Zoo Fan, Ceiling Fan, SmokeVent, Window/Wall, Ezifit

Type:

SPA, SDA, SCP, SCPA, SCD, SCPP, SPP, SLC, SAMF, SMB,

SMC, SMT, SCC, HIT, SJS, SH, SSD, SQS, SQSDCV,STD,

SQT, SQTDCV, SPD, SQU, SQU-HT, SSQU, SSR, SSF,

SSMF, SMF, SSDR, SSDRDCV, STDR, STDRDCV, SGE, SCH,

SCHT, SSFV, SSRV, SSC, SB, SDF, HCF, SEIE, SEWE

The design of the partly completed machines listed below

complies with the Essential Health and Safety Requirements

(EHSRs) of ANNEX I, sections 1.1.2, 1.1.5, 1.4.1, 1.5.1 in EC

Machinery Directive 2006/42/EC

The partly completed machines comply with the requirements

of :- Low Voltage Directive 2006/95/EC, Electromagnetic

Compatibility (EMC) Directive 2004/108/EC, Energy-Related

Products (ErP) Directive 2009/125/EC

The machinery is incomplete and must not be put into service

until such time as the machinery which is partly complete is to

be incorporated and has been assessed and declared in con-

formity with the provisions of the Machinery Directive 2006/42/

EC.

We undertake to transmit, upon reasoned request by appro-

priate national authorities, relevant information on the partly

completed machinery identified above.

Manufacturer:

Elta Fans Limited

17 Barnes Wallis Road

Segensworth East Industrial Estate

Fareham, Hampshire

PO15 5ST, UK

Date / Signature of Manufacturer: Date: 20th May 2013

Name / Position of Signatory: Mr. Robert Rees Q.A.Manager Elta Fans Ltd,

EC DECLARATION OF

CONFORMITY/INCORPORATION

Herewith we declare that the air movement equipment below, on the basis of its design and construction in the form brought onto

the market is in accordance within the relevant health and safety requirements of the EC Directive for

use of machinery.

Issuer: Bob Rees Issue A Date: 20th May 2013

A member of

HEVAC ASSOCIATION

BS EN ISO 9001:2008

FM 556465

GROUP LIMITED

A member of

www.eltafans.com

BUILDING SERVICES

Tel: +44 (0) 1384 275800

Fax: +44 (0) 1384 275810

e-mail: [email protected]

46 Third Avenue

Pensnett Trading Estate

Kingswinford, West Midlands

DY6 7US, United Kingdom

APPLIED TECHNOLOGY

Tel: +44 (0) 1489 566500

Fax: +44 (0) 1489 566555

e-mail: [email protected]

17 Barnes Wallis Road

Segensworth East Industrial Estate

Fareham, Hampshire

PO15 5ST, United Kingdom

EXPORT

Tel: +44 (0) 1489 566500

Fax: +44 (0) 1489 566555

e-mail: [email protected]

17 Barnes Wallis Road

Segensworth East Industrial Estate

Fareham, Hampshire

PO15 5ST, United Kingdom

This manual suits for next models

24

Table of contents

Other Elta Select Fan manuals