Operating Manual Heat Tracing System

ELK-MI-AY825 / ELK-MI-VA

In Hazardous Locations (Ex)

Page 2 of 21

Inhalt

2. System Components ...................................................................................................... 3

2.1 The Single Core Heating Systems comprise the following components:............................ 3

2.2 The Twin Core Heating Systems comprise the following components:.............................. 4

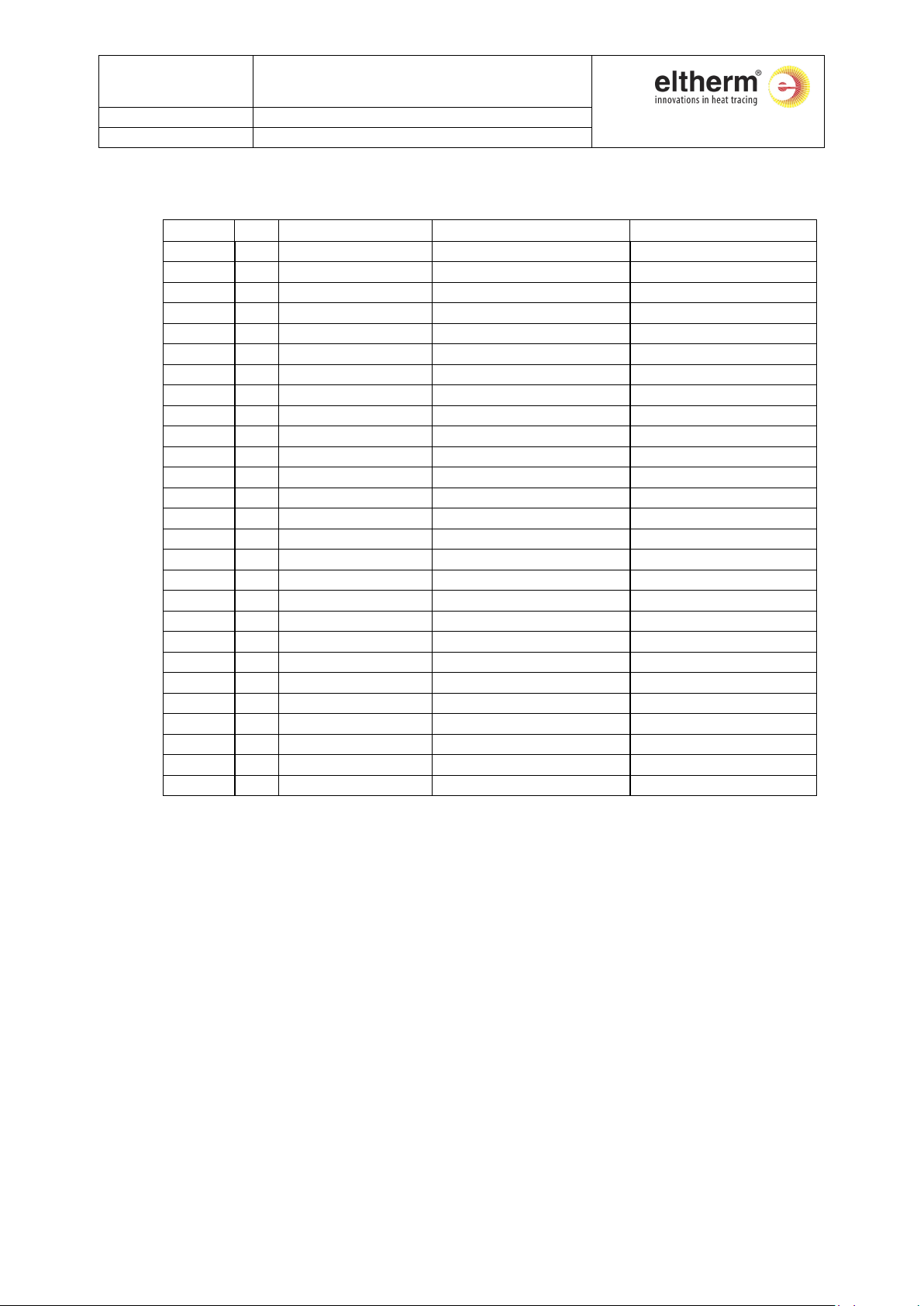

3. Technical Data ............................................................................................................... 4

4. Available Resistances ..................................................................................................... 5

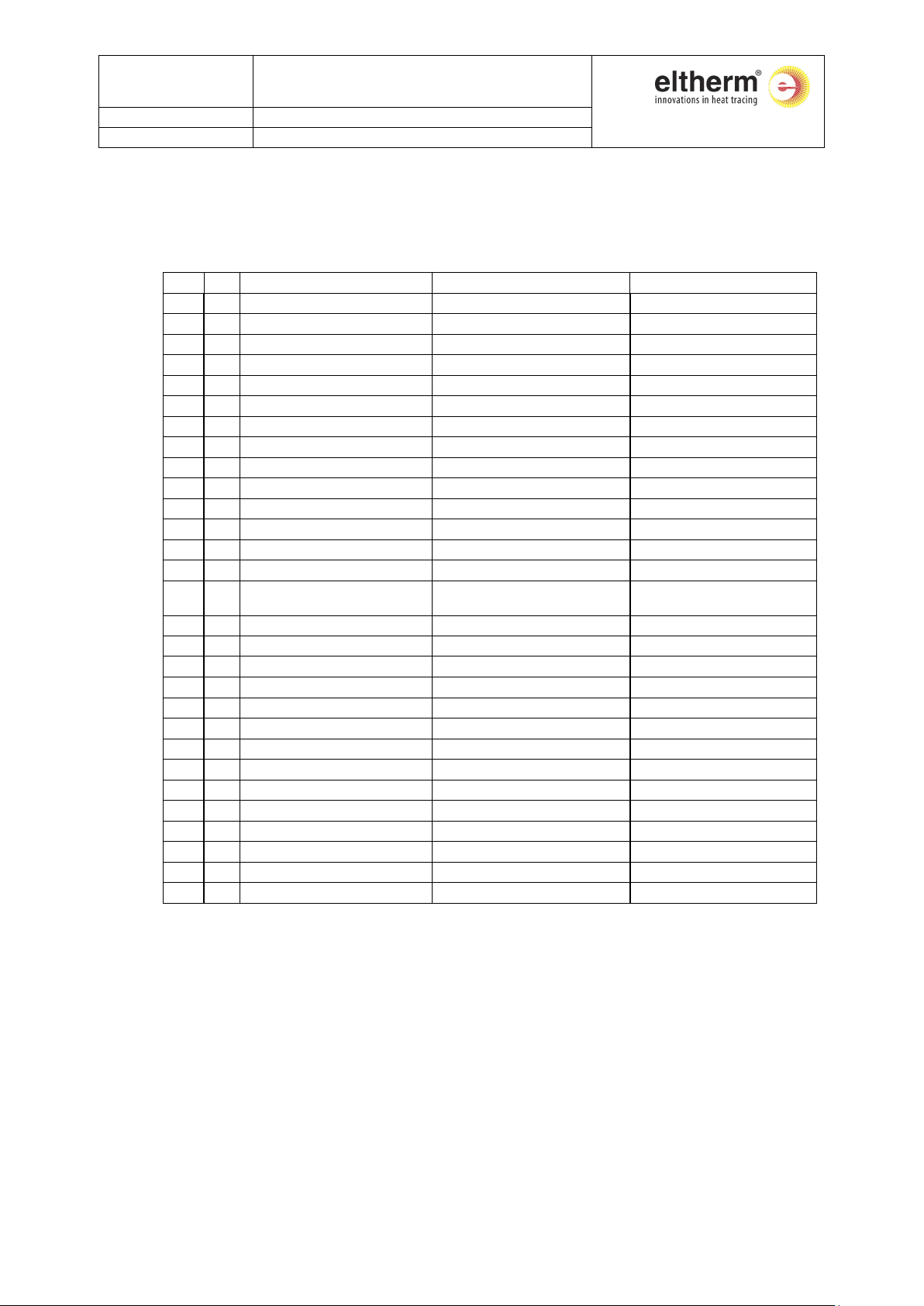

4.1 ELK-MI-VA and VA-T ............................................................................................................ 5

4.2 ELK-MI-AY825 ...................................................................................................................... 7

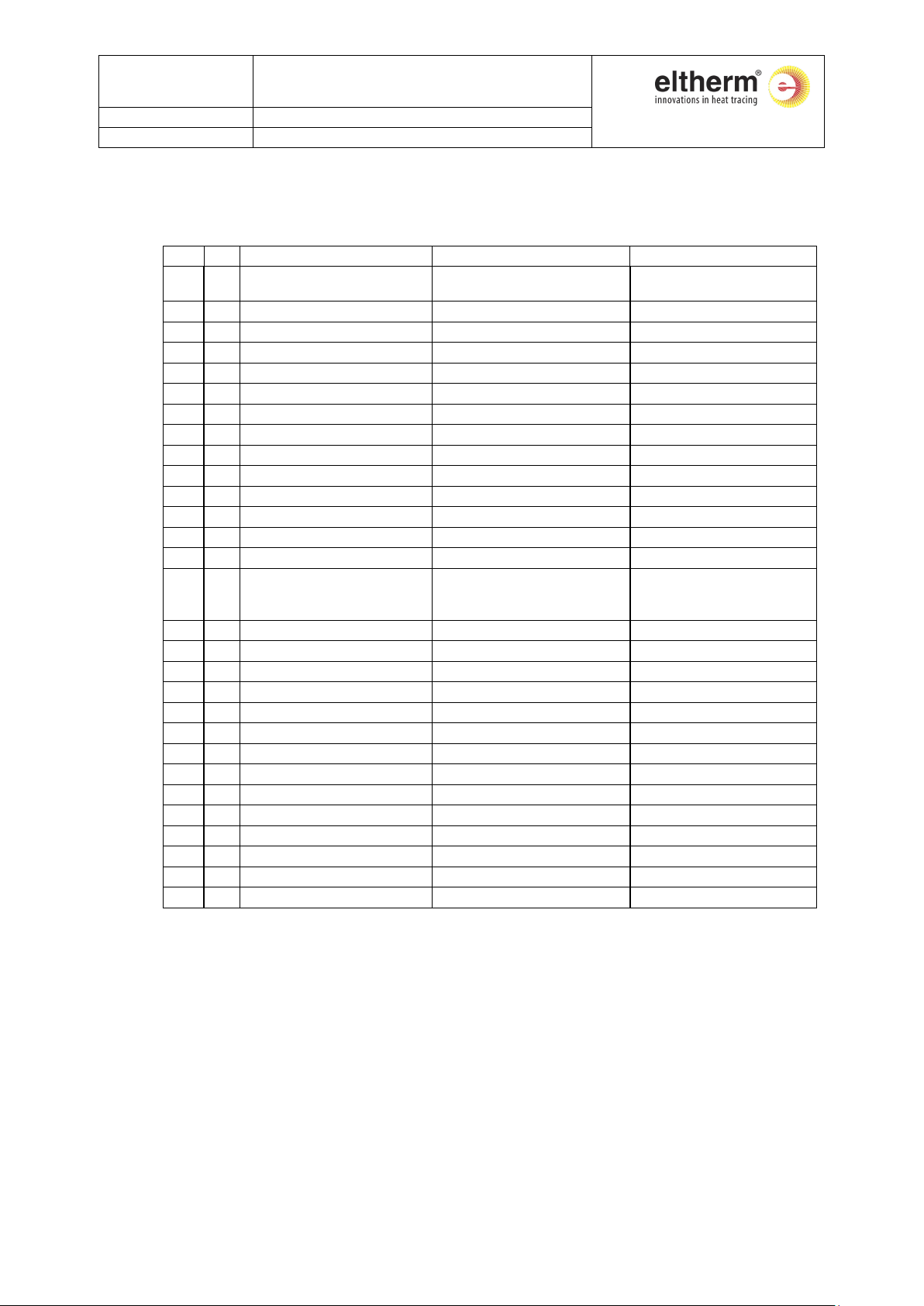

4.3 ELK-MI-AY825 T ................................................................................................................... 8

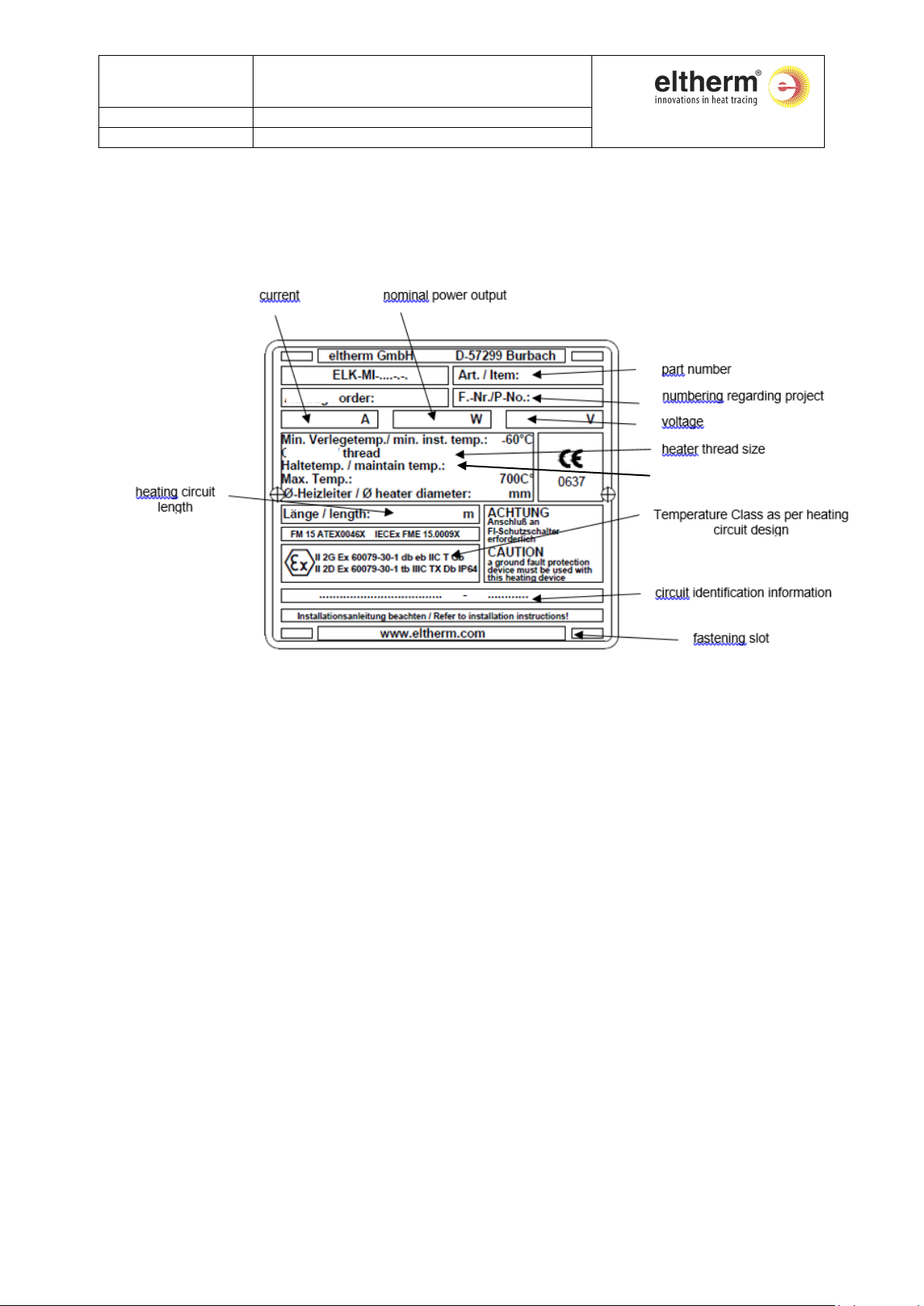

5. Marking ......................................................................................................................... 9

6. Restrictions on thickness and material of thermal insulation........................................... 9

7. Heating Circuit Design .................................................................................................... 9

8. Location of temperature sensors .................................................................................... 9

8.1 Temperature controllers ..................................................................................................... 9

8.2 Temperature limiters......................................................................................................... 10

9. Summary of Conditions of Safe Use as per Type Approval Certificate............................. 11

10. Installation of the Heat Tracing System ELK-MI-**** Ex................................................. 12

10.1 Application......................................................................................................................... 12

10.2 Receipt of Goods ............................................................................................................... 12

10.3 Storage .............................................................................................................................. 12

10.4 Length of Heating Circuit................................................................................................... 12

10.5 Protective Measures.......................................................................................................... 13

10.6 Heater Installation............................................................................................................. 13

10.7 Test and Commissioning.................................................................................................... 15

10.8 Operation and Maintenance: ............................................................................................ 16

11.Installation of ELK-MI Trace Heaters ............................................................................. 17

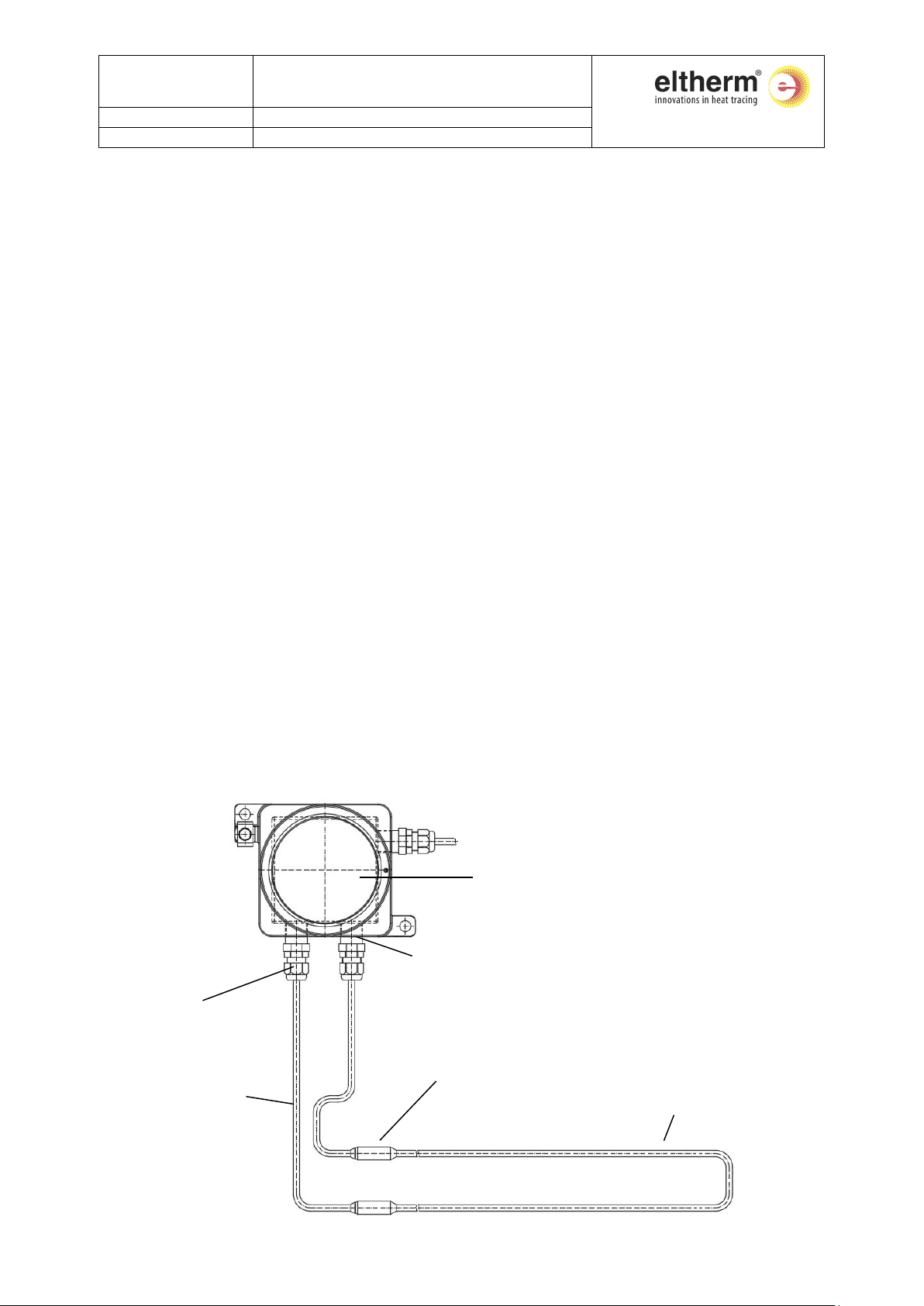

11.1 Typical Installation of Mineral-Insulated Trace Heaters on Pipes..................................... 17

11.2 Typical Installation of Mineral-Insulated Trace Heater on Flanges................................... 18

11.3 Typical Installation of Mineral-Insulated Trace Heater on Elbows ................................... 18

11.4 Typical Installation of Mineral-Insulated Trace Heater on Valves .................................... 19

11.5 Typical Installation of Mineral-Insulated Trace Heater on Pumps.................................... 19

12. Installation of Gland..................................................................................................... 20

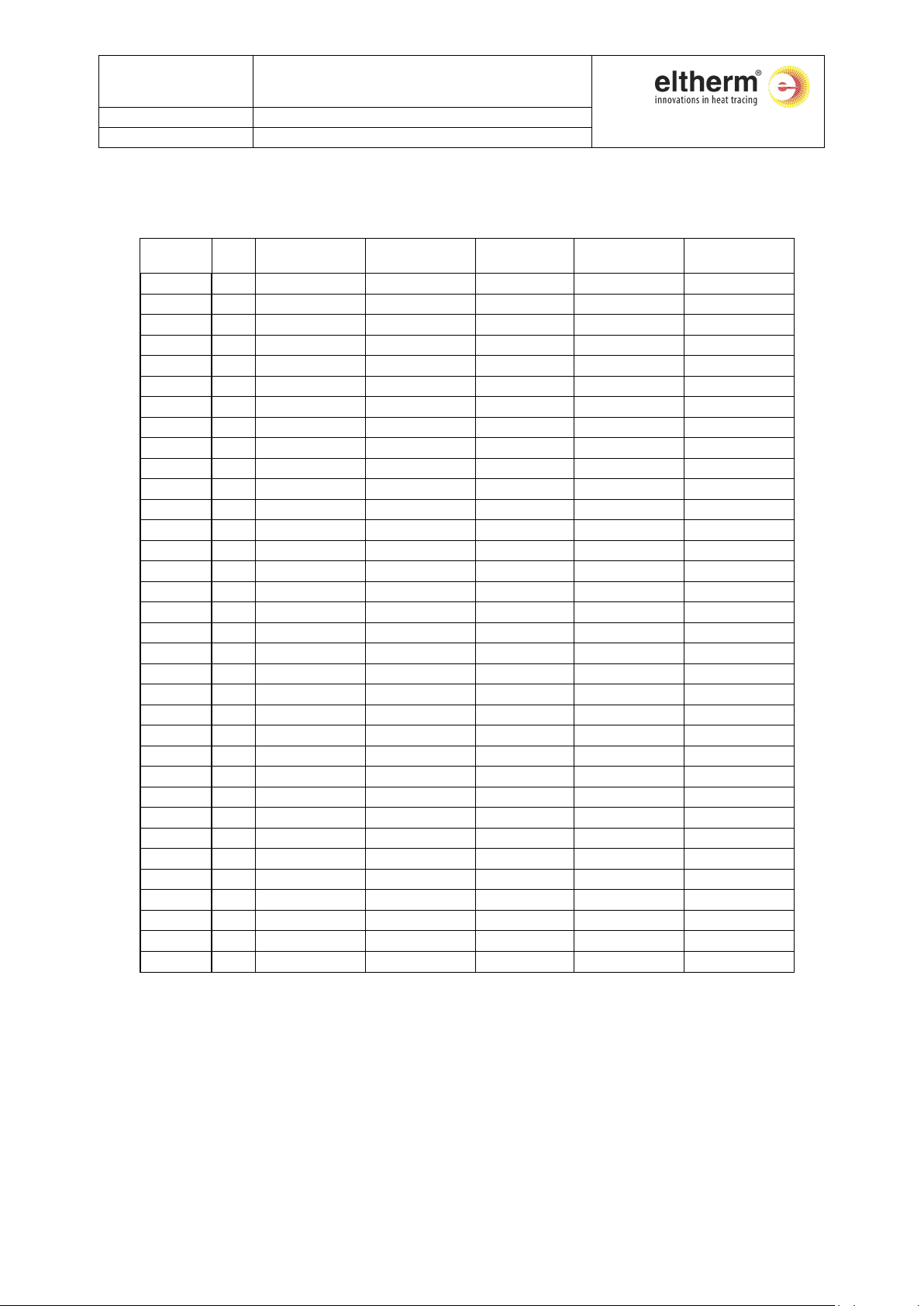

12.1 Design and Technical Data ................................................................................................ 20

12.2 Installation......................................................................................................................... 20

12.3 Operation and maintenance ............................................................................................. 21