elysator PUROTAP Compenso Series Parts list manual

www.elysator.com

Installation

Function

Operation

Service

Minerals and salts in sealed water circuits cause corrosion

and deposits.

PUROTAP filters the aggressive substances out of the fill

water to enable trouble-free operation.

Demineralised heating water

®

PUROTAP compenso

Reliability due to

desalinated water

for heating systems

to VDI 2035 and

SWKI BT 102-01

refill appliance

EN

Copyright 2012: ELYSATOR Engineering AG, Switzerland

www.elysator.com

9

8

10

11

12

7

5

6

4

5

4

Protection against limescale deposits

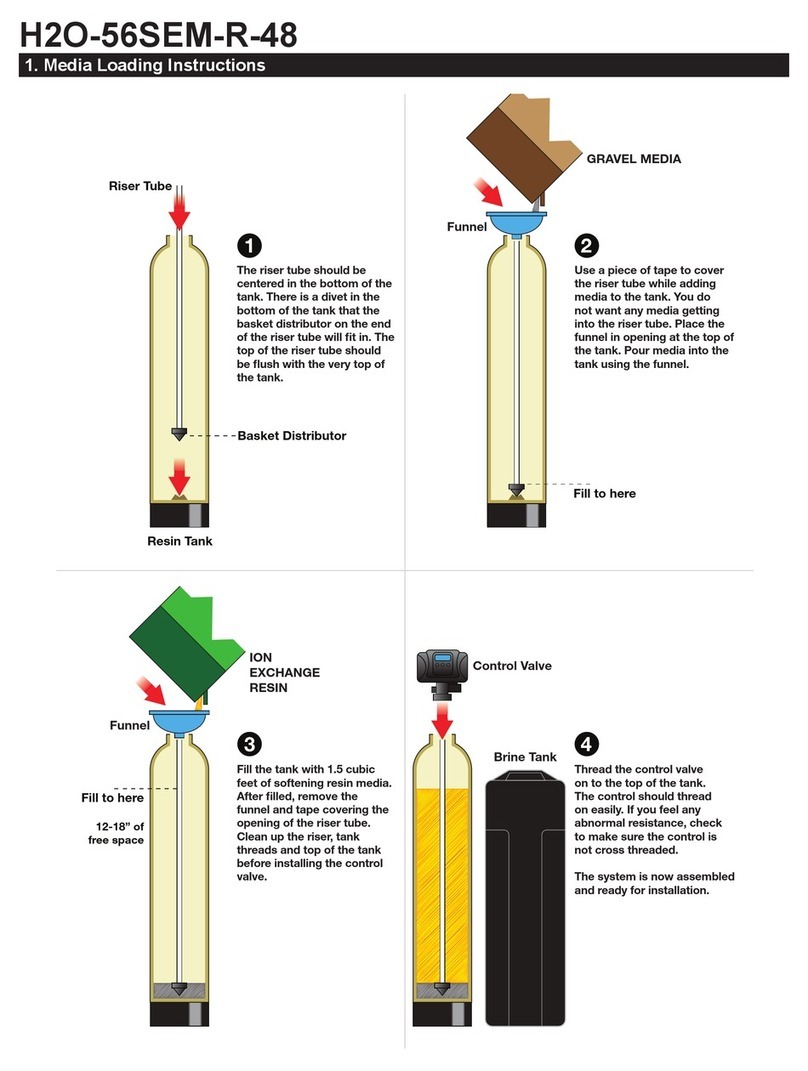

Compenso 12, replacing the resin, capacity

Function

Permanent connection

Operating the combined meter

Compenso 2, replacing the resin, capacity

Use with a heating system fill hose

Protection against corrosion

Compenso 25/50, replacing the resin, capacity

Technical specification

Service record

Contents

EN

Web version supercedes print version.

Updates may be made without notice.

0

3°

6°

11°

17°

20°

22°

25°

28°

14°

8°

100 g 200 g 300 g 400 g 500 g

5°

10°

20°

30°

35°

40°

45°

50°

25°

15°

°dH

°fH

The following table shows the amount of lime accumulating in a heating system

that is filled once with untreated water.

Fully desalinated water no longer contains any substances that can settle out or

be deposited in the boiler and heat exchanger.

VDI 2035, SWKI Directive BT102-01 and other European standards state that

water for filling heating systems should generally be demineralised for low salt

operation. Practical experience has shown that even at a low hardness level, mod-

ern appliances such as wall mounted gas boilers, heat pumps and solar thermal

systems can suffer damage from limescale deposits.

Compared to water that has been softened, demineralised water no longer con-

tains any salts. Its electrical conductivity is extremely low, allowing it to act as a

corrosion inhibitor.

Amount of dissolved calcium carbonate (CaCO )

3

Limescale deposits in the

boiler

Overheating, stress crack

Total hardness °fH

Total hardness °dH

3

Amount of lime in 1 m fill water

in the boiler and heat exchanger

Protection against limescale deposits

Pitting due to high salt content

Protection against corrosion

In line with applicable standards

Full desalination additionally removes all neutral salts such as chlorides,

sulphates and nitrates, which are known to cause corrosion above a certain

concentration and in certain combinations.

It has long been clear to experts in the field that fully desalinated water is ideal for

filling heating systems and that this will extend the service life of all components.

Today, this technology is so user friendly and affordable that it recommends itself

for practical application.

- VDI Guideline 2035

The process of full desalination (demineralisation) is therefore ideal for ensuring

that the water quality requirements of the following directives and standards are

met:

- SWKI BT 102-01

- DIN 50930

- ÖNORM 5195-1

Speed of corrosion

Salt content in the water

EN 4

The PUROTAP compenso filters lime and aggressive substances such as sulphates, nitrates and chlorides out of

the fill water. The appliance uses a mixed bed ion exchanger to provide demineralised, fully desalinated water

for any system size. This method does not emit any chemical additives into the water. The appliance operates

without an external power connection.

Function

2. Refilling the heating system

1. . Flushing the cartridge

Safety instructions

PUROTAP compenso should be pre-flushed

with approx. 10 l water before each use in

order to displace the initial flow water.

It is not permissible for a heating system fill

hose to remain permanently connected.

The refill appliance should never be left un-

attended whilst in use. Where DIN EN 1717

is applied (Germany), observe the regula-

tions regarding system separation.

After use, always close the freshwater tap,

the shut-off valve on the PUROTAP and the

boiler fill valve and remove the fill hose.

The ion exchange resin in the cartridge must

not enter the heating system. As a precau-

tion, a fine filter is fitted in the outlet which

must not be removed.

If the PURTOTAP compenso is occasionally used to refill the heating system via a fill hose, the cartridge should

be pre-flushed with fresh tap water in order to displace the initial flow water.

In doing so, it is important to check full desalination via the integral combined meter. When the system is then

filled, the fill hose must be first bled, in other words filled with water to prevent air entering the system via the

fill valve.

Use with a heating system fill hose 5

3. Close valves; remove hoses

5 EN

If a continuous top-up system will be

fitted, the installation must include all

the necessary safety equipment, such

as system separation, pressure moni-

tor and leak protection.

Safety instructions

Install PUROTAP compenso down-

stream of the top-up monitor.

PUROTAP compenso is pressure-tested to 6 bar and is therefore suitable for making a permanent connection

between the mains supply and the heating system.

Depending on national or local regulations, a direct connection may be subject to technical conditions which

must be observed. Where DIN EN 1717 is applied (Germany), also install a system separator upstream of the fill

appliance.

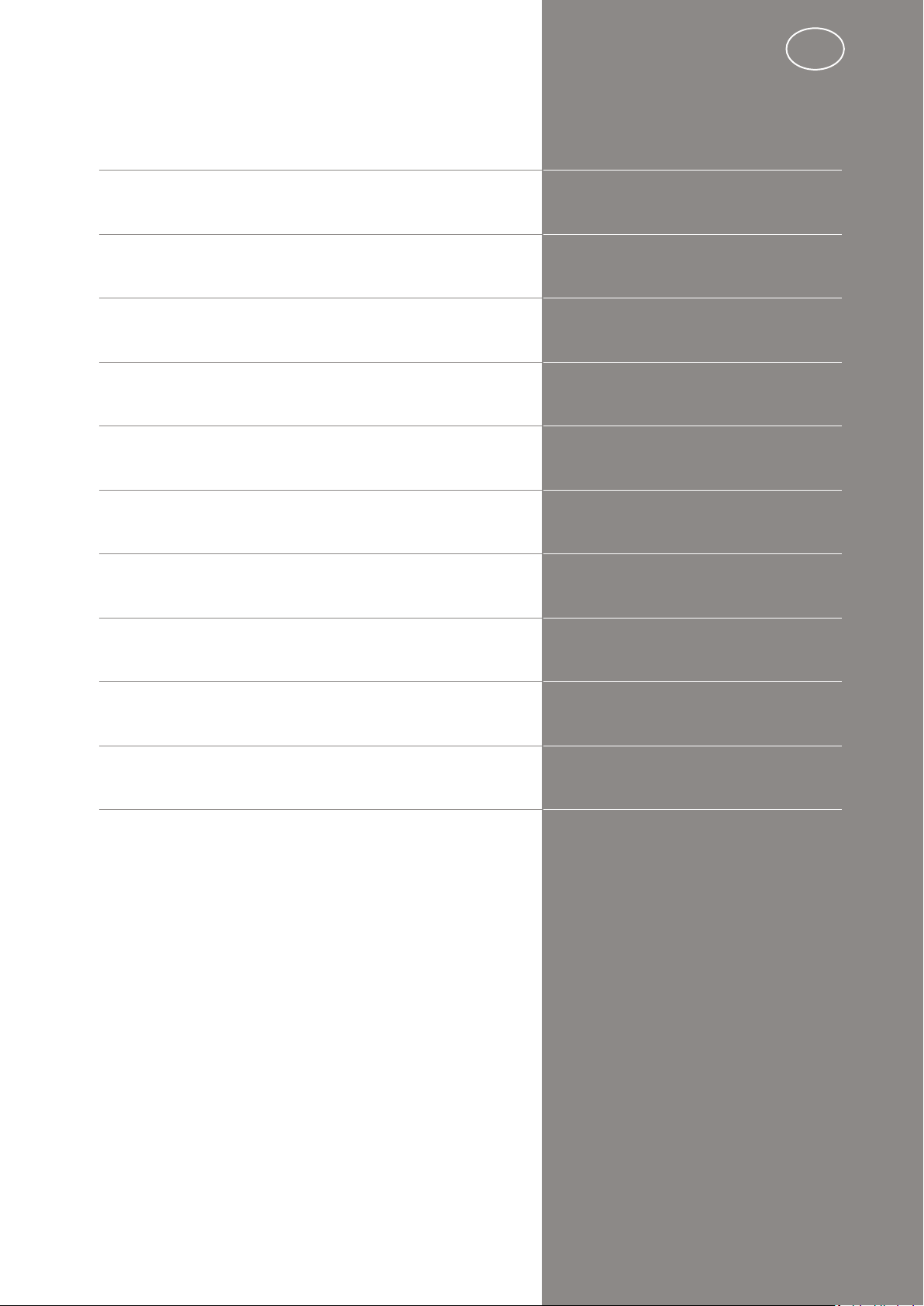

Permanent connection

Simplified permanent connection

Permanent connection in conjunction with automatic top-up

Keep valves closed when not in use

Mains

System separator

Automatic

top-up monitor

Safety instructions

The regulations of the water utility

must be observed when connecting

directly to the mains supply (e.g. sys-

tem separator to DIN EN 1717).

After use, valves to the heating sys-

tem and mains supply must be

closed.

Mains

EN 6

3 x AAA

Recommended limit:

33 TDS/50 µS; above this

the resin will need to be

replaced

7 EN

Set limit for

warning

Limit

Reset

meter

Flow rate

ON/OFF

Total litres treated

Select either

TDS/µS

Automatic quality monitor

Display:

Keys:

Limit warning signal

Operating the combined meter

Changing the batteries

The combined meter is battery-operated. It measures the flow rate in l/min, the total volume in litres and

the concentration of dissolved minerals, either in microsiemens or TDS. In addition, a limit can be set for the

maximum concentration of minerals tolerated in the demineralised water (appliance outlet). The limit and

overall total can both be reset.

Change the batteries when the battery warning symbol

appears or the display is faint or blank. Undo the 4 screws

on the front and carefully open the device. Change the bat-

teries. 3 x AAA.

Each time you touch this key, the boundary value is raised by 6/7 TDS or by 10 µS/cm. Holding down the key

for 3 seconds resets the boundary value to zero. Programming the boundary value serves as a warning as to

when the ion exchanger resin is exhausted.

This key can be used to switch at any time between the TDS unit of measurement (Total Dissolved Solids)

and electrical conductivity. Both are used to measure the concentration of dissolved minerals in the water.

Most European component manufacturers use the µS/cm unit of measurement (microsiemens).

1 °fH equals approx. 20 µS/cm; 1 °dH equals approx. 35 µS/cm.

The water hardness at the outlet of the refill appliance can be calculated using the following rule of thumb:

1

2

Auto mode: If the ON key is pressed for a second time, the combined meter begins automatic monitoring.

The eye symbol appears to indicate that monitoring has been enabled. In auto mode, the meter only takes

measurements when water is actually passing over it. If the water draw-off is interrupted, the meter conti-

nues to show the last captured value. While water is being drawn off, the combined meter measures the

water quality every 40 litres. If the limit is exceeded in two successive measurements, the display conti-

nuously flashes red. This indicates that the ion exchange resin is spent and needs replacing. If the ON key is

pressed for a third time, the meter exits auto mode.

If the ON key is pressed once, the water quality is measured for 10 seconds and compared to the set limit.

The measured value is shown. If it is above the limit, the LED glows red; if it is below, the LED glows green

while the measurement is being taken. If required, the measurement can be repeated manually.

3

Pressing the reset key for 3 seconds resets the overall total on the meter. This is recommended every time

the resin is replaced, as it gives a reference point for the remaining capacity of the ion exchange resin.

4

°fH

5°

10°

20°

30°

35°

40°

45°

50°

25°

15°

0 l

50 l

1'00 l

150 l

200 l

250 l

300 l

350 l

400 l

450 l

500 l

°dH

3°

6°

11°

17°

20°

22°

25°

28°

14°

8°

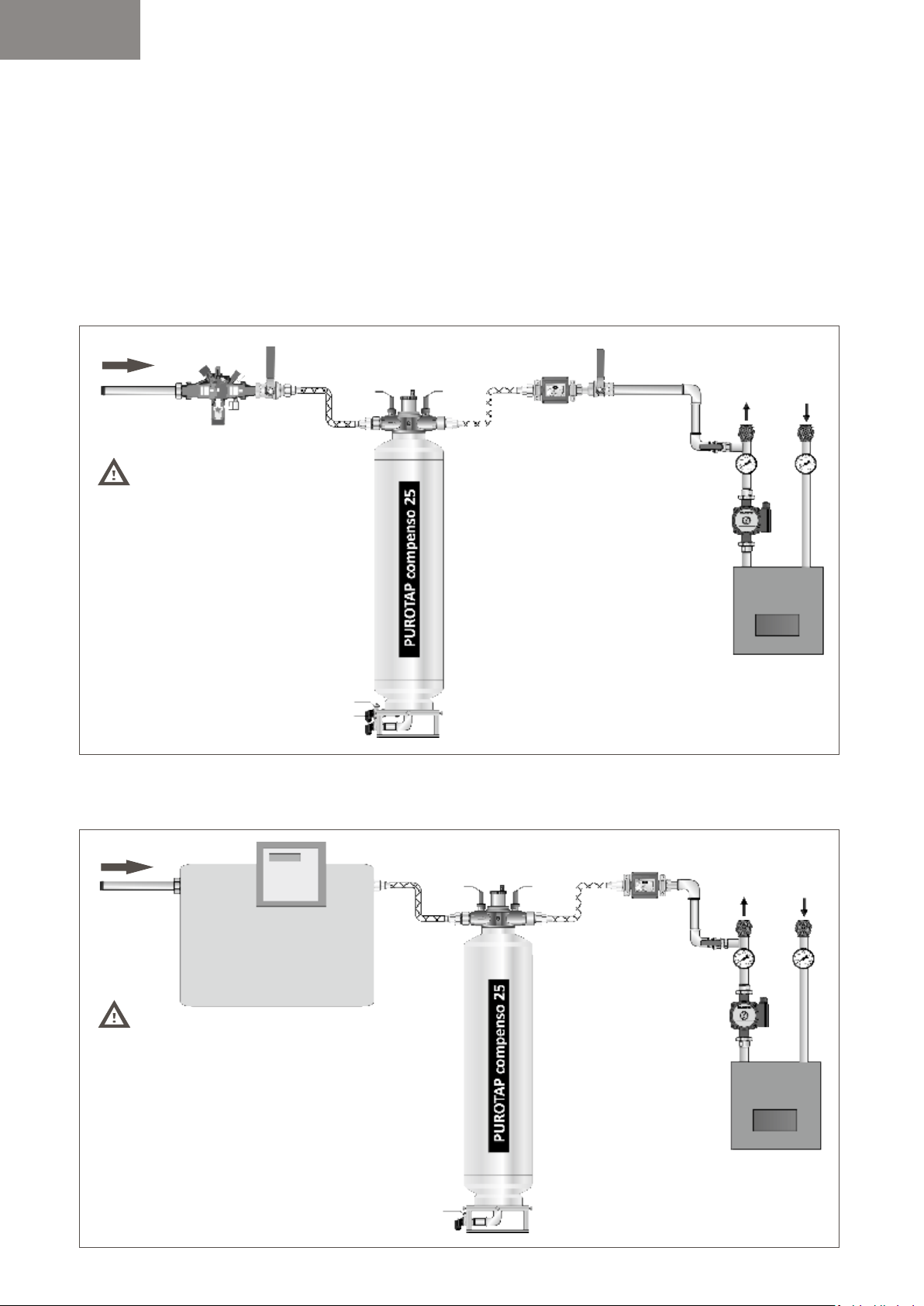

PUROTAP compenso 2

Dispose of spent resin

with household waste;

refill with new resin

2.

Resin

Unscrew the

container;

reset the com-

bined meter

(see instruc-

tions)

3.

Close the ball valves; undo

the container

1.

Household

waste

Capacity of the ion exchanger

For example: If the water hardness is

12.5 °dH, the capacity of the resin will

be exactly 200 l of demineralised

water.

The capacity of the ion exchange resin

depends on the water hardness. The

capacity can be read off the adjacent

table or calculated using the capacity

figure given for the quantity of resin.

The PUROTAP compenso 2 resin filling

has a capacity of 4500 l @ 1 °fH or

2500 l @ 1 °dH.

If using the German hardness scale,

take the number 2500 and divide this

by the water hardness in °dH. If using

the French hardness scale, take the

number 4500 and divide this by the

water hardness in °fH. The result is

the capacity of the resin in litres of

water.

Capacity

Replacing the resin

4'500 l à 1°fH 2'500 l à 1 °dH

Litres of demineralised (fully desalinated) water per cartridge

EN 8

0 l

500 l

1'000 l

1'500 l

2'000 l

2’500 l

3’000 l

3'500 l

4’000 l

4’500 l

5’000 l

°fH °dH

5°

10°

20°

30°

35°

40°

45°

50°

25°

15°

3°

6°

11°

17°

20°

22°

25°

28°

14°

8°

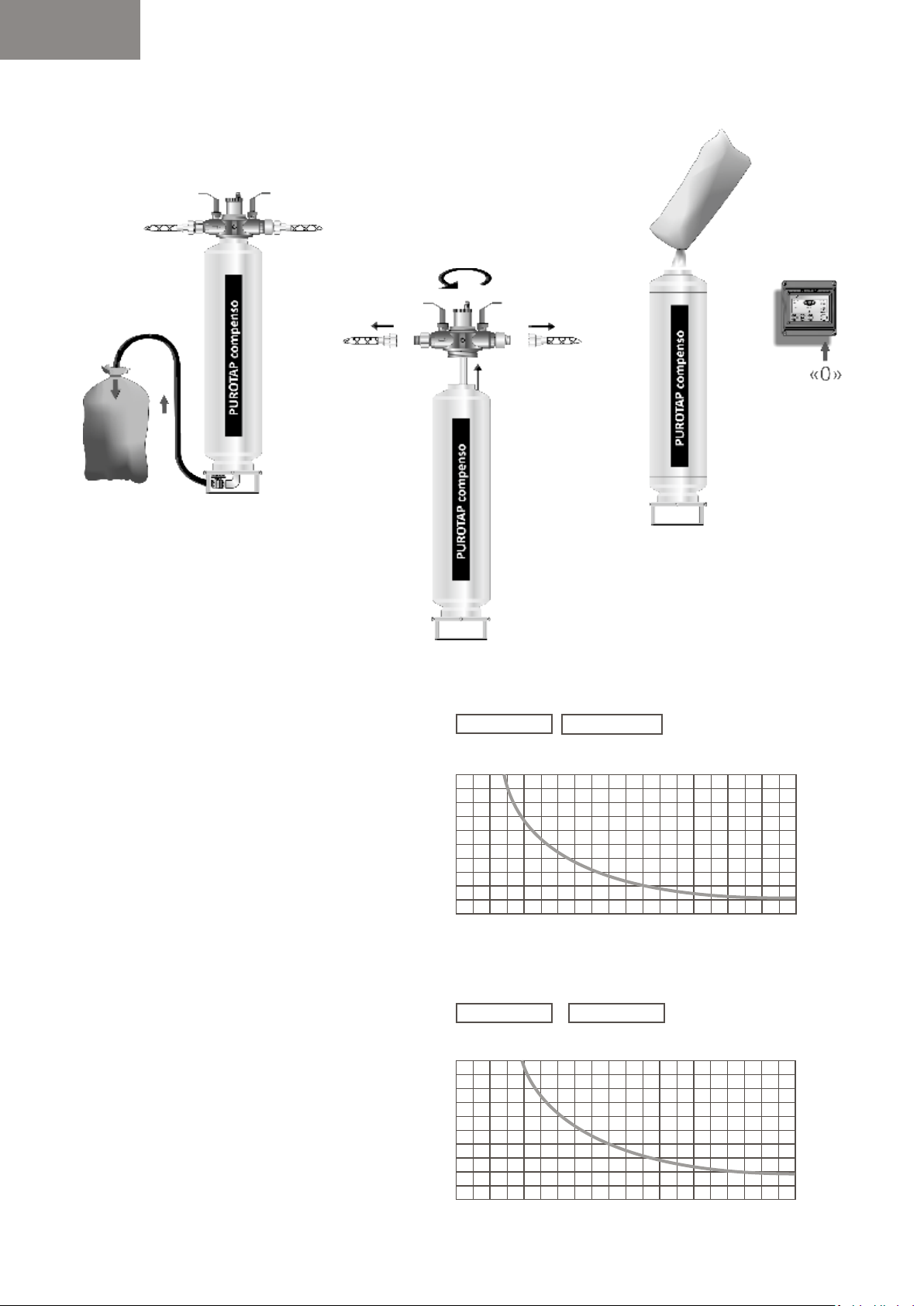

PUROTAP compenso 12

Replacing the resin

Close ball valve in the outlet, con-

nect a hose at the drain valve and

route into the supplied collection

sack; flush out the resin at mains

pressure

Undo wire armoured hoses;

undo head section

Fill with new resin, mount

head section, connect wire

armoured hoses, reset com-

bined meter (see instructions)

1.

2.

3.

Household

waste

Resin

Capacity of the ion exchanger

The capacity of the ion exchange resin

depends on the water hardness. The

capacity can be read off the adjacent

table or calculated using the capacity

figure given for the quantity of resin.

The PUROTAP compenso 12 resin fill-

3

ing has a capacity of 35 m @ 1 °fH or

3

20 m @ 1 °dH.

The result is the capacity of the resin

in cubic metres of water.

If using the German hardness scale,

take the number 20 and divide this by

the water hardness in °dH. If using the

French hardness scale, take the num-

ber 35 and divide this by the water

hardness in °fH.

For example: If the water hardness is

20 °dH, the capacity of the resin will

3

be exactly 1 m (1000 l) of deminera-

lised water.

3

35 m à 1°fH 3

20 m à 1 °dH

Capacity

Litres of demineralised (fully desalinated) water per cartridge

9 EN

0 l

750 l

1’500 l

2’250 l

3’000 l

3’750 l

4’500 l

5’250 l

6’000 l

6’750 l

7’500 l

8’250 l

9’000 l

9’750 l

10’500 l

11’250 l

12’000 l

12’750 l

13’500 l

14’250 l

15’000 l

°fH

°dH

5°

10°

20°

30°

35°

40°

45°

50°

25°

15°

3°

6°

11°

17°

20°

22°

25°

28°

14°

8°

0 l

500 l

1’000 l

1’500 l

2’000 l

2’500 l

3’000 l

3’500 l

4’000 l

4’500 l

5’000 l

5’500 l

6’000 l

6’500 l

7’000 l

7’500 l

8’000 l

8’500 l

9’000 l

9’500 l

10’000 l

°fH °dH

5°

10°

20°

30°

35°

40°

45°

50°

25°

15°

3°

6°

11°

17°

20°

22°

25°

28°

14°

8°

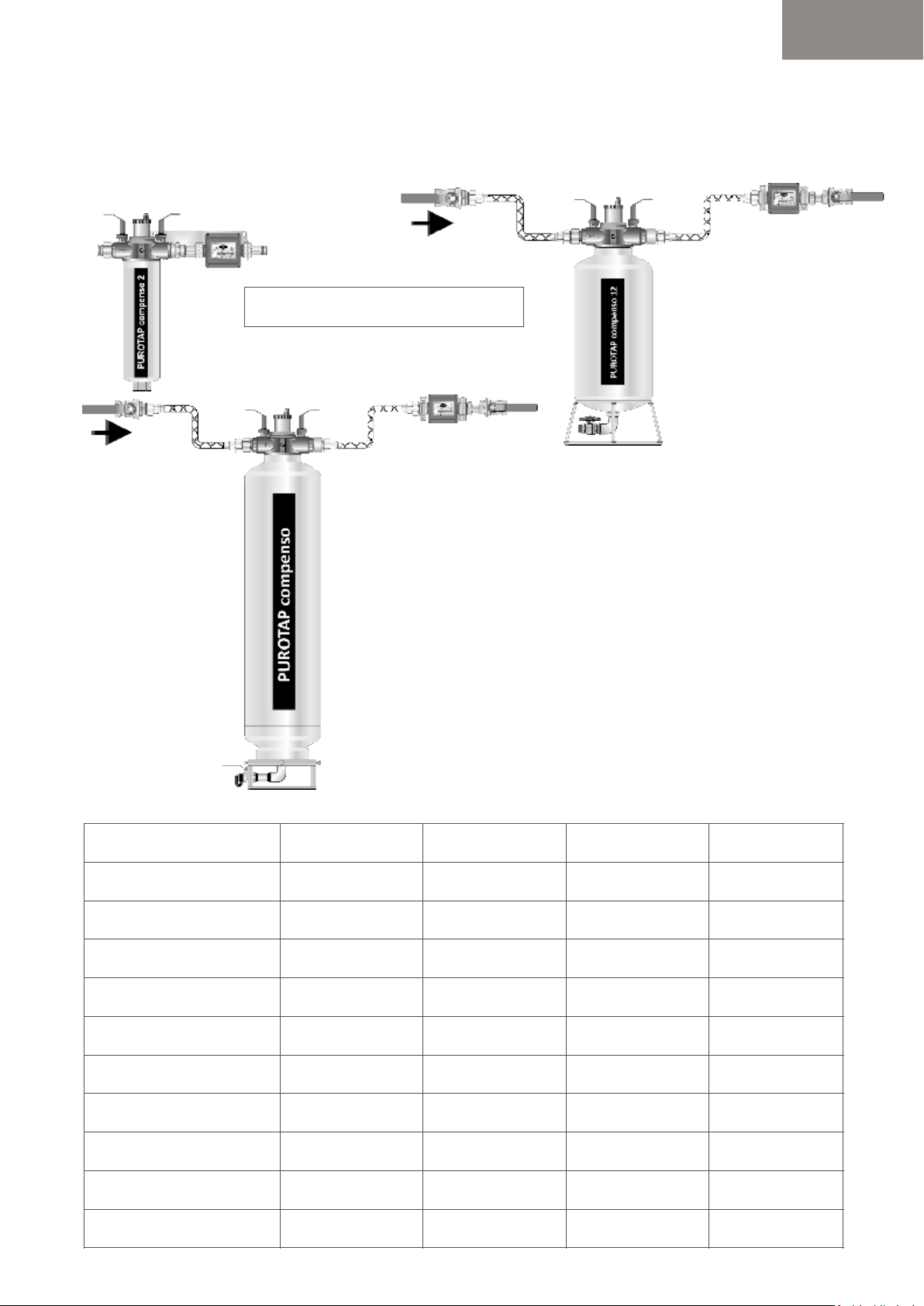

PUROTAP compenso 25 capacity

PUROTAP compenso 50 capacity

Total hardness

Total hardness

Total hardness

Total hardness

For example: If the water hardness is

20 °dH, the capacity of the PUROTAP

compenso 25 resin will be exactly

2000 l of demineralised water. (Ca-

3

pacity figure of 40 m divided by hard-

3

ness 20 °dH = 2 m = 2000 l.)

To calculate the capacity, divide the

capacity figure for the PUROTAP

compenso by the water hardness indi-

cated.

The capacity of the ion exchange resin

depends on the water hardness. The

capacity can be read off the adjacent

table or calculated using the capacity

figure given for the quantity of resin.

The PUROTAP compenso 25 resin fill-

3

ing has a capacity of 70 m of 1 °fH, or

3

40 m of 1 °dH. For the compenso 50

the figures are doubled.

1. Close ball valve in the outlet, con-

nect a hose at the drain valve and

route into the supplied collection

sack; flush out the resin at mains

pressure

Fill with new resin, mount

head section, connect wire

armoured hoses, reset com-

bined meter (see instruc-

tions)

3.

Undo wire armoured hoses;

undo head section

Household

waste

Resin

PUROTAP compenso 25/50

Replacing the resin

2.

3 3

140 m à 1°fH 80 m à 1 °dH

3 3

70 m à 1°fH 40 m à 1 °dH

Capacity of the

ion exchanger

EN 10

Litres of demineralised (fully desalinated)

water per cartr.

Litres of demineralised (fully desalinated)

water per cartr.

PUROTAP compenso 2 compenso 12 compenso 25 compenso 50

< 250 l < 2'500 l < 5'000 l < 10'000 l

3

2.5 m 3

20 m 3

40 m 3

80 m

3

4.5 m 3

35 m 3

70 m 3

140 m

2,5 l/min 10 l/min 20 l/min 20 l/min

< 6 bar < 6 bar < 6 bar < 6 bar

60 °C 60 °C 60 °C 60 °C

45 cm 80 cm 80 cm 80 cm

46 cm 70 cm 115 cm 142 cm

5 kg 7.5 kg 15 kg 18 kg

1,75 l 12.5 l 25 l 50 l

PUROTAP compenso

Technical specification

Direction of flow

compenso 12

compenso 2

compenso 25/50

Standard delivery as depicted

Description:

Integral combined meter for measuring flow rate, total

volume, water quality and for limit control. Battery operated

with automatic switch-on function.

PUROTAP compenso, refill appliance for the production of fully

desalinated heating water to the latest guidelines (VDI 2035

and SWKI BT 102-01), based on ion exchange. Resin vessel in

stainless steel with floor or wall mounting bracket. Head

section with integral shut-off valves and air vent valve. Resin

can be easily replaced by the user on site.

Suitable for permanent connection in conjunction with

specific regulations and engineering guidelines (e.g. DIN EN

1717).

Direction of flow

Annual demand

Capacity at 1 °dH

Capacity at 1 °fH

Delivery capacity

Operating pressure

Tmax. temp.

Installed length

Height

Empty weight

Resin filling

11 EN

E919

Service record

Date

Installer: Property

Product installed

Resin changed

litres

Combined meter Company

Mains water hardness

Calculated capacity

°fH / ° dH / TDS

EN 12

This manual suits for next models

4

Table of contents

Popular Water Dispenser manuals by other brands

Zerica

Zerica REFRESH P HPDC Installation and operation manual

Whirlpool

Whirlpool Hot water dispenser Installation instructions and use and care guide

BRIO

BRIO CLCTPOU620UVF2 instruction manual

Messner

Messner Skimmer 140 operating instructions

Elkay

Elkay EZO8WS 1A Series Installation & use manual

Comet

Comet XRC-3023-WW manual