Embention Veronte 4 Instructions for use

cod:

Veronte-4-HUM.docx

pag:

1/20

Hardware User Manual

Veronte 4

cod:

Veronte-4-HUM.docx

pag:

2/20

Table of Contents

1. OVERVIEW.....................................................................................................................................5

1.1 OPERATION ....................................................................................................................................5

1.2 PLATFORMS ....................................................................................................................................5

2. SAFETY ..........................................................................................................................................7

3. AIRCRAFT MOUNTING ...................................................................................................................7

3.1 ENCLOSURE ....................................................................................................................................7

3.2 OEM ............................................................................................................................................8

3.3 MECHANICAL MOUNTING .................................................................................................................9

3.3.1 Vibration Isolation ..................................................................................................................9

3.3.2 Location ................................................................................................................................10

3.3.3 Orientation ...........................................................................................................................10

3.4 CONNECTOR LAYOUT ......................................................................................................................10

3.5 MATING CONNECTORS....................................................................................................................11

3.6 ANTENNA INTEGRATION ..................................................................................................................11

3.7 PRESSURE LINES ............................................................................................................................12

4. ELECTRICAL..................................................................................................................................12

4.1 POWER ........................................................................................................................................12

4.2 VERONTE I/O SIGNALS....................................................................................................................13

4.3 HARNESS COLOUR CODE ..................................................................................................................15

4.4 JOYSTICK ......................................................................................................................................16

4.5 OEM BOARD PINOUT.....................................................................................................................18

5. PERFORMANCES..........................................................................................................................20

Figures and Tables

FIGURE 1: VERONTE FCS OVERVIEW.....................................................................................................................6

FIGURE 2: VERONTE AIR .....................................................................................................................................7

FIGURE 3: VERONTE DIMENSIONS (MM) ................................................................................................................8

FIGURE 4: VERONTE OEM DIMENSIONS (MM)........................................................................................................8

FIGURE 5: VERONTE DIMENSIONS (MM) ................................................................................................................9

FIGURE 6: VERONTE MOUNTS .............................................................................................................................9

FIGURE 7: AIRCRAFT AXIS .................................................................................................................................10

FIGURE 8: VERONTE CONNECTORS .....................................................................................................................10

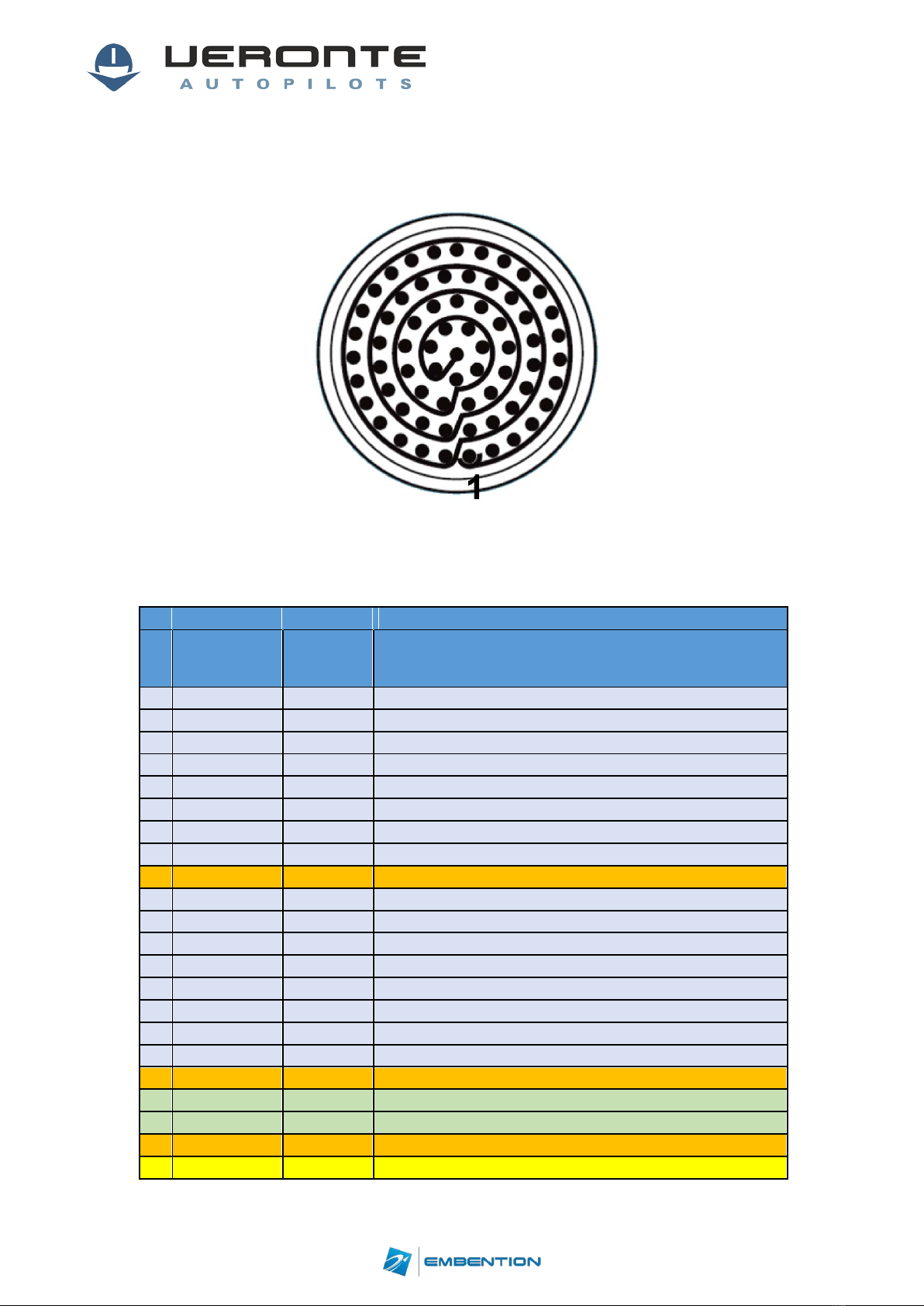

FIGURE 9: 68-PIN REDUNDANT CONNECTOR FOR VERONTE AUTOPILOT (FRONTAL VIEW) ..............................................13

FIGURE 10: FUTABA T10 JOYSTICK .....................................................................................................................17

FIGURE 11: PPM SIGNAL .................................................................................................................................17

FIGURE 12: PPM CONNECTOR...........................................................................................................................17

TABLE 1: VERONTE CONNECTION PANEL...............................................................................................................11

TABLE 2: MATING CONNECTOR TABLE ................................................................................................................11

TABLE 3: ANTENNA INSTALLATION ......................................................................................................................11

TABLE 4: PRESSURE INTAKE CONNECT .................................................................................................................12

TABLE 5: VERONTE I/O INTERFACE .....................................................................................................................15

TABLE 6: COLOUR CODE ...................................................................................................................................16

TABLE 7: OEM BOARD PINOUT ..........................................................................................................................19

TABLE 7: VERONTE PERFORMANCES....................................................................................................................20

cod:

Veronte-4-HUM.docx

pag:

3/20

Acronyms

ADC

Analog to Digital Converter

AWG

American Wire Gauge

CAP

Capture Module

DC

Direct Current

DGPS

Differential GPS

DTS

Digital Transmission System

ECAP

Enhanced CAP

EGNOS

European Geostationary Navigation Overlay Service

EPWM

Enhanced PWM

FCS

Flight Control System

FHSS

Frequency Hopping Spread Spectrum

FTS

Flight Termination System

GIS

Geographical Information System

GND

Ground

GNSS

Global Navigation Satellite Systems

GPS

Global Positioning System

GS

Ground Segment

ISM

Industrial Scientific and Medical

LADGPS

Local Area

LOS

Line of Sight

PWM

Pulse Width Modulation

PWR

Power

RF

Radio Frequency

RS232

Recommended Standard 232

RX

Receiver

SMA

SubMiniature Version A Connector

TX

Transmitter

UAS

Unmanned Aerial System

UAV

Unmanned Aerial Vehicle

cod:

Veronte-4-HUM.docx

pag:

4/20

CHANGES RECORD

Issue

Date

Change description

1.0

10/04/2017

Initial Issue document

1.1

15/05/2017

Safety information added

1.2

19/05/2017

Digital inputs voltage range

changed.

1.3

20/09/2017

Mechanical

drawing updated.

1.4

25/09/2017

Table 1 updated

1.5

20/12/2017

Section 4.4 added.

1.6

21/12/2017

Errata correction on section 4.4

1.7

24/05/2018

Power and torque updated.

Colour code added.

OEM pinout updated.

cod:

Veronte-4-HUM.docx

pag:

5/20

1. Overview

Veronte Autopilot is a miniaturized high reliability avionics system for advanced control of

unmanned systems. This control system embeds a state-of-the-art suite of sensors and

processors together with LOS and BLOS M2M datalink radio, all with reduced size and weight.

1.1 Operation

The unique Plug ´n Fly control system, Veronte Autopilot ads fully autonomous control

capabilities to any unmanned system for complete operation, compatible with: UAV, Drone,

RPAS, USV, UGV…

•Highly configurable: Veronte control system is fully configurable; payload, platform

layout, control phases, control channels… even the user interface layout can be user

defined.

•Custom routines:User selectable automatic actions, activated on system event or

periodically.

•Actions: phase change, activate payload, move servo, go to, onboard log, parachute

release…

•Events: waypoint arrival, inside/outside polygon, alarm, variable range, button…

•Telemetry & log: Embedded datalink for system monitoring and telecommand and

customizable user log in both onboard and control station, all with user defined

variables and frequency record.

•External sensor: Support for external sensor connection: magnetometer, radar,

LIDAR, RPM, temperature, fuel level, battery level, weather…

•Payload & Peripheral:Transponder, secondary radios, satcom transceivers, camera

gimbals, motor drivers, photo cameras, flares, parachute release systems, tracking

antennas, pass through RS232 & CAN tunnel...

1.2 Platforms

The Veronte Autopilot is designed to control any unmanned vehicle, either aircraft such as:

multirotors, helicopters, airplanes, VTOL, blimps… as well as ground vehicles, surface vehicles

or many others. Custom flight phases and control channels provide support for any aircraft

layout and performance by using the same software and hardware for: UAS, RPAS, Drone, USV

/ ASV, UGV…

cod:

Veronte-4-HUM.docx

pag:

6/20

Figure 1: Veronte FCS Overview

Veronte contains all the electronics and sensors needed in order to properly execute all the

functions needed to control the UAV. A Veronte-based FCS contains the following elements:

Veronte (Air): it executes in real time all the guidance, navigation and control algorithms

for the carrying airframe, acting on the control surfaces and propulsion system and

processing the signals from different sensors: accelerometers, gyroscopes,

magnetometer, static pressure, dynamic pressure, GPS (EGNOS/Galileo compatible).

Veronte (Ground): apart from linking to other flying Veronte units and supporting manual

and arcade modes with conventional joysticks, it can also control a directional antenna in

order to expand the maximum range. It communicates to Veronte Pipe (software for

ground segment mission management).

Veronte Pipe: software for mission management at the ground segment. It monitors flying

vehicles in real time and can also reproduce past missions in an offline manner. It is also

the graphical user interface where commands and flight plans are produced.

cod:

Veronte-4-HUM.docx

pag:

7/20

2. Safety

Veronte autopilot includes the following features in order to provide your UAS with the best

safety performances:

•Redundant IMU.

•Redundant GPS receiver.

•Redundant Pressure sensor.

•Dual core principal microprocessor + dissimilar safety microcontroller (comicro).

•Independent power supply for main system and safety microcontroller.

In case any malfunction occurs in the principal microprocessor, the comicro can activate

different safety mechanisms by means of 2 digital outputs and 1 serial port (see table 5).

3. Aircraft Mounting

There are two versions of Veronte autopilot: with or without enclosure.

3.1 Enclosure

Veronte is provided using an anodized-aluminium enclosure with enhanced EMI shielding and

IP protection. A high reliability connector is also provided with this version. The total

approximate weight is 190g.

Figure 2: Veronte Air

cod:

Veronte-4-HUM.docx

pag:

8/20

Figure 3: Veronte dimensions (mm)

3.2 OEM

Veronte can be provided in OEM version too. The total approximate weight is 90g.

Figure 4: Veronte OEM dimensions (mm)

cod:

Veronte-4-HUM.docx

pag:

9/20

3.3 Mechanical Mounting

M4 screws are recommended for mounting.

Figure 5: Veronte dimensions (mm)

Vibration Isolation

Although Veronte ultimately rejects noise and high-frequency modes of vibration with

electronic filters and internal mechanical filters, there might be situation where external

isolation components might be needed.

Veronte can be mounted in different ways in order to reject the airframe vibration. The

simplest could be achieved by just using a double-sided foam tape on the bottom side of

Veronte. Other ways may use some external structure which could be rigidly attached to the

airframe and softly attached to Veronte (e.g. foam, silent blocks, αgel, etc…).

Figure 6: Veronte Mounts

cod:

Veronte-4-HUM.docx

pag:

10/20

The user should take into account that wiring should be loose enough so vibrations may not

be transmitted to Veronte.

In cases where Veronte isolation is not viable, it is possible to use soft engine mounts. It is also

recommended when there are other sensible payloads like video cameras or for high vibration

engines.

Location

The location of Veronte has no restrictions. You only need to configure its relative position

with respect to the centre of mass of the aircraft and the GPS antenna. The configuration of

the location of Veronte can be easily configured using Veronte Pipe Software.

Orientation

The orientation of Veronte has no restrictions either. You only need to configure Veronte axes

with respect to the aircraft body axes by means of a rotation matrix or a set of

correspondences between axes. The configuration of the location of Veronte can be easily

configured using Veronte Pipe Software.

Veronte axes are printed on the box and aircraft coordinates are defined by the standard

aeronautical conventions.

Figure 7: Aircraft Axis

3.4 Connector Layout

Figure 8: Veronte Connectors

cod:

Veronte-4-HUM.docx

pag:

11/20

Index Connector

1 LOS SSMA connector

2 GNSS1 SSMA connector

3 M2M SSMA connector

4 GNSS2 SSMA connector

5 Static pressure port (Fitting 5/64in)

6 Dynamic pressure port (Fitting 5/64in)

7 68-pin connector

Table 1: Veronte connection panel

For both pressure ports, mating with clamped 2mm internal diameter flexible tubing is

recommended.

3.5 Mating Connectors

Index Connector Mating Connector

1

RF antenna

(SSMA Jack Female)

SSMA male Plug, low-loss cable is recommended.

2,4 GPS antenna

(SSMA Jack Female)

SSMA male Plug, low loss cable is recommended. Active Antenna GPS: Gain min

15dB (to compensate signal loss in RF Cable) max 50dB, maximum noise figure

1.5dB, power supply 3.3V max current 20 mA

3

M2M antenna

(SSMA Jack Female)

SSMA male Plug, low-loss cable is recommended.

7

Connector

HEW.LM.368.XLNP

Mating connector P/N: FGW.LM.368.XLCT

Mating harness is available on demand.

Table 2: Mating Connector Table

3.6 Antenna Integration

The system uses different kinds of antennas to operate that must be installed on the airframe.

Here you can find some advices for obtaining the best performance and for avoiding antenna

interferences.

Antenna Installation

•Maximize separation between antennas as much as possible.

•Keep it far away from alternators or other interference generators.

•Always isolate antenna ground panel from the aircraft structure.

•Make sure that the antenna is securely mounted.

•Always use high quality RF wires minimising the wire length.

•Always follow the antenna manufacturer manual.

•SSMA connections shall be tightened applying 1Nm of torque.

GPS Antenna

•Antenna top side must point the sky.

•Install it on a top surface with direct sky view.

•Never place metallic / carbon parts or wires above the antenna.

•It is recommended to install it on a small ground plane.

Table 3: Antenna Installation

cod:

Veronte-4-HUM.docx

pag:

12/20

3.7 Pressure Lines

Veronte has two pressure input lines, one for static pressure to determine the absolute

pressure and one for pitot in order to determine the dynamic pressure.

Absolute pressure connection on the aircraft is mandatory while pitot port can be obviated in

some aircrafts. Pitot port absence must be configured on Veronte Pipe software.

Pressure Intake

•Pressure intakes must be located in order to prevent clogging.

•Never install pressure intakes on the propeller flow.

•Design pressure tubing path in order to avoid tube constriction.

Static Pressure

•It is not recommended to use inside fuselage pressure if it is not properly vented.

Pitot Tube

•Pitot tube must be installed facing the airflow in the direction of the “x” axis of the aircraft.

•It is recommended to install it near the aircraft axis in order to avoid false measures during manoeuvres.

•For low speed aircrafts it is recommended at least 6,3mm tubes for preventing rain obstruction.

Table 4: Pressure Intake Connect

4. Electrical

4.1 Power

Veronte can use unregulated DC (6.5V to 36V). Pins used for power and ground are the same

for both Ground and Air configurations.

LiPo batteries between 2S and 8S can be used without regulation needs. Remaining battery

can be controlled by the internal voltage sensor and by configuring the voltage warnings on

the PC application.

For higher voltage installations, voltage regulators must be used. For dimensioning voltage

regulators take into account that a blocked servo can activate regulator thermal protection.

Caution!! Power Veronte out of the given range can cause irreversible damage

to the system. Please read carefully the manual before powering the system.

Veronte and servos can be powered by the same or different batteries. In case there are more

than one battery on the system, a single point ground union it is needed to ensure a good

performance. The ground signal should be isolated from other noisy ground references (e.g.

engines). If all ground need to be connected, connection should be made on the negative pole

of the battery.

It is recommendable to use independent switches for autopilot and motor / actuators. During

the system initialization, PWM signal will be fixed to low level (0V), please make sure that

actuators / motor connected support this behaviour before installing a single switch for the

whole system.

cod:

Veronte-4-HUM.docx

pag:

13/20

4.2 Veronte I/O Signals

Figure 9: 68-pin redundant connector for Veronte Autopilot (frontal view)

68-PIN CONNECTOR

PIN

SIGNAL

TYPE COMMENTS

1

I/O1

I/O

PWM/DIGITAL OUTPUT/DIGITAL INPUT SIGNAL (0-3.3V)

2

I/O2

I/O

PWM/DIGITAL OUTPUT/DIGITAL INPUT SIGNAL (0-3.3V)

3

I/O3

I/O

PWM/DIGITAL OUTPUT/DIGITAL INPUT SIGNAL (0-3.3V)

4

I/O4

I/O

PWM/DIGITAL OUTPUT/DIGITAL INPUT SIGNAL (0-3.3V)

5

I/O5

I/O

PWM/DIGITAL OUTPUT/DIGITAL INPUT SIGNAL (0-3.3V)

6

I/O6

I/O

PWM/DIGITAL OUTPUT/DIGITAL INPUT SIGNAL (0-3.3V)

7

I/O7

I/O

PWM/DIGITAL OUTPUT/DIGITAL INPUT SIGNAL (0-3.3V)

8

I/O8

I/O

PWM/DIGITAL OUTPUT/DIGITAL INPUT SIGNAL (0-3.3V)

9

GND

GROUND

GROUND SIGNAL FOR ACTUATORS 1-8

10

I/O9

I/O

PWM/DIGITAL OUTPUT/DIGITAL INPUT SIGNAL (0-3.3V)

11

I/O10

I/O

PWM/DIGITAL OUTPUT/DIGITAL INPUT SIGNAL (0-3.3V)

12

I/O11

I/O

PWM/DIGITAL OUTPUT/DIGITAL INPUT SIGNAL (0-3.3V)

13

I/O12

I/O

PWM/DIGITAL OUTPUT/DIGITAL INPUT SIGNAL (0-3.3V)

14

I/O13

I/O

PWM/DIGITAL OUTPUT/DIGITAL INPUT SIGNAL (0-3.3V)

15

I/O14

I/O

PWM/DIGITAL OUTPUT/DIGITAL INPUT SIGNAL (0-3.3V)

16

I/O15

I/O

PWM/DIGITAL OUTPUT/DIGITAL INPUT SIGNAL (0-3.3V)

17

I/O16

I/O

PWM/DIGITAL OUTPUT/DIGITAL INPUT SIGNAL (0-3.3V)

18

GND

GROUND

GROUND SIGNAL FOR ACTUATORS 9-16

19

RS_232_TX

OUTPUT

RS-232 OUTPUT

20

RS_232_RX

INPUT

RS-232 INPUT

21

GND

GROUND

GROUND SIGNAL FOR BUSES

22

ANALOG_4

INPUT

ANALOG INPUT 0-3V

cod:

Veronte-4-HUM.docx

pag:

14/20

23

ANALOG_5

INPUT

ANALOG INPUT 0-3V

24

GND

GROUND

GROUND SIGNAL FOR BUSES

25

CANA_P

I/O

CANbus interface. It supports data rates up to 1 Mbps.

26

CANA_N

I/O

Twisted pair with a 120Ω Zo recommended

27

GND

GROUND

GROUND SIGNAL FOR BUSES

28

CANB_P

I/O

CANbus interface. It supports data rates up to 1 Mbps.

29

CANB_N

I/O

Twisted pair with a 120Ω Zo recommended

30

GND

GROUND

GROUND SIGNAL FOR BUSES

31

I2C_CLK

OUTPUT

CLK LINE FOR I2C BUS

32

I2C_DATA

I/O

DATA LINE FOR I2C BUS

33

GND

GROUND

GROUND FOR 3.3V POWER SUPPLY

34

3.3V

POWER

3.3V-100mA POWER SUPPLY

35

GND

GROUND

GROUND FOR 5V POWER SUPPLY

36

5V

POWER

5V-100mA POWER SUPPLY

37

GND

GROUND

GROUND FOR ANALOG SIGNALS

38

ANALOG_1

INPUT

ANALOG INPUT 0-3V

39

ANALOG_2

INPUT

ANALOG INPUT 0-3V

40

ANALOG_3

INPUT

ANALOG INPUT 0-3V

41

GND

GROUND

GROUND SIGNAL FOR FTS SIGNALS

42

FTS_OUT

OUTPUT

SIGNAL FROM COMICRO TO ACTIVAE SAFETY MECHANISM

(0-3.3V)

43

FTS2_OUT

OUTPUT

SIGNAL FROM COMICRO TO ACTIVAE SAFETY MECHANISM

(0-3.3V)

44

GND

GROUND

GROUND SIGNAL FOR SAFETY BUSES

45

V_ARB_TX

OUTPUT

VERONTE COMICRO UART OUTPUT TO ACTIVATE SAFETY

MECHANISM

46

V_ARB_RX

INPUT

VERONTE COMICRO UART INPUT TO ACTIVATE SAFETY

MECHANISM

47

GND

GROUND

GROUND SIGNAL COMICRO POWER SUPPLY

48

V_ARB-VCC

POWER

VERONTE COMICRO POWER (6.5 to 36V)

49

GND

GROUND

GROUND SIGNAL FOR BUSES

50

OUT_RS485_P

OUTPUT

NON-INVERTED OUTPUT FOR RS-485 BUS

51

OUT_RS485_N

OUTPUT

INVERTED OUTPUT FOR RS-485 BUS

52

IN_RS485_N

INPUT

INVERTED INPUT FOR RS-485 BUS

53

IN_RS485_P

INPUT

NON-INVERTED INPUT FOR RS-485 BUS

54

RS-485_GND

GROUND

GROUND FOR RS-485 BUS

55

EQEP_A

INPUT

ENCODER QUADRATURE INPUT A (0-3.3V)

56

EQEP_B

INPUT

ENCODER QUADRATURE INPUT B (0-3.3V)

57

EQEP_S

INPUT

ENCODER STROBE INPUT (0-3.3V)

58

EQEP_I

INPUT

ENCODER INDEX INPUT A (0-3.3V)

59

GND

GROUND

GROUND FOR ENCODERS

60

V_USB_DP

I/O

VERONTE USB DATA LINE

61

V_USB_DN

I/O

VERONTE USB DATA LINE

62

V_USB_ID

I/O

VERONTE USB ID LINE

63

V_USB_VCC

POWER

VERONTE USB POWER

64

V_USB_VCC

POWER

VERONTE USB POWER

65

GND

GROUND

VERONTE GROUND INPUT

cod:

Veronte-4-HUM.docx

pag:

15/20

66

GND

GROUND

VERONTE GROUND INPUT

67

VCC2

POWER

VERONTE POWER SUPPLY (6.5 to 36V)

68

VCC1

POWER

VERONTE POWER SUPPLY (6.5 to 36V)

Table 5: Veronte I/O interface

4.3 Harness colour code

68-PIN CONNECTOR

PIN

COLOUR

CODE

Description

1

WT

BK

Black

Negro

2

BN

BL

Blue

Azul

3

GN

BN

Brown

Marron

4

YL

GN

Green

Verde

5

GY

GY

Gray

Grís

6

PK

OR

Orange

Naranja

7

BL

PK

Pink

Rosa

8

RD

RD

Red

Rojo

9

BK

VT

Violet

Violeta

10

VT

WT

White

Blanco

11

GY

PK

YL

Yellow

Amarillo

12

RD

BL

13

WT

GN

14

BN

GN

15

WT

YL

16

YL

BN

17

WT

GY

18

GY

BN

19

WT

PK

20

PK

BN

21

WT

BL

22

BN

BL

23

WT

RD

24

BN

RD

25

WT

BK

26

BN

BK

27

GY

GN

28

YL

GN

29

PK

GN

30

YL

PK

31

WT

32

BN

33

GN

cod:

Veronte-4-HUM.docx

pag:

16/20

34

YL

35

GY

36

PK

37

BL

38

RD

39

BK

40

VT

41

GY

PK

42

RD

BL

43

WT

GN

44

BN

GN

45

WT

YL

46

YL

BN

47

WT

GY

48

GY

BN

49

WT

PK

50

PK

BN

51

WT

BL

52

BN

BL

53

WT

RD

54

BN

RD

55

WT

BK

56

BN

BK

57

GY

GN

58

YL

GN

59

PK

GN

60

YL

PK

61

WT

62

BN

63

GN

64

YL

65

GY

66

PK

67

BL

68

RD

Table 6: Colour code

4.4 Joystick

To use the joystick in the system, connect the PPMout of the trainer port to a digital input of

Veronte and configure that digital input as the radio input in Pipe.

If the PPM level is 3.3V, pins 1-8, 10-17 and 55-58 pins can be used.

cod:

Veronte-4-HUM.docx

pag:

17/20

Veronte is compatible with standard Pulse Positon Modulation (PPM) signals, Futaba radios

between 8 and 12 channels are recommended.

Figure 10: Futaba T10 Joystick

Figure 11: PPM Signal

As default, channel 8 is reserved for manual / auto switch. High level is used for automatic

flight and low level for manual control. This channel can be configured on Veronte Pipe.

Caution!! PPM signal must be into the Veronte voltage ranges. Some joysticks

may need an adaptation board, please ask our team to check compatibility.

Veronte connector for CS is provided with 3.5mm stereo plug connector as follows:

Figure 12: PPM connector

cod:

Veronte-4-HUM.docx

pag:

18/20

4.5 OEM Board Pinout

Figure 13: OEM Board

Figure 14: Pinouts for OEM Board

PINOUT

SIGNAL

TYPE COMMENTS

1

LOS SSMA CONNECTOR

2

GNSS1 SSMA CONNECTOR

3

M2M SSMA CONNECTOR

4

GNSS2 SSMA CONNECTOR

5

STATIC PRESSURE PORT (FITTING 5/64IN)

6

DYNAMIC PRESSURE PORT (FITTING 5/64IN)

7C to 28C

GND

GROUND

GROUND SIGNAL

7B

FTS_OUT

O

SIGNAL FROM COMICRO TO ACTIVAE SAFETY

MECHANISM (0-3.3V)

8A

DSPRX_232_D

I

RS-232 INPUT

8B

DSPTX_232_D

O

RS-232 OUTPUT

9

J2

I/O

microUSB CONNECTOR

cod:

Veronte-4-HUM.docx

pag:

19/20

10A

IN_485_P

I

NON-INVERTED INPUT FOR RS-485 BUS

10B

IN_485_N

I

INVERTED INPUT FOR RS-485 BUS

11A

OUT_485_N

O

INVERTED OUTPUT FOR RS-485 BUS

11B

OUT_485_P

O

NON-INVERTED OUTPUT FOR RS-485 BUS

12A

SDA_A_OUT

O

DATA

12B

SCL_A_OUT

O

CLK

13A

CANA_P

I/O

CANbus interface. It supports data rates up to 1 Mbps.

Recommended cable is a twisted pair with a 120Ω Zo.

13B

CANA_N

I/O

14A

ANALIN_1

I

ANALOG INPUT 0-3V

14B

ANALIN_2

I

ANALOG INPUT 0-3V

15A to 27A

PWM1 to

PWM13

I/O

PWM/DIGITAL OUTPUT/DIGITAL INPUT SIGNAL (0-

3.3V)

15B to 27B

V_PWM

I

Servo power (if actuators have an independent

battery)

28A

V_PWM

I

Servo power (if actuators have an independent

battery)

28B

V+

I

6.5 to 36 V

Table 7: OEM board pinout

cod:

Veronte-4-HUM.docx

pag:

20/20

5. Performances

Variable Value

Weight (with enclosure and connector) 190g

Weight (OEM) 90g

Voltage Input 6.5V to 36V

Power Input

5W without M2M

9W with 3.75G M2M

15Wmax with 2G M2M

Minimum Temperature -40ºC

Maximum Temperature +55ºC1

Max. Internal Temperature +85ºC

Minimum Pressure 0kPa

Maximum Pressure 104kPa

Maximum Dynamic Pressure 6kPa 2

Protection Rating IP67 enclosure version

Acceleration Limits (3 axes) ±2g to ±16g 3

Angular Velocity Limits (3 axes) ±125deg/s

to ±2000deg/s4

Magnetic Field Limits (3 axes) ±4 to ±16 Gauss

GPS

72 channels, GPS L1C/A, GLONASS L1OF, BeiDou B1I

Datalink

410 to 480 MHz licensed or FHSS

902-928MHz FHSS

2.4 to 2.483 GHz ISM Band

869.5-869.75 MHz ISM Band

Table 8: Veronte performances

1No convection, ask for increased limits (up to 71ºC)

2Ask for increased limits (up to 50kPa)

3Limit for sustained maneuvers. Transitional higher accelerations are possible (e.g. catapult launch). Ask for increased limits.

4Limit for sustained maneuvers. Transitional higher angular velocities are possible. Ask for increased limits.

Table of contents

Other Embention Autopilot System manuals

Popular Autopilot System manuals by other brands

CUAV

CUAV X7 Plus product manual

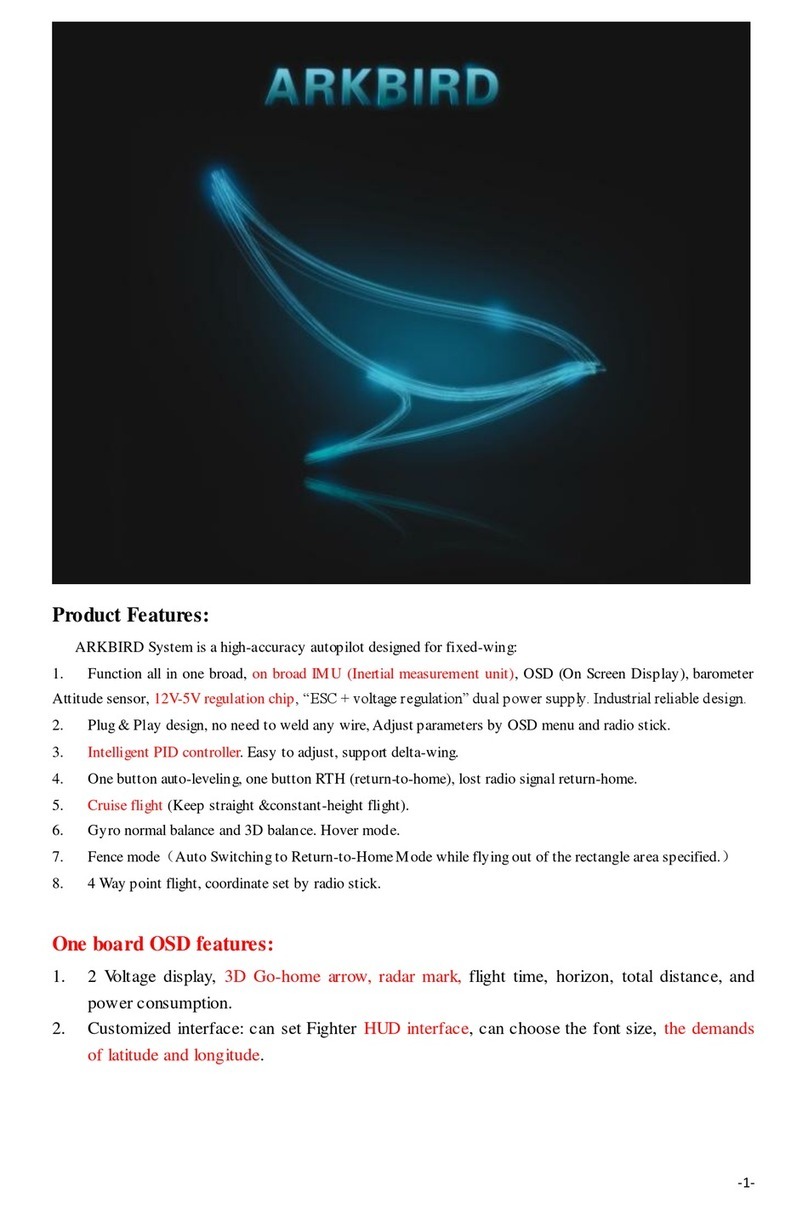

Arkbird

Arkbird Autopilot System manual

Raymarine

Raymarine Verado Installation and commissioning

Trio Avionics

Trio Avionics EZ PILOT Operation and installation manual

Dynon Avionics

Dynon Avionics Cessna 172 F-S Installation & maintenance manual

Garmin

Garmin G3X Touch pilot's guide