EMBLEM Easy Airpress Standard 4 User manual

DATAPLOT GmbH

Gutenbergstraße 15

24558 Henstedt-Ulzburg

Germany

Telephone: +49 4193 995-0 Fax: +49 4193 995-220

support@dataplot.de www.dataplot.de

Page 1 / 28

EASY AIRPRESS

Standard 4 FP

Pneumatic Airpress

>

USER'S MANUAL

Version 1.1

DATAPLOT GmbH

Gutenbergstraße 15

24558 Henstedt-Ulzburg

Germany

Telephone: +49 4193 995-0 Fax: +49 4193 995-220

support@dataplot.de www.dataplot.de

Page 2 / 28

CONTENTS

1Safety ........................................................................................................ 3

1.1 Safety notes ...................................................................................................... 3

1.2 Nameplate and “CE”marking................................................................................ 3

1.3 Warning signs .................................................................................................... 4

2Technical Description................................................................................. 5

2.1 General information............................................................................................ 5

2.2 The eyelet punching process ................................................................................ 5

2.3 Components ...................................................................................................... 6

2.4 Technical data.................................................................................................... 6

3Installation ................................................................................................ 7

3.1 Scope of delivery................................................................................................ 7

3.2 Installation of the handle..................................................................................... 8

3.3 Installation of the die for metal eyelet................................................................... 8

3.4 Installation of the die for plastic eyelets ...............................................................10

3.5 Compressed air connection .................................................................................13

3.6 Optional accessories ..........................................................................................13

3.7 Installation of the optional trolley ........................................................................14

3.8 Installation of the optional LED pointer ................................................................15

3.9 Replacing the batteries of the LED pointer.............................................................17

3.10 Installationof the optional spacer.........................................................................18

4Changing the Dies .................................................................................... 19

4.1 Metal eyelets > metal eyelets .............................................................................19

4.2 Plastic eyelets > plastic eyelets...........................................................................20

4.3 Metal eyelets > plastic eyelets ............................................................................21

4.4 Plastic eyelets > metal eyelets ............................................................................23

5Adjustments ............................................................................................ 25

5.1 Die for metal eyelets .........................................................................................25

5.2 Die for plastic eyelets .........................................................................................26

5.3 Finger guard .....................................................................................................28

6CE Declaration of Conformity ................................................................... 28

DATAPLOT GmbH

Gutenbergstraße 15

24558 Henstedt-Ulzburg

Germany

Telephone: +49 4193 995-0 Fax: +49 4193 995-220

support@dataplot.de www.dataplot.de

Page 3 / 28

Thank you for deciding to purchase the EMBLEM Easy Airpress Standard 4. Before

using your new machine please carefully read the safety notes and the

explanations for installation, operation and changing dies in this manual.

1Safety

1.1 Safety notes

Always disconnect the device from the compressed air supply before performing the

following work on the machine:

Changing the dies

Cleaning, adjustment or maintenance

Repairs

The outlet pressure of the compressor must be regulated so that a maximum pressure of

7 bars (101 psi) in the device is never exceeded. A pressure higher than 7 bars can

damage the device and cause serious injuries to the operator.

The device operates with a pressure of 5-7 bars. It is designed to give the best results for

an air pressure of 6 bars. Permanent operation with a pressure above 6 bars increases

wear.

1.2 Nameplate and “CE” marking

DATAPLOT GmbH

Gutenbergstraße 15

24558 Henstedt-Ulzburg

Germany

Telephone: +49 4193 995-0 Fax: +49 4193 995-220

support@dataplot.de www.dataplot.de

Page 4 / 28

1.3 Warning signs

Caution!

Risk of injury

Warning!

Do not operate or repair the device unless you have read and

understood the User's Manual.

Failure to do so jeopardises your health.

Caution!

Only qualified technicians may adjust the finger guard.

Danger!

Do not remove this part.

Finger guard adjustments

should only be carried out

by a qualified technician.

Do not start, operate or service

machine until you read and

understand operators manual.

Failure to do so could

result in serious injury.

D

O

N

O

T

R

E

M

O

V

E

T

H

I

S

P

A

R

T

.

DANGER

DATAPLOT GmbH

Gutenbergstraße 15

24558 Henstedt-Ulzburg

Germany

Telephone: +49 4193 995-0 Fax: +49 4193 995-220

support@dataplot.de www.dataplot.de

Page 5 / 28

2Technical Description

2.1 General information

The Easy Airpress Standard 4 is a portable pneumatic air press with which one can safely and

efficiently attach eyelets to different materials, such as banners, marquees, tarpaulins, flags, signs or

posters.

The pneumatic pressing of the eyelets is executed in a single step, i.e. punching the banner and

setting in the eyelet.

By replacing the die, the device can press different metal eyelets from 8mm to 18.2mm in addition to

transparent 12mm plastic eyelets.

With both the plastic dies and the metal dies, the cut out parts of the banner are pressed through the

upper die into a practical collecting container which can be easily emptied from time to time.

2.2 The eyelet punching process

The operator presses the grommet into the upper die, where it is automatically held. The

washer is placed into the lower die. The banner is then positioned between the two dies and

the punching process started with the footpedal. Alternatively, the operator can start the

process by actuating the manual operating lever.

The compressed air drives the piston downwards and the eyelet is pressed in a single step.

After releasing the pedal or the manual operating lever the piston returns to the upper

position and the finished banner with eyelet can be removed.

DATAPLOT GmbH

Gutenbergstraße 15

24558 Henstedt-Ulzburg

Germany

Telephone: +49 4193 995-0 Fax: +49 4193 995-220

support@dataplot.de www.dataplot.de

Page 6 / 28

2.3 Components

1. Handle

2. Housing

3. Cylinder

4. Manual operating lever

5. Finger guard

6. Punch waste

collecting container

7. LED pointer (optional)

8. Speed control

for finger guard

9. Footpedal

2.4 Technical data

Device description

EMBLEM Easy Airpress Standard 4FP

Safety system

Sensor-controlled finger guard

Compressed air supply

8mm directly connected

Operating pressure

5-7 bars (72-101 psi)

Air consumption

3.15L (0.83 gallons) per punching process, at 6 bars (85psi) operating

pressure

Recommended

compressor

8 bars, tank capacity min. 10L at 85L/min suction capacity

Noise level

76dB (A)

Pressing force

4.7kN / 480kgF / 1058 lbf at 6 bars (85 psi) operating pressure

Weight

7.2 kg

Dimensions

120mm x 245mm x 285mm

DATAPLOT GmbH

Gutenbergstraße 15

24558 Henstedt-Ulzburg

Germany

Telephone: +49 4193 995-0 Fax: +49 4193 995-220

support@dataplot.de www.dataplot.de

Page 7 / 28

3Installation

3.1 Scope of delivery

1Footpedal

2Handle

3Open-end spanner

4Allen wrench 4mm

5Allen wrench 3mm

7M5x16 screw

8A5.3 washer

9M6x60 screw

10 M6 nut

11 A6.4 washer (18mm)

12 A6.4 washer

13 Airpress (not pictured)

14 This manual

DATAPLOT GmbH

Gutenbergstraße 15

24558 Henstedt-Ulzburg

Germany

Telephone: +49 4193 995-0 Fax: +49 4193 995-220

support@dataplot.de www.dataplot.de

Page 8 / 28

3.2 Installation of the handle

Screw the handle onto the upper side of the device.

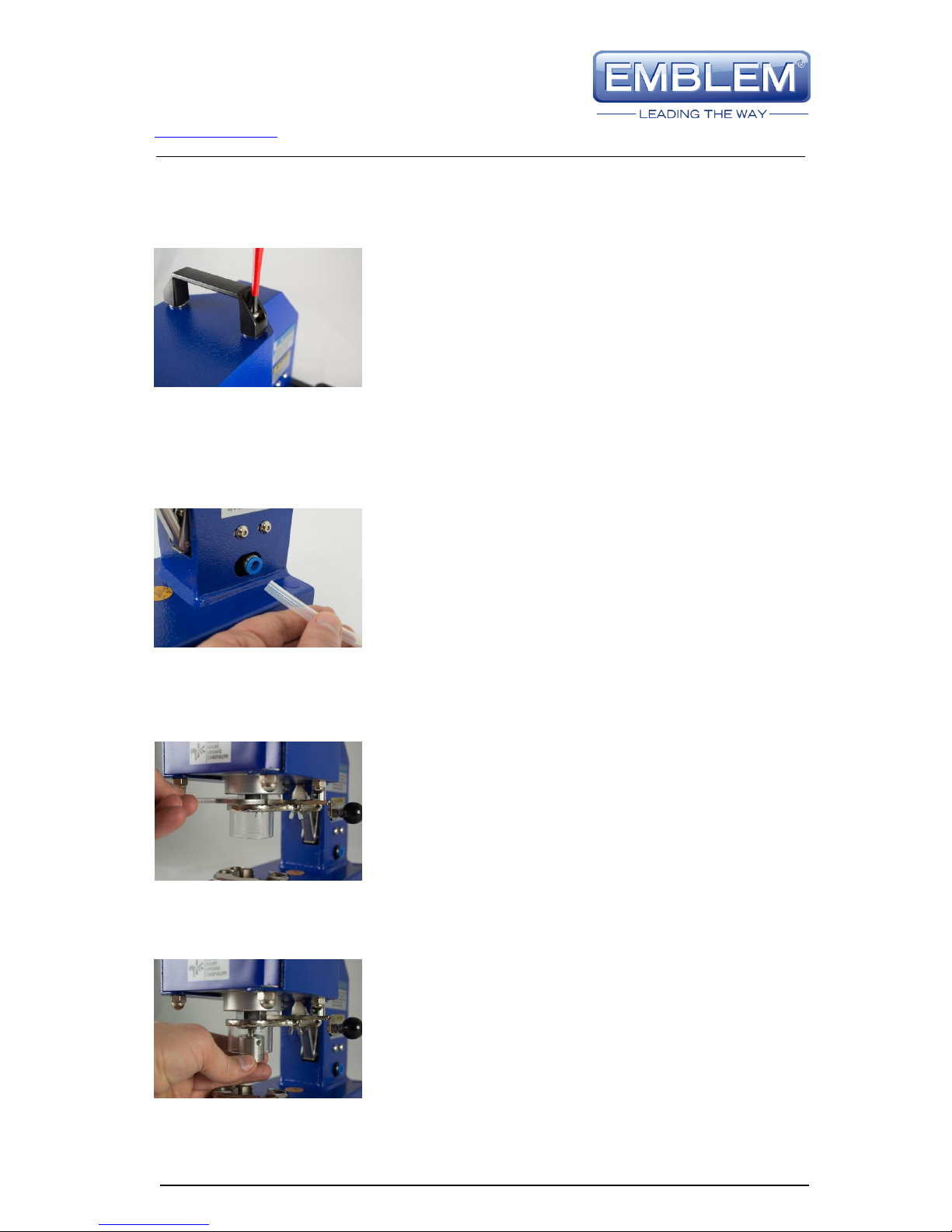

3.3 Installation of the die for metal eyelets

1. Remove the compressed air hose.

For the remainder of the installation procedure there

must be no pressure on the device!

!

2. Make certain that the adapter nut is firmly tightened,

using the open-end spanner supplied.

3. Turn the upper die as far as possible into the adapter

nut.

DATAPLOT GmbH

Gutenbergstraße 15

24558 Henstedt-Ulzburg

Germany

Telephone: +49 4193 995-0 Fax: +49 4193 995-220

support@dataplot.de www.dataplot.de

Page 9 / 28

4. Actuate the manual operating lever to drive the finger

guard downwards.

Turn the upper die all the way into the adapter nut and

tighten with the fingers.

5. Loosen the right screw for the lower die with a

screwdriver.

6. Turn out the screw until it is no longer visible in the

hole.

7. Insert the lower die into the hole and press up to the

stop.

8. Tighten the screw for the lower die and then check the

adjustment as described in Section 5.1.

Faulty adjustment causes poor results and can damage

the die.

DATAPLOT GmbH

Gutenbergstraße 15

24558 Henstedt-Ulzburg

Germany

Telephone: +49 4193 995-0 Fax: +49 4193 995-220

support@dataplot.de www.dataplot.de

Page 10 / 28

3.4 Installation of the die for plastic eyelets

1. Remove the compressed air hose.

For the remainder of the installation procedure there

must be no pressure on the device!

2. Remove the adapter nut using the open-end spanner.

The adapter nut is not required for this die. Save the

adapter nut for later use with a die for metal eyelets.

3. Actuate the manual operating lever to drive the finger

guard downwards.

Slide the upper die over the finger guard and turn the

die into the upper mount.

4. Tighten the upper die using the open-end spanner

supplied.

5. Loosen the right screw for the lower die with a

screwdriver.

DATAPLOT GmbH

Gutenbergstraße 15

24558 Henstedt-Ulzburg

Germany

Telephone: +49 4193 995-0 Fax: +49 4193 995-220

support@dataplot.de www.dataplot.de

Page 11 / 28

6. Turn out the screw until it is no longer visible in the

hole.

7. Insert the lower die into the hole and press up to the

stop.

8. Tighten the screw for the lower die.

9. Loosen the two front screws on the lower bracket.

10. Pull the upper die downwards with the fingers and

move the lower bracket so that the upper die fits into

the hole of the lower die without snagging.

DATAPLOT GmbH

Gutenbergstraße 15

24558 Henstedt-Ulzburg

Germany

Telephone: +49 4193 995-0 Fax: +49 4193 995-220

support@dataplot.de www.dataplot.de

Page 12 / 28

11. Tighten the two front screws on the lower bracket.

12. Slide the upper die several times completely into the

lower die and control that the upper die is centred in

the lower die without snagging.

13. Connect the compressed air hose.

14. Drive the finger guard with the manual operation lever

slowly downwards and control that the upper die is

centred in the lower die without snagging. If this is not

the case, adjust the die as described in Section 5.1.

Faulty adjustment causes poor results and can damage the die. Such damage is not under

warranty!

DATAPLOT GmbH

Gutenbergstraße 15

24558 Henstedt-Ulzburg

Germany

Telephone: +49 4193 995-0 Fax: +49 4193 995-220

support@dataplot.de www.dataplot.de

Page 13 / 28

3.5 Compressed air connection

The device has a quick coupling connection on the right side. Attach the open 8mm

compressed air hose to the coupling, which automatically holds the hose. To remove the

hose, press the snap ring on the connection and simultaneously pull out the hose.

The outlet pressure of the compressor must be regulated so that a maximum pressure of 7

bars (101 psi) in the device is never exceeded. A pressure higher than 7 bars can damage

the device and cause serious injuries to the operator.

The device operates with a pressure of 5-7 bars. It is designed to give the best results for

an air pressure of 6 bars. Permanent operation with a pressure above 6 bars increases

wear.

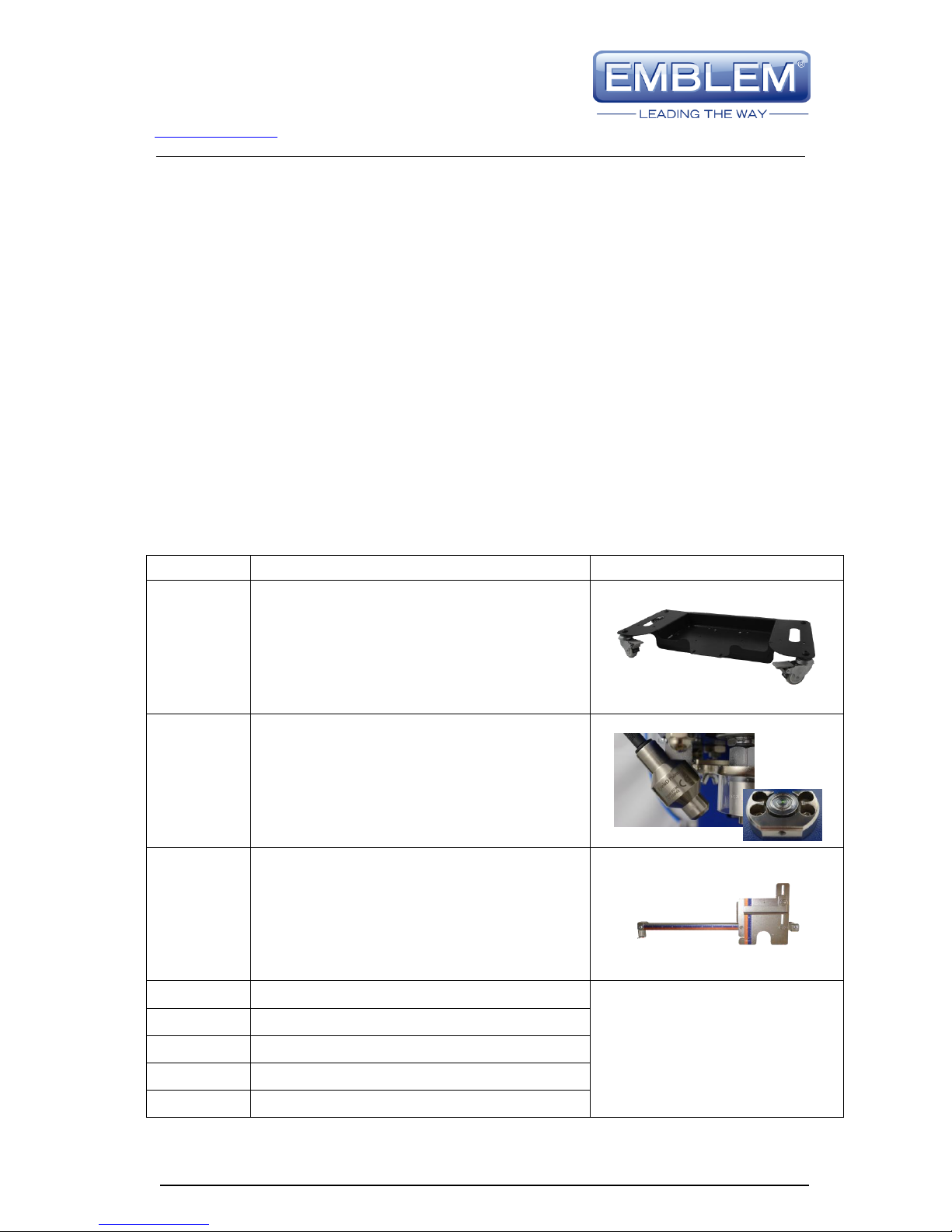

3.6 Optional accessories

The following optional accessories are available:

Art. no.

Description

Illustration

25044

Trolley

including two holders for the grommets and washers

and angular adapter for compressed air connection

25045

LED pointer

I

including power supply and battery compartment

20918

Spacer

25102

Eyelet mount for 8mm metal eyelets

Not pictured

25103

Eyelet mount for 9.5mm metal eyelets

25042

Eyelet mount for 11mm metal eyelets

25104

Eyelet mount for 18.2mm metal eyelets

25043

Eyelet mount for 12mm plastic eyelets

DATAPLOT GmbH

Gutenbergstraße 15

24558 Henstedt-Ulzburg

Germany

Telephone: +49 4193 995-0 Fax: +49 4193 995-220

support@dataplot.de www.dataplot.de

Page 14 / 28

3.7 Installation of the optional trolley

1. Remove the four blue stickers over the drill holes.

2. Remove the four plastic feet on the lower side.

3. Screw the device onto the trolley.

LED pointer

Trolley

DATAPLOT GmbH

Gutenbergstraße 15

24558 Henstedt-Ulzburg

Germany

Telephone: +49 4193 995-0 Fax: +49 4193 995-220

support@dataplot.de www.dataplot.de

Page 15 / 28

4. Cut away a piece (approx. 25mm long) of the

compressed air hose (not supplied) and attach it to the

angular piece supplied.

5. Attach the other end of the 25mm long hose to the

connection on the device.

3.8 Installation of the optional LED pointer

1. Prepare the LED pointer as shown in the photo at the

left. You may have to screw this onto the bracket.

2. Remove the nut from the rear left screw.

3. Attach the Laser pointer on the screw, but don't yet

tighten the nut.

DATAPLOT GmbH

Gutenbergstraße 15

24558 Henstedt-Ulzburg

Germany

Telephone: +49 4193 995-0 Fax: +49 4193 995-220

support@dataplot.de www.dataplot.de

Page 16 / 28

4. Lay a punched banner section in the centre of the die.

For multi-layer punching lay several accordingly over

each other. Then adjust the laser point so that it points

to the centre of the punched section.

5. To adjust towards the front and rear rotate the bracket

in the horizontal plane.

6. To adjust towards the left and right rotate the pointer.

The Phillips-head screw is the fulcrum and under the

wing screw is an elongated hole for adjusting the

position.

7. Actuate the manual operating lever downwards to check

that the upper die cannot collide with the LED pointer.

8. Connect the power supply to the pointer or glue the

battery compartment to a suitable spot und connect.

DATAPLOT GmbH

Gutenbergstraße 15

24558 Henstedt-Ulzburg

Germany

Telephone: +49 4193 995-0 Fax: +49 4193 995-220

support@dataplot.de www.dataplot.de

Page 17 / 28

3.9 Replacing the batteries of the LED pointer

1. To replace the batteries in the battery compartment

remove the locking screw.

2. Then insert a flat screwdriver into the mount and

carefully rotate.

3. The cover should then lift on this side.

4. Pull the cover in the direction of the arrow A and

carefully turn it upwards. Take care that the nib B does

not break off.

5. Replace the two batteries with the battery type AA-Mignon.

Ensure the correct polarity.

Then proceed in the opposite sequence to close the battery compartment again.

B

A

DATAPLOT GmbH

Gutenbergstraße 15

24558 Henstedt-Ulzburg

Germany

Telephone: +49 4193 995-0 Fax: +49 4193 995-220

support@dataplot.de www.dataplot.de

Page 18 / 28

3.10 Installation of the optional spacer

1. Remove the yellow sticker and the upper and lower

dies.

2. Remove the left screw.

3. Position the spacer so that pins A, B and C fit into the

corresponding holes A, B and C. Press the spacer all the

way down.

4. Fix the spacer with the left screw.

A

B

C

A

B

C

DATAPLOT GmbH

Gutenbergstraße 15

24558 Henstedt-Ulzburg

Germany

Telephone: +49 4193 995-0 Fax: +49 4193 995-220

support@dataplot.de www.dataplot.de

Page 19 / 28

4Changing the dies

4.1 Metal eyelets > metal eyelets

1. Remove the compressed air hose.

For the remainder of the installation procedure there

must be no pressure on the device!

2. Actuate the manual operating lever to drive the finger

guard downwards.

Loosen the upper die with the open-end spanner and

turn out as far as possible.

3. Actuate the manual operating lever to drive the finger

guard upwards and turn out the die completely.

4. Loosen the right screw for the lower die with a

screwdriver.

DATAPLOT GmbH

Gutenbergstraße 15

24558 Henstedt-Ulzburg

Germany

Telephone: +49 4193 995-0 Fax: +49 4193 995-220

support@dataplot.de www.dataplot.de

Page 20 / 28

5. Remove the punch waste collecting container. Press the

lower die upwards with the finger and remove the die.

Continue as described from Step 2 in Section 3.3.

4.2 Plastic eyelets > plastic eyelets

1. Remove the compressed air hose.

For the remainder of the installation procedure there

must be no pressure on the device!

2. Actuate the manual operating lever to drive the finger

guard downwards.

Loosen the upper die with the open-end spanner

supplied and turn it out completely.

3. Loosen the right screw for the lower die with a

screwdriver.

Table of contents