- 8 -

4. Clothes drying mode: Place the appliance in a room with closed doors along with the clothes rack. There will

be high fan speed under this mode and the humidity cannot be changed. The environmental humidity is

shown on the panel.

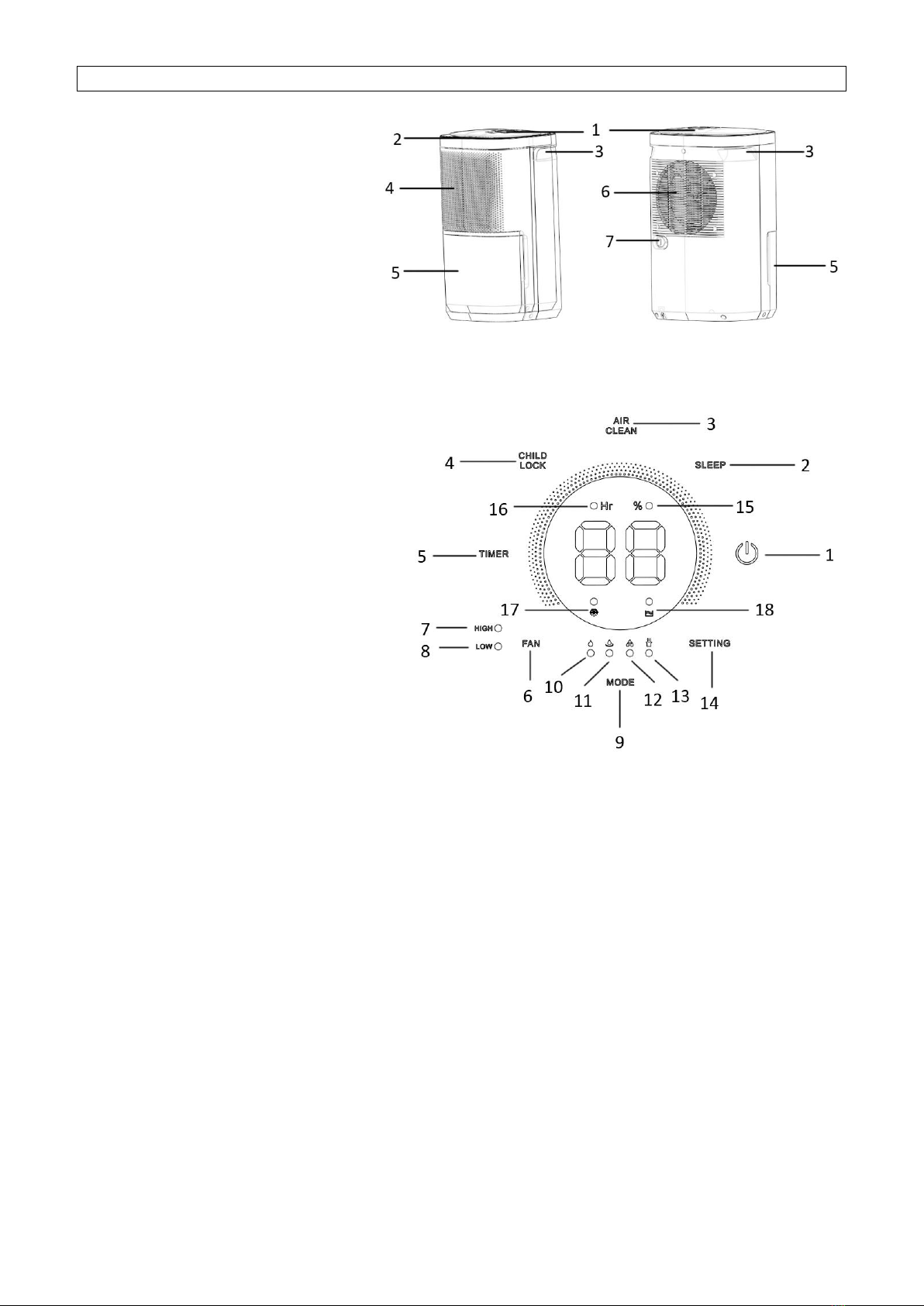

TIMER:

Auto-OFF setting

-When the appliance is ON, press the timer button to select a desired auto-OFF time from 1 to 24 hours.

-Each press will increase the set time by one hour and after 24 hours, the figure will return to 1 for another

circulation. You can also long press the timer button for rapid adjustment.

-The timer will flash for several seconds, then the timer indicator light will illuminate still; The panel will

show the environmental humidity. The timer setting is confirmed.

-The appliance will automatically turn off once the select time has passed.

Auto-ON setting

-When the appliance is OFF, press the timer button to select a desired auto-ON time from 1 to 24 hours.

-The way to adjust the timer is the same as that of the auto-OFF setting.

-The functions of fan speed, mode, air clean, child lock and sleep are activated; the humidity setting can

only be adjusted in auto mode.

-The appliance will automatically turn on with the set functions once the select time passed.

To cancel the timer, set the time to 0 hour; the timer will falsh several times, then the timer indicator light will

turn off.

CHILD LOCK:

-Press and hold the button for more than 3 seconds to lock all the other buttons in the panel.

-Press and hold the button again for more than 3 seconds to unlock all the other buttons.

AIR CLEAN:

-Press the air clean button to enter into the air clean mode, press the button again or press the mode

button to turn off the air clean mode

-Under this mode, dehumidification does not operate. Fan, timer, sleep and child lcok functions are

effective.

SLEEP MODE:

-Press the sleep button to enter into the sleep mode; press the button again to exit the sleep mode.

-Under this mode, all indicators will be off except sleep indicator light and water tank full indicator light.

Notice:

1. Environmental indicator light:

When environmental humidity is < 53%, the indicator will be in blue;

When environmental humidity is ≥ 53% and ≤67%, the indicator will be in green;

When environmental humidity is > 67%, the indicator will be in red;

If the water tank is not placed correctly or is full, the indicator will be in red and flash.

2. This appliance is equipped with memory function in case of power-down, except timer function.

3. Important: If the fault code “E2” appears on the display, that means temperature sensor / humidity sensor

gets failure. Please contact a professional for inspection and maintenance.

DRAIN THE COLLECTED WATER

When the water tank is full, the water tank full indicator light will illuminate. The operation will stop