- 8 -

2. Dehumidification mode: the indicator light illuminates. The fan speed can be switched between low and

high. The humidity can be set between 30-90%RH or set to “Co” (Continuous). Press the button “+” / “-” to

adjust the setting. The setting will be in effect in approx. 10 seconds with no further operations. The digital

display will turn back to show the room humidity.

1) When the room humidity ≥ set humidity + 3%, the compressor starts working and the fan keeps running

at the set speed. After dehumidifying, when the room humidity ≤ set humidity - 3%, the compressor is

turned off and the dehumidifying is stopped. Once the room humidity ≥ set humidity + 3% again, the

compressor resumes working. Thus, the indoor humidity can be maintained at the set humidity

according to the above cycle operations.

2) When the set humidity is "Co", the compressor runs continuously without the limitation of the set

humidity, and the fan speed is adjustable.

3. Silence mode: the indicator light illuminates. The fan speed cannot be adjusted and the unit works at a

lower fan speed by default. Other operations follow the dehumidification mode.

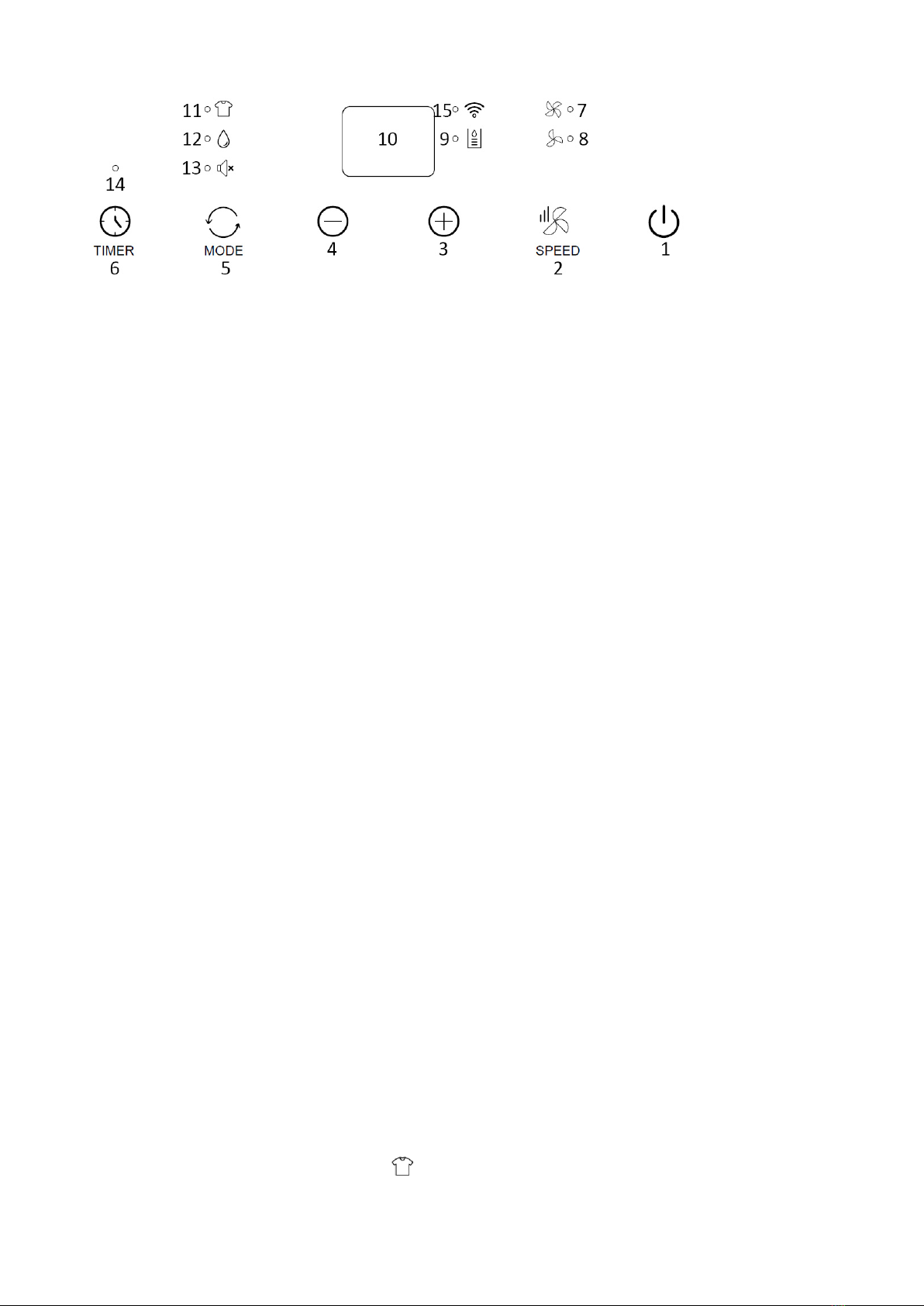

Increasing/decreasing setting buttons

Press the buttons “+” / “-” to adjust the setting of humidity or timer.

Fan speed button

Press the fan speed button to select low or high fan speed. The corresponding indicator light will illuminate.

Timer button

Timer ON setting:

- When the appliance is off, press the button “TIMER”, the corresponding indicator light will flash.

- Press the button “+” / ”-” to select a desired ON time from 0-24 hours. The value will flash on the digital

display and the setting will be in effect in approx. 5 seconds.

- The appliance will automatically turn on once the set time has passed.

Timer OFF setting:

- When the appliance is working, press the button “TIMER”, the corresponding indicator light will flash.

- Press the button “+” / ”-” to select a desired OFF time from 0-24 hours. The value will flash on the digital

display and the setting will be in effect in approx. 5 seconds. The digital display will turn back to show the

humidity.

- The appliance will automatically turn off once the set time has passed.

Note: Press the button “TIMER” again to check the remaining time. Continue to press the button “TIMER”, the

timer function will be cancelled.

Notice:

1. The room humidity display range is 35~95%RH (room humidity < 35%, display “Lo”; room humidity > 95%,

display “Hi”). The working environment temperature of this appliance is 5~35 ℃, and the working

environment humidity is 10~95%RH.

2. The compressor has a three-minute delay protection function. When the compressor is working and the

power is cut off accidentally, the compressor will not restart immediately after turned on again. It will start

to work in 3 minutes.

After switching mode or after the full water fault is removed, the compressor may enter the protection state

too. You must wait for 3 minutes before the compressor can start again.