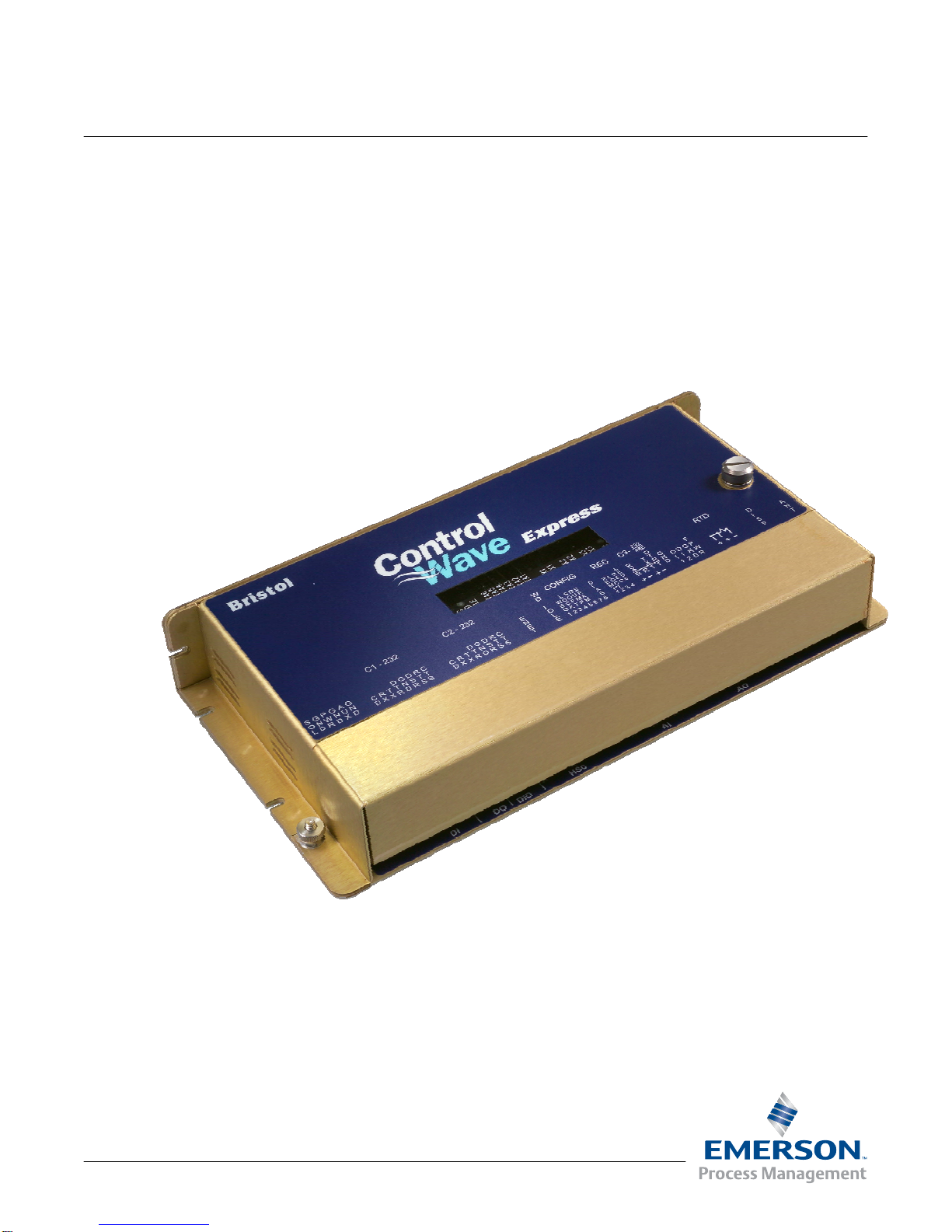

ControlWave Express Instruction Manual (CI-ControlWave Express)

Issued Mar-2011 Contents v

Contents

Chapter 1 – Introduction 1-1

1.1 Scope of the Manual.................................................................................................................1-2

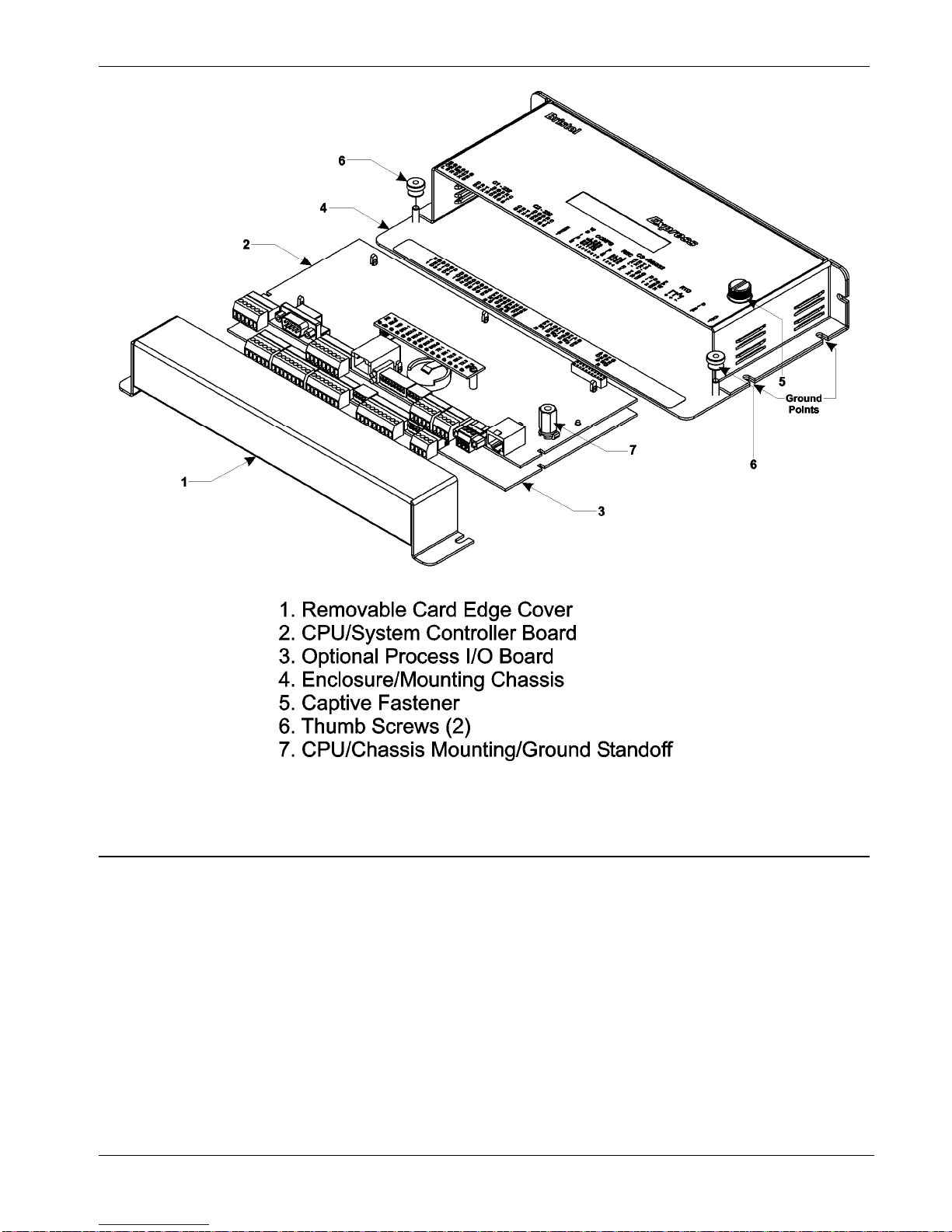

1.2 Physical Description..................................................................................................................1-2

1.3 CPU/System Controller Board ..................................................................................................1-3

1.4 Power Options...........................................................................................................................1-5

1.5 I/O Options................................................................................................................................1-5

1.6 Software Tools ..........................................................................................................................1-6

Chapter 2 – Installation 2-1

2.1 Site Considerations...................................................................................................................2-1

2.1.1 Class I, Div 2 Installation Considerations......................................................................2-3

2.2 Installation Overview.................................................................................................................2-3

2.2.1 Unpacking Components................................................................................................2-4

2.2.2 Mounting the Housing...................................................................................................2-4

2.2.3 Grounding the Housing.................................................................................................2-6

2.3 Configuring the CPU/System Controller Board.........................................................................2-7

2.3.1 Setting DIP Switches on the CPU/System Controller Board ........................................2-8

2.3.2 Setting Jumpers on the CPU/System Controller Board..............................................2-10

2.3.3 General Wiring Guidelines..........................................................................................2-11

2.3.4 Wiring Power to the CPU/System Controller Board....................................................2-11

2.3.5 Connections to RS-232 Serial Port(s) on the CPU/System Controller Board.............2-14

2.3.6 Connections to the COM3 (RS-485/RS-232) Serial Port on the CPU/System Controller

Board .........................................................................................................................2-19

2.3.7 Connections to the Ethernet Port on the CPU/System Controller Board....................2-21

2.4 Optional Display/Keypads.......................................................................................................2-22

Chapter 3 – I/O Configuration and Wiring 3-1

3.1 I/O Options................................................................................................................................3-1

3.2 Process I/O Board.....................................................................................................................3-2

3.2.1 Setting Jumpers on the Process I/O Board...................................................................3-2

3.2.2 Setting DIP Switches on the Process I/O Board...........................................................3-2

3.3 I/O Wiring ..................................................................................................................................3-4

3.3.1 Non-Isolated Discrete Inputs (DI) on TB2 and TB3 of Process I/O Board....................3-6

3.3.2 Non-Isolated Discrete Outputs (DO) on TB3 of Process I/O Board..............................3-7

3.3.3 Non-Isolated Analog Inputs (AI) on TB6 of Process I/O Board.....................................3-8

3.3.4 Non-Isolated Analog Output (AO) on TB7 of Process I/O Board..................................3-9

3.3.5 Non-Isolated Pulse Counter/Discrete Inputs on TB5 of CPU/System Controller Bd..3-10

3.3.6 Non-Isolated High Speed Counter (HSC) / Discrete Inputs (DI) on TB4 of Process I/O

Board .........................................................................................................................3-11

3.3.7 Resistance Temperature Device (RTD) Inputs on CPU/System Controller Board.....3-12

3.3.8 Connections to a Bristol Model 3808 Transmitter.......................................................3-14

Chapter 4 – Operation 4-1

4.1 Powering Up/Powering Down the ControlWave Express .........................................................4-1

4.2 Communicating with the ControlWave Express........................................................................4-2

4.2.1 Default Comm Port Settings..........................................................................................4-2

4.2.2 Collecting Data from the ControlWave Express............................................................4-2

4.3 Creating and Downloading an Application (ControlWave Project) ...........................................4-3