Emerson

Radio

Par.

TABLE

OF

CONTENTS

SECTION

1—GENERAL

DESCRIPTION

Page

1

Facilities

3

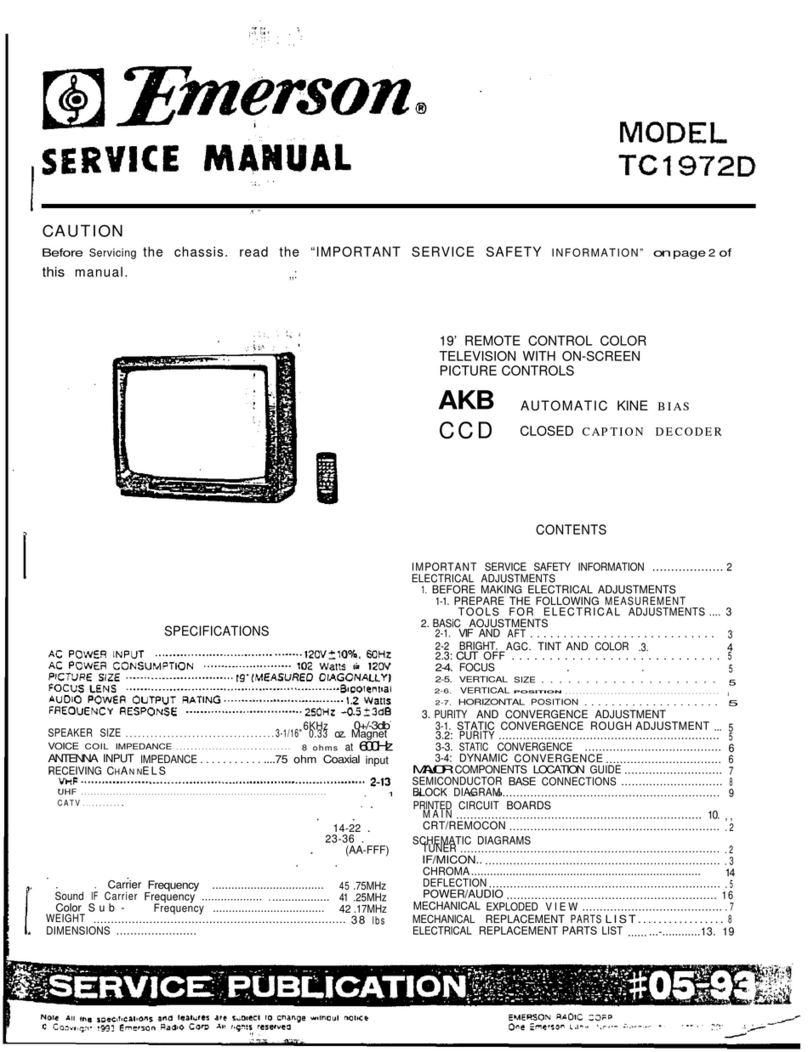

2

Specifications

4

SECTION

2—INSTALLATION

LIST

OF

TABLES

Table

DESCRIPTION

Page

I

TubeComplements

3

II

ReceiverCharacteristics

4

III

AdjustmentsControlSettings

11

IV

GeneratorFrequencies_.._

14

V

Audio

I-F

Alignment

15

VI

Video

I-F

Alignment

16

VII

TunerAlignment

.-.17

VIII

DeflectionWaveformTestPoints

18

\

3

1

2

1

?

3

4

5

6

7

1

?

3

4

•>

6

7

8

ft

in

11

T>

13

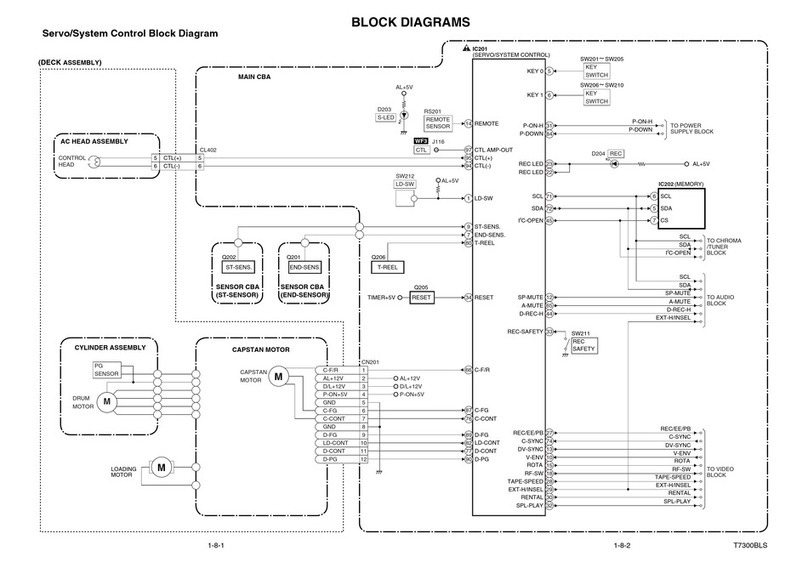

SECTION

3—

OPERATION

SECTION

4 —

CIRCUIT

DESCRIPTION

General

...

Tuner

Video

Section

.

_ _ ..

Deflection

Section

,.

— , _ _

Power

Supplies

Intercarrier

Sound

—

Deflection

Yoke

and

Focus

Coil

Assembly

SECTION

5—

MAINTENANCE

AND

ALIGNMENT

ChassisRemoval

.„

KinescopeReplacement

Mechanical

Deflection

Adjustments

...

..«___,

Electrical

Deflection Adjustments

...

Alignment

Test

Equipment

-

Alignment

...

.,

. .

Voltage

and

ResistanceAnalysis

;

Deflection

CircuitWaveforms

Production

Changes

Secondary

Area

Reception

Cabinet

Parts

List

Chassis

Parts

List

4

4

5

5

5

7

8

8

9

9

10

10

10

10

10

10

11

14

14

17

17

19

21

21

22

Fig.

1-1

1-2

1-3

3-1

3-2

3-3

3-4

3-5

3-6

3-7

3-8

3-9

4-1

4-2

5-1

5-2

5-3

5-4

5-5

5-6

5-7

5-8

5-9

5-10

5-11

5-12

5-13

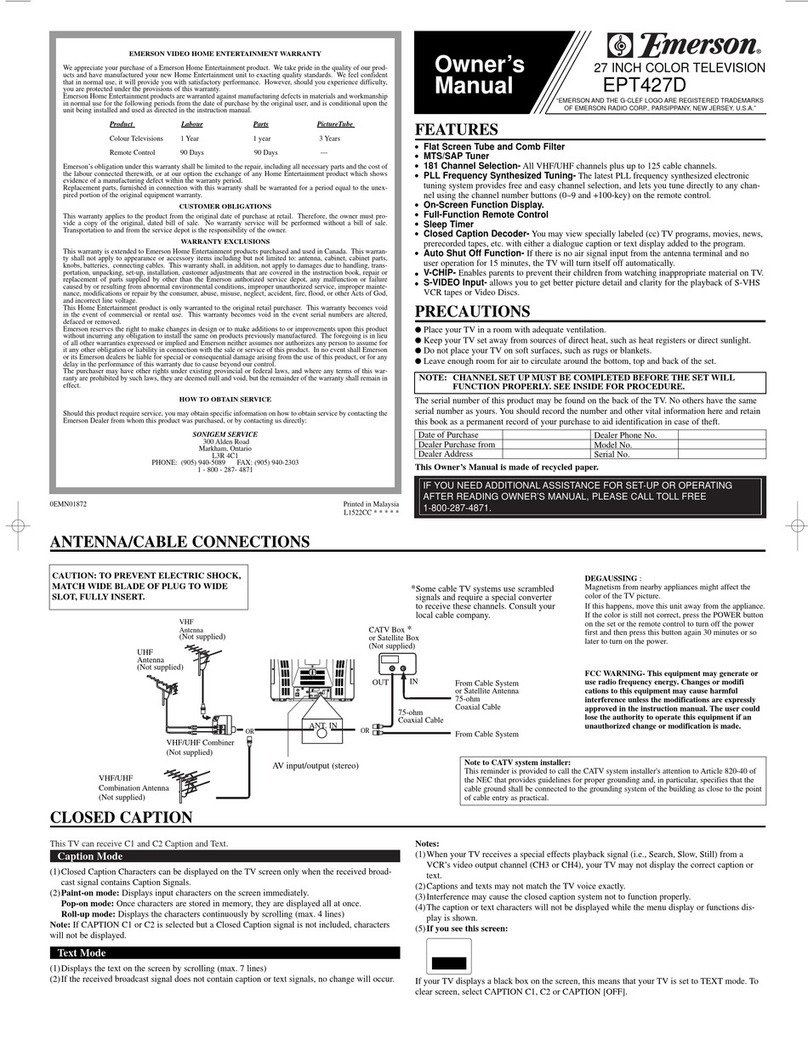

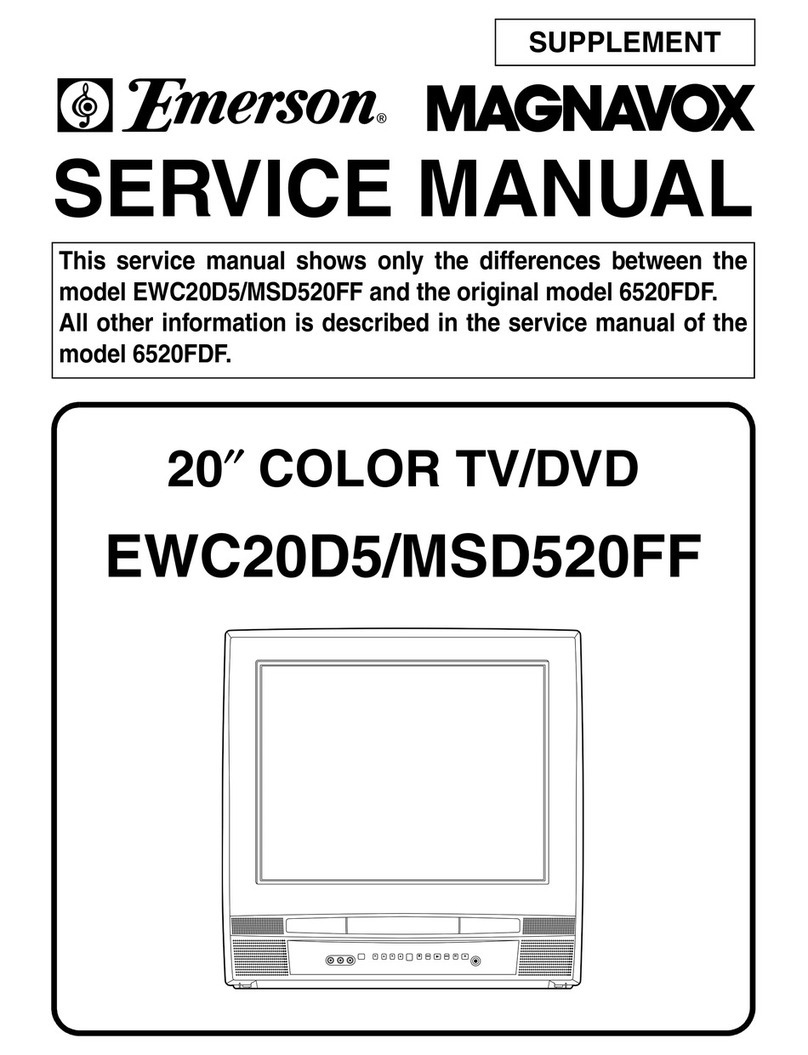

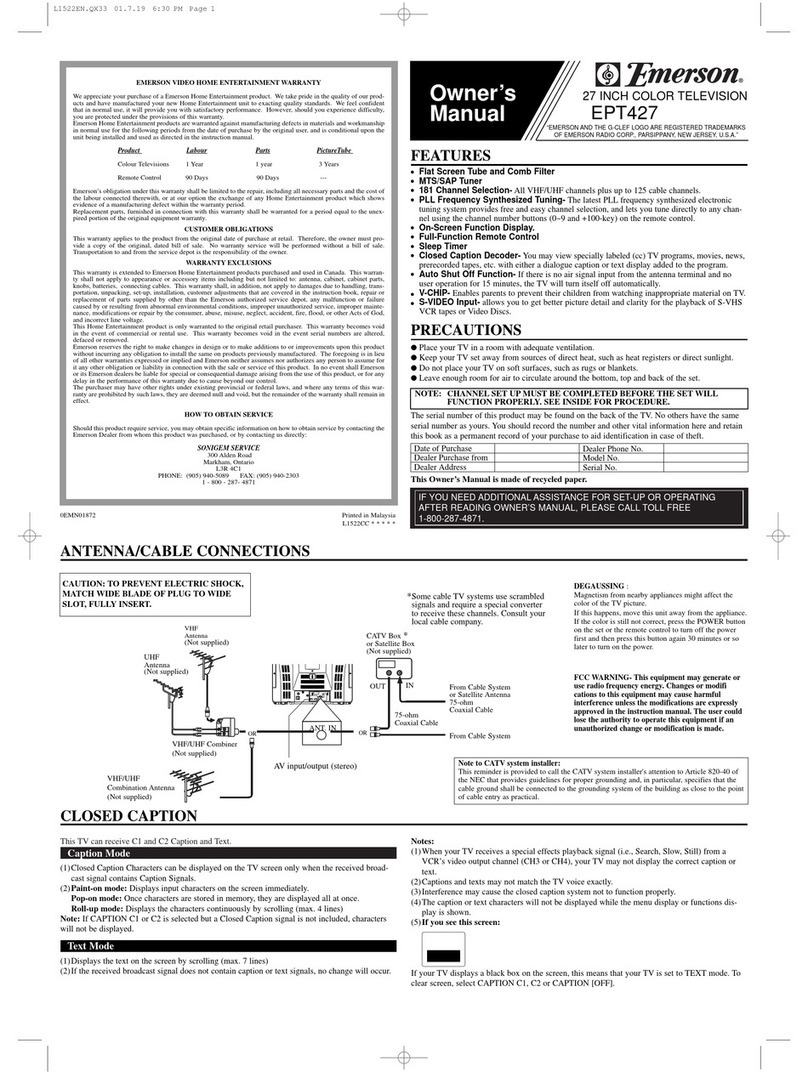

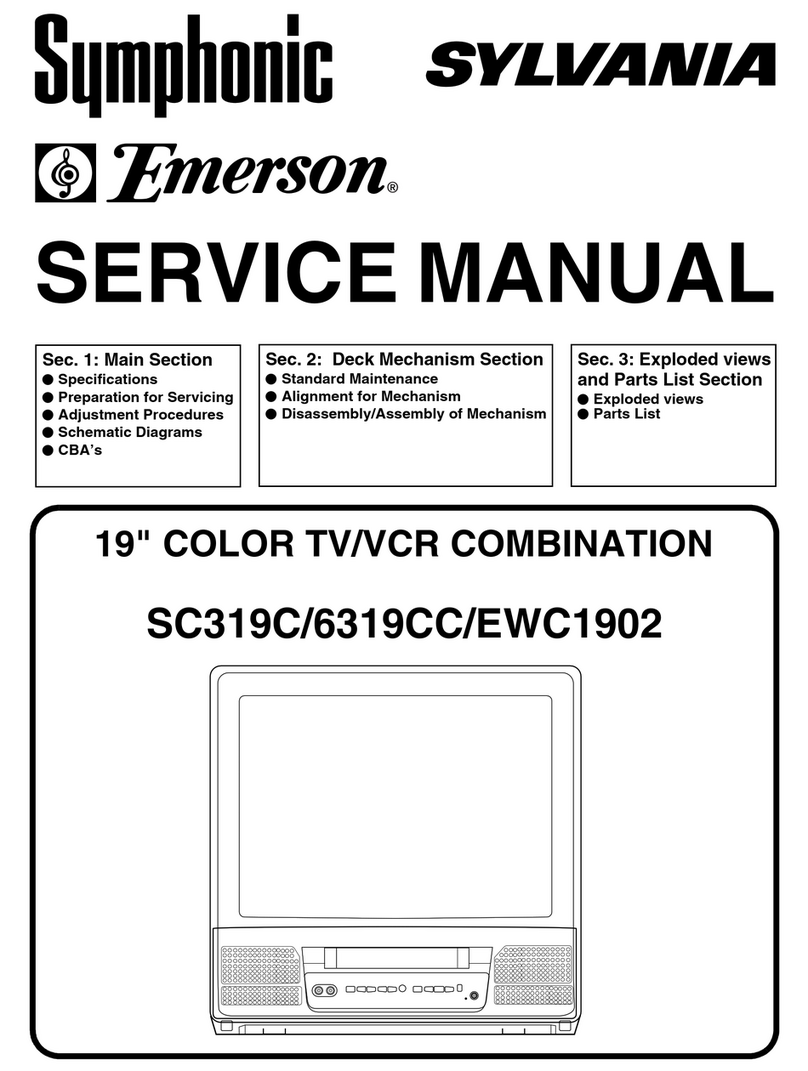

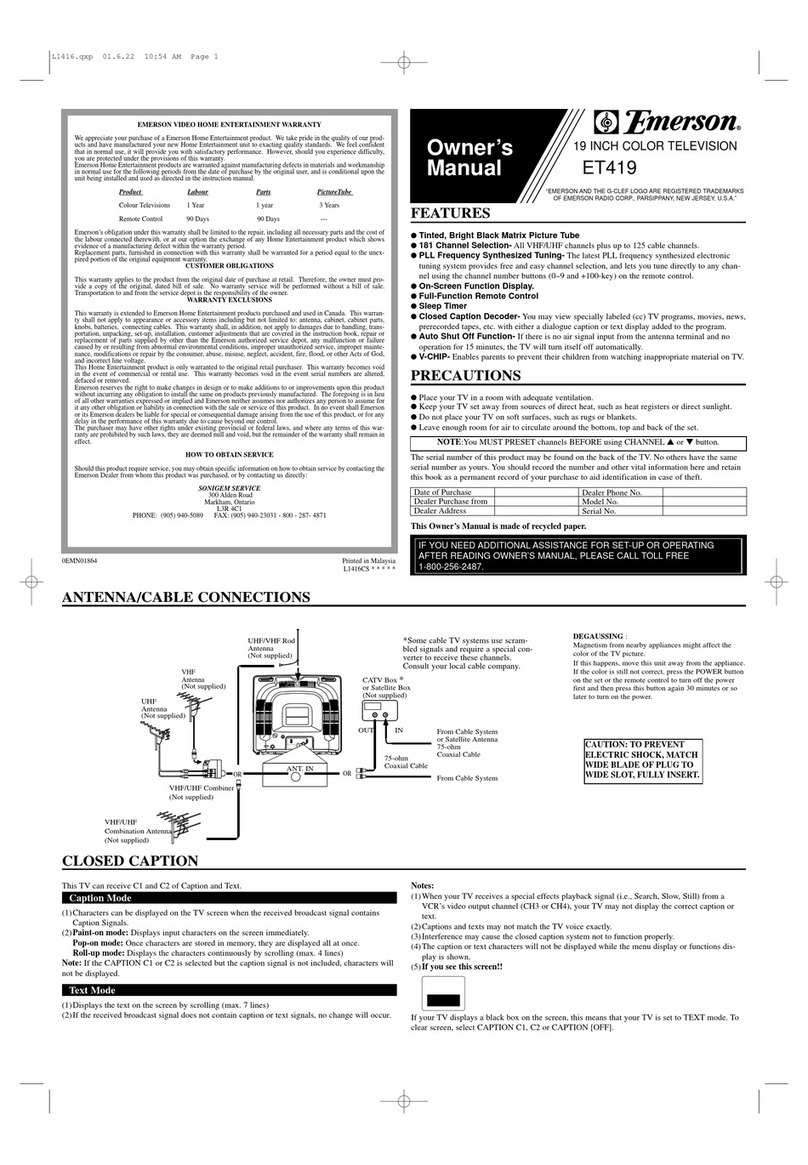

LIST

OF

ILLUSTRATIONS

DESCRIPTION

Page

FrontView

of

Chassis

120098B

3

TubeLocationDiagram

4

Video,

Audio,

and

OscillatorFrequencies

4

FrontPanelControls

_.

5

Test

Pattern,Correctly

Adjusted

6

TestPattern,

Tuning

Misadjusted

6

Test

Pattern,ExcessiveContrast

6

TestPattern,ExcessiveBrightness

6

TestPattern,VerticalHoldMisadjusted

6

TestPattern,Horizontal

Hold

Misadjusted

6

TestPattern,FocusMisadjusted

6

TestPattern,WeakSignal

6

Block

Diagram—Chassis

12O110B,120113B

7

Schematic

Diagram

of

Tuner

8

DeflectionYoke

and

FocusCoilAdjustments

CombinedMechanical

and

ElectricalCentering

11

FocusCoilAdjustments,MechanicalCentering

11

SchematicDiagramChassis120110B12,13

Rear

DeflectionAdjustments

14

GeneratorMatchingNetwork

14

ScopeDetectorNetwork

— 14

Location

of

AlignmentPoints

15

TunerAlignmentPoints

16

SideView

of

Tuner

17

Voltage

and

ResistanceDiagram

18

Sweep

CircuitWaveforms

19

High

Voltage

PowerSupply,Chassis120113B

20

BottomView

of

Chassis

21