Emery Thompson CB-100 User manual

OPERATING MANUAL

BATCH FREEZER INSTALLATION

OPERATING, MAINTENANCE

AND CLEANING MANUAL

CB-100 Countertop

World’s Best Built Batch Freezers –100% Made in the U.S.A.

by the People Who Invented Them!

~ 1 ~

v. 1.03

TABLE OF CONTENTS

Section 1:

UNPACKAGING

FIGURE 1-1

FIGURE 1-2

FIGURE 1-3

FIGURE 1-4

FIGURE 1-5

page 2

Section 2:

OVERVIEW

CB-100 NOMENCLATURE

page 6

Section 3:

OPERATION

FIGURE 3-1

FIURE 3-1R

FIGURE 3-2

FIGURE 3-3

FIGURE 3-4

FIGURE 3-5

FIGURE 3-6

page 7

Section 4:

CLEANING AND SANITIZING

page 12

Section 5:

CARE and MAINTENANCE

PHOTO 5-1

page 14

Section 6:

PARTS DIAGRAMS

FIGURE 6-1

FIGURE 6-2

FIGURE 6-3

FIGURE 6-4

FIGURE 6-5

page 16

Section 7:

WARRANTY

page 20

~ 2 ~

v. 1.03

Section 1: UNPACKAGING

When your shipment arrives, please inspect it very carefully. Look

particularly for damage to the box covering it. If it looks crushed,

cut or punctured, have the freight driver wait until you can cut the

box off, and inspect the machine itself. Also, look for damage to

the wooden skid itself. Broken wood can signify rough treatment.

Any damage should be photographed.

The machine and skid weigh about 100 pounds total. Two people,

one on each side, should easily be able to carry it, and it will fit

through a standard 36" exterior door.

If you haven't already, remove the box from the skid by cutting

through it as close as possible to the skid, then lift it off. Look for

a small box inside which contains 4 black plastic feet, and an Allen

wrench to change out blades in the future.

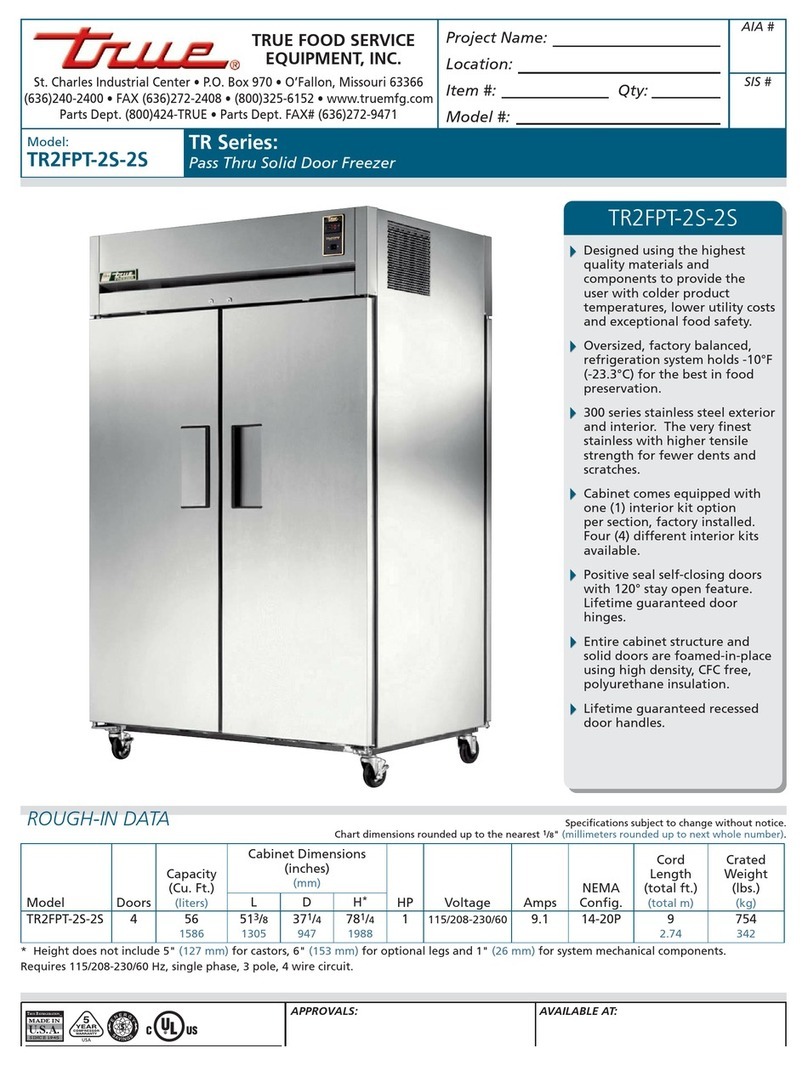

The machine is held in place by two runners along its sides, which

have a clip at their middles that hooks into the middle bottom

louver on each side of the machine. The clips are screwed down to

the runner, and these screws must be removed to free the machine

from the skid. (See Figures 1-1, 1-2, 1-3)

Once the machine is free, place it up onto the intended work

surface. To install the feet, refer to Figures 1-4 & 1-5. The feet

simply plug into the 4 holes that are molded into the machine's

base.

Remove the wire ties holding the power cord in place, and unravel

it. The machine is now ready for use.

~ 3 ~

v. 1.03

Figure 1-1

Figure 1-2

~ 4 ~

v. 1.03

Figure 1-3

Figure 1-4

~ 5 ~

v. 1.03

Figure 1-5

~ 6 ~

v. 1.03

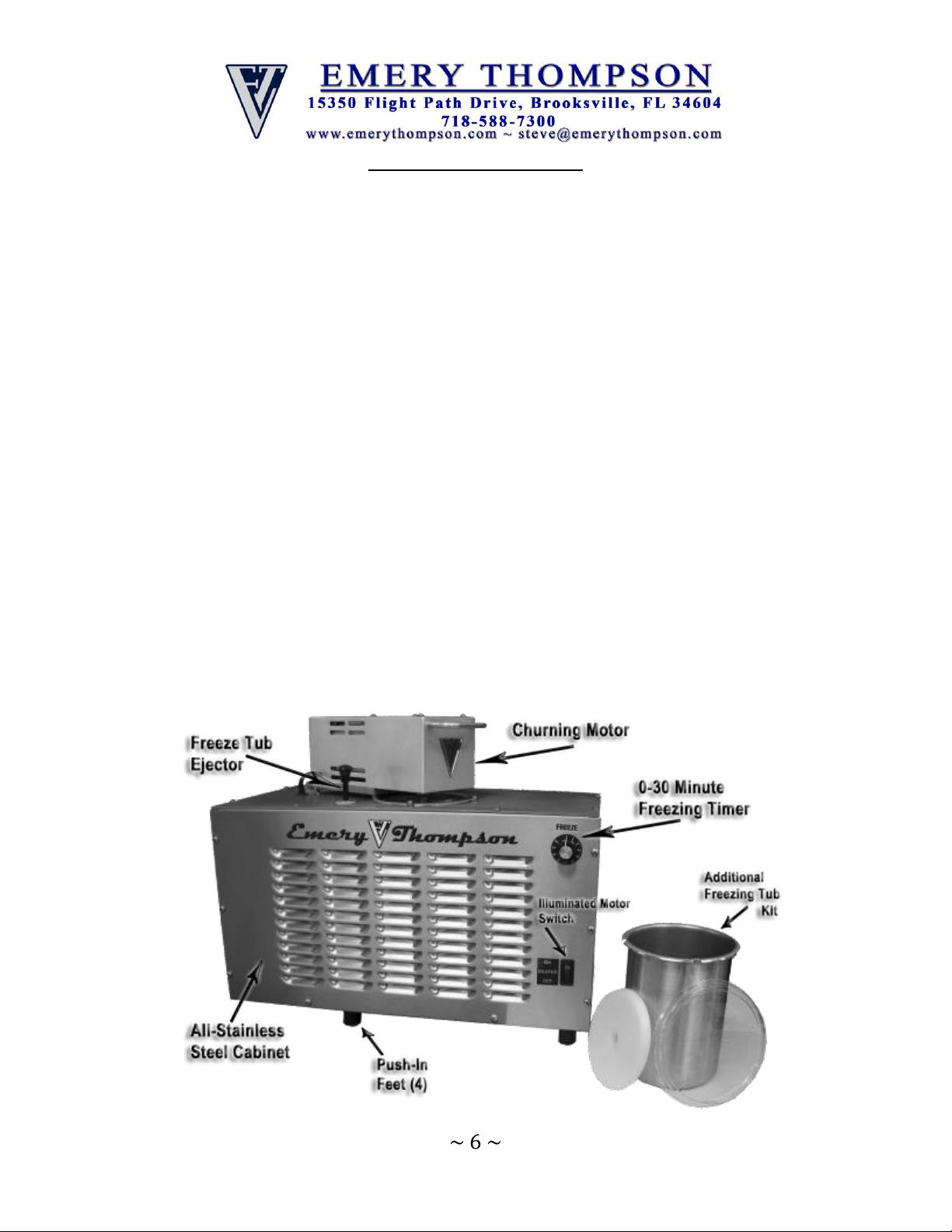

Section 2: OVERVIEW

Your new model CB100 Countertop Batch Freezer is a self-

contained air-cooled unit that is designed to sit on any countertop

and be easily moved for cleaning. It runs on standard

residential/commercial 115V service, and comes equipped with a

plug for such. The machine pulls in room air from the left end, and

distributes it out on the other 3 sides. One unique feature of the

machine is that it freezes product in what will be your serving or

hardening container. Each additional container purchased comes

with a bearing disc and a clear lid.

This machine will produce premium ice cream, Italian ices,

sorbets, and gelato in 20 minutes or less per tub. Various

inclusions can be added prior to churning, and/or after production

in the same container it was just made in.

To make it even easier to use, the CB100 has an ejection

mechanism that pushes your freezing tub up and out of the freezing

chamber, and the machine has very few parts to be cleaned and

sanitized.

~ 7 ~

v. 1.03

Section 3: OPERATION

The normal sequence of operating the CB100 is as follows:

1. Insert a clean, sanitized (See Section 4) freezing tub into the

freezing cylinder, making sure the rim of the tub engages all

4 of the round drive lugs and that the rim sits flush with the

top surface (See Figure 3-1).

2. Insert the bearing disc, with radiused edge down, into the

freezing tub. The disc should sit flat and rounded edge of

disc must match rounded profile of tub bottom. (see Figure 3-

1R).

3. Insert the dasher shaft with blade into the tub with the

hexagonal drive end facing upward. Be sure the round end of

the shaft goes into the round hole in the bearing disc, and

push it all the way down until the bottom edge of the blade

touches the surface of the disc. (See Figure 3-2).

4. Pour the mix you intend to freeze into the tub. NOTE: do not

add more than your flavorings and ONE quart of mix to the

freeze tub. You do not want overflow out of the top of the

freeze tub.

5. Lay the splash plate on top of the dasher. It will fit just inside

of the freeze tub. (See Figure 3-3).

6. Tilt the churning motor down gently until the driveshaft

touches the top of the dasher. Let the weight of the churning

motor rest atop the dasher. (See figures 3-4 and 3-5). When

you are ready to begin the cycle, simply turn on the motor

switch, and it will engage with the dasher and drop down

~ 8 ~

v. 1.03

approximately another 1/4" and stop on its rubber bumper.

7. Once the dasher is spinning, turn the freezing timer to 20

minutes. The refrigeration will start, and continue until the

timer either times-out, or you manually twist it to the "0"

position. (See figure 3-6).

8. When the desired consistency is reached, turn the

refrigeration timer to the zero (0) position and the compressor

will stop. Now turn the rocker switch off, and the churning

motor stops. Raise the motor into its upright position. Push

down firmly on the ejection knob, making the freezing tub

rise up enough to grasp the rim and remove it from the

machine. Remove the splash disc and dasher from the freeze

tub and put a cover on the tub, then transfer to your

hardening cabinet.

Figure 3-1

~ 9 ~

v. 1.03

Figure 3-1R

Figure 3-2

~ 10 ~

v. 1.03

Figure 3-3

Figure 3-4

~ 11 ~

v. 1.03

Figure 3-5

Figure 3-6

~ 12 ~

v. 1.03

Section 4: CLEANING AND SANITIZING

It is very important to have a stringent, repeatable procedure for

cleaning and sanitizing any type of food equipment. Fortunately,

the model CB100 Batch Freezer has very few parts to clean and

sanitize. You will need to have a commercial sanitizer on hand at

all times. Emery Thompson recommends Purdy Products

"SteraSheen Green Label" sanitizer and cleaner, which was

included with your machine. It is a powder that is dissolved in

water.

On the model CB100, there are only 4 food-contact parts that must

be thoroughly cleaned and sanitized: the freezing tub, the bearing

disc, the splash plate and the dasher/blade assembly. After the last

batch of the day or shift is made, these parts should be either hand-

cleaned with detergent and warm water, or run through a

dishwasher. The sanitizing is done just prior to use, so the parts

should be washed, dried, and stored in a clean place until ready to

use the machine.

When assembling the 4 parts mentioned above for use, have a

gallon bucket of sanitizing solution ready, as well as a roll of paper

towels, and a clean work surface. Put the bearing disc into the

freezing tub, then the dasher/blade assembly into the tub.

Submerge the entire assembly into the bucket of sanitizer for at

least one minute. Then, pull the tub out, and pour the sanitizer out

of it. Consult with your local health Inspector for any additional

sanitizing methods he/she may require.

IMPORTANT: the next step is crucial! Just before you put the tub

into the machine YOU MUST DRY THE OUTSIDE of the tub!

Failure to do this important step will cause the freezing tub to lock

~ 13 ~

v. 1.03

into the freezing cylinder! Once the outside of the tub is

completely dry, it can be inserted into the freezing cylinder, and

locked onto the 4 drive pins. At this point, you are ready to add

mix/ingredients, and begin.

Keep in mind: the cleaner you work, the easier cleanup will be.

Rather than a sponge or rag, use disposable paper towels. Damp or

wet sponges and rags harbor bacteria! Wipe up spills and throw

away wrappers, paper towels, or anything that may accumulate.

After production is complete, any spilled product on the outer

casing or top of the machine should be wiped up thoroughly, and

then wiped down with some of the sanitizer that was made earlier.

Look into the freezing cylinder. If there is anything in it, including

water/condensate, it too should be wiped out thoroughly.

You simply cannot be too thorough when it comes to food and

cleanliness!

~ 14 ~

v. 1.03

Section 5: CARE and MAINTENANCE

Your model CB100 requires very little in the way of care and

maintenance. There are some functions of the machine that bear

paying attention to.

1) Airflow - your machine uses airflow from its surroundings to

extract heat from each batch of product you make. So it goes to

reason that good airflow is imperative to the efficient operation of

the unit. After about 100 batches (depending on the environment

the machine is used in) take a good look at the left side of the

machine, where air is drawn in. Look past the square perforations

in the stainless steel cabinet, and check the surface of the

condensing coil assembly. It should be clean and free of dust, lint,

etc. that may in time accumulate on its surface. A strong vacuum

cleaner with a soft brush can be used to loosen and pull out any

accumulations.

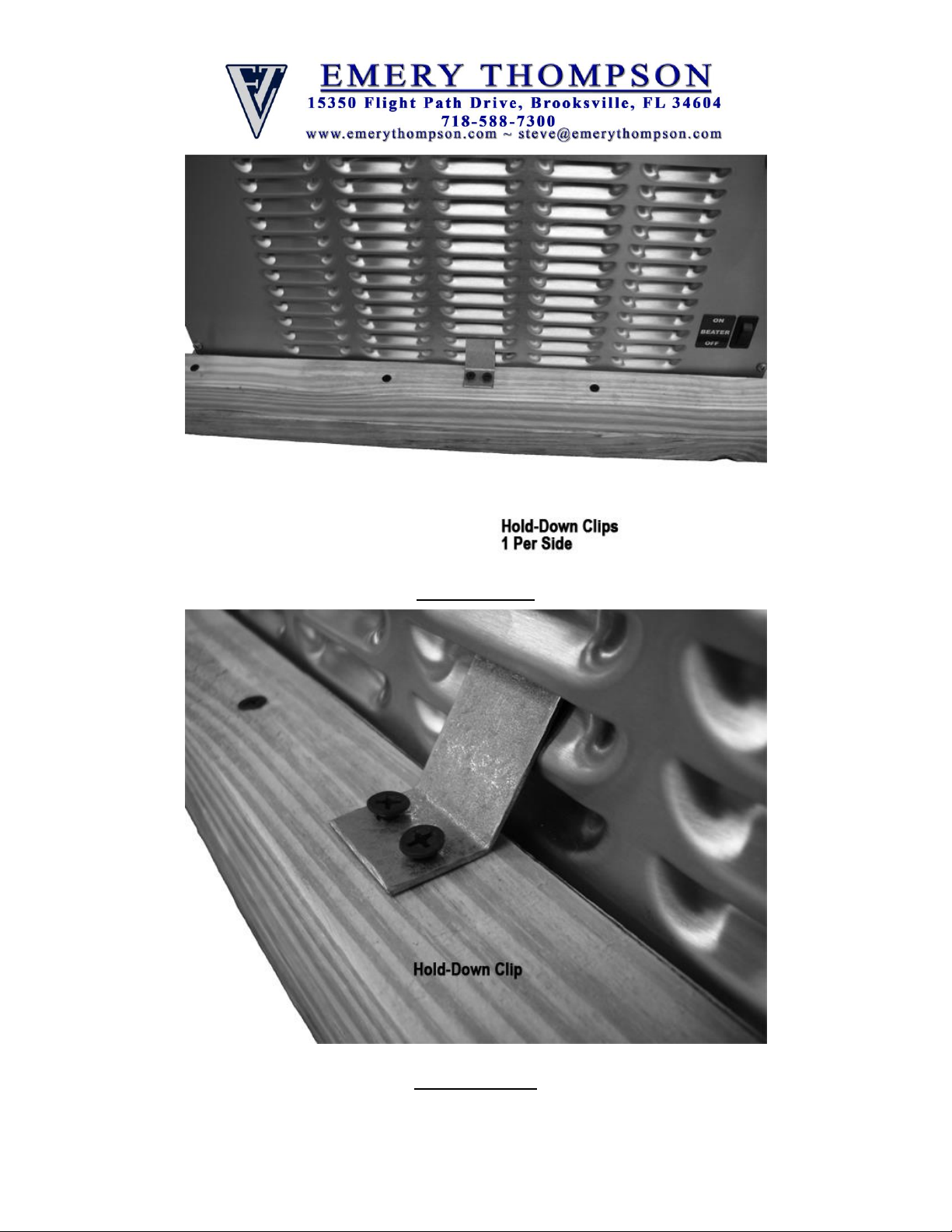

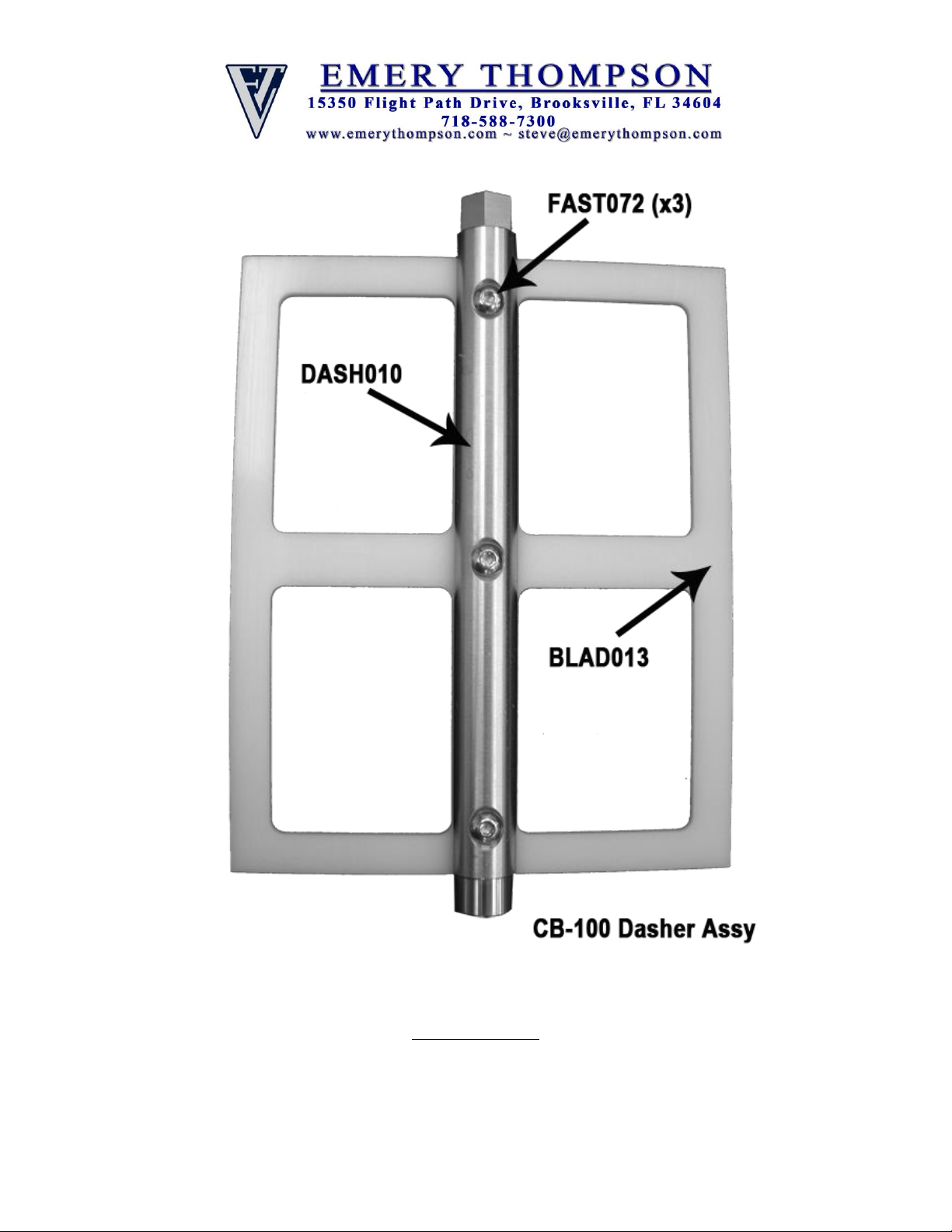

2) Blade condition - the scraping blade is made of food-grade high

density polyethylene. Eventually, the surface that touches the

freezing tub will wear down. When you notice a change in the

amount of product being left on the inside surfaces of the freezing

tub, it will be time to change the blade. You should be able to see

the gray/silver of the tub after each swipe around of the blade.

There will always be a film of product on the surface of the tub,

but if you can longer see through it to notice the color of the

stainless steel beneath it, then change the blade. A hex key is

included with the machine that fits the 3 screws that secure the new

blade into the dasher shaft. Simply remove the screws, and push

the old blade out sideways. When sliding the new blade in place,

note that there is a top and bottom. The bottom of the blade has a

very slight taper near where it rides along the bearing disc (see

photo 5-1) Be sure to insert it the correct way into the dasher

shaft. Line up the holes in the blade with the holes in the dasher

~ 15 ~

v. 1.03

shaft, and replace and tighten the 3 securing screws. Start the

screws threading into each hole before tightening any of them all

the way. Do not over tighten.

3) Bearing discs - the small centering hole in the bearing disc may

show signs of wear (oblonging) after many hundreds of batches.

To check this, insert the round end of the dasher shaft into the

bearing disc's hole. There should be some clearance, but equal all

around the hole. If questionable, replace the disc.

4) Power cord - be sure to keep the power cord routed in a safe

path to your outlet. If for some reason the cord becomes damaged

or frayed, or the plug does, have an electrician replace the entire

cord. You can purchase this part from Emery Thompson.

5) General cleanliness - aside from the normal day-to-day cleanup

of the machine, and to keep the machine looking it's best, a

stainless steel cleaner/polish can be used on all stainless surfaces to

bring back its luster. Do not use abrasive cleaners, or cleaners with

high bleach content.

Photo 5-1

~ 16 ~

v. 1.03

Section 6: PARTS DIAGRAMS

Figure 6-1

Figure 6-2

~ 17 ~

v. 1.03

Figure 6-3

~ 18 ~

v. 1.03

Additional Freezing Tub Kit

Figure 6-4

~ 19 ~

v. 1.03

Figure 6-5

Table of contents

Other Emery Thompson Freezer manuals