Emery Thompson CB-200 User manual

0

v. 3.07

EMERY THOMPSON

BATCH FREEZER

INSTALLATION

OPERATING, MAINTENANCE

AND CLEANING MANUAL

MODEL CB-200 COUNTERTOP

~ 1 ~

v. 1.23

Congratulations and thank you for purchasing your new model

CB200 batch freezer. With the CB200, you will be able to produce

some of the finest Super Premium Hard Ice Cream, Fresh Fruit

Sorbets, Artisan Gelatos, Old World Italian Ice and New England

Style Frozen Lemonade. Your new machine has been built for

speed, versatility, and longevity, as well as safety. It has been

meticulously crafted and tested to give you many years of satisfied

service. Please be sure to go over the entire instruction manual

prior to using your new machine.

STATE LAW REQUIRES THAT THE ELECTRIC POWER TO

THIS MACHINE BE INSTALLED BY A LICENSED

ELECTRICIAN –ONLY

FAILURE TO ADHERE TO THIS WILL VOID YOUR WARRANTY

~ 2 ~

v. 1.23

YOUR FROZEN DESSERTS

(FREEZING UP YOUR MACHINE)

What you did wrong!

When our customers first run their new Emery Thompson CB-200,

what we too often hear is how they froze the machine up solid and

the machine just stopped spinning.

Here is a list of what went wrong:

1. They did not read the instruction manual. Unlike a cell phone

(that does not come with an instruction manual), your

investment comes with a very comprehensive manual. Your

new batch freezer is not “Intuitive.” You must read and

understand the entire instruction manual –and especially

read the warnings! It’s a lot of money to spend and not

operate it properly.

2. If the scraper blades (the two long pieces of Delrin plastic)

are not installed properly, the machine will start making

noise in a few minutes and either freeze up or take three

times as long to make a batch. The curved tip of the blade

goes to the back of the machine and the other tip of the blade

which is cut off on a 90 degree angle goes to the front of the

machine. If this is wrong the machine will not operate

properly. You need to be aware of this Each and Every time

you assemble the machine. We have added a dimple on the

front of each blade so that you can more easily see which

way the front of the blade faces.

~ 3 ~

v. 1.23

3. You cannot do “test” half batches. You must have two quarts

of product in the freezing cylinder of the CB-200 in order to

make a batch. Less than this will freeze up the machine! Do

not turn on the refrigeration switch with only water in the

machine. Water is not a dairy blend nor is it a water ice. No

sugar or no dairy and your machine will freeze up solid.

4. YOUR BLEND: You’re going to have to trust me on this one

–I’ve been building and running Emery Thompson Batch

Freezers since I was sixteen years old. Your “blend” which

came from a magazine, cookbook or you made it up will

work fine in your home ice cream freezer or a cheap Italian

or Chinese machine. Why? Because it takes a very long time

to freeze –40 minutes or more as compared to ¼ of that time

in your new Emery Thompson. And it has little or no

freezing capabilities beyond your home refrigerator. Your

Emery Thompson has tremendous freezing ability. But

without the proper level of solids, your recipe is going to

freeze up in a modern piece of dairy equipment. Solids come

in the form of sugars, cream and some nuts like cashews.

Splenda, Stevia and Xylitol have no solids.. Milk does not

have enough solids. Coconut water has virtually no solids.

Cream of Coconut does. While you can use all these products

in your formula, they alone will not freeze. You are welcome

to call us and we can discuss your formula with you… but

physics and the laws of freezing cannot be changed. Water

and flavor do not alone make a sorbet and milk alone does

not make an ice cream.

~ 4 ~

v. 1.23

CAUTION

On 115 volt models of

the CB200:

Be sure that the batch freezer

is the ONLY appliance

running on the circuit you

use, otherwise, overload

WILL occur!

No toasters No blenders

No microwaves

No coffeepots No irons

~ 5 ~

v. 1.23

SUPPLEMENTAL

BULLETIN

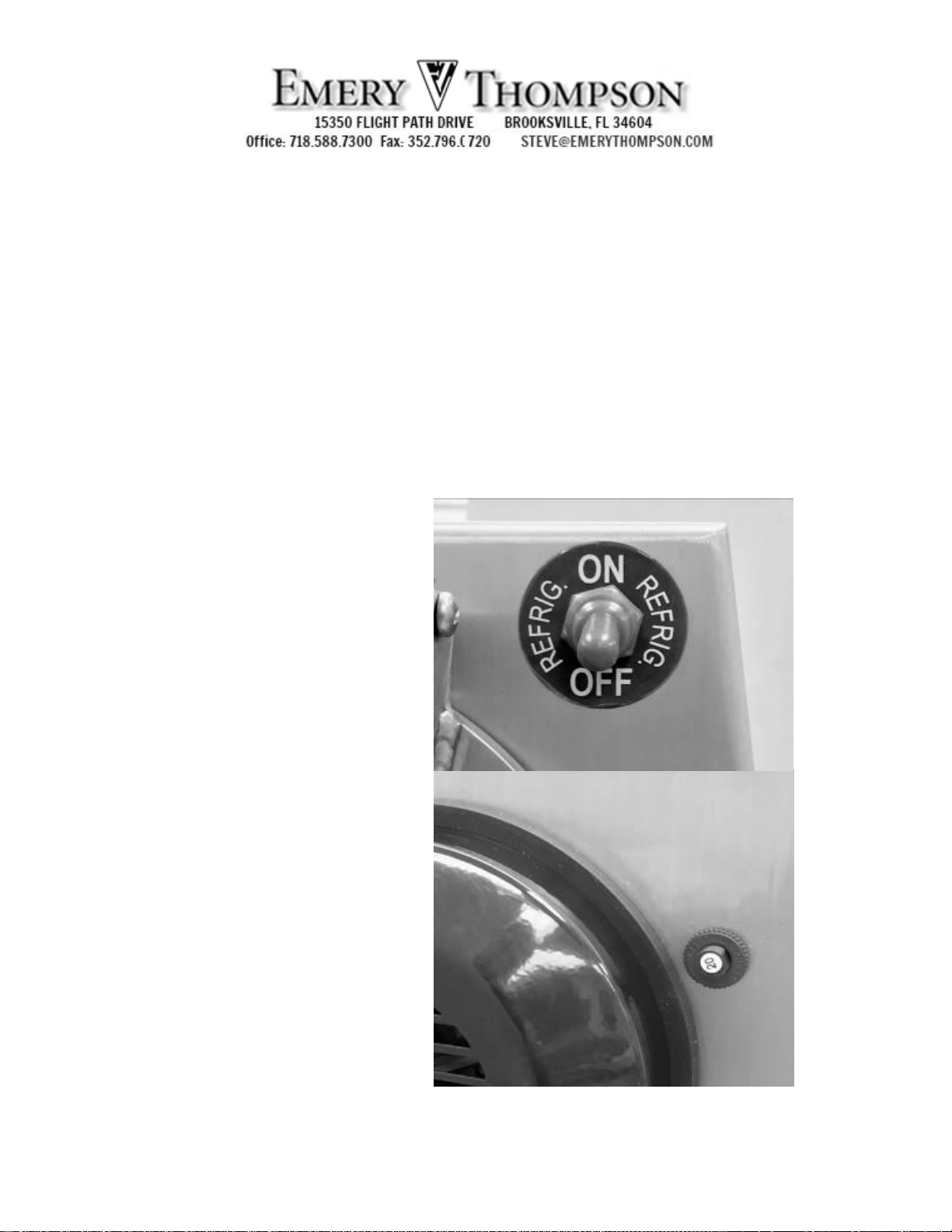

PLEASE NOTE THAT DEPENDING ON THE

MANUFACTURING DATE OF YOUR MACHINE, THERE

ARE TWO FEATURES THAT MAY HAVE CHANGED:

1) The refrigeration

control is a toggle switch.

2) We have incorporated

an external, resettable

circuit breaker, located at

the top rear panel of the

machine.

~ 6 ~

v. 1.23

TABLE OF CONTENTS

IMPORTANT WARNING INFORMATION

page 1

DON'T DO THIS! (AND WHY)

page 2

ELECTRICAL LOAD WARNING

page 4

SUPPLEMENTAL BULLETIN

Page 5

Section 1:

OVERVIEW

page 7

Section 1:

UNPACKAGING

page 8

Section 2:

WORK AREA REQUIREMENTS

page 9

Section 3:

SAFETY

page 10

Section 4:

OPERATION

page 12

Section 5:

CLEANING, ASSEMBLY, AND SANITIZING

page 14

Section 6:

CARE and MAINTENANCE

page 16

Section 7:

RECIPES

page 18

Section 8:

PARTS DIAGRAMS

page 20

DIAGRAM 3-A

DIAGRAM 3-B

DIAGRAM 5-A

page 20

page 21

page 22

Section 9:

WARRANTY

page 23

~ 7 ~

v. 1.23

Section 1: OVERVIEW

~ 8 ~

v. 1.23

Section 1: UNPACKAGING

Your CB200 will arrive to you on a small pallet with a

heavyweight cardboard box covering it. The machine and pallet

combined weigh approx. 175 pounds; the machine by itself weighs

118 pounds. Please use a helper to unpackage and move the

machine safely.

Upon delivery, immediately inspect the pallet and packaging for

any sign of damage. If possible, have the delivery driver wait if

you suspect damage and follow below:

Begin by cutting all the way around the cardboard box at 2" above

the pallet surface. Use a short box-cutter, and go around the box

several times to cut all the way through the cardboard. Once cut

through, lift the box straight up and off the pallet/machine.

Carefully remove the shrink-wrap off of the exterior of the

machine.

The machine is bolted through its' feet from the underside of the

pallet. Use a 1/2" wrench to remove all four bolts, and the

machine will be free of the pallet. With the assistance of a helper,

lift the machine and move to your work area.

The pallet and box can be saved so that if the machine is ever

moved, it can be done so safely.

~ 9 ~

v. 1.23

Section 2: WORK AREA REQUIREMENTS

As stated in section 1, the machine weighs 118 pounds, and has

some momentum when running, so it is necessary to position it on

a solid work surface that can easily support this weight, and resist

wobbling. For reference, the machine height should be set up so

that the top of the spout is at chest height of the operator.

ELECTRICAL CONNECTION: The model CB200 machine

comes with a 72 inch long flexible power cord that has an L14 - 20

locking male plug installed on it. It MUST ONLY be connected to

a matching receptacle which has been wired to a dedicated and

fused 20-amp circuit. Your machine has a wiring tag on its cord,

as well as electrical specifications on its serial number tag on the

rear of the machine. Your electrician can also call us for technical

information if necessary during business hours.

Clearance around the machine is critical for airflow and

performance. Also, please be sure to remove all plastic protective

film from the sheet metal surfaces. The distance away from walls,

other equipment, etc. should be 8" in the rear, 18" on each side,

18" on top, and its' front open to the room. It also should remain

on the four feet it was shipped on, not only for airflow but also for

cleaning beneath it.

The surrounding area should be kept free of clutter, the floors dry,

and with at least some air circulation.

~ 10 ~

v. 1.23

Section 3: SAFETY

First, be sure to read and understand this machine manual, and

familiarize yourself and other operators with the machine features,

its operation, cleaning, and maintenance.

Your machine is equipped with several important safeguards that

should never be removed or altered. DO NOT remove the

following items:

Inlet spout combination lid and gate –restricts fingers

from coming in contact with moving blades/dasher, and

helps control splashing.

Door discharge guard –restricts fingers and utensils

from coming in contact with moving blades/dasher.

Also, in combination with the discharge chute, funnels

product into smaller containers neatly.

The sides, front, and rear section of the machine have ventilation

openings in them. All but the rear panel are louvered to deflect

food and splashing liquids away from the inside. Never spray

water directly at/into these openings.

If your machine is set up with a plug on the end of its cord, make

absolutely sure your hands are dry when plugging it in, or

unplugging it.

When operating the machine, avoid distractions such as

conversations, television, small children, etc.

The door and the dasher are heavy parts, and are slippery when

wet. Use extreme care handling them. Keep the floor and work

area neat and dry to avoid slippage. Do not use the top of the

machine as a storage spot.

~ 11 ~

v. 1.23

Section 3: SAFETY (Cont’d)

In addition to the above:

DO NOT operate your machine unless it is connected to a

circuit wired, grounded, and properly fused by a licensed

electrician.

DO NOT put fingers, hands or any utensils in either the inlet

spout or door outlet.

DO NOT operate the machine unless it is properly

assembled and all guards are in place.

DO NOT force any of the (washable) parts together or

into/on the machine. All parts should fit together easily.

DO NOT operate the machine with the freezing cylinder

empty.

DO NOT turn on the machine’s refrigeration switch with

only water in the freezing cylinder.

DO NOT let your product over-freeze during production.

This is the most common mistake a new operator makes.

~ 12 ~

v. 1.23

Section 4: OPERATION

Your new CB200 batch freezer is very easy to operate, having only

two controls on it. The dasher/blade assembly (mixer or beater) is

controlled by an illuminated rocker switch at the upper left-hand

corner of the machine. When the switch is "rocked" upward, it

illuminates signifying that the dasher is spinning. This switch also

functions as a circuit breaker to protect the drive motor. If your

product is being over-frozen and gets too stiff, the switch will

automatically trip like a circuit breaker, and automatically switch

itself off.

The second control is for the refrigeration, and is an ON/OFF

toggle switch. Turning the switch on will start the refrigeration

process. Products freeze at different times, so it is best to log

actual freezing times for repeatability. Eight to ten minutes is a

good starting point. NEVER LEAVE THE MACHINE

UNATTENDED WHILE IN OPERATION. As mentioned in the

above paragraph, if the machine is allowed to run too long or left

unattended it will eventually freeze your product solid and turn

itself off. The machine will then be unusable until either your

product thaws, or the product is manually removed from the

cylinder.

Also remember that different products will take on different

amounts of air (overrun), so depending on the product you are

making, you will be filling your machine with less than the 3

quarts/liters maximum output capacity.

~ 13 ~

v. 1.23

Section 4: OPERATION (Cont’d)

The normal sequence of operation, assuming the machine is

cleaned and sanitized, would be as follows:

- flip the inlet spout guard open.

- pour in the mix/ingredients.

- close the inlet spout guard

- turn on the beater switch (upper left).

- turn the toggle switch to the ON position.

- check the stiffness of the mix by slightly and quickly opening the

gate to allow a small amount of product to come out.

- when the desired stiffness is achieved, MAKE SURE you

immediately turn off the refrigeration.

- open the discharge gate and allow the product to come out as fast

as it will flow, and fill your container(s).

See the next section for cleaning and sanitizing.

~ 14 ~

v. 1.23

Section 5: CLEANING , ASSEMBLY and SANITIZING

Note: Your local or state health inspector will always have

jurisdiction over the methods and chemicals that he/she prefers for

use on this machine. Our instructions are based on industry

standards, and should be discussed with your inspector.

The first step toward insuring a clean and sanitary machine is to

identify the various parts that will or could come in direct or

indirect contact with food. (see diagram 5-A, p.19) These parts

have to be cleaned and sanitized at the end of each use or period of

use that lasts one hour or more without refrigeration/freezing. In

other words, if you leave mix residue in the machine for an hour or

more before your next batch, the machine should be disassembled,

cleaned, and sanitized. All of the parts to be cleaned are

dishwasher top rack safe, or can be manually cleaned with warm

water and dish washing detergent, along with an abrasive hand

pad. The inside surface of the freezing cylinder will have to be

manually washed with detergent and thoroughly rinsed.

Once the parts have been hand or machine washed, then dried,

there are three areas that require a coating of food-grade grease on

them prior to assembly, the rear section of the dasher shaft, the

door outer surface where the gate slides against it (see diagram 5-

A, p.19), and the inside (bore) of the white rear bushing in the

cylinder. On the dasher shaft, coat the surface of the last 2 1/2

inches of the REAR of the shaft with a film of food grease, then

install two blade springs, the blade, and then while holding that

blade on do the same for the other blade. Then smear grease into

the bore of the white plastic bushing that goes through the freezing

cylinder. Now the dasher can be inserted into the freezing cylinder.

~ 15 ~

v. 1.23

Section 5: CLEANING, ASSEMBLY and SANITIZING (Cont’d)

Put the drive end of the dasher into the bushing in the rear of the

cylinder, and push it all the way into the bushing. Rotate the

dasher assembly so it engages onto the drive motor, and the

assembly moves backward until the blades touch the rear of the

cylinder. Wipe off any excess food grease that has smeared off at

the bushing.

Smear a thin film of food grease on the door surface where the

round discharge gate slides against it during opening and closing of

the handle. (see diagram 5-A, p.19) The round gate has an O-ring

under it, and if the O-ring gets dry, it has a tendency to roll out of

its groove. Check and be sure the small round bushing is in the

pocket on the backside center of the door, and put the door in place

on the two mounting studs. The nose of the dasher shaft should go

into the round bushing in the door. Now install and evenly tighten

each of the two knurled knobs. The unit is now ready for

sanitizing.

Sanitization is the important step of using a chemical to kill any

remaining bacteria just prior to introducing food products to the

machine. Emery Thompson uses and recommends the sanitizer

"Stera-Sheen Green Label" made by Purdy Products Company.

Mix a 2-quart batch of sanitizer (following the manufacturer's

instructions) and pour the mixture into the CB200. Turn on the

beater motor, and agitate this mixture for a full minute (NOTE: DO

NOT run the refrigeration at this time!) After a minute, discharge

the sanitizing fluid, and from this point forward, do not put fingers

or dirty utensils on any surface that could introduce bacteria into

your product. The sanitizer (once diluted) is food-safe, and does

not need to be rinsed from the machine with water.

~ 16 ~

v. 1.23

You are now ready to add your product to the machine! BE SURE

that when making any product that will take on air, enough room is

left in the freezing cylinder to accommodate it. (i.e.- ice cream mix

add approximately 2 quarts, and w/ 50% overrun you will yield 3

finished quarts)

Section 6: CARE and MAINTENANCE

One of the best features of an Emery Thompson batch freezer is

the small amount of maintenance and the ease of care required to

keep it running and looking new. The materials we use for our

parts are the best available for their intended purpose, and are

designed for maximum longevity.

The outer casing of your machine is all heavy-gauge stainless steel,

and will only require a daily wipe down w/ a mild detergent and

warm water. Using a stainless steel cleaner/polish will also help

keep it looking new.

There are three areas mentioned previously that require food

grease to be applied daily: the area of the dasher shaft that goes

through the rear bushing in the cylinder, the door face where the

gate slides against it, and the bore of the rear bushing. (see diagram

5-A, p.19) Keeping these three areas clean and lubricated will

directly affect the life of the parts involved, and must be addressed

DAILY.

Your machine should be operated in the cleanest environment

possible, but the potential exists for an eventual accumulation of

dust/lint/debris on the surface of the condensing fins. This is the

area just behind the expanded metal grate on the rear surface of the

~ 17 ~

v. 1.23

Section 6: CARE and MAINTENANCE (Cont’d)

machine. It can be cleaned using a strong (shop-type) vacuum

cleaner with a soft brush attached.

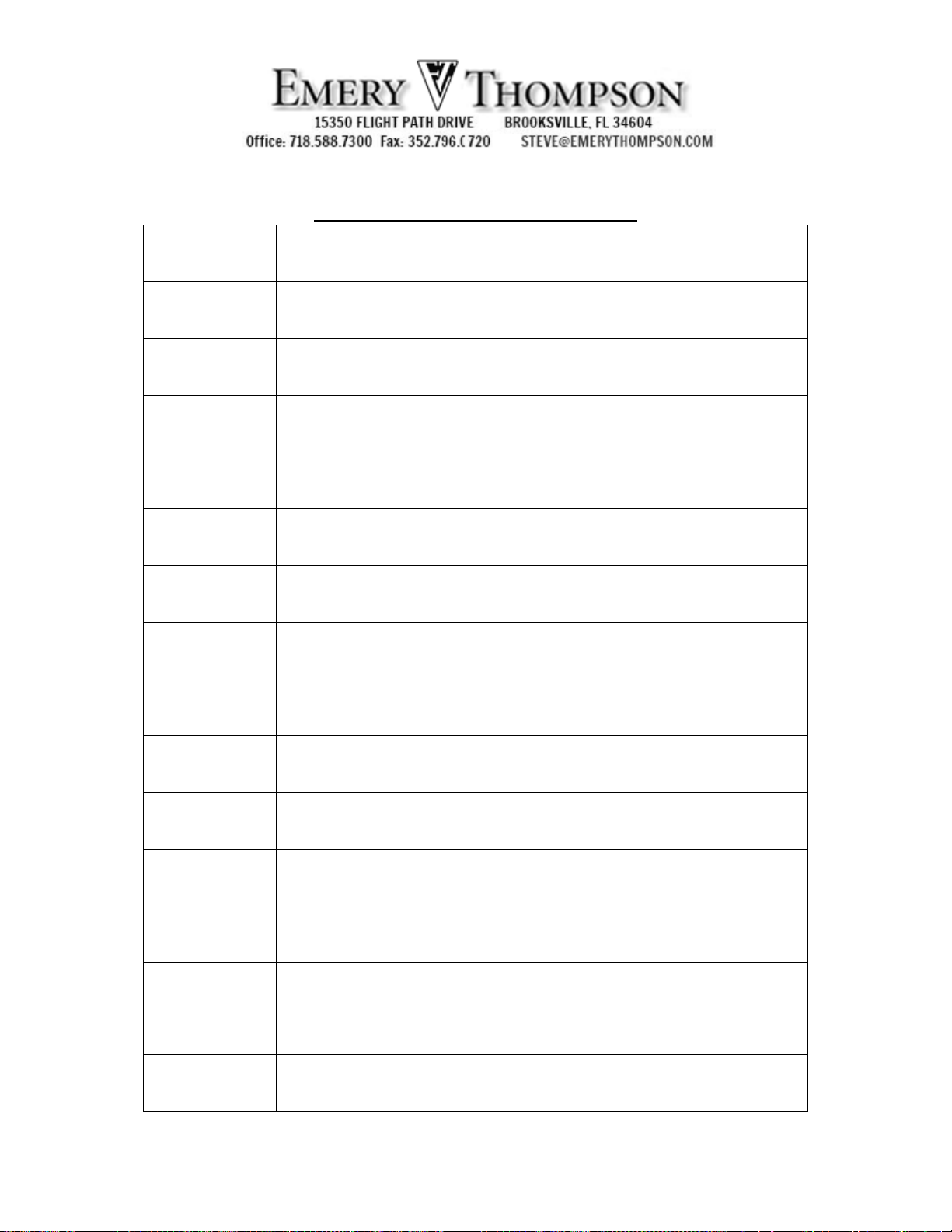

The following parts are wearable and should be inspected at least

weekly:

DIAGRAM 5-A

APPROX. LIFE

Part # SEAL011 - o-ring, square, inside rear bushing 1,000 hrs./ 1 year

Part # SPRG005 - blade Springs ................................2,000 hrs./2 years

Part # BRNG002 - bearing, dasher front.................... 2,000 hrs./2 years

Part # BLAD010 - blade, scraping...........................5,000 hrs./4.5 years

Part # SEAL013 - o-ring, gate ...................................1,000 hrs./ 1 year

Part # FAST024 - washer, Teflon...............................1,000 hrs./ 1 year

Part # SEAL012 - o-ring, door seal ..........................4,000 hrs./ 4 years

Part # SPRG006 - spring, gate pressure ...................4,000 hrs./ 4 years

If your batch freezer has been stored in an unheated area and is

brought into a warm area for use, allow it to sit for at least 12 hours

in the warmer temperature; condensation could build up on cold

surfaces.

Never transport, store, or use your machine in any position other

than upright on its feet; Oil in the refrigeration system could

travels into areas of the machine's piping where it could remain

trapped.

Your machine has been tested and is rated for use in ambient air

temperatures as high as 104 degrees Fahrenheit, and as low as 50

degrees Fahrenheit. Operation in temperatures at the high end of

capacity may slightly increase freezing time and vice versa at the

cold end.

~ 18 ~

v. 1.23

Section 7: RECIPES

The following recipes are very basic, and require few ingredients,

but are a good starting point to familiarize yourself with freezing

times and consistencies, as well as begin to form a production

routine. NEVER put undissolved sugar into your machine for any

recipe. Dissolve it first, then add to machine.

Lemon Ice

-2 quarts of cool tap water

-1pounds of sugar

-Zest grated from 2 large lemons

-10 ounces of fresh-squeezed lemon juice

Mix the sugar with the water in a clean container until the sugar is

dissolved. Slowly pour this into your CB200 machine. Add the

lemon juice and lemon zest; start the dasher and set at 234 RPM.

Then turn on the refrigeration and freeze for 8-10 minutes,

depending on desired consistency. Store and serve at 16 degrees F.

Coffee Ice Cream

-2 quarts 14% ice cream mix

-1/2 ounce of vanilla extract

-1 ounces Taster’s Choice instant coffee crystals

-Hershey’s chocolate syrup to taste

Pour first three ingredients into machine and start dasher. Turn on

refrigeration, and freeze for 10-12 minutes. Add chocolate syrup

approximately one tablespoon at a time to taste (takes away

bitterness of coffee).

~ 19 ~

v. 1.23

Section 7: RECIPES (Cont’d)

Bordeaux Wine Sorbet

-1 pound of sugar

-24 ounces of tap water

-1 bottle (750 ml) red Bordeaux wine

-12 ounces red raspberries

-(optional) 4 grams of stabilizer

Mix the sugar with the water in a clean container until the sugar is

dissolved. Slowly pour this and the remaining ingredients into the

machine; start dasher, then the refrigeration. Freeze for

approximately 12 minutes

Fresh Mango Sorbet

-1 pound of sugar

-26 ounces of tap water

-3 pounds of fresh mango

-juice of one lemon

Mix the sugar with the water in a clean container until the sugar is

dissolved. Slowly pour this and the remaining ingredients into the

machine; start dasher, then the refrigeration. Freeze for

approximately 12 minutes.

Table of contents

Other Emery Thompson Freezer manuals

Popular Freezer manuals by other brands

Heinner

Heinner HCF-H306F+ quick start guide

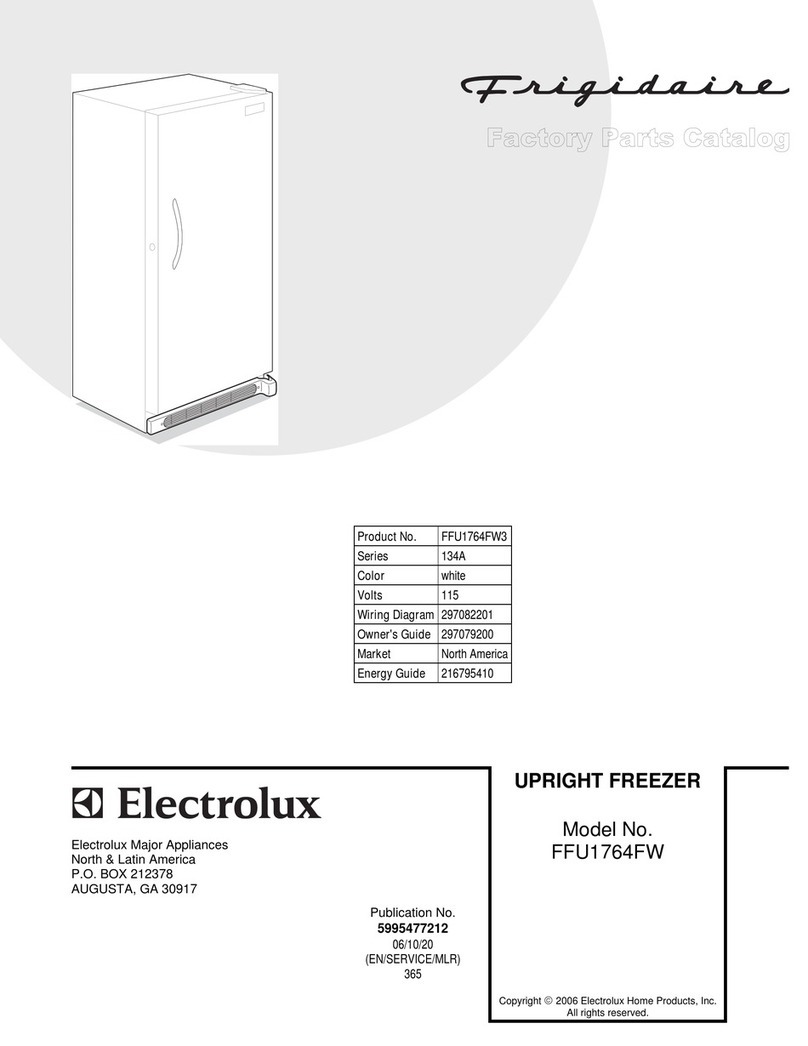

Frigidaire

Frigidaire FFU17FK1CW Factory parts catalog

Baltimore Aircoil Company

Baltimore Aircoil Company S3000E Operating and maintenance instructions

ekwb

ekwb EK-MLC PHOENIX Series user guide

Kernau

Kernau KFUF 08252.1 W Instruction booklet

Frigidaire

Frigidaire FFU1764F Factory parts catalog