EMIS META 215 User manual

www.emis-meter.com

EMIS-META

215.00.00.OM

version

11.11.2021

v.1.3.05

METAL ROTAMETER

EMIS-META 215

Operation manual

EMIS

Russia, Chelyabinsk

EMIS-META 215

OPERATION MANUAL

https://emis-meter.com/

2

General information

This operation manual contains general technical parameters, directions for usage, transportation and

storage, and other information for accurate operation of EMIS-META 215 rotameters.

EMIS® and EMIS logo are registered trade marks of EMIS CJSC.

HART® is the registered trade mark of HART© FieldCom Group.

EMIS CJSC has the right to update the product and documents without prior notice. For any

information about present Operation Manual or other EMIS equipment please contact your local dealer or

EMIS head office.

Any use of the present manual, partial or full, is prohibited without copyright holder permission.

Attention!

Present Manual EMIS-META 215 can be applied only for EMIS-META 215 rotameters. This document is

not applicable to other equipment of EMIS or other companies.

Attention!

Carefully study this Manual before starting operation. Please make sure that you have carefully read and

learned the present manual before installation, operation or maintenance of the equipment. The above is strictly

required to provide safety operation and equipment efficiency.

Contact your local dealer or our technical service:

tel/fax: +7 (351) 729-99-12, 729-99-13, 729-99-16

e-mail: support@emis-kip.ru

EMIS-META 215

OPERATION MANUAL

https://emis-meter.com/

3

CONTENTS

General information .................................................................................................................................2

1. Description and operation.................................................................................................................4

1.1 Application ................................................................................................................................4

1.2 Structure and Operation Principle.............................................................................................4

1.3 Specification..............................................................................................................................6

1.4 Explosion protection .............................................................................................................. 13

1.5 Marking and sealing............................................................................................................... 14

1.6 Supply scope ......................................................................................................................... 17

1.7 Order sheet............................................................................................................................ 19

2. Intended use.................................................................................................................................. 26

2.1 Selection recommendations .................................................................................................. 26

2.2 Safety requirements............................................................................................................... 30

2.3 Mounting on the pipeline........................................................................................................ 30

2.4 Electrical connection.............................................................................................................. 37

2.5 Operation and maintenance .................................................................................................. 39

2.6 Calibration.............................................................................................................................. 41

3. Transportation and Storage........................................................................................................... 43

3.1 Transportation............................................................................................................................. 43

3.2 Storage........................................................................................................................................ 43

4. Recycling ................................................................................Ошибка! Закладка не определена.

5. List of possible failures .................................................................................................................. 43

5.1 List of possible failures (including critical)................................................................................... 43

5.2 Personell mistakes leading to failure, emergency or accidents.................................................. 43

6. Personell actions in case of accident, critical failure or breakdown .............................................. 44

7. Limit state criteria........................................................................................................................... 44

Appendix A............................................................................................................................................ 45

Appendix B............................................................................................................................................ 57

Appendix C ........................................................................................................................................... 58

Appendix D ........................................................................................................................................... 59

Appendix E...................................................................................Ошибка! Закладка не определена.

EMIS-META 215

OPERATION MANUAL

https://emis-meter.com/

4

1. DESCRIPTION AND OPERATION

1.1 Application

EMIS-META 215 rotameters (hereinafter referred to as rotameters) are designed for measuring of

volume of smoothly changing flow of liquids and gases, including chemically corrosive mediums at fuel and

energy plants and other enterprises. Rotameters equipped with LED display can also calculate and show total

accumulated volume, % of the maximum flow, actual current value at current output.

Rotameters are installed in automatic control, adjustment and operation systems and used at variable

industries, stationary plants and pump stations.

This equipment has the following features:

- broad range of medium temperature;

- remote control of readings;

- application for chemically corrosive mediums.

Rotameters can be used for both safe and explosive environments.

Ex-proof rotameters EMIS-META 215-Ex have explosion protection called "intrinsically safe circuit” of

“i” level under GOST 31610.11-2014 (IEC 60079-11:2014) and ex-proof marking 1Ex ib IIB/IIC T4/T2/T1 Gb X

for explosive gas mediums and Ex ib IIIB/IIIC T100°C/T250°C/T420°C Db X for explosive dust mediums.

Ex-proof rotameters EMIS-META 215-Vn have explosion protection called "ex-proof enclosure” of “d”

level under GOST IEC 60079-1-2013 and ex-proof marking 1Ex d IIB/IIC T4/T2/T1 Gb X for explosive gas

mediums and Ex tb IIIB/IIIC T100°C/T250°C/T420°C Db X for explosive dust mediums.

Rotameters without outputs and LED display belongs to non-electrical equipment and have explosion

protection called "design safety” of “c” level under GOST 31441.5-2011 and ex-proof marking II Gb c

T4/T2/T1 X for explosive gas mediums and III Db c T100°C/T250°C/T420°C X for explosive dust mediums.

Rotameter of K version (oxygen application) has separate sign "Oxygen. Dangerous!". Indicator cover

is painted blue.

1.2 Structure and Operation Principle

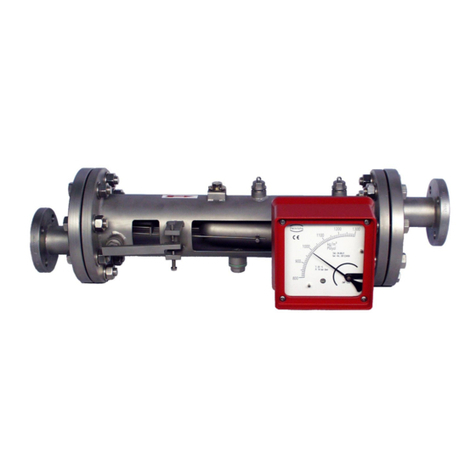

Rotameters of general application with vertical installation on the pipeline (see. fig.1.1).

EMIS-META 215

OPERATION MANUAL

https://emis-meter.com/

5

Fig.1.1 - Measuring assembly of standard version rotameter

Rotameter consists of two main assemblies - measuring and indication parts. Indication assembly can

be equipped with current output signal or digital HART for remote control of readings.

Liquid or gas inside the flow tube 7 pushes the float 3 with some force (see fig.1.2 - 1.3). Pushed by

this force the float starts to move along the flow tube. While the area between the float and the tapered tube 8

through which the medium flows increases, the drag force decreases.

At a certain position the drag force and gravity (for version G- the spring force) reaches mechanical

equilibrium and the float stops. The distance that the float passed depends on the flow speed and is submitted

to the display through the electromagnetic device. Indicator hand shows current flow speed, the LED display

shows current flow speed and total flow volume.

Fig.1.2 - Measuring assembly of standard version rotameter

EMIS-META 215

OPERATION MANUAL

https://emis-meter.com/

6

Fig.1.3 - Measuring assembly of standard version rotameter

Table 1.1 - Measuring assembly

NO in fig.

Description

1

Float axis

2

Lower stop

3

Float

4

Damper (for gas rotameters)

5

Upper stop

6

Flanges

7

Flow tube

8

Tapered tube

9

Spring

1.3 Specification

1.3.1 Brief description of technical parameters

Brief description of technical parameters is shown in Table 1.2.

Table 1.2 - Technical parameters of rotameter

Name

Description

Flow tube diameter

15; 25; 40; 50; 80; 100; 150

Tolerance limits

- for accuracy class 1.0.

- for accuracy class 1.5.

- for accuracy class 2.5.

- for accuracy class 4.0.

±1 %

±1.5 %

±2.5 %

EMIS-META 215

OPERATION MANUAL

https://emis-meter.com/

7

Name

Description

±4 %

Absolute pressure of medium, MPa;

0.101-32.0

0.15 - 32.01)

Medium temperature, °С

- standard configuration 100

-high-temperature configuration 250

-high-temperature configuration 420

From -40 to +100ºС

From -80 to +250ºС

From -40 to +420ºС

Max density of

medium

for Dn 15mm

5 MPa-s

for other versions

250 MPa-s

Output signals and indication

- indicator

- current 4-20 mA,

- digital HART™,

- up to 2 limit switches

Input voltage

From 14V to 30V DC

Explosion protection:

EMIS-META 215-Ex

EMIS-META 215-Vn

EMIS-META 215-Gbc2)

1Ex ib IIC T4/T2/T1 Gb X;

Ex ib IIIC T100°C/T250°C/T420°C Db X.

1Ex d IIC T4/T2/T1 Gb X;

Ex tb IIIC T100°C/T250°C/T420°C Db X.

II Gb c T4/T2/T1 X;

III Db c T100°C/T250°C/T420°C X.

Atmospheric pressure

84 to 106.7 kPa

Ambient temperature:

From -60 - +703)

Relative humidity of environment

not more than 98% (under 35º С)

Climate version (under GOST 15150-69)

NF climate, device category 1, but for operation

temperature from -60 up to +70°С under 90±3% humidity,

non-condensing

Category of storage and transportation (under

GOST 15150-69)

Category 4 ( at -60 up to +70°С);

Category 1 if without package

Dust and water protection

IP66, IP67

Magnetic field intensity

less than 250 A/m

Vibration

group V1 under GOST R 52931

group V1 under GOST R 52931

Flow range

water

2,5 to 100000 l/h

EMIS-META 215

OPERATION MANUAL

https://emis-meter.com/

8

Name

Description

gas

0,07 to 3000 cbm/h

Calibration interval

5 years

Average time between failure ATBF

over 100 000 hours

Service life

over 10 years

Dimensions and weight

see Appendix A

Content of precious metals

do not contain

1) - for horizontal version of rotameter;

2) - configuration without output signals and display;

3) - as per order sheet (for this range of operating temperature, display indication before -30ºС);

4) - Upon prior agreement with EMIS engineering service.

Attention!

Table data refers to standard version of rotameter. Customized order is available to provide any special

requirements.

1.3.2 Measuring range

Standard flow ranges under normal conditions for liquid are presented in the table 1.3. Water at 20° C,

density of 1000 kg/cbm is taken as standard medium.

Please contact EMIS engineers if any non-standard version or Dn is required for your special purpose.

Table 1.3 - Standard measurement ranges for volume flow of liquid (water) under normal

conditions

Size

Flow range, m3/h

Flow tube material

H, H2**

FT**

015А

0.0025 to 0.025

-

015B

0.004 to 0.04

0.0025 to 0.025

015C

0.0063 to 0.063

0.004 to 0.04

015D

0.01 to 0.1

0.0063 to 0.063

015E

0.016 to 0.16

0.01 to 0.1

015F

0.025 to 0.25

0.016 to 0.16

015G

0.04 to 0.4

0.025 to 0.25

015H

0.063 to 0.63

0.04 to 0.4

EMIS-META 215

OPERATION MANUAL

https://emis-meter.com/

9

025А

0.1 to 1.0

0.063 to 0.63

025B

0.16 to 1.6

0.1 to 1.0

025C

0.25 to 2.5

0.16 to 1.6

015D

0.4 to 4.0

0.25 to 2.5

040А

0.5 to 5.0

0.4 to 4.0

040B

0.6 to 6.0

0.5 to 5.0

050А

0.63 to 6.3

0.6 to 6.0

050B

1.0 to 10

0.63 to 6.3

050C

1.6 to 16

1.0 to 10

080А

2.5 to 25

1.6 to 16

080B

4.0 to 40

2.5 to 25

100

6.3 to 63

4.0 to 40

150

20 to 100

-

Standard flow ranges under normal conditions for gases are presented in the table 1.4. Oxygen of

1.204 kg/nm3 density at 20°C and 0.1013 Mpa is taken as standard.

Please contact EMIS engineers if any non-standard version or Dn is required for your special purpose.

Table 1.4 - Standard measurement ranges for gas (oxygen) under normal conditions

Size

Flow range, m3/h

Flow tube material H, H2, FT

015А

0.07 to 0.7

015B

0.11 to 1.1

015C

0.18 to 1.8

015D

0.28 to 2.8

015E

0.48 to 4.8

015F

0.7 to 7.0

015G

1.0 to 10

015H

1.6 to 16

025А

3.0 to 30

025B

4.5 to 45

025C

7.0 to 70

015D

11 to 110

EMIS-META 215

OPERATION MANUAL

https://emis-meter.com/

10

040А

12 to 120

040B

16 to 160

050А

18 to 180

050B

25 to 250

050В

40 to 400

080А

60 to 600

080B

80 to 800

100

100 to 1000

150

600 to 3000

1.3.3 Accuracy

Accuracy limits are presented below:

± 1,0 % for 1,0 accuracy class;

± 1,5 % for 1,5 accuracy class;

± 2,5 % for 2,5 accuracy class;

± 4.0 % for 4.0 accuracy class.

Accuracy class shall be stated when placing the order (see clause 1.7 of the Order sheet)

1.3.4 Output signals

Rotameters have the following output signals:

indicator;

LED display (optionally)

analog current signal (optionally);

digital HART™ (optionally);

up to 2 limit switches (optionally; if no output signal and LED display are installed).

1.3.4.1 Analog current output signal

Current in the range of 4 to 20 mA has linear dependence with flow volume. Current of 4mA is taken

as "zero" flow. Current of 20mA is taken as upper limit of range.

Parameters of current signal are shown in the Table 1.5.

Table 1.5 - Output current signal parameters

Analog current signal

Range limits, mA

4..20

Load resistance, Ohm

not more than 750

Power supply voltage, V

14 to 30

Nominal output, W

Less than 1

1.3.4.2 Digital signal

EMIS-META 215

OPERATION MANUAL

https://emis-meter.com/

11

Digital signal transmits data by frequency modulation at 4-20 mA output under Bell 202 standard.

HART™ protocol version 5

Rotameter can be connected as point-to-point or multislot.

In point-to-point it is directly connected to master device.

In multislot it is connected to common bus along with other slave devices (up to 15 devices). Only

digital connection is available and current is set as 4 mA.

The following parameters transmitted with digital signal:

rotameter serial number;

total volume

current flow

network address

All HART™ commands are listed in the Appendix F.

1.3.4.3 Indicator

Built-in indicating arrow shows current flow of measuring medium. Additional LED display can be

installed (see fig.1.4). Displays have 2 lines to show current flow and total volume.

Fig. 1.4 - LED Display

1.3.4.4 Limit switch

Rotameters can be equipped with one or two limit switches.

Fig. 1.5 shows front panel of a rotameter with installed limit switches. When the arrow reaches the

upper (1) or lower (2) limit switch activates. Limit switch signals can be used for light/sound alarm or other

purposes.

Loosen the screw to move the limit switch to another position, then tighten it again to fix it.

Table 1.6 - technical parameters of limit switches

Name

Description

Function

Open contact

Commutation voltage, V DC

1... 30

Commutation frequency, Hz, not higher than

500

Commutation current I, mA

0... 100

Idling current I, mA

≤ 15

EMIS-META 215

OPERATION MANUAL

https://emis-meter.com/

12

Fig. 1.5 - Limit switches

Hysteresis of limit switch is rated as ±10% from the specified set-up value.

Attention!

Version with limit switch can be manufactured if no output signal and LED display are installed.

1.3.5 Used materials

Materials used in rotameter construction are listed in table 1.7

Table 1.7 - Materials of rotameter parts and elements

Details and assemble units

Material

Indication unit body and lid

Aluminum alloy

Flanges

stainless steel 304 (12Х18Н10Т) (application Н)

stainless steel 316 (08Х17Н13М2) (application Н2)

Flow tube

stainless steel 304 (12Х18Н10Т) (application Н)

stainless steel 316 (08Х17Н13М2) (application Н2)

PTFE-teflon for pressure up to 6,3 MPa, fluorine plastic F46 for pressure

10MPa (application Ft)

Float

stainless steel 304 (12Х18Н10Т), magnet steel (application Н)

stainless steel 316 (08Х17Н13М2), magnet steel (application Н2)

fluorine plastic F46; magnet steel (application Ft)

Flange seal (for socket and

As per order sheet line (for flange version)

EMIS-META 215

OPERATION MANUAL

https://emis-meter.com/

13

Details and assemble units

Material

clamp connections)

silicone rubber (for socket and clamp versions)

Magnet filter

stainless steel 304 (12Х18Н10Т), magnet steel (standard application Н)

Lining: PTFE-teflon (F4/F46); stainless steel 304; magnet steel (application

Ft)

1.4 Explosion protection

Electrical elements of ex-proof transmitter are covered with ex-proof enclosures, which withstand

internal explosion without transferring the ignition to the external gas air environment. The explosion

resistance and explosion protection of the transmitter enclosure comply with the requirements for electrical

equipment of Group IIС subgroup according to GOST IEC 60079-1-2013. The enclosure is tested for

explosion proofness under GOST IEC 60079-1-2013. Ex-proof connections: axial length of the thread and the

number of full turns in the engagement shall comply with the requirement of GOST IEC 60079-1-2013 for IIС

group electrical equipment; Inspection window is sealed inside the metal rim of the casing cover to provide

integrity;

- EMIS-META 215-Ex configurations shall be operated with power supply unit and recorder with

intrinsically safe circuits under GOST 31610.11-2014 (IEC 60079-11:2011) and intrinsic safety parameters

(circuit level and electrical equipment subgroup) complying with operating conditions in hazardous

environment.

Capacity and inductance of circuits are adjusted according to intrinsic safety requirements for

electrical equipment of Group IIС subgroup under GOST 31610.0-2014 (IEC 60079-0:2011).

Circuit redundancy of “ib” level intrinsic circuits is executed according to GOST 31610.11-2014

(IEC 60079-11:2011).

Electric load of intrinsic circuit elements shall not exceed 2/3 of specified values under normal and

emergency operation.

Clearance, leakage path and electrical endurance of isolation comply with GOST 31610.0-2014

(IEC 60079-0:2011).

Protection from flammable dust ignition is provided using “t” type enclosures under GOST

IEC 60079-31-2013 and explosion protection “c” according to GOST 31441.5-2011 (EN13463-5:2003).

Max temperature of surface heating under operating conditions shall not exceed the values specified

in GOST 31610.0-2014 (IEC 60079-0:2011) for specific temperature classes.

Rotameters are executed under general requirements of GOST 31610.0-2014 (IEC 60079-0:2011) for

electrical equipment located in explosive environment. Mechanical rigidity of transmitter casing complies with

GOST 31610.0-2014 (IEC 60079-0:2011) requirements for electrical equipment of group II with high risk of

mechanical damage. Materials provide friction spark protection under GOST

31610.0-2014 (IEC 60079-0:2011).

Table 1.8 - Input parameters of circuits

Parameter

Parameter value

Max input voltage Ui, B

30

EMIS-META 215

OPERATION MANUAL

https://emis-meter.com/

14

Max input current Ii, mA

160

Max input power Pi, W

1

Max input capacity Ci, pF

0.01

Max input inductance Li, µH

0.01

There is a marking sign for explosion-proof rotameters. The plate is shown in the fig.1.6

1.5 Marking and sealing

1.5.1 Marking

Marking is applied on the plate attached to the rotameter body as shown in the fig.1.6. Marks are

shown in the table 1.9.

Fig.1.6 - Name plate of rotameter

Table 1.9 - Marking on the name plate

NO in fig.

Description

1

Manufacturer trade mark

2

Ingress protection

3

Accuracy class

4

Model

5

Medium type

6

Flow range

7

Max pressure of environment (Pmax)

EMIS-META 215

OPERATION MANUAL

https://emis-meter.com/

15

8

Output signal supply

9

Serial number

10

Equipment mark

11

EAC sign

12

Max temperature of medium (Tmax)

13

Ex-proof sign

14

Ex-proof marking

15

Date of manufacturing

16

Manufacturer information

17

Certification authority and certificate number.

Scale of the rotameter contains the following info (see the fig.1.7-1.9, the table 1.10):

Fig. 1.7 - Scale of rotameter without LED display

EMIS-META 215

OPERATION MANUAL

https://emis-meter.com/

16

Fig. 1.8 - Scale of rotameter with LED display

Table 1.10 - Scale signs

NO in fig.

Description

1

Logo

2

Rotameter model

3

Flow tube diameter

4

Accuracy class

5

Scale units

6

LED display*

7

Measuring medium

8

Medium temperature (for gases)

9

Medium pressure (for gases)

10

Density of measuring medium

*Optionally

Attention!

Please make sure that all information applied on the plates conform with your order sheet.

EMIS-META 215

OPERATION MANUAL

https://emis-meter.com/

17

1.5.2 Sealing

Sealing shall be done to avoid unauthorized access to indicator and parameters change.

Rotameter sealing scheme and marking location are presented in the fig.1.9.

Fig.1.9 - Sealing scheme

1.6 Supply scope

The standard supply scope and additional supply kit are shown in the fig.1.10, 1.11 and tables 1.11,

1.12.

Fig.1.10 - Scope of supply

Table 1.11 - Standard supply scope

NO in fig.

Description

1

Rotameter

2

Operation manual

3

Data sheet

4

TR TS certificate 012/2011 on "The safety of equipment in explosion hazardous

environments" with enclosure.

5

TR TS certificate 032/2013 on "The Safety of equipment working under excessive

pressure"*

* –Provided upon request

Sealing place

EMIS-META 215

OPERATION MANUAL

https://emis-meter.com/

18

Fig. 1.11 - Additional supply kit

Table 1.12 - Additional supply kit

No

Description

1

Mounting kit (flanges, gaskets, studs, nuts, washers, clamps)*

2

Mounting sleeve EMIS-META 215-ВТ

3

Filter and/or gas separator EMIS-VECTA

4

Power adapter EMIS-BREEZE

5

Magnet filter

6

HART modem

7

Spare parts kit, tools and accessories. It includes cable glands, flange gaskets and fixing

accessories for flanges mounting. Other accessories can be included according to customer

needs.

8

Other certificates (on demand)

Depends on the type of connection to the pipeline;

** - Additional kit to mount magnet filter.

Attention!

Please follow the steps below after receiving the rotameter:

check package for damages.

check supply kit.

compare rotameter parameters to ones specified in order sheet.

In case of any damages, supply kit or parameters mismatch, make a report.

EMIS-META 215

OPERATION MANUAL

https://emis-meter.com/

19

1.7 Order sheet

EMIS-META 215 Rotameter configurations are shown in the table 1.13. Order sheet completion is

shown below.

EMIS-META 215-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

-

-

-

-

050

A

-

G

-

N

-

F

-

1.6

-

100

-

2.5

-

-

-

A

-

L

-

-

15

16

17

18

19

-

SC

.

MF

-

GOST

-

V

-

-

Data as shown in order sheet: EMIS-META 215-050А-G-N-F-1.6-100-2.5-A-L-SC.MF-GOST-V

Table 1.13 - Rotameter versions

1

Explosion protection

–

n/a

Ex

Intrinsically safe electrical circuit

Equipment for explosive environments:

1Ex ib IIB/IIC T1/T2/T4 Gb X.

For dust hazardous environments:

Ex ib IIIB/IIIC T100°C/T250°C/T420°C Db X.

Vn

Ex-proof enclosure

Marking of explosion protection for explosive gas environments:

1Ex db IIB/IIC T1/T2/T4 Gb X.

Marking of explosion protection for dust hazardous environments:

Ex tb IIIB/IIIC T100°C/T250°C/T420°C Db X.

Gbc*

Structural safety

Marking of explosion protection for explosive gas environments:

II Gb c T1/T2/T4 X.

Marking of explosion protection for dust hazardous environments:

III Db c T100°C/T250°C/T420°C Db X

IP65/IP67.

X

special order

* -configuration without output signals and no display;

2

Rotameter version

–

vertical installation on pipeline (standard)

Г

horizontal installation on pipeline

3

Size

015

Dn = 15 mm

080

Dn = 80 mm

025

Dn = 25 mm

100

Dn = 100 mm

040

Dn = 40 mm

150

Dn = 150 mm

050

Dn = 50 mm

X

special order

EMIS-META 215

OPERATION MANUAL

https://emis-meter.com/

20

4

Flow range*

A

flow range A

F

flow range F

B

flow range B

G

flow range G

C

flow range C

H

flow range H

D

flow range D

Х

customized flow range

E

flow range E

* - Rotameters flow range can be customized, in this case you put X after flow range (see order sheet

example)

5

Medium type*

L

Liquid

G

gas

O

Oxygen

* - initially rotameters are calibrated for standard conditions Standard conditions are as follows:

liquid - water under 20° C, density 1000 kg/cbm

gas - air under 20° C pressure of 0,1013 MPa, density 1,204 kg/cbm.

To measure other medium please specify it in the order sheet.

6

Flow tube material

N

stainless steel (SS304)

N2

stainless steel (SS316)

Ft*

PTFE-teflon **

X

customized flow tube material

* - Ft version is not applicable for horizontally mounted rotameters (application Г);

** - fluorine plastic for application up to 4,0 MPa.

7

Connection type

F

flange connection

S*

socket connection

C*

clamp connection

X

customized (various connection types under GOST, EN, ASME; please specify)

- configurations with connection S and C are not available for rotameters with flow tubes made of Ft. If you

choose S or C connection, add mounting kit MK symbol after the magnet filter.

For example: EMIS-META 215-050А-G-N-F-1.6-100-2.5-A-L-SC.MF-MK

8

Working pressure*

1.6

max pressure - 1,6 MPa

2.5

max pressure - 2,5 MPa

4.0

max pressure - 4,0 MPa

6.3

max pressure - 6,3 MPa

10

max pressure - 10,0 MPa

16

max pressure - 16,0 MPa

25

max pressure - 25,0 MPa

32

max pressure - 32,0 MPa

Table of contents

Other EMIS Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Beko

Beko FLM SF53 Installation and operating manual

Michell Instruments

Michell Instruments OptiCal user manual

DeWalt

DeWalt DW0165 user manual

Spectrum Technologies

Spectrum Technologies Field Scout TDR 250 product manual

Milwaukee

Milwaukee L4 CLL Original instructions

Brooks Instrument

Brooks Instrument SLA5800 Series Installation & operation manual