EMIS EMIS-VIHR 200 User manual

www.emis-kip.ru

EV-200.000.

000.000.00OM

30.09.2019

V4.2.3

___________

Vortex Flow meters

EMIS-VIHR 200 (EV-200)

For versions EV-200, EV-

205,

EV-200-PPD

Operation manual

High accuracy

Accuracy does not

depends on

process

parameters

Working under

high pressure and

temperature

Protection against

water hammer

Simulation test

LED display with

optical buttons

In-built self-check

USB connection

EMIS CJSC

Russia,

Chelyabinsk

EMIS-VIHR 200

OPERATION MANUAL

www.emis-kip.ru/ru/prod/ev200 2

The present manual intended for learning the device operation, operating rules, maintenance and

calibration of the vortex flow transducers “EMIS-VORTEX 200 (EV-200)” (hereinafter referred to as “transducer,

“flow meter”).

This operation manual contains general technical parameters, directions for usage, calibration,

transportation and storage, and other information for accurate operation of the flow meter.

The design of the transducer is constantly being improved, so the device you purchased may have

minor differences from the descriptions in this document that do not affect the performance, technical

characteristics and usability.

The list of documents referenced in this manual is given in Appendix A.

Any use of the trade marks and present manual, partial or full, is prohibited without copyright holder

permission.

EMIS CJSC has the right to update the product and documents without prior notice if it does not affect

product performance.

EMIS-VIHR 200

OPERATION MANUAL

www.emis-kip.ru/ru/prod/ev200

3

CONTENTS

1 DESCRIPTION AND OPERATION

4

1.1 Intended use of the flow meter

4

1.2 Parameters

12

1.3 Explosion protection

21

1.4 Flow meter parts

23

1.5 Configuration and operation

24

1.6 Marks and seals

26

2 APPLICATION

27

2.1 Operating features

27

2.2 Mounting requirements

32

2.3 Operation

40

3 MAINTENANCE

44

4 CALIBRATION

44

5 LIST OF POSSIBLE FAILURES

45

6 STORAGE

46

7 TRANSPORTATION

46

8 RECYCLING

46

9 PRECIOUS MATERIALS CONTENT

46

Appendix A Reference documents

47

Appendix B Connection diagrams

49

Appendix C Installation scheme, dimensions, connection size and weight

54

Appendix D Mounting kit

70

Appendix E EMIS Integrator guide

82

Appendix F Explosion protection scheme

83

Appendix G «Modbus» protocol description

91

Appendix H «HART» protocol description

103

Appendix I List of measuring instruments used for calibration

105

Appendix J Insertion type flow meter adjustment according to application conditions

106

Appendix K In-process installation of 1,6MPa insertion type flow meter without flow

interruption

109

EMIS-VIHR 200

OPERATION MANUAL

www.emis-kip.ru/ru/prod/ev200 4

1 DESCRIPTION AND OPERATION

1.1. Intended use of the flow meter

1.1.1 Flow transducer is designed for measuring flow and volume of liquids, gases (natural, associated

petroleum gas, air, oxygen, etc), saturated and superheated vapour, corrosive mediums under working pressure

and temperature and can be applied in different manufacturing spheres and as a part of heat, gas, steam

metering systems.

Flow transducer of PPD version shall be used as part of reservoir pressure maintenance systems, for

measuring of Senomanian water or other liquids under high pressure.

Flow transducers can be used as part of automatic control and monitoring systems and local automation

schemes using a pulse frequency signal under GOST 26.010, current signal under GOST 26.011 and digital

signal ModBus (RS485, USB) and HART.

1.1.2 By the measurement method, the transducers are divided into full bore (EV-200) and submersible

(EV-205). There are two types of installation on the pipe:

- non-flange, wafer type, code C or C1, for 15mm to 300mm pipe size;

- flange, code F or F1, for 15mm to 300mm pipe size;

- flange with integrated reducer, code FR or FR1, for 25mm to 100mm pipe size;

- clamp connection, code T, for 50mm to 80mm pipe size;

- for reservoir pressure maintenance systems, code PPD, for 50mm, 80mm, 100mm and 150mm pipe

size. Submersible transducer EV-205 has installation code PR for 300mm to 2000mm pipe size.

Measuring method of EV-205 corresponds to GOST 8.361.

1.1.3 Flow meter is designed for measuring flow and volume of medium corresponding the the below

parameters:

1) temperature range from -60 to +450ºС; temperature ranges and corresponding flow meter types are

given in table 1.1.

Table 1.1 Temperature versions

Version Code

Medium temperature, °С

min

max

EV-200

«70»

- 40 (- 60*)

+ 70

EV-200

«100»

- 40 (- 60*)

+ 100

EV-200

«250»

- 40 (- 60*)

+ 250

EV-200

«320»

- 40 (- 60*)

+ 320

EV-200

«450»

- 40 (- 60*)

+ 450

PPD

«100»

0

+ 100

EV-205

«100»

-40

+ 100

EV-205

«250»

-40

+ 250

Note: * As special order, the minimal temperature can be decreased to -60 ºС, except for ex-proof versions RV,

RVI, RO.

2) exessive pressure:

- max 25 MPa for C version;

- max 16 MPa for F1 version;

- max 6,3 MPa for C1, F, FR, FR1 versions;

- max 4.0 MPa for T version;

- max 4.0 MPa for PR version;

- max 25 MPa for PPD and X versions (special version).

3) solid particles shall not exceed 250 mg/m3 for gases and 1g/l for liquids;

4) gas inclusions in liquid shall not exceed 2,5% of the volume for 0,5% accuracy version and 4% for

1,5% and 1% accuracy flow meters. When the content of gas inclusions is up to 10% by volume, the total

relative error does not exceed ± 5%;

5) dynamic viscosity for liquids shall not exceed 7mPa*s;

6) measuring liquid shall not be corrosive to flow tubes.

1.1.4 General purpose flow transducers shall be used in explosion proof environment.

Flow transducer of explosion proof configuration Вн is intended for use in explosive environment with

explosive mixtures of IIC type, and has explosion safety called "explosion proof enclosure" and 1Ex d IIC(T1-

T6)Gb X marking.

Flow transducer of explosion proof configuration ЕхВ intended for use in explosive environment with

explosive mixtures of IIB type, and has explosion protection called "intrinsically safe circuit" and 1Ex ib IIB(T1-

EMIS-VIHR 200

OPERATION MANUAL

www.emis-kip.ru/ru/prod/ev200

5

T6) Gb X marking.

Flow transducer of explosion proof configuration ЕхC intended for use in explosive environment with

explosive mixtures of IIC type, and has explosion protection called "intrinsically safe circuit" and 1Ex ib IIС(T1-

T6)Gb X marking.

Flow transducer of explosion proof configuration ЕхiaВintended for use in explosive environment with

explosive mixtures of IIB type, and has explosion protection called "intrinsically safe circuit" and 1Ex ia IIB(T1-

T6)Gb X marking.

Flow transducer of explosion proof configuration ЕхiaC intended for use in explosive environment with

explosive mixtures of IIC type, and has explosion protection called "intrinsically safe circuit" and 1Ex ia IIС(T1-

T6)Gb X marking.

Ex-proof flow meters are equipped with ex-proof casing marked as РВ ExdI Хand can be used in

underground mines, pits and its gas- and dust-hazardous overground facilities.

Flow transducer of explosion proof configuration РВI intended for underground use in mines, pits and

related overground facilities hazardous with mine gas and combustible dust. Is provided with combined

explosion protection "intrinsically safe circuit" and "explosion proof enclosure", masked as РВ Ex d ib I Mb Х.

Flow transducer of explosion proof configuration РО intended for underground use in mines, pits and

related overground facilities hazardous with mine gas and combustible dust. This configuration has explosion

protection called "intrinsically safe circuit" and РО Ex ia I Ma Хmarking.

Explosion proof configurations РВ, РВI and РО are supplied with ex-proof boxes.

Explosion proof safety aspects are described in 1.3. Explosion protection

1.1.5 Flow transducer has IP67 protection under GOST 14254, and conform with standard configuration

underGOST Р52931.

1.1.6 Flow transducer is resistant to external magnetic field up to 400 A/m under GOST Р50648.

1.1.7 Transducers in the range from Qp to Qmax (see table 1.7) are resistant to 10-100 Hz vibration with

acceleration not exceeding 4,9 m/s2 and refers to NX group underGOST Р52931.

1.1.8 Flow transducer refers to P1 type as classified in GOST Р52931 by air pressure resistance class

in the range of 84 to 106,7 kPa.

1.1.9 Flow meters can be operated in boreal climates location class 1 under GOST 15150.

Ambient temperature for all transducers (not include mine configuration) shall be in the range of -40°С

to +70°С(for special configurations of -50°Сto +70°Сor -60°Сto +70°С), humidity 95±3% non-condensing at

+35°С. For mine configurations РВ, РВI and РО ambient temperature shall be 0 to +70°С.

For ExB, ЕхC, ЕхiaВ, ЕхiaC configurations LCD display works at temperature not lower than -20ºC.

For Вн configuration LCD display works at temperature not lower than -40ºC.

For T version transducer with 2-wire connection type the LCD display works at temperature not lower

than -20ºC.

1.1.10 To place the order correctly please see symbols as listed in the table 1.2.1 and table 1.2.2.

EMIS-VIHR 200

OPERATION MANUAL

www.emis-kip.ru/ru/prod/ev200 6

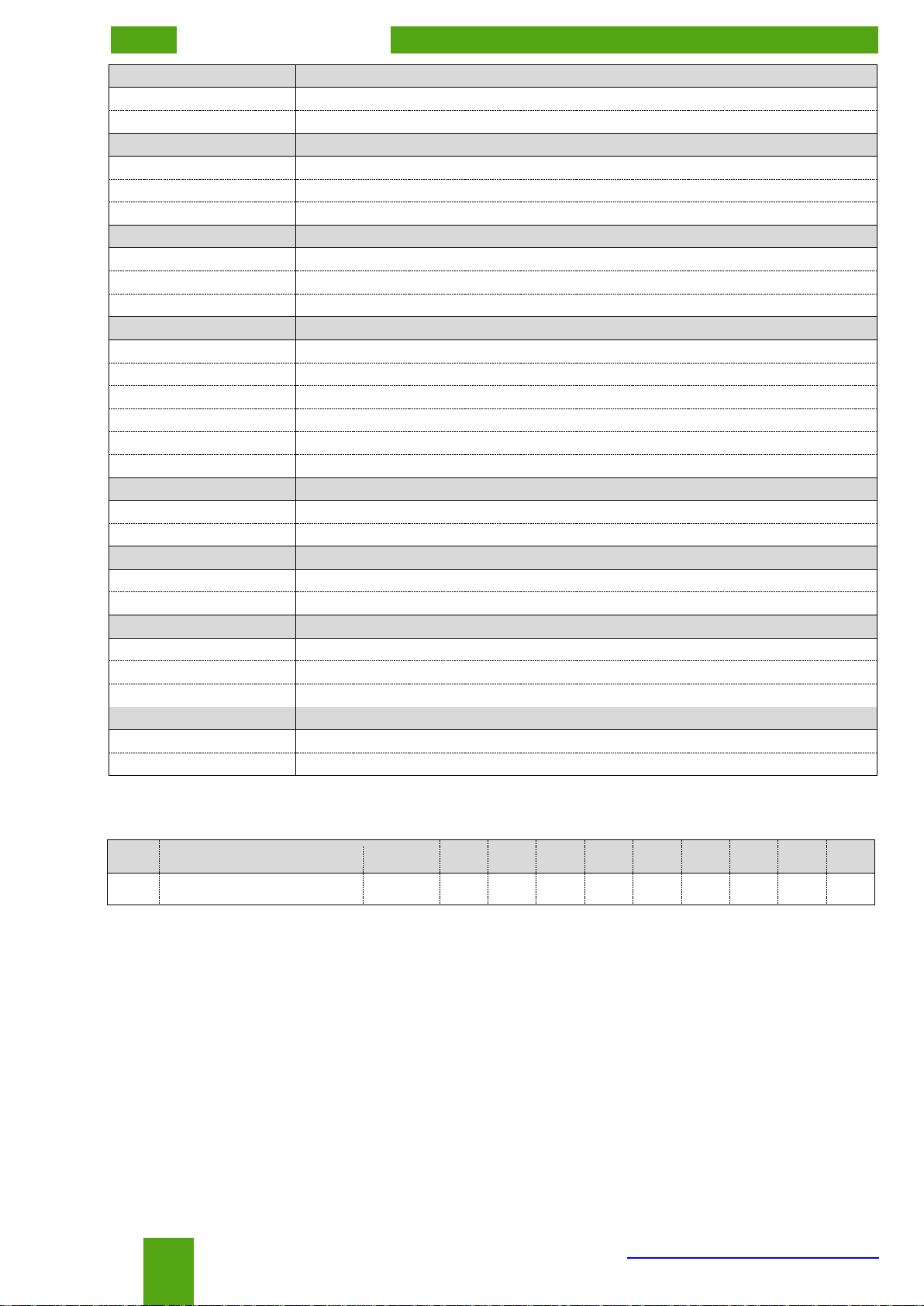

Table 1.1.1 - EV-200 and EV-205 symbols

Code

0

Item name

EMIS-VIHR 200

Full-bore

EMIS-VIHR 205

Insertion type

Code

1

Explosion protection

–

No ex-proof

ЕхВ

1Ex ib IIB (T1-T6) Gb Х***

ЕхС

1Ex ib IIС (T1-T6) Gb Х ***

ЕхiaВ

1Ex ia IIB (T1-T6) Gb Х***

ЕхiaC

1Ex ia IIС (T1-T6) Gb Х ***

Вн

1Ex d IIC (T1-T6) Gb Х

РВ

РВ Ex d I Mb Х

PBI

РВ Ex d ib I Mb Х***

PO

РО Ex ia I Ma X ***

Code

2

Flow meter size (Pipe DN)

015

15 mm

100

100 mm

350

350 (fro EV-205 only)

025

25 mm

125

125 mm

400

400 (fro EV-205 only)

032

32 mm

150

150 mm

….

…. (for EV-205 only)

040

40 mm

200

200 mm

050*

50 mm

250

250 mm

065

65 mm

300

300 mm

2000

2000 (fro EV-205 only)

080

80 mm

Х

special order

Code

3

Accuracy class (see table 1.7)

A

Accuracy class A

B

Accuracy class B

C

Accuracy class C

Code

4

Flow range

–

standard

Х

special order

Code

5

Medium

L

liquid

G

gas/ saturated vapour/ superheated vapour

C

oxygen (for EV-200 only)

Code

6

Flow tube material

Н

stainless steel by default (see table 1.10)

HH

steel 12Х18Н10Т

Х

special order

Code

7

Pipeline connection (for EV-200 only)

C

wafer (Dn 15-300mm)

C1

wafer (Dn 15-100mm) male-female under GOST 33259

F

flanged

F1

flanged with male-female connection under GOST 33259**

FR

flanged connection with reducers (Dn 25-100mm)

FR1

flanged connection with integrated reducers (Dn 25-100mm) male-female

connection type under GOST 33259

T

clamp (Dn50 and Dn80)

Х

special order

Code

8

Flow meter mounting

–

integrated with sensor

R

remote installation (3m cable length) ****

RXX

specify cable length for remote installation (up to 50m)

EMIS-VIHR 200

OPERATION MANUAL

www.emis-kip.ru/ru/prod/ev200

7

Code

9

Max pressure of medium

1.6

up to 1.6MPa

2.5

up to 2.5MPa

4.0

up to 4.0MPa

6.3

up to 6.3MPa (for EV-200 only)

10

up to 10MPa (for EV-200 only)

16

up to 16MPa (for EV-200 only)

20

up to 20MPa (for EV-200 only)

25

up to 25MPa (for EV-200 only)

Х

special order

Code

10

Max medium temperature

70

up to +70ºС

100

up to +100ºС

250

up to +250ºС

320

up to 320ºС(for EV-200 only) ****

450

up to 450ºС(for EV-200 DN≥40mm flanged version only) ****

Х

special order

Code

11

Display

–

n/a

SIM

integrated display with mechanical keyboard ****

SIO

integrated display with optical keyboard ****

SI

integrated display without keyboard ****

Х

special order

Code

12

Flow meter mounting

C

base

BB

extended (with computer) (for EV-200 only)

C

special low temperature application

T

2-wire connection (current loop)

Code

13

Output signals

–

pulse-frequency, digital ModBus

A

analog, pulse, digital ModBUS ***

A1

analog, pulse, ModBUS ***

H

analog, pulse, digital ModBUS, HARTTM v6 ***

H1

analog w/o additional error, pulse, digital ModBUS, HARTTM v6 ***

H2

analog w/o additional error, digital HARTTM v7, 1st pulse-frequency with NAMUR,

2nd pulse-frequency *****

H3

analog with NAMUR w/o additional error, digital HARTTM v7, 1st pulse-frequency

with NAMUR, 2nd pulse-frequency *****

Х

special order

Code

14

Transmitter version

–

with two cable glands

У

with four cable glands (except for ex-proof versions PB, PBI, PO)

Code

15

Calibration

–

manufacturer calibration at 5 points, pressure test

ГП

state calibration

Code

16

Min ambient temperature

–

-40 и -50 ºС

60

-60 ºС ****

EMIS-VIHR 200

OPERATION MANUAL

www.emis-kip.ru/ru/prod/ev200 8

Code

17

Min medium temperature;

–

-40 ºС

И60

-60 ºС (for E-200 only)

Code

18

Industrial versions

–

standard version

AST

for hydrogen sulfide mediums

Note: «–» means standard configuration;

* - for clamp connection «Т» Dn50 connected to the pipe of Dn65;

** - for 10-25 MPa connected with oval gasket;

*** - except for special version of transmitter;

**** - except for version with 2-wire connection;

***** - for version with 2-wire connection only;

Full-bore EV-200 symbolic specification

Code

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Order

EMIS-VIHR

200

ЕхВ 050

A – L НF1 R 2.5

250

SIO C Н– ГП – И60 –

Full-bore EV-205 symbolic specification

Code

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Order

EMIS-VIHR

205

– 400

B – L Н– – 2.5

100

SIO C A – ГП – – –

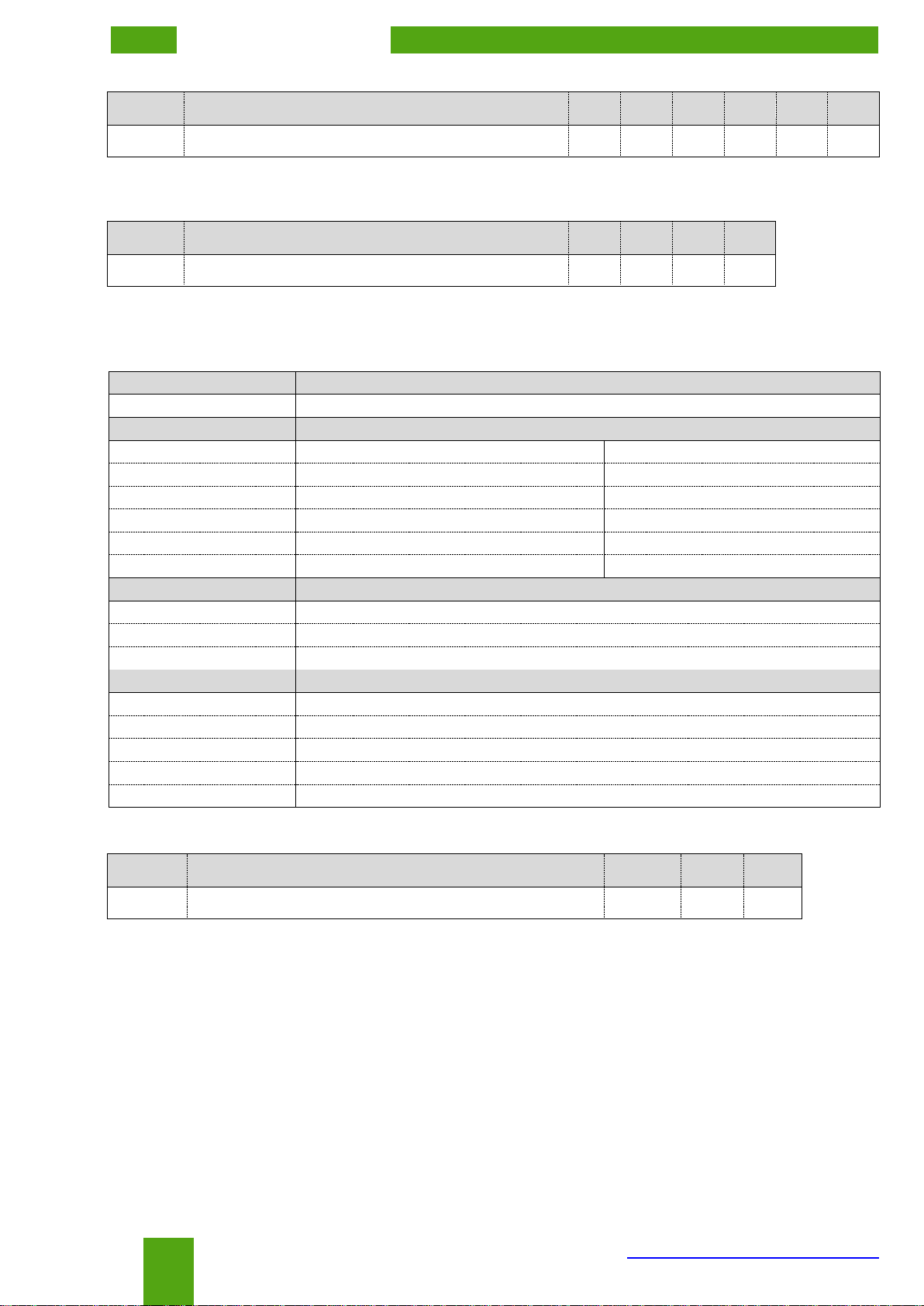

Table 1.2.2 -PPD version symbolic specification

0

Item name

EMIS-VIHR 200-PPD

PPD version

1

Size (pipe diameter/flow range code)

Configuration

50/10

Pipe Dn 50mm, flow range 10

–

50/20

Pipe Dn 50mm, flow range 20

–

50/25

Pipe Dn 50mm, flow range 25

–, 1

50/50

Pipe Dn 50mm, flow range 50

–

50/60

Pipe Dn 50mm, flow range 60

–

80/20

Pipe Dn 80mm, flow range 20

–

80/25

Pipe Dn 80mm, flow range 25

1

80/35

Pipe Dn 80mm, flow range 35

–

80/50

Pipe Dn 50mm, flow range 80

–, 1

80/100

Pipe Dn 80mm, flow range 100

1

80/150

Pipe Dn 80mm, flow range 150

–

100/25

Pipe Dn 100mm, flow range 25

–

100/50

Pipe Dn 50mm, flow range 100

–

100/120

Pipe Dn 100mm, flow range 120

–

100/200

Pipe Dn 100mm, flow range 200

–, 1

100/300

Pipe Dn 100mm, flow range 300

–

150/500

Pipe Dn 150mm, flow range 500

1

Х

special order

2

Accuracy class (see table 1.7)

–

Accuracy class C (standard version)

A

Accuracy class A

B

Accuracy class B

EMIS-VIHR 200

OPERATION MANUAL

www.emis-kip.ru/ru/prod/ev200

9

3

Max pressure of medium

–

up to 25 MPa (standard version)

20

up to 20 MPa

4

Display

–

n/a

SIM

integrated display with mechanical keyboard

SIO

integrated display with optical keyboard

5

Configuration

-

standard version

1

version 1

Х

special order

6

Output signals

–

pulse-frequency, digital ModBus

A

analog, pulse, digital ModBUS ***

A1

analog w/o additional error, pulse, ModBUS

H

analog, pulse, digital ModBUS, HARTTM v6

H1

analog w/o additional error, pulse, digital ModBUS, HARTTM v6

Х

special order

7

Calibration

–

manufacturer calibration at 5 points, pressure test

ГП

state calibration

8

Min ambient temperature

–

-40 и -50 ºС

60

-60 ºС

9

Flow tube material

–

steel 20Х13 - standard version

HH

steel 12Х18Н10Т

Х

special order

10

Industrial versions

–

standard version

AST

for hydrogen sulfide mediums

PPD version symbolic specification

Code

0

1

2

3

4

5

6

7

8

9

10

Order

EMIS-VIHR 200-PPD

100/50

–

–

SIO

–

A

ГП

–

–

–

1.1.11 PPD configuration has the following parameters:

- 1Ex d IIC T5 Gb Хex-proof marking for EV-200Вн

- measuring medium - liquid;

- measuring medium temperature from 0 to 100 °С;

- flangless version;

- integrated with sensor

1.1.12 AST version are designed for operation when the content of hydrogen sulfide in the environment

in normal mode does not exceed 10 mg / m3, in an emergency mode - up to 100 mg / m3 during 1 hour. The

content of dissolved hydrogen sulfide in the liquid is up to 6% by volume.

1.1.13 To place the order for mounting kit correctly please see symbols as listed in table 1.2.3 and table

1.2.4.

EMIS-VIHR 200

OPERATION MANUAL

www.emis-kip.ru/ru/prod/ev200 10

Table 1.2.3 - EV-200 and EV-205 mounting kit symbols

Code

0

Item name

EMIS-VIHR 200

Full-bore type mounting kit

EMIS-VIHR 205

Insertion type mounting kit

Code

1

Flow meter size (Pipe DN)

015

15 mm

100

100 mm

350

350 (fro EV-205 only)

025

25 mm

125

125 mm

400

400 (fro EV-205 only)

032

32 mm

150

150 mm

….

…. (for EV-205 only)

040

40 mm

200

200 mm

050

50 mm

250

250 mm

065

65 mm

300

300 mm

2000

2000 (fro EV-205 only)

080

80 mm

Х

special order

Code

2

Pipeline connection (for EV-200 only)

C

wafer (Dn 15-300mm)

C1

wafer (Dn 15-100mm) male-female under GOST 33259

F

flanged

F1

flanged with male-female connection under GOST 33259*

FR

flanged connection with reducers (Dn 25-100mm)

FR1

flanged connection with integrated reducers (Dn 25-100mm) male-female

connection type under GOST 33259

T

clamp (Dn 50 and Dn 80)

Х

special order

Code

3

Max pressure of medium

1.6

up to 1.6MPa

10

up to 10MPa (for EV-200 only)

2.5

up to 2.5MPa

16

up to 16MPa (for EV-200 only)

4.0

up to 4.0MPa

20

up to 20MPa (for EV-200 only)

6.3

up to 6.3MPa (for EV-200 only)

25

up to 25MPa (for EV-200 only)

Х

special order

Code

4

Max medium temperature (for EV-200 only)

70

up to +70ºС

100

up to +100ºС

250

up to +250ºС

320

up to +320ºС

450

up to +450ºС

Х

special order

Code

5

Flange material

–

Steel 09Г2С

St20

Steel 20

Н

stainless steel

13ХФА

Steel 13ХФА

Х

special order

Code

6

Flange standard (for EV-200 only)

–

version according to the Manual

ASME

ANSI / ASME standard

EN

EN1092-1 standard

Х

special order

Code

7

Ball valve (for EV-200 only)

–

None

C

with ball valve

Note: * - for 10-25 MPa connected with oval gasket;

EMIS-VIHR 200

OPERATION MANUAL

www.emis-kip.ru/ru/prod/ev200

11

Full-bore EV-200 symbolic specification

Code

0

1

2

3

4

5

6

Order

Mounting kit EMIS-VIHR 200

050

C1

2.5

100

Н

–

Insertion type EV-205 mounting kit symbolic specification

Code

0

1

3

5

7

Order

Mounting kit EMIS-VIHR 200

800

1.6

Н

–

Table 1.2.4 - Mounting kit symbols for PPD version

0

Item name

EMIS-VIHR 200-PPD

PPD version mounting kit

1

Size (pipe diameter/flow range code)

50/10

80/20

100/25

50/20

80/25

100/50

50/25

80/35

100/120

50/50

80/50

100/200

50/60

80/100

100/300

80/150

150/500

2

Configuration

-

standard version

1

version 1

Х

special order

3

Flange material

–

Steel 09Г2С

St20

Steel 20

Н

stainless steel

13ХФА

Steel 13ХФА

Х

special order

PPD version mounting kit symbolic specification

Code

0

1

2

3

Order

Mounting kit EMIS-VIHR 200-PPD

100/50

-

Н

EMIS-VIHR 200

OPERATION MANUAL

www.emis-kip.ru/ru/prod/ev200 12

1.2 Parameters

1.2.1 EV-200 and EV-205 minimum (Qmin) and maximum (Qmax) volume flow rate of water and air

measured at 20°Сand zero pressure are shown in table 1.3 and 1.4 accordingly.

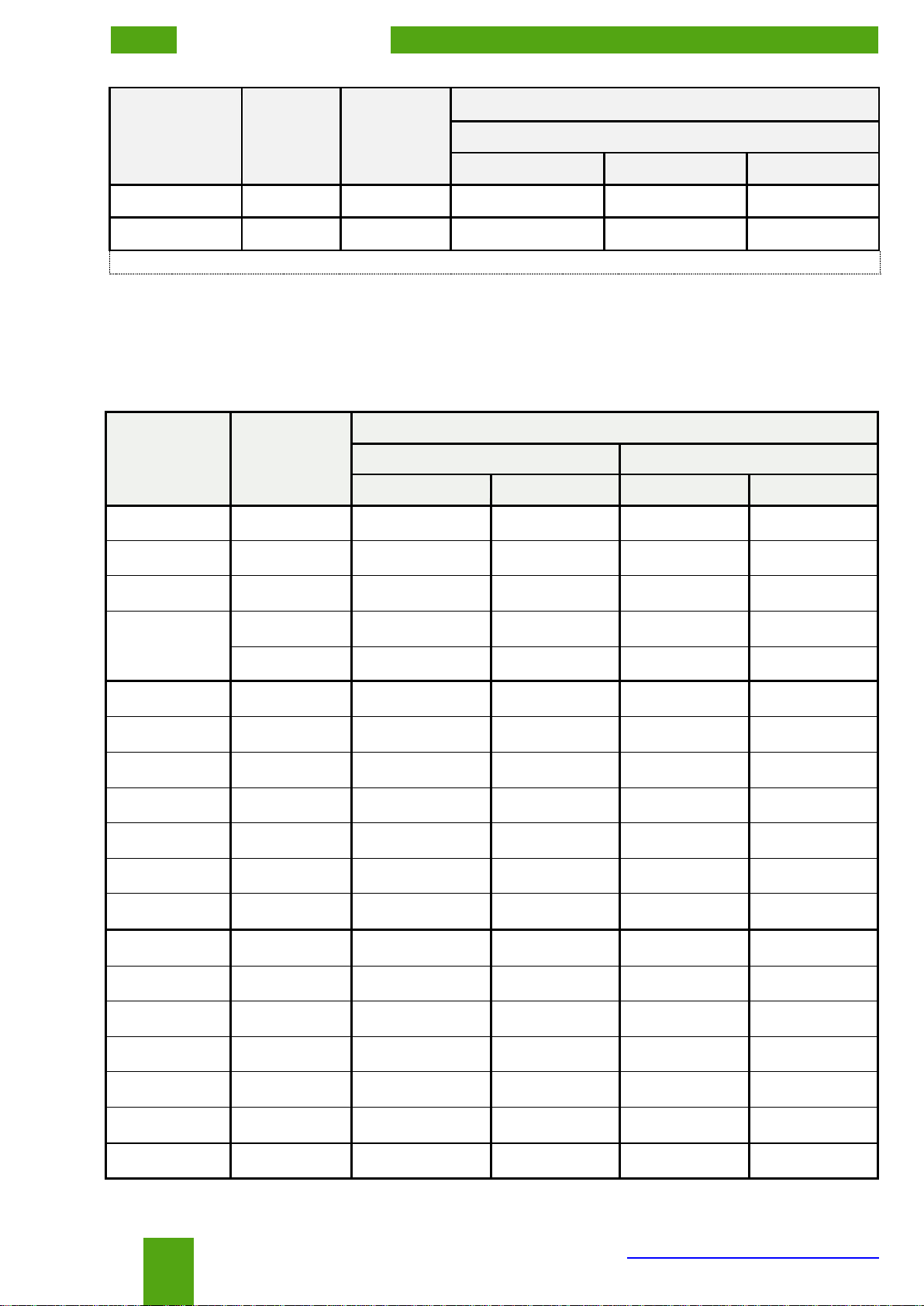

Table 1.3 - EV-200 flow ranges

Flow meter

size

(DN), mm Pipeline

connection code Temperature code

for medium

Flow volume*, cbm/h

Water

Air

Qmin

Qmax

Qmin

Qmax

15 C, F,

C1, F1

70, 100

0.5

5

4.5

32

250.320

0.5

5

7

32

25 FR, FR1

70, 100

0.5

5

4.5

32

250.320

0.5

5

7

32

25 C, F,

C1, F1

70, 100

0,6 (0,4)

16

8

120

250.320

0.6

16

12.5

120

32 FR, FR1

70, 100

0,6 (0,4)

16

8

120

250.320

0.6

16

12.5

120

32 C, F,

C1, F1

70, 100

0,8 (0,6)

26

10

200

250.320

0.8

26

13

200

40 C, F,

C1, F1

70, 100

1,4 (1)

41

12

310

250.320

1.4

41

20

310

450

3.4

41

31

310

50 FR, FR1

70, 100

0,8 (0,6)

26

10

200

250.320

0.8

26

13

200

50 C, F,

C1, F1

70, 100

2 (1,4)

64

18 (14)

480

250.320

2

64

30

480

450

5.3

64

48

480

65 C, F,

C1, F1

70, 100

3 (2,6)

107

33 (24)

810

250.320

3

107

55

810

450

9

108

81

810

80 FR, FR1

70, 100

2 (1,4)

64

18 (14)

480

250.320

2

64

30

480

80 C, F,

C1, F1

70, 100

4,6 (4)

160

53 (36)

1230

250.320

4.6

160

60

1230

450

13

160

123

1230

100 FR, FR1

70, 100

4,6 (4)

160

53 (45)

1230

250.320

4.6

160

60

1230

EMIS-VIHR 200

OPERATION MANUAL

www.emis-kip.ru/ru/prod/ev200

13

Table 1.3: continued

Flow meter

size

(DN), mm Pipeline

connection code Temperature code

for medium

Flow volume*, cbm/h

Water

Air

Qmin

Qmax

Qmin

Qmax

100 C, F,

C1, F1

70, 100

8 (6)

250

80 (60)

1920

250.320

8

250

90

1920

450

21

250

192

1920

125 C, F, F1

70, 100

13 (10)

400

130 (90)

3000

250.320

13

400

130

3000

450

33

390

290

2900

150 C, F, F1

70, 100

18 (14)

575

190 (130)

4325

250.320

18

575

190

4325

450

47

560

420

4200

200 C, F, F1

70, 100

34 (26)

1060

320 (235)

8000

250.320

34

1060

330

8000

450

90

1080

810

8100

250 C, F, F1

70, 100

60 (42)

1700

470 (380)

12900

250.320

60

1700

500

12900

450

142

1670

1260

12600

300 C, F, F1

70, 100

95 (60)

2460

680 (550)

18600

250.320

95

2460

800

18600

450

200

2400

1820

18200

50, 80 ** T70, 100

3 107 33 810

250 3 107 55 810

Note:

1.* As special order for temperature configurations under +100°С, we can produce transducer with extended

flow range, the lower limit of extended range is indicated in brackets next to the main range lower limit. It shall be

specified in order sheet by placing X after Dn and accuracy class (e.g. 080-Б-Х means transducer of Dn80mm

with Б accuracy class and extended flow range). In this case the accuracy for flow range lower than standard is

not specified.

2.** For T configuration the flow range can be other than standard which is specified in transducer passport. It

shall be specified in order sheet by placing X after Dn and accuracy class.

3.Flow ranges for other mediums depend on medium density, pressure, temperature and can be defined

based on data sheet filled in by a customer.

EMIS-VIHR 200

OPERATION MANUAL

www.emis-kip.ru/ru/prod/ev200 14

Table 1.4 - EV-205 flow ranges

Flow meter

size (DN), mm Pipeline

connection code Temperature code

for medium

Flow volume*, cbm/h

Water

Air

Qmin

Qmax

Qmin

Qmax

40

Flow sensor

PR

70, 100, 250 1.4 18 23 144

300

PR

70, 100, 250

75

2030

1670

15230

350

PR

70, 100, 250

100

2770

2280

20770

400

PR

70, 100, 250

130

3630

2980

27240

450

PR

70, 100, 250

165

4600

3780

34550

500

PR

70, 100, 250

200

5700

4680

42750

600

PR

70, 100, 250

300

8200

6770

61800

700

PR

70, 100, 250

400

11300

9260

84500

800

PR

70, 100, 250

530

14800

12140

110800

900

PR

70, 100, 250

690

19200

15810

144300

1000

PR

70, 100, 250

850

23900

19600

178900

1100

PR

70, 100, 250

1030

29000

23790

217200

1200

PR

70, 100, 250

1240

34600

28420

259500

1300

PR

70, 100, 250

1460

40700

33460

305500

1400

PR

70, 100, 250

1700

47400

38930

355400

1500

PR

70, 100, 250

1950

54600

44830

409300

1600

PR

70, 100, 250

2200

62200

51100

466600

1800

PR

70, 100, 250

2800

79000

64880

592400

2000

PR

70, 100, 250

3500

98000

80430

734300

1.2.2 Qmin and Qmax for gas mediums under working conditions are calculated as follows:

Qmin = max (Qmin * �/or Vmin * π* d2 / 4 * 0,0036) ),cbm/h (1.1)

Qmin = min (Qmax * �/or Qmax)),cbm/h,(1.2)

where

Qmin and Qmax are the max and min flow according to the tables 1.3 and 1.4;

ρ- air density under working conditions kg/cbm;

d - inner diameter of flow body (at the point of sensor installation), mm (see fig.C.3 - C.13 Appendix

C); Vmin - min flow velocity, m/s (see table 1.5);

K1, K2 - empirical coefficients (see table 1.5).

EMIS-VIHR 200

OPERATION MANUAL

www.emis-kip.ru/ru/prod/ev200

15

Table 1.5 - Coefficients for gas flow range calculation under working conditions

Flow meter size

(DN), mm Coefficient

K1 Coefficient

K2

Min velocity Vmin, m/s

Medium temperature code

70, 100

200,250,320

450

15 или 25-ФР1

1.2

47.4

2

3

-

other

1.2

26

1,5 (1,3*)

2

3

Note: * Min velocity for extended range is shown in brackets.

1.2.3 Flow meter shall be selected according to the flow under working conditions. If gas flow is given

under N.C. Nm3 / h in order sheet then it shall be recalculated for operating conditions.

1.2.4 Min and max value of full and operating flow of water for PPD version are shown in table 1.6.

Table 1.6 - PPD version flow ranges

Flow meter

size (DN/max

flow) Configuration

Flow volume, cbm/h

Operating range

Full range

Qmin'

Qmax'

Qmin

Qmax

50/10

–

0.5

8

0.3

10

50/20

–

0.7

20

0.5

25

50/25

–, 1

0.8

25

0.6

32

50/50

–

1,5

50

1.1

55

50/60

–

1.8

60

1.3

65

80/20

–

0.9

20

0.6

25

80/25

1

1

25

0.8

32

80/35

–

1.2

35

0.8

40

80/50

–

1,6

50

1.1

60

80/50

1

2

50

1.2

55

80/100

1

3

100

2.5

110

80/150

–

5

150

3.5

160

100/25

–

1

25

0.8

32

100/50

–

2

50

1.2

55

100/120

–

5

120

4

132

100/200

–

8

200

5

220

100/200

1

5

200

4

200

100/300

–

12

300

8.2

330

150/500

1

15

500

12.5

520

EMIS-VIHR 200

OPERATION MANUAL

www.emis-kip.ru/ru/prod/ev200 16

1.2.5 Working pressure for PPD configuration shall not be less than:

0,3 MPa – for Q ≤ Qmin’;

0,4 MPa – for Qmin’ < Q ≤ 0,5•Qmax’;

0,8 MPa – for Q > 0,5•Qmax’.

1.2.6 Relative accuracy for volume and volume flow rate measured at frequency, pulse and digital

signals and current signal for version A1, H1, H2, H3 depending on flow meter accuracy class is shown in Table

1.7.

Table 1.7 – Accuracy limits

Flow meter type Medium

Accuracy limits for A,B,C accuracy classes, %

Transition flow

Qt

Qt≤ Q ≤ Qmax

Qmin ≤ Q ≤ Qt

A

B

C

A

B

C

Full-bore Liquid ± 0,5 ± 1,0 ± 1,5 ± 1,0 ± 1,5 ± 2,5 0,06·Qmax **

Gas and

vapour

± 1,0 ± 1,5 ± 2,0 ± 2,0 ± 2,5 ± 3,5 0,1·Qmax **

Full-bore PPD Liquid ± 0,5 ± 1,0 ± 1,5 ± 1,0 ± 1,5 ± 2,5 Qmin'

Insetion type Liquid ± 1,5 ± 2,0 ± 3,0 ± 3,5 0,125·Qmax

Gas and

vapour

± 2,5 ± 3,0 ± 4,0 ± 4,5 0,15·Qmax

Flow sensor of

insertion type flow

meter

Liquid ± 0,5 ± 1,0 ± 1,0 ± 1,5 0,125·Qmax

Gas and

vapour

± 1,0 ± 1,5 ± 2,0 ± 2,5 0,15·Qmax

Note:

1. Qt – transition flow,

Qmax - max measuring flow according to the tables 1.3, 1.4 and 1.6

Qmin' - lower limit of operation flow for PPD version according to the table 1.6.

2. ** Transition flow for full-bore flow meters of DN-15mm or Dn25FR(FR1) Qt = 0,6 cbm/h for liquid and 8

cbm/h for gas and vapour. Transition flow for DN=25mm or Dn32FR(FR1) Qt = 15 cbm/h for gas and vapour.

3. Transition flow for 450 temperature version Qt = 0,1·Qmax for liquid and 0.15·Qmax for gas and vapour.

1.2.7 Relative accuracy limits of the flow measured at current output for version A and H does not

exceed

δQI = ± [|δ| + 0,2 * Imax / (4 + 16 * Q / Qmax)], % (1.3)

where δ– accuracy limit according to Table 1.7, %;

Imax = 20mA - max current value in the loop;

Q - flow, cbm/h;

Qmax - max flow referring to 20mA at current output as specified in flow meter data sheet, cbm/h.

1.2.8 Flow meter can be equipped with the following outputs:

•pulse or digital output signal;

•analog (current) output signal (except for special version of flow meter);

•digital signals, see Table 1.8.

Table 1.8 - Digital signals

Protocol Physical interface

Modbus RTU

RS-485, USB

HART Current loop 4-20 mA

Note:

1. When USB is connected, RS-485 is disabled.

2. HART is not available for special version flow meters.

EMIS-VIHR 200

OPERATION MANUAL

www.emis-kip.ru/ru/prod/ev200

17

1.2.9 Pulse or digital output signal.

An output can work in different modes: frequency, pulse or digital. Output signal can be in two logical

states: "closed"/"opened". It is passive output of open collector type.

There are two pulse outputs for T version with 2-wire connection type. One of them corresponds to

NAMUR standard.

For "Frequency output" mode signal frequency is proportional to currently used variable. The following

values can be used as variables: volume flow rate, volume flow rate under normal conditions, mass flow rate,

absolute pressure, temperature.

Note: Hereinafter referred to as N.C.): - normal conditions (atmospheric pressure is 101325 Pa = 760 mm Hg.

and air temperature 273,15 K = 20° C).

Minimum and maximum values comply with:

FMIN = 0 Hz - minimum value of current variable;

FMAX = 1000 Hz - maximum value of current variable:

Typical pulse values m for gas and liquid measuring at maximum frequency of 1000Hz are specified in

Table.2.2.

Pulse value m can be calculated as follows:

m = Q’max / (3,6 * 1000 Hz), L (1.4)

where Q’max is maximum possible flow rate (see table 2.2) for this size of flow meter, m3/h.

For "Pulse output" mode every output pulse means exact value of currently used variable which is called

pulse value. Volume, volume under normal conditions or mass can be used as currently used variable. Pulse

value and minimum pulse length can be specified according to customer needs. Signal frequency for pulse

mode shall not exceed 500Hz.

For "Digital output" mode an output switches between "closed/opened" when instantaneous flow ("flow

switch" mode) or total volume/mass ("dosing" mode) reach specified limit value.

Dosing mode operating procedure.

1) resettable totalizer set to zero, digital output set to initial state. This state is taken as normal (basic).

Flow meter is ready to accumulate flow.

2) External automatic control device will turn the valve or pump upon output signal change. Flow meter

counts amount of medium. External automatic device can stop flow counting if there is no technological need.

3) digital output change the state once the specified limit is reached. External automatic device stops the

flow according to output state, switch the flow or change tare, if required.

4) Simultaneously with the step 3, the timeout timer is started in milliseconds (from 1 to 65535) specified

in register 40011. At the end of the timeout, go to step 1 of the algorithm.

In any mode allowed external voltage for pulse (digital) output shall be 5V to 27V. Maximum current

shall be 50 mA. Recommended resistance of load resistor Rload shall comply with:

(U-1)/0,04<Rload. < (U-1)/0,02, Ohm, (1.5)

where U – external voltage, V.

Connection diagrams for recorder are shown in Appendix B.

All modes 0...11 are implemented on the same terminals so that only one mode can be applied at a

time. Modes and maximum/minimum values can be adjusted via Modbus or flow meter keyboard. For more

details see Appendix G.

1.2.10 Analog (current) output signal.

Current in the circuit lies within 4-20 mA range and varies linearly with currently used variable. The

following values can be used as variables: volume flow rate, volume flow rate under normal conditions, mass

flow rate, absolute pressure, temperature. Modes can be adjusted via Modbus or flow meter keyboard. Values

for 4 mA and 20 mA can be adjusted via HART. For more details see Appendix I.

Analog signal is not available for transmitter of C version.

For T version with 2-wire connection the output signal lies in the 4-20mA range and corresponds to

NAMUR standard.

By default for EV-200 and EV-200-PPD 20mA corresponds to the max flow Qmax for the DN as

specified in the tables 1.3 and 1.4.

For EV-205 the current value of 20mA corresponds to 28 cbm/h for liquid and 210 cbm/h for gas and

vapour. 4mA corresponds ot zero flow. Values for 4 mA and 20 mA can be adjusted according to specific needs.

For guaranteed operation of the current output, the total resistance of the current output circuit R1 must

correlate to the following:

R1 ≤ (Uп- Ui) / 0,024, Ohm, (1.6)

where Up – power supply unit voltage, V.

Ui = 12 V for standard and extended versions of the transmitter,

Ui = 15,5 V for version with 2-wire connection scheme;

EMIS-VIHR 200

OPERATION MANUAL

www.emis-kip.ru/ru/prod/ev200 18

For general industrial version and for explosion-proof versions Вн, РВ the voltage at the terminals of the

current output should be in the range from 12 to 27 V.

For explosion-proof versions ЕхВ, ЕхС, ЕхiaВ, ЕхiaС, РВI, РО the voltage at the terminals of the

current output should be in the range from 12 to 25,3 V.

1.2.11 Digital output signals.

Modbus is the main digital output signal. It complies with EIA/TIA-422-B and ITU V.11 requirements,

provides data transfer through Modbus RTU (Modicon Modbus Protocol Reference Guide P1-MBUS-300 Rev.

G) and provides network connection and measured data transfer.

ModBUS transfers the following data to Windows PC with installed EMIS-Integrator software (supplied

with flow meter upon request and available on our web-sitewww.emis-kip.ru):

-flow tube diameter, mm;

-flow range, m³/h;

-flow meter serial number;

-instantaneous flow during damping time, m³/h;

-total volume of measured medium, m³;

-total and instantaneous mass flow, total and instantaneous volume flow under N.C. (if the

function is activated);

-low signal cut-off, units;

-damping rate (shall be chosen from integer values from 0 to 10);

-medium type: liquid, gas, steam;

-specified temperature range for medium, С°;

-K-factor (medium volume per one vortex), l/pulse;

-piezoelectric cell signal amplitude, units;

-temperature and pressure from connected sensors;

-adjustable parameters of flow meter.

Wiring diagram is shown in Appendix B.

ModBUS is not available the transmitter with a two-wire connection scheme.

Additional digital output signal complies with HART TM standard.

Adjustment of the first, second, third and fourth variables for HART output is made via separate

Modbus protocol. Adjustment of any other parameters for 4-20 mA output is made through modem or

communicator.

1.2.12 Display

Types of display:

- display with mechanical keyboard, «SIM» configuration,

- display with optical keyboard, «SIO» configuration.

- display without keyboard - SI configuration (for the transmitter with 2-wire connection scheme only).

SIM and SIO configuration display shows the following information:

- volume flow rate and total volume under normal conditions;

- volume flow rate and total volume under working conditions; Measuring units m³ and m³ / h blink on

the display *;

- for EV-205 it also shows total volume of the DN40 sensor and current flow along the pipeline/

Measuring units m³ and m³ / h blink while the current flow is displayed *;

- mass flow and total mass;

- transducer and medium temperature*;

- medium pressure;*

- instantaneous flow as a percent of maximum flow rate;

- signal values on current(*) and pulse outputs;

- control totals and metrological data;

- current access level;

- service messages.

* - except for special version of transmitter;

Display appearance and operation guide are shown in fig.B.4 and B.5 of the Appendix B.

SI configuration display shows the following information:

- volume flow (under W.C.), and the flow disregarding the temperature, etc.;

- total flow (under W.C.), and the flow disregarding the temperature, etc.;

- resettable volume totalizer (under W.C.);

- for EV-205 it also shows volume flow and total flow via DN40 sensor and current flow along the

pipeline; - sensor temperature;

- vortex shedding frequency;

signal amplitude in specified units;

- instantaneous flow as a percent of maximum flow rate;

- sensor temperature;

EMIS-VIHR 200

OPERATION MANUAL

www.emis-kip.ru/ru/prod/ev200

19

- signal values on current and pulse outputs;

- pulse value and length;

- flow value corresponding to 4 and 20 mA at the current output and to 1000Hz at the frequency

output; - cut-off value corresponding to the specified signal amplitude;

- other parameters.

1.2.13 Electrical insulation between electrical circuits and transmitter body at ambient temperature of

23±5°Сand relative humidity 30 to 80% withstands 45 to 65 Hz AC sine wave with 500V r.m.s. during 1 minute.

1.2.14 Power supply and consumption

Transmitters of general purpose industrial versions and ex-proof versions shall be connected to

separate 12-27 VDC supply unit. T version with 2-wire connection scheme the power is supplied from the

current loop 4-20mA (see 1.2.10)

Power consumption in steady operation state is shown in the table 1.9.

Table 1.9 - Power consumption

Display version Ex-proof version

Power consumption, W

Flow meter mounting

Basic and

extended

special 2-wire

No

preheating

Preheating

without display no explosion

protection,

Вн, РВ

0.9 1.5 6.1 0.5

SIM display 3.4 4.0 8.7 -

SIO display 3.5 5.3 9.9 -

SI display - - - 0.5

without display

ExB, ExC,

ExiaB, ExiaC,

PBI, PO

0.9 - - 0,5

SIM display 0.9 - - -

SIO display 1.0 - - -

SI display - - - 0,5

Power supply parameters for ex-proof configurations are shown in 1.3 "Explosion protection".

1.2.15 Transducer refers to repairable, single-order devices of II group I type as defined in GOST

27.003. 1.2.16 Dimensions, connection sizes and weight of flow meter are shown in Appendix В.

1.2.17 Pressure drop depends on measuring medium, flow meter size and flow speed. Calculation

formula is shown in 2.1.4.

1.2.18 Transducer reliability parameters:

- mean time before failure shall not be less than 75000 hours and depends on maintenance as specified

in the manual;

- standard deviation of failures not less than 0.15;

- failure rate is normal (Gaussian law)

- mean time to recover for repaired transmitter not exceeds 3 hours;

- service life 15 years.

Transmitter failure means its non-compliance with 1.2.2. requirements

1.2.19. Materials for process-wetted elements of the flow meter are specified in the table 1.10.

EMIS-VIHR 200

OPERATION MANUAL

www.emis-kip.ru/ru/prod/ev200 20

Table 1.10 -List of materials

Version Dn, mm

Pressu

re, Mpa

Tmea

s., °С Materia

l code

Material

Flow tube Bluff body Sensor

Sensor

gasket*

EV-200 C, F,

FR

All 1,6-6,3 ≤ 320 НAISI 304 AISI 304 AISI 304

Fluorine

plastic, graflex

EV-200 C 15-50 10-25 ≤ 320 Н20Х13 12Х18Н10Т

titanium

BT1-0

Copper,

titanium

EV-200 C 65-300 10-25 ≤ 320 Н20Х13 20Х13

titanium

BT1-0

Copper,

titanium

EV-200 F, F1

40-300

1,6-6,3

450

Н

12Х18Н10Т

12Х18Н10Т

EP202

Titanium

EV-200 C1,

F1, FR1

15-50 1,6-6,3 ≤ 320 Н20Х13 12Х18Н10Т

titanium

BT1-0

Copper,

titanium

EV-200 C1,

F1, FR1

65-100 1,6-6,3 ≤ 320 Н20Х13 20Х13

titanium

BT1-0

Copper,

titanium

EV-200 F1 125-300

1,6-6,3 ≤ 320 Н12Х18Н10Т 12Х18Н10Т

titanium

BT1-0

Copper,

titanium

EV-200 F1 15-100 10-16 ≤ 320 Н20Х13 12Х18Н10Т

titanium

BT1-0

Copper,

titanium

EV-200 F1 125-300

10-16 ≤ 320 Н12Х18Н10Т 12Х18Н10Т

titanium

BT1-0

Copper,

titanium

EV200-PPD All All All –20Х13 12Х18Н10Т

titanium

BT1-0

Copper

EV-205 All All All НAISI 304 AISI 304 AISI 304

Fluorine

plastic, graflex

EV-200 All All All HH 12Х18Н10Т 12Х18Н10Т

titanium

BT1-0

Copper,

titanium

EV200-PPD All All All HH 12Х18Н10Т 12Х18Н10Т

titanium

BT1-0

Copper

Note:

1* Fluorine gaskets used for Tmed up to +100°С, graflex gaskets for +250 and +320°С

, copper gaskets up to

+250°С, titanium gaskets for +320 and +450°С;

2 Paronite,TEG or steel gaskets are used to seal the flow meter and pipeline flanges.

3 Flow meter parts can be made of other materials upon the agreement with the customer;

4 The flow tube and the bluff body of the AST version are made of 12Х18Н10Т

steel, the sensor gasket is made

of titanium, electronic boards are additionally coated with AK-113 varnish.

Table of contents

Other EMIS Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Precision Digital Corporation

Precision Digital Corporation PD6907 instruction manual

Fema Electronica

Fema Electronica migan FI user manual

PMK

PMK TETRIS Series instruction manual

Vanguard Instruments

Vanguard Instruments DigiTMR S2 user manual

Sloan

Sloan TruFlush TRF 8156 Repair Parts and Maintenance Guide

Anton

Anton Sprint eVo user manual

Eurotops

Eurotops Ezcap 613P quick start guide

PPS

PPS PPS36 user manual

Nidec

Nidec PG-100B Series instruction manual

Dwyer Instruments

Dwyer Instruments Series 2-5000 Minihelic II Specifications-installation and operating instructions

Knick

Knick Portavo 904X COND user manual

Aczet

Aczet MB 54 operating instructions