EMIS MASS 260 User manual

www.emis-meter.com

EM-260.000.000.000.00 OM

12.11.2021

v1.0.9

CORIOLIS FLOW METER EMIS-

MASS 260

Operation manual

Direct mass flow

measurement

High accuracy

Digital processing of signals

No straight run required

Applicable for high viscous

liquids

EMIS

Russia, Chelyabinsk

EMIS-MASS 260

OPERATION MANUAL

2

General information

This operation manual contains general technical parameters, directions for usage, transportation and

storage, and other information for accurate operation of EMIS-MASS 260 Coriolis mass flow meters (hereinafter

referred to as the flow meter or EM-260)

EMIS CJSC has the right to update the product and documents without prior notice if it does not affect

product performance. For any information about present Operation Manual or other EMIS equipment please

contact your local dealer or EMIS head office.

Any use of the present manual, partial or full, is prohibited without copyright holder permission.

Attention!

Carefully study this Manual before starting operation. Please make sure that you

have carefully read and learned the present manual before installation, operation or

maintenance of the equipment. The above is strictly required to provide safety

operation and equipment efficiency.

Contact your local dealer or our technical service: Company profile

tel/fax: +7 (351) 729-99-12

e-mail: support@emis-kip.ru

Attention!

Present Manual can be applied only for EMIS-MASS 260 flow meters. This

document is not applicable to other equipment of EMIS or other companies.

EMIS-MASS 260

OPERATION MANUAL

3

Contents

1Description and operation ................................................................................................................................5

1.1 Application......................................................................................................................................................5

1.2 Structure and Operation Principle..................................................................................................................6

1.3 Order Sheet....................................................................................................................................................9

1.4 Technical Parameters..................................................................................................................................16

1.4.1 Brief description of technical parameters..............................................................................................16

1.4.2 Measuring ranges..................................................................................................................................17

1.4.3 Pressure configurations.........................................................................................................................21

1.4.4 Accuracy................................................................................................................................................22

1.4.5 Parameters of electrical power supply ..................................................................................................23

1.4.6 Output signals........................................................................................................................................23

1.4.7 Flow meter reliability parameters: .........................................................................................................25

1.5 Pressure loss ...............................................................................................................................................25

1.6 Explosion protection.....................................................................................................................................25

1.7 Marking ........................................................................................................................................................29

1.8 Scope of Supply...........................................................................................................................................30

2 Intended Use ......................................................................................................................................................34

2.1 Configuration selection ................................................................................................................................34

2.2 Safety requirements.....................................................................................................................................34

2.3 Mounting on the pipeline..............................................................................................................................35

2.3.1 Installation options.................................................................................................................................35

2.3.2 Pipeline direction...................................................................................................................................36

2.3.3 Preparation of pipeline ..........................................................................................................................37

2.3.4 Pipe body preparation and flow meter mounting...................................................................................39

2.3.5. Heat insulation......................................................................................................................................41

2.3.6 Preheating.............................................................................................................................................42

2.3.7 Rotation of electronic unit......................................................................................................................42

2.4 Power connection.........................................................................................................................................44

2.4.1 General directions .................................................................................................................................44

2.4.2 Explosion protection while mounting.....................................................................................................45

2.4.3 Connection recommendations...............................................................................................................47

EMIS-MASS 260

OPERATION MANUAL

4

2.4.4 Ingress protection..................................................................................................................................47

2.4.5 Grounding..............................................................................................................................................48

2.5 Operation and maintenance.........................................................................................................................48

2.5.1 General directions .................................................................................................................................48

2.5.2 Flow meter start/stop.............................................................................................................................48

2.5.3 Zero point adjustment............................................................................................................................48

2.5.4 Flow meter cleaning ..............................................................................................................................48

3 Transportation, Storage and Recycling..............................................................................................................50

3.1 Transportation.............................................................................................................................................50

3.2 Storage.........................................................................................................................................................50

3.3 Recycling......................................................................................................................................................51

4 Calibration...........................................................................................................................................................52

5 List of possible failures .......................................................................................................................................53

5.1 List of possible failures (including critical)....................................................................................................53

5.2 Personell mistakes leading to failure, emergency or accidents...................................................................53

Personnel emergency response ........................................................................................................................53

5.4 КLimit state criteria .......................................................................................................................................53

Appendix A ............................................................................................................................................................54

Appendix B ............................................................................................................................................................68

Appendix C ............................................................................................................................................................69

EMIS-MASS 260

OPERATION MANUAL

5

1 Description and operation

1.1 Application

The flow meter EMIS-MASS 260 is designed to measure the mass flow rate, weight, temperature,

density, volume flow, volume of liquids and gas.

The flow meter is used as a meter for gasoline, liquefied gas, kerosene, diesel fuel, oil, oil with water,

fuel oil, other liquids and corrosive media under operating pressure and working temperature at chemical,

petrochemical, oil, food, pharmaceutical and other industries and public utilities.

Flow meters are installed in automatic control, adjustment and operation systems and used at variable

industries, stationary plants and

ground-based mobile refueling and transfer facilities, commercial accounting systems.

Flow meters can be used for both standard and explosive environments. Ex-proof flow meters EMIS-

MASS 260-Ex are equipped with ex-proof enclosure under GOST IEC 60079-1-2013, intrinsically safe circuit of

"ib" protection level under GOST 31610.11-2014.

The flow meter EMIS-MASS 260 is an indicating device operating under excessive pressure, categories

1 and 2, in accordance with the requirements of TR TS 032/2013 “On safety of equipment operating under

excessive pressure”.

Attention!

The flow meter is not intended for operation at nuclear facilities.

EMIS-MASS 260

OPERATION MANUAL

6

1.2 Structure and Operation Principle

Flow meter consists of the following assemblies (fig.1.1):

Electronic unit (1).

Sensor (primary transducer) (2).

a)

b)

Fig.1.1 - External view of flow meter

Electronic unit can be mounted integrally with the flow meter (integral version, fig.1.1 a) and separately

from the flow meter (remote version, fig.1.1 b).

The sensor is a measuring chamber with inlet and outlet pipes and flanges for pipeline connection. The

magnetic coil and the magnet induce vibrations on the two U-shaped parallel flow tubes. Electromagnetic coils

with magnets, called detectors, are installed on the flow tubes.

When a measured medium moves through a measuring chamber, a physical phenomenon appears,

known as the Coriolis effect (Figure 1.2). The progressive movement of the medium in the oscillating flow tube

leads to the occurrence of Coriolis acceleration, which, in turn, leads to the appearance of Coriolis force. This

force is directed against the motion of the tube imparted to it by the driver coil, i.e. when the tube moves up

during the half of its own cycle, the Coriolis force is directed downward for the fluid flowing inward. As the fluid

passes through the bend of the tube, the direction of the force changes to the opposite Having been forced

upward, the liquid flowing out of the sensor resists having its vertical motion decreased by pushing up on the

tube. This action causes the tube to twist. When the tube is moving downward during the second half of its

vibration cycle, it twists in the opposite direction.

1

2

EMIS-MASS 260

OPERATION MANUAL

7

a)

b)

b)

Fig.1.2 - The forces affecting the tube during the vertical movement

Fig.1.2: a) flow meter without power supply; b) power supplied, the coil cause the vibration in the

measuring tubes; c) flow supply, generation of Coriolis effect.

Coriolis force and the amount of twist is directly proportional to the mass flow rate. The detectors

measure the phase shift when the opposite sides of the flow tubes move, and as a result, out of phase signals

are generated. Mass flow rate Q is proportional to time delay Δt .

, kg/h

(1.1)

where K is a calibration coefficient g/s/µs

Δt - time delay between the signals from the coils, µs

The density of the medium being measured is determined by measuring the period of oscillation of the

flow tubes, which is proportional to the density of the medium. While calibrating the density measuring channel

for two different fluids with known (measured with density meter) density (air and water) the period of oscillation

of the flow tubes corresponding to this density shall be measured. Medium density and oscillation period shall

be specified via the transmitter display or digital interface. Due to the linear dependence based on the period of

oscillation of the flow tubes we can calculate the density of the medium.

The integrated platinum sensor Pt100 measures the temperature. Measured temperature is used for

automatic correction of the flow rate and density related to the temperature changes. Temperature correction

coefficients for the flow rate and density are set as default at the plant and can be adjusted through the display

menu.

The flow rate can be manually corrected depending on the pressure changes. In correction mode the

electronic unit adjust the current flow of medium according to the working pressure inside the pipe. Pressure

can be adjusted by inputting directly in the electronic unit or connecting to pressure gauge. Communication with

external pressure gauge is performed via Modbus.

EMIS-MASS 260

OPERATION MANUAL

8

The sensor forms the primary signal containing the data on the time delay between the sensors. The

primary signal is transmitted to the electronic unit mounted integrally with the flow meter or remotely.

The electronic unit processes the primary signal, calculates mass and volume flow, temperature

compensation, forms output signals and show these info on the display. There are two version of the electronic

unit: standard and extended. Detailed description of each type is presented in the Operation manuals EM-

260.000.000.002.01 or EM-260.000.000.000.01. Operation manuals can be found in the website www.emis-

kip.ru/ru/books1 in the related section EMIS-MASS 260.

Measurement advantages:

•direct measurement of mass flow rate in the pipeline without changes in parameters

leading to further inaccuracy.

•high precision and stability for a long time;

•measurement of highly viscous fluids, non Newtonian fluids, fluids with solid and gas

inclusions;

•no moving parts (small oscillation amplitude can be ignored) and wearing parts which

extend the service life of the flow meter;

•no barrier for the flow path inside the tubes;

•temperature and density measurement;

•no straight pipes before/after the flow meter or the flow conditioner are required.

Vertical and horizontal installation at different angles to the flow body.

EMIS-MASS 260

OPERATION MANUAL

9

1.3 Order Sheet

EMIS-MASS 260 order sheet is presented in the Table 1.1.

Example of the completed order sheet:

EMIS-МАСС-260 –Ex –050K –И –Ж –2,5 –100 –24 –А1 – 0,25 –1,0 –1,0 –У –SC –Е –GOST

Table 1.1 - Flow meter configurations

1

Explosion protection

–

No explosion protection (standard version)

Ex

Ex-proof marking:

Flow meter: 1Ех ib IIC Т6…T1 Gb X; 0Ех ia IIC Т6…T1 Ga X1);

Electronic unit: 1Ех db [ib] IIС Т6 Gb X; 1Ех db [ia Ga] IIС Т6 Gb X1);

Amplifier: 1Ех db [ib] IIС Т6 Gb X (amplifier is used for Dn≥100 with electronic unit of standard

and extended versions).

ExBB2)

Ex-proof marking:

Flow meter: 0Ех ia IIC Т6…T1 Ga X;

Electronic unit: 1Ех db [ia Ga] IIС Т6 Gb X.

RV3)

Ex-proof marking:

Flow meter: RV Ex d ia I Mb X;

Electronic unit: RV Ex db [ib] I Mb X;

Terminal block: РВ Ex db I Mb X4);

Additional terminal box: РВ Ex ib I Mb X4).

RO-RV5)

Ex-proof marking:

Flow meter: РО Ex ia I Ma X;

Electronic unit: РВ Ex db [ia Ma] I Mb X;

Terminal block: РВ Ex db I Mb X;

Additional terminal box: РО Ex ia I Ma X.

RO-RVBB2)5)

Ex-proof marking:

Flow meter: РО Ex ia I Ma X;

Electronic unit: РВ Ex db [ia Ma] I Mb X;

Terminal block: РВ Ex db I Mb X;

Additional terminal box: РО Ex ia I Ma X.

1) –Marking is applied to flow meter with extended electronic unit;

2) –Consider electrical parameters for this configuration, which are described in the clause 1.6 Explosion

protection, it is equipped with special version of electronic unit only.

3) –Configuration is equipped with electronic unit of standard or extended version.

4) –Terminal box and additional terminal boxes applied to the remote type flow meters;

5) –Available with special version electronic unit only.

2

Flow tube diameter

010

Dn 10

080

Dn 80

015

Dn 15

100

Dn 100

025

Dn 25

150

Dn 150

040

Dn 40

200

Dn 200

050

Dn 50

3

Body type

–

Standard U-shaped

C

Compact

EMIS-MASS 260

OPERATION MANUAL

10

Х

Special config.

4

Flow meter mounting

I

Integral version - sensor and transmitter as integral assembly

R

remote installation with cable length of 3m

RXX

Remote version with cable length of XXm. Max length - 100m1)

1) –for ex-proof configuration - 50m

5

Calibration

L

Liquid calibration

G

Gas calibration, additional liquid calibration

6

Flow tube material

–

Stainless steel (standard configuration)

X

by order

7

Medium pressure

1.61

max pressure - 1.6 MPa

2.51

max pressure - 2.5 MPa

4.0

max pressure - 4.0 MPa

6.3

max pressure - 6.3 MPa

10

max pressure - 10 MPa

16

max pressure - 16 MPa

25

max pressure - 25 MPa

1) Flow meters for 1.6 and 2.5 pressure are equipped with 4.0Mpa flanges.

8

Medium temperature

75

measuring medium temperature from -60 to +75 °С

95

measuring medium temperature from -60 to +95 °С

100

measuring medium temperature from -60 to +100 °С

135

measuring medium temperature from -60 to +135 °С (remote type only)

200

measuring medium temperature from -60 to +200 °С (remote type only)

9

Power supply

24

24V DC

220

220V AC

10

Output signals

Standard electronic unit

–

digital RS-485 + pulse output signal (active)

A

digital RS-485 + pulse output signal (active)+ current output signal 4-20mA (active)

A1

digital RS-485 + pulse output signal (active)+ current output signal 4-20mA (passive)

EMIS-MASS 260

OPERATION MANUAL

11

A2

digital RS-485 + pulse output signal (passive)+ current output signal 4-20mA (active)

A3

digital RS-485 + pulse output signal (passive)+ current output signal 4-20mA (passive)

TA

digital RS-485 + pulse output signal (active)+ current output signal 4-20mA with digital HART

(passive)

Н

digital RS-485 + pulse output signal (active)+ current output signal 4-20mA with digital HART

(passive)

Н1

digital RS-485 + pulse output signal (passive)+ current output signal 4-20mA with digital HART

(active)

Н2

digital RS-485 + pulse output signal (passive)+ current output signal 4-20mA with digital HART

(active)

Н3

digital RS-485 + pulse output signal (passive)+ current output signal 4-20mA with digital HART

(active)

TH

RS-485 + current output signal 4-20mA with digital HART (active) + current output 4-20mA

(active)

ТН1

RS-485 + current output signal 4-20mA with digital HART (passive) + current output 4-20mA

(passive)

F

digital RS-485 + pulse output signal (active) + pulse output signal (active)

F1

digital RS-485 + pulse output signal (passive) + pulse output signal (passive)

F2

digital RS-485 + pulse output signal (passive)

Extended electronic unit

–

digital RS-485 + pulse output signal (active)

A1

digital RS-485 + pulse output signal (active)+ current output signal 4-20mA (passive)

A3

digital RS-485 + pulse output signal (passive)+ current output signal 4-20mA (passive)

TA

digital RS-485 + pulse output signal (active)+ current output signal 4-20mA with digital HART

(passive) without additional error

THF

digital RS-485 + current output signal 4-20mA (passive) with digital HART + current output

signal 4-20mA (passive) + pulse output signal (switchable active/passive)

TTF

digital RS-485 + current output signal 4-20mA (passive)+ current output signal 4-20mA

(passive) + current output signal (switchable active/passive)

Special version electronic unit

F2

digital RS-485 + pulse output signal (passive)

11

Accuracy

0.1

Accuracy class 0.1

0.15

Accuracy class 0.15

0.2

Accuracy class 0.2

0.25

Accuracy class 0.25

0.5

Accuracy class 0.5

12

Density measuring error1)

1.0

Error for liquid and gas ±1,0 kg/m3

0,32)

Error for liquid ±0,3 kg/m3

0,52)

Error for liquid ±0,5 kg/m3

2.0

Error for liquid and gas ±2,0 kg/m3

EMIS-MASS 260

OPERATION MANUAL

12

5.0

Error for liquid and gas ±5,0 kg/m3

10.0

Error for liquid and gas ±10,0 kg/m3

1) After simulation test density measurement error is ±20,0 kg/m3.

2) Upon prior agreement, for liquid only.

13

Temperature error

1.0

Standard error ±1,0°С

0,51)

Error ±0,5°С

1) Upon prior agreement.

14

Electronic unit version1)

–

Standard version

U

Extended version2)

UIP

Extended version, simulation test function2)

S

Special version

SIP

Special version, simulation test function2)

1) –For flow meters with electronic unit of “-”, “У” and “С” versions only flow calibration is available for

periodical testing. For flow meters with electronic unit of “УИП” and “СИП” versions flow calibration and

simulation test are available for periodical testing.

2) –Amount of output pulse signals can be increased to 3 upon special request.

15

Display

-

LED display

ND

No LED display

1) Version without display is available for electronic unit of “C” and “СИП” versions.

16

Configuration1)

-

Standard version

FR

Flanged connection with reducers

1) –Use table 1.4 and 1.5 to choose the configuration.

17

Calibration

–

manufacturer calibration

SC

state calibration

18

Register map

–

ЭМИС register map

P

ProLink registry map

19

Sealing surface

B

Flange connection, flange face - type B “Raised face” under GOST 33259

B1

Flange connection, flange face - type B1 Raised face under EN 1092-1

C

Flange connection, flange face - type C Male under GOST 33259 or EN 1092-1

D

Flange connection, flange face - type D Female under GOST 33259 or EN 1092-1

E

Flange connection, flange face - type E Raised face under GOST 33259 (standard) or EN

1092-1

EMIS-MASS 260

OPERATION MANUAL

13

F

Flange connection, flange face - type F Female under GOST 33259 or EN 1092-1

J

Flange connection, flange face - J type Oval gasket under GOST 33259 (standard version 10-

25 MPa)

RF

Flange connection, flange face - RF type Raised face under ASME B16.5

RTJ

Flange connection, flange face - RTJ type Oval gasket under ASME B16.5

S

socket (for flow meters up to 4MPa connection according to DIN11851)

X

customized (various connection types under GOST, EN, ASME; please specify)

20

Flange standards

GOST

GOST 33259

EN

EN 1092-1

ASME

ASME (ANSI) B16.5

DIN

GOST 11851

21

Industrial versions

-

standard version

AST

for environments containing hydrogen sulfide

Hyd

for hydrogen, hydrogen-containing gases

22

Installation length

-

Standard version (length according to the Appendix A)

Х

Upon request (installation length shall not be shorter than specified in the Appendix A)

23

Heating jacket

-

standard version

J

With heating jacket (for compact versions)

Mounting kit parts are listed in the table 1.2.

Example of the completed order sheet:

Mounting kit EMIS - MASS 260 050 - 2.5 - 11 - F - GOST - 09G2S

Table 1.2 - Mounting kit versions

1

Flow tube diameter

010

Dn 10

080

Dn 80

015

Dn 15

100

Dn 100

025

Dn 25

150

Dn 150

040

Dn 40

200

Dn 200

050

Dn 50

X

by order

2

Medium pressure

1.6

max pressure - 1,6 MPa

10

max pressure - 10 MPa

EMIS-MASS 260

OPERATION MANUAL

14

2.5

max pressure - 2,5 MPa

16

max pressure - 16 MPa

4.0

max pressure - 4,0 MPa

25

max pressure - 25 MPa

6.3

max pressure - 6,3 MPa

3

Flange type

01

Flat flange

11

Weld neck flange

4

Sealing surface

B

Flange connection, flange face - type B “Raised face” under GOST 33259

B1

Flange connection, flange face - type B1 Raised face under EN 1092-1

C

Flange connection, flange face - type C Male under GOST 33259 or

EN 1092-1

D

Flange connection, flange face - type D Female under GOST 33259 or

EN 1092-1

E

Flange connection, flange face - type E Male under GOST 33259 or

EN 1092-1-2007

F

Flange connection, flange face - type F Female under GOST 33259 or EN 1092-1

J

Flange connection, flange face - type J Oval gasket under GOST 33259

RF

Flange connection, flange face - RF type Raised face under ASME B16.5

RTJ

Flange connection, flange face - RTJ type Oval gasket under ASME B16.5

S

socket (for flow meters up to 4MPa connection according to DIN11851)

X

customized (various connection types under GOST, EN, ASME; please specify)

5

Flange standards

GOST

GOST 33259

EN

EN 1092-1

ASME

ASME (ANSI) B16.5

Х

by order

6

Flange material

EMIS-MASS 260

OPERATION MANUAL

15

09G2С

Steel 09G2S

Ст20

Steel 20

Н

Stainless steel 12Х18Н10Т

13ХFА

Steel 13ХFА

Х

by order

EMIS-MASS 260

OPERATION MANUAL

16

1.4 Technical Parameters

1.4.1 Brief description of technical parameters

Brief description of technical parameters is shown in Table 1.3

Table 1.3 - Technical parameters of flow meter

Name

Description

Dn, mm

10; 15; 25; 40; 50; 80; 100; 150; 200

Accuracy

0,1; 0,15; 0,2; 0,25; 0,5

Excessive pressure of medium, MPa

1,6; 2,5; 4,0; 6,3; 10; 16; 25

(see table 1.6 and 1.7)

Temperature range, ºС

From -60 to +200ºС

Explosion protection

Version

Marking

Ex

Ex-proof marking:

Flow meter: 1Ех ib IIC Т6…T1 Gb X; 0Ех ia IIC Т6…T1

Ga X;

Electronic unit: 1Ех db [ib] IIС Т6 Gb X; 1Ех db [ia Ga]

IIС Т6 Gb X;

Amplifier: 1Ех db [ib] IIС Т6 Gb X.

ExBB

Ex-proof marking:

Flow meter: 0Ех ia IIC Т6…T1 Ga X;

Electronic unit: 1Ех db [ia Ga] IIС Т6 Gb X.

RV

Ex-proof marking:

Flow meter: RV Ex d ia I Mb X;

Electronic unit: RV Ex db [ib] I Mb X;

Terminal block: RV Ex db I Mb X;

Additional terminal box: RV Ex ib I Mb X.

RO-RV

Ex-proof marking:

Flow meter: РО Ex ia I Ma X;

Electronic unit: RV Ex db [ia Ma] I Mb X;

Terminal block: RV Ex db I Mb X;

Additional terminal box: РО Ex ia I Ma X.

RO-RVBB

Ex-proof marking:

Flow meter: РО Ex ia I Ma X;

Electronic unit: RV Ex db [ia Ma] I Mb X;

Terminal block: RV Ex db I Mb X;

Additional terminal box: РО Ex ia I Ma X.

Atmospheric pressure, kPa

84.0 to 106.7

Ambient temperature, °С

From -60 to +70ºС

Relative humidity, % less than

90 ± 3 % (non-condensing under 25ºС)

Magnetic field resistance

up to 40 A/m, 50Hz

Vibration resistance

From 10 to 150Hz with acceleration not exceeding 9.8 m/s2, V1 group

under GOST 52931-2008.

From 5 to 2000Hz with acceleration not exceeding 49 m/s2, G1 group

EMIS-MASS 260

OPERATION MANUAL

17

under GOST R 52931-2008 upon prior agreement.

Dust and water protection

IP66 / IP67

Calibration interval

5 years

Temperature gauge

Pt100

Service life

over 20 years

Dimensions and weight

see Appendix A

Materials

Flow meter body - stainless steel AISI 304.

Flow meter casing - stainless steel AISI 304.

Sensor tubes - stainless steel AISI 316L.

Electronic unit - aluminum alloy

Does not contain precious metals.

* Upon prior agreement with EMIS engineering service.

Note: You can customize flow meter parameters according your specific demands.

1.4.2 Measuring ranges

Flow meter provides mass flow measurement with accuracy of δml, which is numerically equal to the

accuracy class in the flow range from Qmin to Qmax according to the table 1.4.

When measuring flow of liquid, flow meter performance is provided within the flow ranges from Qmin to

Qmax according to the table 1.4.1.

In the range from Qmin to Qmax as specified in the table 1.5, flow meter provides gas measurement

accuracy of δmg, %:

δmg = Кt+0.25,

(1.2)

Where Kt - flow meter accuracy class according to the order sheet.

When measuring gas flow, flow meter performance is provided within the flow ranges from Qmin to

Qmax according to the table 1.5.

Flow meter is designed for measure of single-phase mediums (liquid or gas).

Qmin depends on the medium parameters and shall be specified in the order sheer.

Table 1.4.1 - Mass flow rate measuring ranges for liquid

Dn

Configuration

Qmin,

kg/h

Qmin, kg/h

**Qmax,

kg/h

Zero stability,

kg/h

Accuracy class

0.1; 0.15; 0.2;

0,25 и 0,5

10

-

10

–

50*

1,100

0.04

15

FR

10

–

50*

1,100

0.04

15C

-

10

200

150

3,000

0.2

EMIS-MASS 260

OPERATION MANUAL

18

25C

FR

10

200

150

3,000

0.2

25C

-

30

600

400

9,000

0.6

25

-

40

600

300

10,000

0.4

40C

FR

30

600

400

9,000

0.6

40

FR

40

600

300

10,000

0.4

40C

-

180

3,600

2,400

25,000

3.6

40

-

160

2,200

1,500

35,000

1.28

50

FR

160

2,200

1,500

35,000

1.28

50C

FR

180

3,600

2,400

25,000

3.6

50К

-

250

5,000

3,500

50,000

5

50

-

250

3,500

2,500

55,000

2

80

FR

250

3,500

2,500

55,000

2

80C

FR

250

5,000

3,500

50,000

5

80К

-

600

12,000

8,000

140,000

12

80

-

700

9,500

6,000

200,000

6

100

FR

700

9,500

6,000

200,000

6

100C

FR

600

12,000

8,000

140,000

12

100C

-

1,000

20,000

15,000

240,000

20

100

-

1,000

15,000

10,000

430,000

8

150

FR

1,000

15,000

10,000

430,000

8

150C

FR

1,000

20,000

15,000

240,000

20

150C

-

2,500

50,000

35,000

430,000

50

150

-

2,500

35,000

25,000

500,000

20

200C

-

5,000

100,000

70,000

1,000,000

100

* For flow meters of Dn10 0.5 accuracy can be provided.

** Qmax - flow complies with the pressure drop of 1bar when measuring flow of liquid at 20°C.

EMIS-MASS 260

OPERATION MANUAL

19

Table 1.4.2 - Extended liquid flow ranges

Dn

Configuration

Qmin,

kg/h

Qmin, kg/h

**Qmax,

kg/h

Zero stability,

kg/h

Accuracy class

0.1; 0.15; 0.2;

0,25 и 0,5

10

-

10

–

50*

1,600

0.04

15

FR

10

–

50*

1,600

0.04

15C

-

10

200

150

4,600

0.2

25C

FR

10

200

150

4,600

0.2

25C

-

30

600

400

14,000

0.6

25

-

40

600

300

14,000

0.4

40C

FR

30

600

400

14,000

0.6

40

FR

40

600

300

14,000

0.4

40C

-

180

3,600

2,400

34,000

3.6

40

-

160

2,200

1,500

51,000

1.28

50

FR

160

2,200

1,500

51,000

1.28

50C

FR

180

3,600

2,400

34,000

3.6

50C

-

250

5,000

3,500

64,000

5

50

-

250

3,500

2,500

77,000

2

80

FR

250

3,500

2,500

77,000

2

80C

FR

250

5,000

3,500

64,000

5

80C

-

600

12,000

8,000

188,000

12

80

-

700

9,500

6,000

288,000

6

100

FR

700

9,500

6,000

288,000

6

100C

FR

600

12,000

8,000

188,000

12

100C

-

1,000

20,000

15,000

375,000

20

100

-

1,000

15,000

10,000

550,000

8

150

FR

1,000

15,000

10,000

550,000

8

150C

FR

1,000

20,000

15,000

375,000

20

150C

-

2,500

50,000

35,000

574,000

50

150

-

2,500

35,000

25,000

900,000

20

200C

-

5,000

100,000

70,000

1,000,000

100

* For flow meters of Dn10 0.5 accuracy can be provided.

** Qmax - flow complies with the pressure drop of 2bars when measuring flow of liquid at 20°C.

EMIS-MASS 260

OPERATION MANUAL

20

Table 1.5 - Mass flow rate measuring ranges for gas

Dn

Configuration

Qmin,

kg/h

Qmin, kg/h

**Q(mg)max

, kg/h

Zero stability,

kg/h

Accuracy class

0.1, 0.15, 0.2

0,25 и 0,5

10

-

10

–

50*

15.7∙ρg

0.04

15

FR

10

–

50*

15.7∙ρg

0.04

15C

-

10

200

150

42.9∙ρg

0.2

25C

FR

10

200

150

42.9∙ρg

0.2

25C

-

30

600

400

128.6∙ρg

0.6

25

-

40

600

300

142.8∙ρg

0.4

40C

FR

30

600

400

128.6∙ρg

0.6

40

FR

40

600

300

142.8∙ρg

0.4

40C

-

180

3,600

2,400

357.1∙ρg

3.6

40

-

160

2,200

1,500

500∙ρg

1.28

50

FR

160

2,200

1,500

500∙ρg

1.28

50C

FR

180

3,600

2,400

357.1∙ρg

3.6

50C

-

250

5,000

3,500

714.3∙ρg

5

50

-

250

3,500

2,500

785.7∙ρg

2

80

FR

250

3,500

2,500

785.7∙ρg

2

80C

FR

250

5,000

3,500

714.3∙ρg

5

80C

-

600

12,000

8,000

2,000∙ρg

12

80

-

700

9,500

6,000

2,857.1∙ρg

6

100

FR

700

9,500

6,000

2,857.1∙ρg

6

100C

FR

600

12,000

8,000

2,000∙ρg

12

100C

-

1,000

20,000

15,000

3,428.6∙ρg

20

100

-

1,000

15,000

10,000

6,142.9∙ρg

8

150

FR

1,000

15,000

10,000

6,142.9∙ρg

8

150C

FR

1,000

20,000

15,000

3,428.6∙ρg

20

150C

-

2,500

50,000

35,000

6,142.9∙ρg

50

150

-

2,500

35,000

25,000

7,142.9∙ρg

20

200C

-

5,000

100,000

70,000

14,285.7∙ρg

100

* For flow meters of Dn10 0.5 accuracy can be provided.

Maximum gas flow can be calculated using the formula Q(mg)max =(Qmax∙ρg)/ кg

Where ρg–gas density under working conditions, kg/cbm;

Kg- empirical coefficient, Kg= 70 kg/cbm;

Maximum mass flow of gas Q(mg) shall not exceed maximum mass flow of liquid Qmax as specified in the table 1.4.1.

Reduce mass flow to volume flow using the formula below:

Qv= Q/ρ,

(1.3)

Where Q –upper or lower limit of the full range, kg/h.

ρ –is medium density under working conditions, kg/m3;

Manufacturer set up low flow cut-off value as 1% of the maximum value to avoid self running. If

required, it can be decreased locally at the installation site. The low flow cut off value can be changed through

the menu or Modbus.

Flow density range from 1 to 3000 m3/h.

Maximum dynamic viscosity of the medium 1500 mPa * s.

Gas inclusions in liquid shall not exceed 1% of the volume for 0.1%, 0.15%, 0.2%, 0,25% and 3% for

0,5% accuracy flow meters.

Table of contents

Other EMIS Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

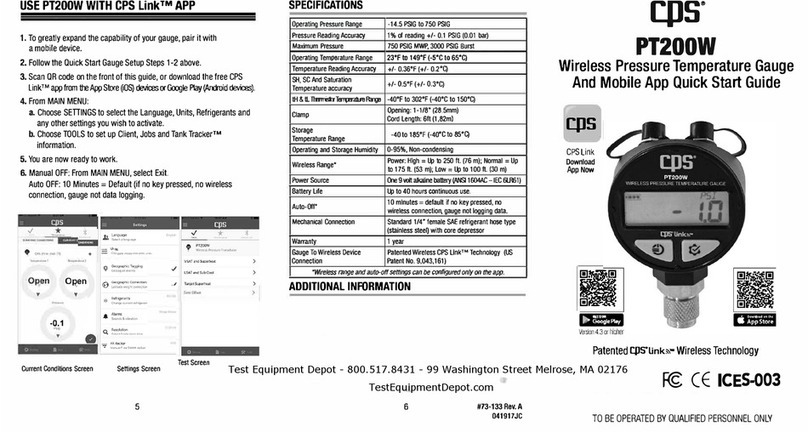

CPS

CPS PT200W quick start guide

TSI Instruments

TSI Instruments 3082 quick start guide

AETOOL

AETOOL BESA 11 quick start guide

Sper scientific

Sper scientific 300005 instruction manual

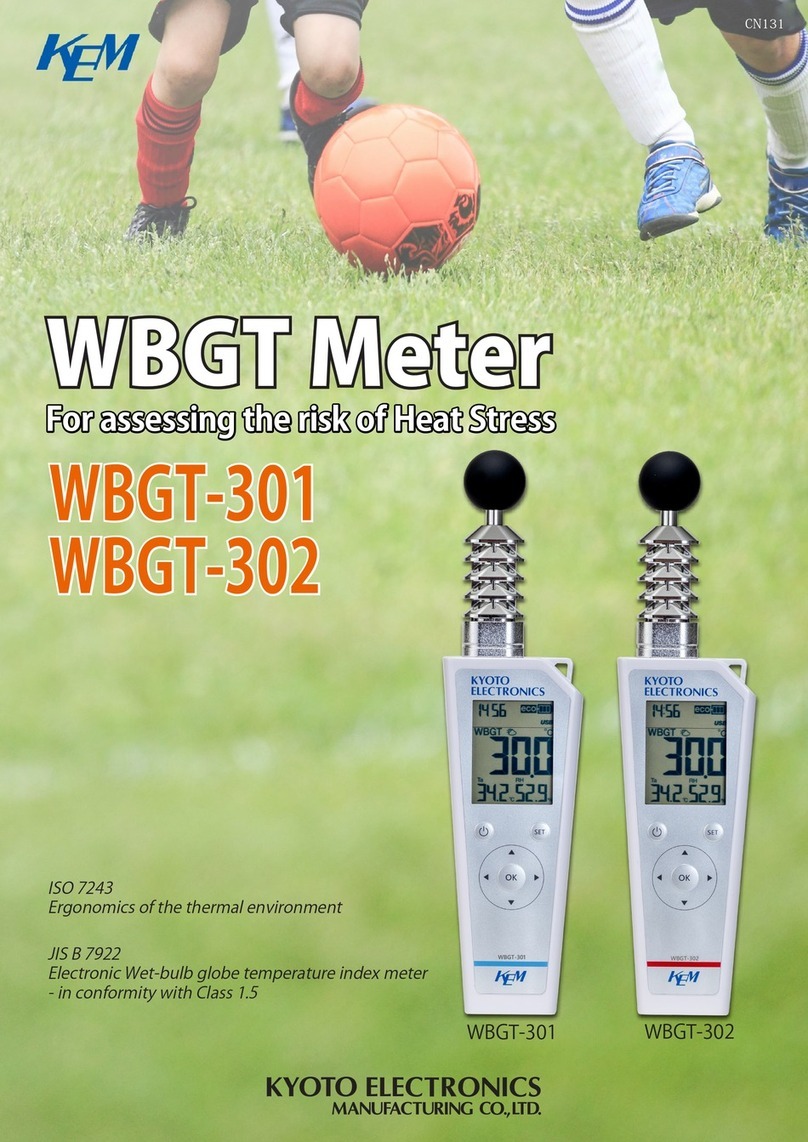

Kyoto Electronics Manufacturing

Kyoto Electronics Manufacturing KEM WBGT Series manual

LI-COR

LI-COR LI-200R installation guide

Leica

Leica 3D Disto user manual

Siemens

Siemens SITRANS F operating instructions

Endress+Hauser

Endress+Hauser Proline Promag W 300 PROFINET operating instructions

Campbell

Campbell CDM-VW300 Series user manual

Vega

Vega VEGAPULS 61 operating instructions

Emerson

Emerson Rosemount 8800D Series Reference manual