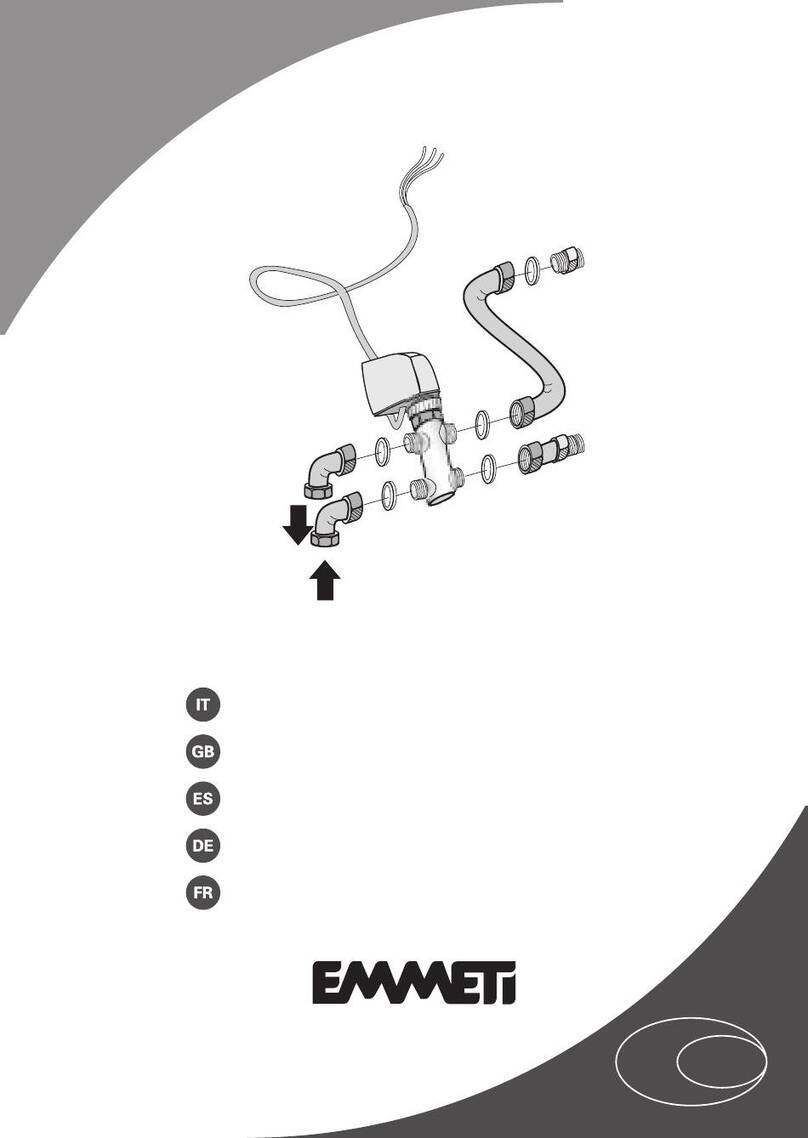

2. Installation

2.4 Bend radius

• Whenformingbendsinthepipepleasereferto

table 3 to obtain the minimum bend radius.

Pipe

dimension

(Ø x S)

Minimum

radius

of bend R

Min. radius

of bend R

with spring

pipe bender

Min.radius

of bend R

with

hydraulic

bender

14 x 2 5 x Ø 3 x Ø

16 x 2 5 x Ø 3 x Ø

20 x 2 5 x Ø 3 x Ø

26 x 3 8 x Ø 4 x Ø 4 x Ø

32 x 3 4 x Ø

40 x 3.5 4 x Ø

50 x 4 4 x Ø

63 x 4.5 4.5 x Ø

R

Ø

S

x

• FortoolingtoformbendsinGerpexpipeplease

refer to our pricelist.

• Itispreferabletousettingsratherthanbendsfor

pipe with greater than 26mm diameter

• Whenbendingpipepleaseavoidplacingany

existingttingsunderunduepressure.Please

refertog2.4whichshowstheminimumdistance

betweenattingandthebeginningofabend.

Minimum distance is 5 x pipe diameter.

2.5 Thermal Expansion

• Duringinstallationpleasepayattentiontothe

thermal expansion characteristics of Gerpex pipe.

The longitudinal expansion of the pipe is affected

by a variation in temperature and can be calculated

using the following data found in table 4 and Fig. 2.5.

Copper

PE-X polyethylene mesh

PP polypropylene

PB polybutylene

Steel

Inox Steel

.

.

.

.

Gerpex

ΔT 10 20 30 40 50 60 70

LΔL

0.1 0.026 0.052 0.078 0.104 0.130 0.156 0.182

0.2 0.052 0.104 0.156 0.208 0.260 0.312 0.364

0.3 0.078 0.156 0.234 0.312 0.390 0.468 0.546

0.4 0.104 0.208 0.312 0.416 0.520 0.624 0.728

0.5 0.130 0.260 0.390 0.520 0.650 0.780 0.910

0.6 0.156 0.312 0.468 0.624 0.780 0.936 1.092

0.7 0.182 0.364 0.546 0.728 1.910 1.092 1.274

0.8 0.208 0.416 0.624 0.832 1.040 1.248 1.456

0.9 0.234 0.468 0.702 0.936 1.170 1.404 1.638

1.0 0.260 0.520 0.780 1.040 1.300 1.560 1.820

2.0 0.520 1.040 1.560 2.080 2.600 3.120 3.640

3.0 0.780 1.560 2.340 3.120 3.900 4.680 5.460

4.0 1.040 2.080 3.120 4.160 5.200 6.240 7.280

5.0 1.300 2.600 3.900 5.200 6.500 7.800 9.100

6.0 1.560 3.120 4.680 6.240 7.800 9.360 10.920

7.0 1.820 3.640 5.460 7.280 9.100 10.920 12.740

8.0 2.080 4.160 6.240 8.830 10.400 12.480 14.560

9.0 2.340 4.680 7.020 9.360 11.700 14.040 16.380

10.0 2.600 5.200 7.800 10.400 13.000 15.600 18.200

In order to calculate the longitudinal expansion please

use the following formula:

ΔL=αxLxΔT

where:

αisthecoefcientoflinearexpansion,equalto0.026

mm/m K for insulated pipes;

Listheinitiallengthofthepipe(m);

ΔTisthetemperaturedifference(K).

Example:

Length of pipe: 12 m

Temperature difference: 50 K

ΔL=0.026x12x50=15.6mm

Fig 2.4

Table 3

Table 4

Fig 2.5