Emotiontek MCU 2 Axis User manual

User’s Manual (2 AXES)

MOTION CONTROLLER MCU

User Manual

( MCU 2Axes Series )

V1.1

Special Note

zThis document is subject to change without prior notice.

zPlease contact us if you find something missing or incorrect in this document.

zYou will get a refund or exchange if there is incorrect collating or missing page.

Emotiontek

M

MC

CU

U

2

2

A

Ax

xi

is

s

C

Co

on

nt

tr

ro

ol

ll

le

er

r

U

Us

se

er

r

M

Ma

an

nu

ua

al

l

1206 Byuksan Digital Valley 5 Cha, 244, Beotkkot-ro Geumcheon-gu, Seoul

Tel : 82-2-2082-5790

Fax: 82-2-2082-4466

http://www.emotiontek.com

MOTION CONTROLLER MCU

(Make sure to read before use)

Be sure to read this document and all relevant auxiliary documents and get familiar with operational guidelines

regarding installation, operation, maintenance and inspection for a proper use of this controller. Don’t forget to

read and familiarize yourself with details on the equipment, safety information and precautions before

proceeding to use it.

This Instruction Manual has used marks, [Danger] and [Warning] to indicate safety warning and precautions

depending on the severity.

Danger:Ifhandledimproperly,theequipmentmaycausesevere

consequences such as personal injury or even death

Warning: If handled improperly, the equipment may cause serious/slight

personal injury or physical damage.

In addition, the events classified into Attention may lead to critical consequences. Therefore, it is required to take

extra care to preserve the instruction manual that comes with the product so that you can read it whenever it is

needed and to make sure to have it delivered to end users.

Safety Precautions

MOTION CONTROLLER MCU

Design Precautions

Danger Reference

Page

Install the safety circuit in this controller so that the equipment can operate in safe

mode when unplanned events such as faulty external power or outage of

controller.

The current for input/output power of this controller is limited.

zIf there is an overload caused by an external source a voltage drop

automatically occurs and the entry of I/O does not work while all outputs

are turned off.

Therefore, it is recommended to design external circuit or apparatus to

make the equipment operate in safe mode.

If there is a faulty output transistor, the output may keep remaining either on or

off. Therefore, when it comes to the output signal which may lead to serious

accidents, design an external circuit or apparatus in order to make the equipment

operate in safe mode.

The IMPULSE noise stems from the power and if the level of noise measured on

the power unit does not meet the requirements of this controller or if there is

noise excessive enough to distort the input voltage waveform, it is required to

install a noise filter or an isolated power transformer on the power input.

If there is a frequent occurrence of short interruption or the equipment is subject

to an unstable power environment it is necessary to use UPS orAVR to stabilize

power supply for the controller.

Warning Reference

Page

Make sure to use the product in a general environment described in manual.

Do not use the product in an environment subject to dust, soot, conductive dust,

corrosive gas, flammable gas, high temperature, condensation, rainstorm,

vibration and shock.

zHarsh conditions described above may cause a variety of negative side

effects, including electric shock, fire , malfunction, product damage or

blazing flame.

Take extra cautions not to let foreign particles or cable debris slip into the

ventilating window of the product when conducting hole machining or wiring

work.

zIt may cause fire, breakdown or malfunction.

Make sure to completely mount connection cable or memory cassette onto the

designated connector.

MOTION CONTROLLER MCU

zPoor connection may cause malfunction.

It is required to install a anti-dust filter if the product is used in a dusty

environment.

Clean the filter using a vacuum cleaner once every month.

Wiring Works

Danger Reference

Page

Make sure to cut off the external power supply before conducting installation,

wiring work etc.

zOtherwise, electric shock or product damage may be incurred.

Make sure to put the terminal cover on the product prior to power supply and

operation upon completion of installation and wiring work. .

zOtherwise, electric shock may be incurred.

Warning Reference

Page

DC power supply of this controller must be connected to the dedicated terminal

as described in the manual.

zIf you mistakenly connect AC power supply into the DC input/output

terminal or input power supply, the MC parts and components may be burnt.

zGetting an external power supply for this controller may cause product

damage.

Make sure to apply type-3 earth grounding on the ground terminal of the

controller using cable longer than 2m.

Do not apply the common earthing under strong electric field.

The input/output signal or telecommunication lines should be installed at

least 100mm away from the high voltage lines or power lines.

Otherwise, incorrect output or malfunction may be incurred.

MOTION CONTROLLER MCU

Precautions in startup and maintenance

Danger Reference

Page

Do not touch the terminal while power supply is plugged in.

You may get electric shock or cause malfunction.

Turn the power off before cleaning or tightening the terminal further.

You may get electric shock, otherwise.

Do not recharge, disassemble, apply heat, put it in fire or perform short-circuit.

It may lead to burst or outbreak of fire.

Make sure to read the manual carefully before you modify the program while in

operation, perform forceful output, or manipulate the controller using various

functions such as RUN or STOP.

Incorrect handling of the product may cause product damage or unplanned

events.

Make sure to get your body earthed if you need to open the controller cover and

touch the inside to prevent static from flowing into the controller.

Warning Reference

Page

Make sure to turn the power off before you detach or attach the controller

memory.

zDetaching it while power supply is connected may cause damage on

controller or memory.

Do not disassemble or remodel the product.

It may cause breakdown, malfunction, or even fire.

Contact the nearest customer care center or sales agency for after-sales services.

Make sure to turn the power off before you detach or attach additional connection

cables.

zOtherwise, breakdown or malfunction may be incurred.

Disposal

Warning Reference

Page

Treat the product as industrial waste when you throw it away.

MOTION CONTROLLER MCU

I. Installation Considerations

①Place the product at least 100mm away from the wall to ensure easy accessibility for

maintenance and ventilation.

②Do not install it in the following installation environment.

-Places with the surrounding temperature beyond the range between 0 and 50℃or

operating panel where high-voltage equipment is installed.

-Places with a strong and direct shock to the main body on a constant basis.

II. Power Wiring

① The input power supply is DC24V (allowable range 24V +/ 10%).

② It is recommended to install a separate captive power supply equipment if the product is

installed in an environment with a frequent change in voltage.

③ Anti-noise measures such as filter installation should be taken against power supply with

excessive noise.

④ Separate the power supply of the main body from the input/output lines of PLC, and power

supply lines from the system.

⑤ The telecommunication input/output lines must be installed separately from the power

supply lines.

III. Grounding

① Apply the dedicated grounding. Conduct type-3 grounding work as illustrated in the

picture below with the grounding cable 2㎟or longer.

② Place the grounding point near the main body and make the length of grounding cable

short.

Con t rol l er

The3rd T

y

p

e Wire

A

)

Excl usi ve Ear th : The best

Anot her Devi ce

Controller

Anot her Devi ce Controller

Anot her Devi ce

B) Excl usi ve Ear th :Good C) Excl usi ve Ear th : Bad

The3rd T

y

p

e Wire The3rd T

y

p

e Wire

[Figure. Grounding methods]

Installation Guideline

Controll

er Controll

er Controll

er

Others Others

Others

Type-3 Grounding Type-3 Grounding Type-3 Grounding

Exclusive Grounding: Exclusive Grounding:

Good Exclusive Grounding:

Bad

- 1 -

Table of Contents

Table of Contents

Chapter 1. About the Product………………………………………………………

3

Chapter 2. Programming

2.1 Types of MC program commands, variables and contacts usable………

2.2 MC program command details……………………………………………………………

2.3 MC program variable details…………………………………………………………

7

12

47

Chapter 3. Homing

3.1 Homing …………………………………………………………………………………………

3.2 Homing parameters…………………………………………………………………………

3.3 Execution of homing ……………………………………………………………………

3.4 Example of a homing………………………………………………………………………

51

51

52

56

Chapter 4. PLC Program

4.1 Types of PLC commands……………………………………………………………………

4.2 Types of application commands related to PLC contacts and motion

4.3 Description of PLC commands…………………………………………………………

4.4 Description of application commands related to PLC contacts………

4.5 Description of PLC motion related application commands………………

57

58

60

69

78

Chapter 5. Parameters

5.1 Types of parameters ………………………………………………………………………

5.2 Description of parameters ……………………………………………………………

103

104

Chapter 6. Connection

6.1 MCU-X………………………………………………………………………………………………

6.2 MCU-A2……………………………………………………………………………………………

6.3 MCU-P2……………………………………………………………………………………………

6.4 MCU-L………………………………………………………………………………………………

6.5 MCU-E………………………………………………………………………………………………

6.6 Wiring diagram………………………………………………………………………………

6.7 External appearance diagram…………………………………………………………

115

116

119

122

124

126

132

- 2 -

Table of Contents

Chapter 7. Operation

7.1 MSW-MCU2(for PC) …………………………………………………………………………

134

Chapter 8. Alarm………………………………………………………………………………

152

Chapter 9. Standard Input/Output Signal

9.1 MC output signal(MC Æ PLC) …………………………………………………………

9.2 MC input signal(PLC Æ MC) …………………………………………………………

9.3

Example of using an MC input/output signal for automatic operation

………

9.4

Example of using an MC input/output signal for manual operation

……………

9.5 Input, output and flag contact memory map……………………………………

9.6 PLC COMMUNICATION INTERFACE…………………………………………………………

9.7 Driver interface……………………………………………………………………………

154

156

162

168

175

181

186

- 3 -

Chapter 1. About the Product

Chapter 1. About the Product

1.1 Overview of the MCU

This can be used for one of the next purposes depending on the slave board combined with the

Main Board.

- for 2 axes servo motor drive by means of analog signal output

- for 2 axes step motor drive by means of pulse signal output

- High-end I/O controller

- 4 -

Chapter 1. About the Product

1.2 Features of the MCU

- Small size: 108mm * 80mm * 26mm

- Simple and easy to use

- Economical subminiature 2-axis motion controller

- Linear and arc interpolation

- Various operation variables(position, velocity, dwell, L variable)

- PLC function

- PLC, Touch panel communication

1.3 Application fields of the MCU

- For transportation and assembly: FEEDER, LOADER/UNLOADER, CONVAYOR

- Industrial device: Packer, semiconductor equipment, machine, cutter, XY TABLE

- Peripheral: Pallet

1.4 Product type name

MCU -

Motion Control Unit

Base B/D Type

X Built-in Main Base,

I/O(2/3)

E Extension base(Ext. Base-I/O)

Function

A2 Analog Output

P2 Pulse Output

L General input/output(Logic I/O)

- 5 -

Chapter 1. About the Product

1.5 General specification

Type name

Item

MCU-

XA2 XP2 XL E EL

Input

power

Input voltage DC 24V(+/- 10%)

Current consumption 150mA 180mA 121mA 77mA 105mA

Operator PC(Win98 or later) Serial communication

program

- -

Communica

tion

RS232 Max. 38400Bps

RS485 Max. 38400Bps, 64 Nodes

Analog

output

Number of channels 2Ch. - - - -

Output voltage -10V ~ +10V

Encoder type Incremental

Differential

Line drive,

Phase A/B/Z

- - - -

Encoder frequency Max. 2.5 MHz - - - -

Pulse

Output

Number of channels - 2Ch.

Output type - Differential

Line Drive

- - -

Output mode - CW/CCW

Pulse/Directi

on

- - -

Output frequency - 1~3.75Mpps - - -

External

separate

encoder

Number of input

channels

1Ch. 2Ch.

Input type Incremental Differential Line

drive, Phase A/B

- -- -

Input frequency Max. 2.5 MHz - - -

Extended

I/O

Cable Length/type Max. 10m 16Pin Flat Cable - -

Communication speed 1.5M Bps - -

No. of maximum

extended I/O

2EA(64(in)/48(out)) - -

I/O

In

pu

t

No. of

contacts

16 22 14 20 32

Input voltage 12V/24V(Min ON: 10V, Max OFF: 5V)

Input current 5mA/24V

Ou

tp

ut

No. of

contacts

11 13 13 14 24

Output voltage 5V / 12V / 24V

Output current Max. 80mA Sink Current

MC

program

No. of possible

registrations

10 EA

Maximum capacity 37.5 kBytes

Operation

variable

Position variable

(P)

100 EA

Speed variable (F) 10 EA

Pause variable (D) 10 EA

L variable (L) 2,000 EA

Program for PC MSW-MCU2

1.6 Use environment

Environment Condition

Ambient temperature 0ºC ~ +45ºC(no freezing)

Ambient humidity 85% RH or less(no dew condensation)

Storage temperature -15ºC ~ +65ºC(no freezing)

Storage humidity 90% RH or less(no dew condensation)

Ambient condition Dust and corrosion free(no gas)

Vibration 0.6G or less

- 6 -

Chapter 1. About the Product

1.7 Caution during installation and use

- When wiring a cable, make sure not to cross to or to be adjacent to noise sources such as AC

power cables, motor power cables, etc.

- When installing this product, allow enough ventilation to the vent. Otherwise, this product

may be over-heated to cause a malfunction.

- When connecting an extended I/O module(MCU-E/EL), wire a flat cable completely, select an ID

number by a dip switch, and then turn on power.

- When connecting this product to a serial port of a PC, do not connect it to other pins but

2(RxD), 3(TxD), 5(GND). This can damage the PC or cause a malfunction of the product.

- When using the RS485 communication, do not connect to other pins but 7(TRxD+), 8(TRxD-),

1(Protocol), 5(GND).

- Use termination resistance(120~220Ω)on both ends of the pin 7(TRxD+) and 8(TRxD-) when

using the RS485 communication.

- When connecting a communication cable, do not connect the RS232/485 Port 5(GND) of this

product to the external F.G.

This product may be electrically shocked seriously.

- When connecting a differential signal line such as an encoder, pulse output, etc., be sure

to use a twisted pair of shield wires.

- 7 -

Chapter 2. MC Programming

Chapter 2. MC Programming

2.1 Types of MC program commands, variables and contacts usable

A) MC program commands can be grouped into 8 categories in large.

(1) Program control related command: Commands for branching, ending, etc. of a program.

(2) Conditional branching related command: Controls program branching via an input/output

condition and an IF condition comparison sentence.

(3) Coordinate setting related command: Commands for resetting coordinate.

(4) Velocity setting related command: Commands for velocity setting.

(5) Movement related command: Commands for motor movement.

(6) Input/output contact related command: Controls execution of input, output and auxiliary

contacts and programs.

(7) Condition comparison related command: Used as a comparison operator for an IF condition

comparison sentence.

(8) Variable manipulation related command: Used as an operator for a variable manipulation

sentence.

B) The variables usable for MC programs can be grouped into 4 categories in large.

(1) P variable: Used to designate 2-dimensional position data.

(2) F variable: Used to designate velocity data.

(3) D(E) variable: Used to designate dwell data.

(4) L variable: Used to designate 2-dimensional position, velocity, time, pulse,

manipulation and comparison data as a variable with multi-purpose functions.

C) The input, output and auxiliary contacts used in MC programs can be grouped into 3

categories in large.

(1) X contact: Used to designate an input contact.

(2) Y contact: Used to designate an output contact.

(3) M contact: Used to designate an auxiliary contact.

Table 2.1 List of MC program commands

Division Command Function Type Example of use

Program

/* Declaration of a program comment /* <comment> /* TEST PROGRAM

LABL Designation of a program branching point block LABL <label name> LABL LB1

GOTO Program Branching command GOTO <label name> GOTO LB1

STOP Program pause command STOP STOP

END Program ending END END

DWL Program pause

DWL <D variable

number(0~9)>

DWL <L variable>

DWL 0

DWL L0

Conditio

nal

branchin

g

IF

Branching of a program and proceeding of the

next command according to the result of a

comparing sentence

IF <condition comparing

sentence> <label name> IF L0 .LE 0 LB1

IN0

Branching of a program if the designated

contact satisfies‘0’, otherwise proceeding of

the next command

IN0 <designated contact>

<label name>

IN0 X0.0 LB1

IN0 Y0.0 LB1

IN0 M0.0 LB1

IN1

Branching of a program if the designated

contact satisfies‘1’, otherwise proceeding of

the next command

IN1 <designated contact>

<label name>

IN1 X0.0 LB1

IN1 Y0.0 LB1

IN1 M0.0 LB1

- 8 -

Chapter 2. MC Programming

Division Command Function Type Example of use

Input/ou

tput

IN0 Execution of programs waiting until the

designated contact signal becomes‘0’

IN0 <input contact>

IN0 <output contact>

IN0 <auxiliary contact>

IN0 X0.0

IN0 Y0.0

IN0 M0.0

IN1 Execution of programs waiting until the

designated contact signal becomes‘1’

IN1 <input contact>

IN1 <output contact>

IN1 <auxiliary contact>

IN1 X0.0

IN1 Y0.0

IN1 M0.0

IIN0

Waiting until the designated input contact

signal becomes‘0’(used to check an input

contact at a high speed)

IIN0 <input contact> IIN0 X0.0

IIN1

Waiting until the designated input contact

signal becomes‘1’(used to check an input

contact at a high speed)

IIN1 <input contact> IIN1 X0.0

OUT0

Outputting‘0’to the designated contact (turn

OFF the designated contact and then execute the

next command)

OUT0 <output contact>

OUT0 <auxiliary contact>

OUT0 Y0.0

OUT0 M0.0

OUT1

Outputting‘1’to the designated contact (turn

ON the designated contact and then execute the

next command)

OUT1 <output contact>

OUT1 <auxiliary contact>

OUT1 Y0.0

OUT1 M0.0

Coordina

te

setting

SET Coordinate system setting(absolute coordinate)

SET <position point>

SET <L variable> <L

variable>

SET P0

SET L0 L1

XSET X-axis coordinate system setup(absolute

coordinate)

XSET <position point>

XSET <L variable> <L

variable>

XSET P0

XSET L0 L1

YSET Y-axis coordinate system setup(absolute

coordinate)

YSET <position point>

YSET <L variable> <L

variable>

YSET P0

YSET L0 L1

SET2 Coordinate system setting(absolute, machine

coordinate)

SET2 <position point>

SET2 <L variable> <L

variable>

SET2 P0

SET2 L0 L1

XSET2 X-axis coordinate system setup(absolute,

machine coordinate)

XSET2 <position point>

XSET2 <L variable> <L

variable>

XSET2 P0

XSET2 L0 L1

YSET2 Y-axis coordinate system setup(absolute,

machine coordinate)

YSET2 <position point>

YSET2 <L variable> <L

variable>

YSET2 P0

YSET2 L0 L1

Velocity

setting

VEL Movement velocity setting command

VEL <F variable number

(0~9)>

VEL <L variable>

VEL 0

VEL L0

XVEL

X-axis movement velocity command (Used for the

X-axis velocity command of the PTP and IPTP

movement command)

XVEL <F variable number

(0~9)>

XVEL <L variable>

XVEL 0

XVEL L0

YVEL

Y-axis movement velocity command (Used for the

Y-axis velocity command of the PTP and IPTP

movement command)

YVEL <F variable number

(0~9)>

YVEL <L variable>

YVEL 0

YVEL L0

A Acceleration time setting command A <D variable number(0~9)>

A <L variable>

A0

A L0

XA

X-axis acceleration time command (Used for the

X-axis acceleration time command of the PTP and

IPTP movement command)

XA <D variable number(0~9)>

XA <L variable>

XA 0

XA L0

YA

Y-axis acceleration time command (Used for the

Y-axis acceleration time command of the PTP and

IPTP movement command)

YA <D variable number(0~9)>

YA <L variable>

YA 0

YA L0

D Deceleration time setting command D <D variable number(0~9)>

D <L variable>

D0

D L0

XD

X-axis deceleration time command (Used for the

X-axis deceleration time command of the PTP and

IPTP movement command)

XD <D variable number(0~9)>

XD <L variable>

XD 0

XD L0

YD

Y-axis deceleration time command (Used for the

Y-axis deceleration time command of the PTP and

IPTP movement command)

YD <D variable number(0~9)>

YD <L variable>

YD 0

YD L0

- 9 -

Chapter 2. MC Programming

Division Command Function Type Example of use

Movement

MOV Move by interpolation from the current position

to the target point, decelerate and then stop

MOV <position point>

MOV <L variable> <L

variable>

MOV P0

MOV L0 L1

IMOV Move by interpolation from the current position

to the increment, decelerate and then stop

IMOV <position point>

IMOV <L variable> <L

variable>

IMOV P0

IMOV L0 L1

PTP

Move individually from the current position to

the target point, decelerate and then

stop(individual velocity)

PTP <position point>

PTP <L variable> <L

variable>

PTP P0

PTP L0 L1

IPTP

Move individually from the current position to

the increment, decelerate and then

stop(individual velocity)

IPTP <position point>

IPTP <L variable> <L

variable>

IPTP P0

IPTP L0 L1

XMOV Move the X-axis only from the current position

to the target point, decelerate and then stop

XMOV <position point>

XMOV <L variable>

XMOV P0

XMOV L0

YMOV Move the Y-axis only from the current position

to the target point, decelerate and then stop

YMOV <position point>

YMOV <L variable>

YMOV P0

YMOV L0

XIMOV Move the X-axis only from the current position

to the increment, decelerate and then stop

XIMOV <position point>

XIMOV <L variable>

XIMOV P0

XIMOV L0

YIMOV Move the Y-axis only from the current position

to the increment, decelerate and then stop

YIMOV <position point>

YIMOV <L variable>

YIMOV P0

YIMOV L0

CW

CW arc interpolation from the current

position(start point) to the target point(end

point)

CW <target point> <radius> CW P0 P1

CW PL0 PL1

CCW

CCW arc interpolation from the current

position(start point) to the target point(end

point)

CCW <target point> <radius> CCW P0 P1

CCW PL0 PL1

ICW

CW arc interpolation from the current

position(start point) to the increment(end

point)

ICW <increment> <radius> ICW P0 P1

ICW PL0 PL1

ICCW

CCW arc interpolation from the current

position(start point) to the increment(end

point)

ICCW <increment> <radius> ICCW P0 P1

ICCW PL0 PL1

PMOV Palletizing movement PMOV <data> <position> PMOV L0 P0

PMOV L0 L10

PCLR Palletizing counter clear PCLR <data> PCLR L0

FOS Pre-execution of the next block

FOS <D variable

number(0~9)>

FOS <L variable>

FOS 0

FOS L0

RET Move to the home RET RET

IF

conditio

n

comparis

on

.EQ Used for the comparison of ‘equal to(=)’in an

IF condition comparing sentence

IF <variable> .EQ

<variable>

<label name>

IF <variable> .EQ <number>

<label name>

IF L0 .EQ L1

LB1

IF L0 .EQ 0 LB1

.LE Used for the comparison of ‘less than or equal

to(<=)’in an IF condition comparing sentence

IF <variable> .LE

<variable>

<label name>

IF <variable> .LE <number>

<label name>

IF L0 .LE L1

LB1

IF L0 .LE 0 LB1

.LT Used for the comparison of ‘less than(<)’in

an IF condition comparing sentence

IF <variable> .LT

<variable>

<label name>

IF <variable> .LT <number>

<label name>

IF L0 .LT L1

LB1

IF L0 .LT 0 LB1

.GE

Used for the comparison of ‘greater than or

equal to(>=)’in an IF condition comparing

sentence

IF <variable> .GE

<variable>

<label name>

IF <variable> .GE <number>

<label name>

IF L0 .GE L1

LB1

IF L0 .GE 0 LB1

.GT Used for the comparison of ‘greater

than(>)’in an IF condition comparing sentence

IF <variable> .GT

<variable>

<label name>

IF <variable> .GT <number>

<label name>

IF L0 .GT L1

LB1

IF L0 .GT 0 LB1

- 10 -

Chapter 2. MC Programming

Division Command Function Type Example of use

.NE Used for the comparison of ‘not equal

to(!=)’in an IF condition comparing sentence

IF <variable> .NE

<variable>

<label name>

IF <variable> .NE <number>

<label name>

IF L0 .NE L1

LB1

IF L0 .NE 0 LB1

Variable

manipula

tion

= Used for the movement of manipulation results

in a variable manipulation sentence

<variable> = <variable>

<variable> = <number>

<variable> = <operation

sentence>

L0 = L1

L0 = 1234

L0 = L0 + 1

+ Used for addition in a variable manipulation

sentence

<variable> + <variable>

<variable> + <number>

<variable> + <operation

sentence>

<operation sentence> +

<operation sentence>

L0 = L1 + L2

L0 = L0 + 1

L0 = L1 + (L2-

1)

(L1*2) + (L2*4)

- Used for subtraction in a variable manipulation

sentence

<variable> - <variable>

<variable> - <number>

<variable> - <operation

sentence>

<operation sentence> -

<operation sentence>

L0 = L1 - L2

L0 = L0 - 1

L0 = L1 - (L2-

1)

(L1*2) - (L2*4)

* Used for multiplication in a variable

manipulation sentence

<variable> * <variable>

<variable> * <number>

<variable> * <operation

sentence>

<operation sentence> *

<operation sentence>

L0 = L1 * L2

L0 = L0 * 2

L0 = L1 * (L2-

1)

(L1+2) *

(L2/4))

/

Used for division in a variable manipulation

sentence

(used to obtain the ‘quotient’ of a division

result)

<variable> / <variable>

<variable> / <number>

<variable> / <operation

sentence>

<operation sentence> /

<operation sentence>

L0 = L1 / L2

L0 = L0 / 100

L0 = L1 / (L2-

1)

(L1*2) / (L2*4)

%

Used for division in a variable manipulation

sentence

(used to obtain the ‘remainder’ of a division

result)

<variable> % <variable>

<variable> % <number>

<variable> % <operation

sentence>

<operation sentence> %

<operation sentence>

L0 = L1 % L2

L0 = L0 % 100

L0 = L1 % (L2-

1)

(L1*2) % (L2*4)

(, )

Used to adjust the priority of operation in a

variable manipulation sentence(available up to

5 nesting)

(handle the operation sentence in the

parenthesis() first)

(((<operation sentence>))) ((L1+2)*(L2-4))

- 11 -

Chapter 2. MC Programming

Table 2.2 List of MC program variable functions

Division Variable Function Amount Example of use

Data

classifica

tion

P variable

Used to designate 2-dimensional position

data

Input range:

-2,147,483,648 ~ 2,147,483,647

P0 ~ P99 MOV P0, IMOV P1, SET2 P99, ..

F variable Used to designate velocity data F0 ~ F9 VEL 0, VEL 1, VEL 2, ~ VEL 9

D(E)

variable

Used to designate dwell data

Used to designate acceleration time data

Used to designate deceleration time data

-------------------------

Used as comparison data in a comparing

condition sentence

Used as manipulation data in a variable

manipulation sentence

Used to designate position data indirectly

D0 ~ D9

(E0 ~ E9)

DWL 0, DWL 1, DWL 2, ~ DWL 9

A0, A1, A2, ~ A9

D0, D1, D2, ~ D9

IF E8 .LT E9 LB1

E0=E8-E9

MOV PE0

L variable

Used to designate position data

Used to designate velocity data

Used to designate dwell data

Used to designate acceleration time data

Used to designate deceleration time data

Used as comparison data in a comparing

condition sentence

Used as manipulation data in a variable

manipulation sentence

Used to designate data indirectly

L0~ L1999

MOV L0 L1,IMOV L0 L1,

SET2 L1998 L1999, ..

VEL L0, VEL L1, ~ VEL L1999

DWL L0, DWL L1, ~ DWL L1999

A L0, A L1, A L2, ~ A L1999

D L0, D L1, D L2, ~ D L1999

IF L0 .LT L1999 LB1

L0=L0-L1999

MOV PL0, MOV LL0 LL1, VEL LL0, ..

Table 2.3 List of MC program contact functions

Division Variable Function Amount Example of use

Contact

classifica

tion

X contact

XP2 Main unit input contact

XA2 Main unit input contact

Extended No.1 unit input contact(MCU-E)

Extended No.1 unit input contact(MCU-L)

Extended No.2 unit input contact(MCU-E)

Extended No.2 unit input contact(MCU-L)

X0.0~X1.5

X0.0~X0.F

X2.0~X3.3

X3.4~X3.F

X4.0~X5.3

X5.4~X5.F

IIN0 X0.0, ~ IIN0 X0.F

IIN1 X0.0, ~ IIN1 X0.F

IN0 X0.0, ~ IN0 X5.F

IN1 X0.0, ~ IN1 X5.F

IN0 X0.0 LB1, ~ IN0 X5.F LB16

IN1 X0.0 AA1, ~ IN1 X5.F AA16

Y contact

XP2 Main unit output contact

XA2 Main unit output contact

Extended No.1 unit output contact(MCU-E)

Extended No.1 unit output contact(MCU-L)

Extended No.2 unit output contact(MCU-E)

Extended No.2 unit output contact(MCU-L)

Y0.0~Y0.C

Y0.0~Y0.A

Y1.0~Y1.D

Y1.E~Y2.7

Y3.0~Y3.D

Y3.E~Y4.7

IN0 Y0.0, ~ IN0 Y4.F

IN1 Y0.0, ~ IN1 Y4.F

IN0 Y0.0 LB1, ~ IN0 Y4.F LB16

IN1 Y0.0 AA1, ~ IN1 Y4.F AA16

OUT0 Y0.0, ~ OUT0 Y4.7

OUT1 Y0.0, ~ OUT1 Y4.7

M contact

Internal auxiliary contact

(used for control interlocked with a PLC

program)

M0.0

~M199.F

IN0 M0.0, ~ IN0 M199.F

IN1 M0.0, ~ IN0 M199.F

IN0 M0.0 LB1,~IN0 M199.F LB16

IN1 M0.0 AA1,~IN1 M199.F AA16

OUT0 M0.0, ~ OUT0 M199.F

OUT1 M0.0, ~ OUT1 M199.F

[Caution] : Do not use an area of M contacts reserved for an MC program contact.

- M50.0 ~ M79.F: MC output (MC PLC) flag contact area

- M80.0 ~ M99.F: MC input (PLC MC) flag contact area

- 12 -

Chapter 2. MC Programming

2.2 MC Program command details

1) LABL

Input type LABL <label name>

Terminology <Label name>: Set the name of a label. Possible up to 7 digits including English and

number.

Related

command GOTO,IF,IN0,IN1

Explanation Set a block to be branched by GOTO,IF,IN0,IN1.

(Note) The label name shall not be the same as a command or variable name.

Example

LABL LB0

…

GOTO LB0

Set a label with a name‘LB0’.

2) GOTO

Input type GOTO <label name>

Terminology <Label name>: Designate the name of a label to branch.

Related

command LABL

Explanation

Command a label to move to a ‘LABELED’ sentence to a set block with an absolute

branch command of program execution.

(Note) Designate the name of a label set by a LABL command, and if the name of the

designated label is not set, then an alarm takes place.

Example

VEL 0

MOV P0

LABL LB0

MOV P1

MOV P2

GOTO LB0

Move to a ‘LABELED’ sentence from a command “GOTO LB0”to“LABL LB0”.

Move to a ‘LABELED’ sentence, repeating commands “MOV P1”and “MOV

P2”.

3) STOP

Input type STOP

Explanation

Command pause of program execution.

The execution of a program stopped by a STOP command is restarted by a START signal.

The START signal is generated by an MSW-MCU2 program, a PLC contact ‘M80.2’, a PLC

command ‘START’, or an external input“X0.6” by parameter reservation.

Example

VEL 0

MOV P0

STOP

MOV P1

“MOV P0” is executed and then stopped, and the next command is

executed by a START signal.

4) END

Input type END

Explanation Command the end of program execution.

Example VEL 0

MOV P0

END

MOV P1

“MOV P0”is executed and then program execution is ended.

- 13 -

Chapter 2. MC Programming

5) DWL

Input type DWL <number> or DWL <L variable>

Terminology <Number>: Set a dwell time from the Dwell(E) Table.(0 ~ 9)

<L variable>: Set a dwell time from the L-VAR Table.(L0 ~ L1999)

Related

variable D variable, L variable

Explanation Program execution stops as much as the set dwell time(unit: msec) for the designated

variable.

Example of

use

DWL 0

DWL L0

Operation stops for the set time of a variable ‘DO’ in the Dwell(E)

Table, and then continues

Operation stops for the set time of a variable ‘L0’ in the L-VAR Table

and then continues.

Example

VEL 0

MOV P0

DWL 0

VEL 1

MOV P1

Fig. 2.1 Time pause function

Pause as much as the DO variable value by a command “DWL 0”.

[Reference: External encoder pause function]

Pause by an external encoder

Parameter P62: Encoder accumulation dwell during automatic operation

P63: Encoder Dwell [M80.5] during dwell

Explanation Setting basic parameter P63 stops program execution as many as the number of set

pulses of the designated variable.

See the Fig.2.2 Pulse pause function.

Setting basic parameter P62 stops program execution as many as the number of set

accumulated pulses of the designated variable.

See the Fig.2.3 Accumulated pulse pause function.

(Note) The time and the pulse pause function cannot be simultaneously used.

Do not set the parameters P62 and P63 simultaneously.

Velocity

Time

F0

F1

Current position P0

p

osition P1 position

Time pause

Table of contents

Popular Controllers manuals by other brands

Linak

Linak Techline Linear Actuator Technology brochure

National Instruments

National Instruments 3100 user manual

Regin

Regin RVAPC-230 quick start guide

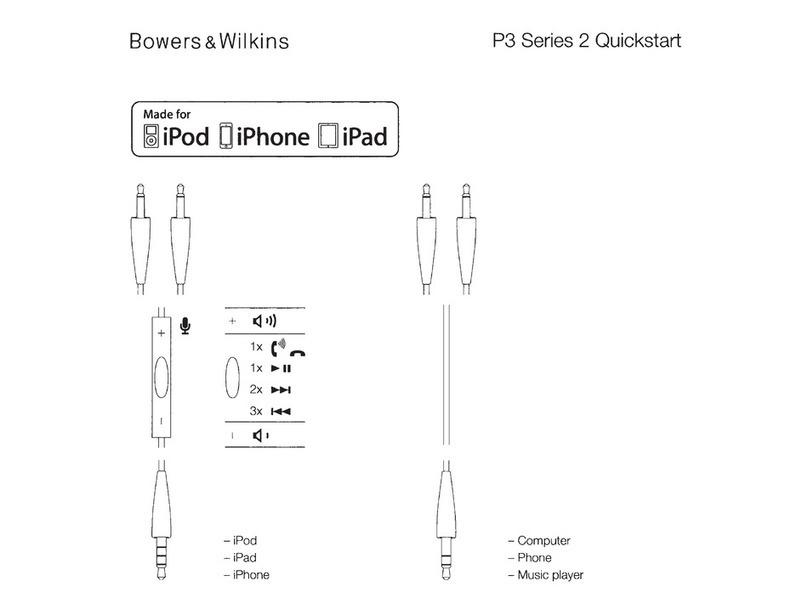

Bowers & Wilkins

Bowers & Wilkins P3 Series quick start

Software Bisque

Software Bisque TheSky Fusion user guide

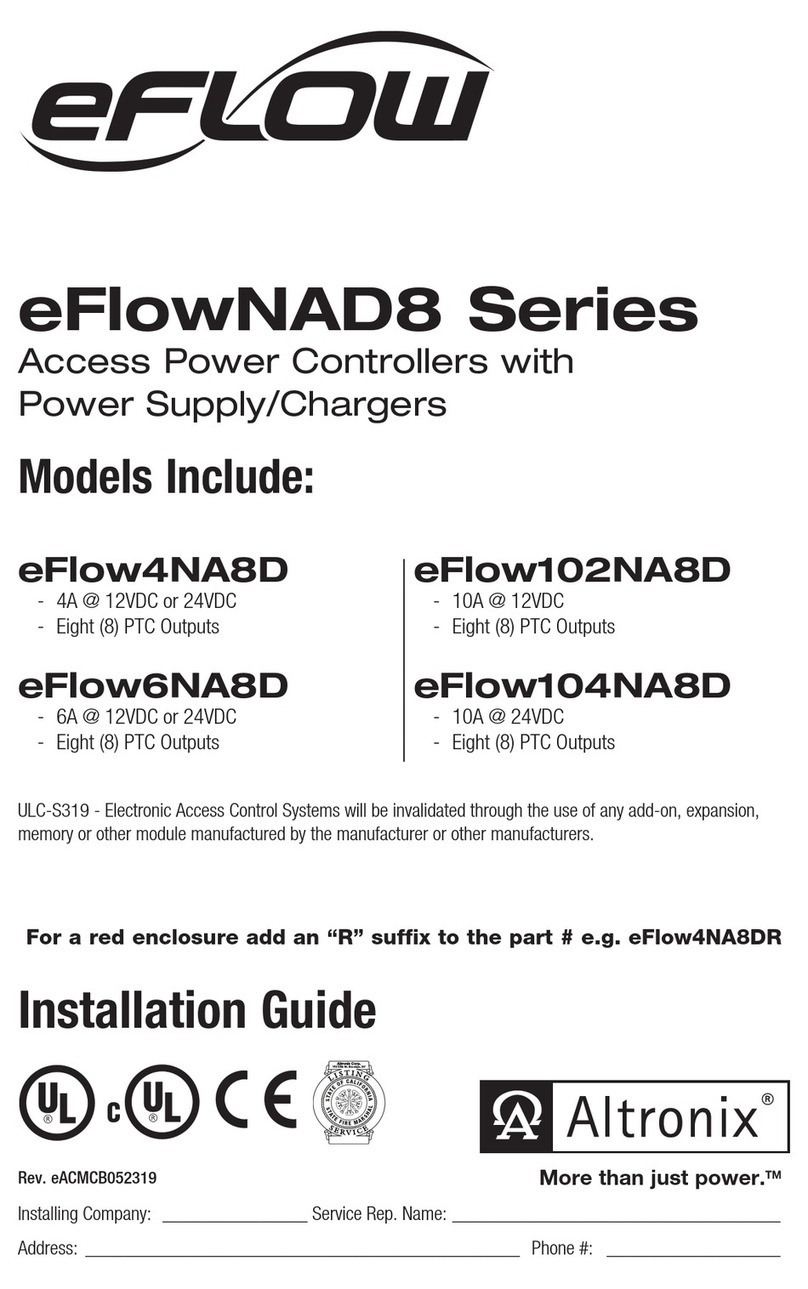

Altronix

Altronix eFlowNAD8 Series quick start guide