Emotron AB 01-3993-01r1

Quick Start Guide

This guide is designed to assist in installing and running the

variable speed drive to verify that the drive and motor are

working properly. Starting, stopping and speed control will

be from the keypad. If your application requires external

control or special system programming, consult the VSA

Instruction Manual supplied with your variable speed drive.

Step 1 Before starting the VSD

Please refer to the chapters Preface and Safety Precautions in

the VSA Instruction Manual. Verify that the drive is

installed in accordance with the procedures described in the

chapter Environment description and installation. If not, do

not start the drive until qualified personnel have corrected

the installation. (Failure to do so could result in serious

injury.)

• Check VSD and motor nameplates to determine that

they have the same power and voltage ratings. (Ensure

that full load motor current does not exceed that of the

VSD.)

• Remove the terminal cover to expose the motor and

power terminals.

a. Verify that AC power is wired to L1, L2, and L3.

b. Verify that motor leads are connected to T1, T2, and

T3.

c. If a brake module is necessary, please connect terminal

voltage of the braking unit to + and - of the VSD.

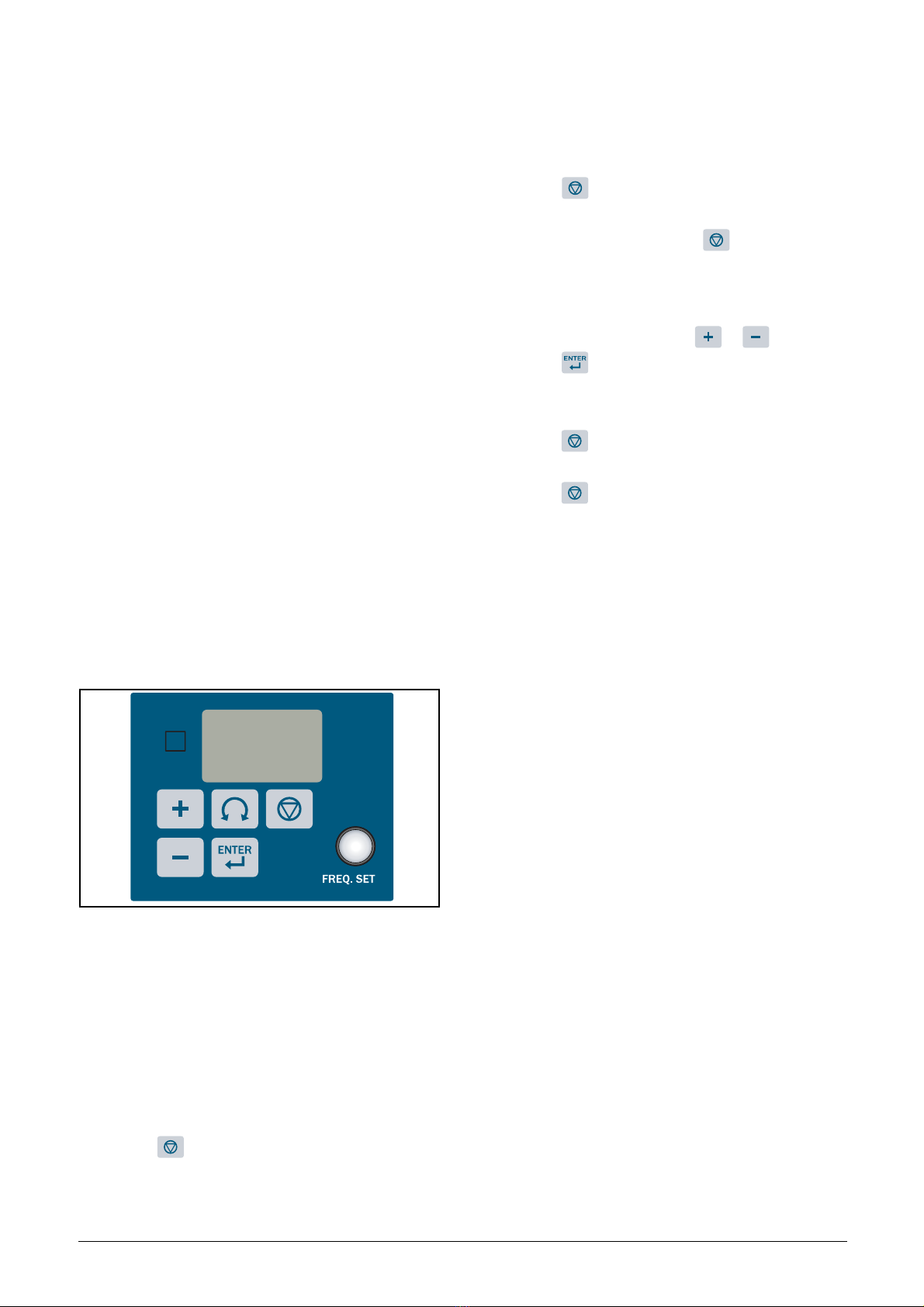

Step2 Apply power to the drive

Apply AC power to the drive and observe operator. Three 7-

segment display should show power voltage for 3 to 5 sec-

onds and observe how it runs, factory sets 5.00. (Frequency

Command of 7-segment display should be flashed all the

time.)

Step3 Check motor rotation under no-

load conditions

• Press the key. The 7-segment display will indicate

the output frequency 00.0 to 05.0 Hz.

• Check the operation direction of the motor.

• If the direction of the motor is incorrect:

• Press the key, turn off the AC power supply. Once

Power indicator LED is off, change over theT1 and T2.

• Apply power again and press the key and check the

motor operation direction.

Step4 Check full speed at 50Hz/60Hz

• Change the frequency with the or and please

press the key to confirm the setting.

• Set frequency to 50Hz/60Hz according to the above reg-

ulations.

• Press the key, inspect the motor operation as motor

accelerates to full load.

• Press the key, inspect the motor operation as motor

deceleration.

Step5 Other settings

As for other function, please refer to VSA user manual.

Set acceleration time, page 37

Set deceleration time, page 37

Set upper frequency limit, page 38

Set lower frequency limit, page 38

Set motor rated current, page 32

Set control mode (Vector, V/F), page 30

Step6 vector Mode Settings

When the VSD is set to run in Vector Mode (211=000), the

motor parameters needs to be set. The required in formation

should be readily available on the nameplate of the motor.

(Motor kW=0.75 x HP)

The parameters to set for vector operation:

Motor Rated Current (Amps) [223], see page 32

Motor Rated Voltage (Volts) [221], see page 32

Motor Rated Frequency (Hz) [224], see page 32

Motor Rated Power (KW) [222], see page 32

Motor Rated Speed (RPM) [225], see page 32

Additional Vector Mode Settings to adjust for optimum

operations are:

Torque boost gain [351], see page 39

Slip compensation gain [354], see page 41

Low Frequency Voltage Compensation [352], see page 39.