Table of Contents

© 2011 EMP, Inc. 3

Table of Contents

Product Overview ..............................................................................................................................................2

Introduction........................................................................................................................................................4

Purpose .........................................................................................................................................................4

Service Technician Responsibilities ...............................................................................................................4

Liability Disclaimer .........................................................................................................................................4

More Information............................................................................................................................................4

Routine Maintenance .....................................................................................................................................4

Technical Help ...............................................................................................................................................4

Warranty ........................................................................................................................................................4

About This Document ........................................................................................................................................5

Warnings, Cautions and Notes.......................................................................................................................5

Definition of Terms.........................................................................................................................................5

Product Safety Warnings ...................................................................................................................................6

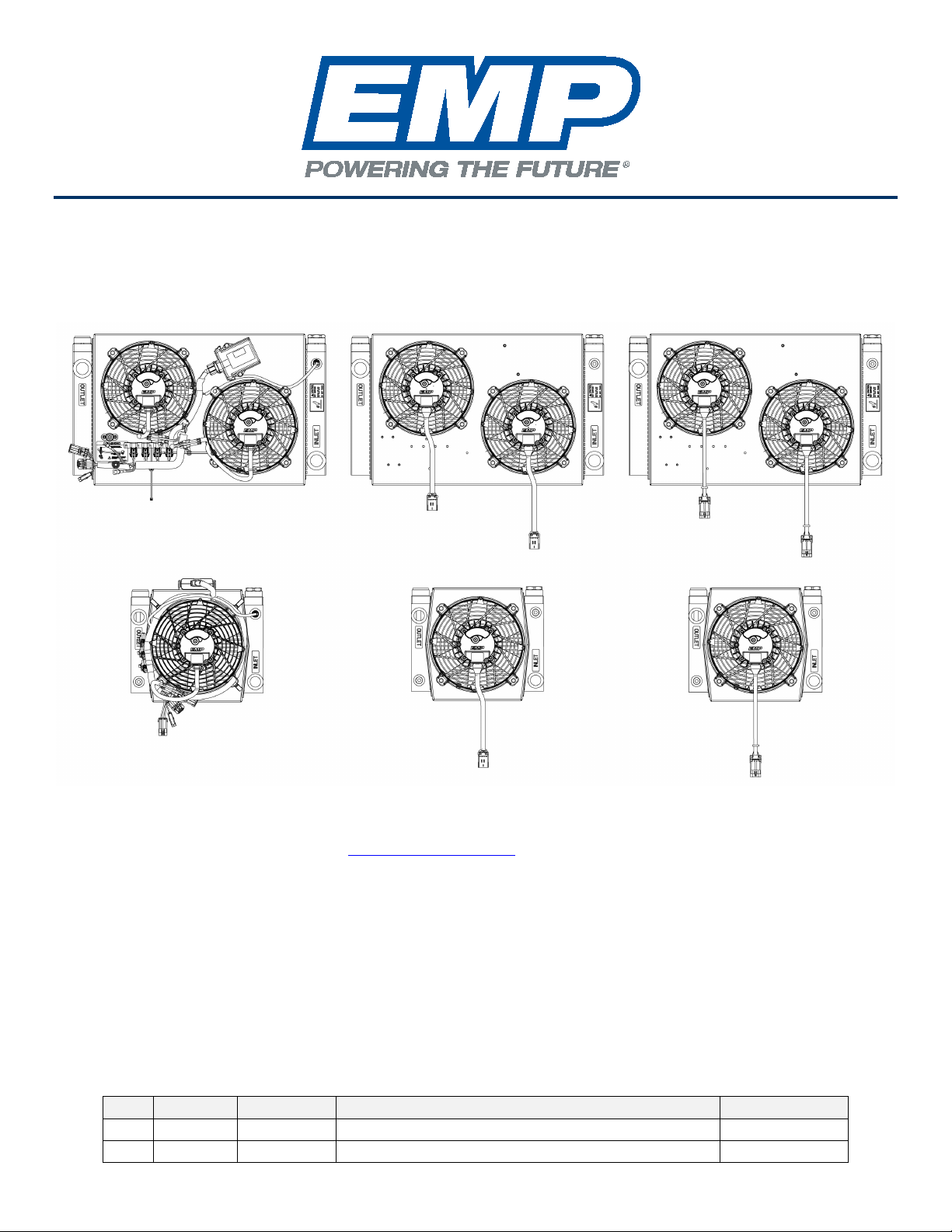

System Configurations.......................................................................................................................................7

Product Identification......................................................................................................................................7

Model Codes..................................................................................................................................................7

Airflow Direction .............................................................................................................................................7

System Part Numbers ....................................................................................................................................8

System Information............................................................................................................................................9

Operation .......................................................................................................................................................9

OK1 ...............................................................................................................................................................9

OK2 .............................................................................................................................................................10

Common Specifications and Operating Limits .............................................................................................. 11

Wiring and Fusing Requirements .................................................................................................................11

Heat Rejection .............................................................................................................................................12

μTMC Controlled Systems ...........................................................................................................................13

Installation .......................................................................................................................................................17

Orientation ...................................................................................................................................................17

Mounting ......................................................................................................................................................18

Plumbing......................................................................................................................................................20

Wiring and Fusing Recommendations..........................................................................................................21

Software Calibration Options........................................................................................................................22

Troubleshooting...............................................................................................................................................22

Service Parts Replacement .............................................................................................................................23

Connector Greasing .....................................................................................................................................23

Fuse Replacement .......................................................................................................................................23

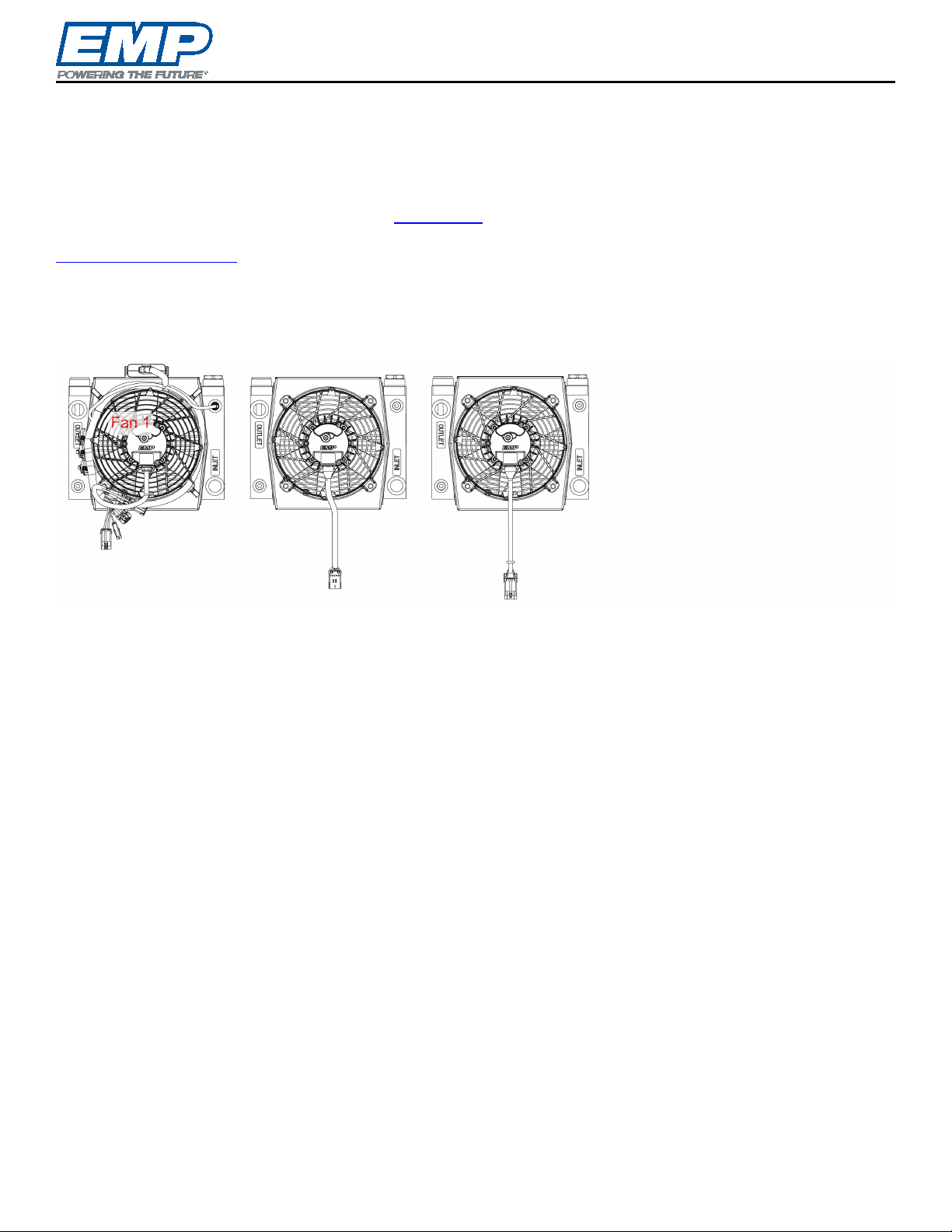

FIL11 Fan ....................................................................................................................................................24

μTMC System Controller.............................................................................................................................. 25

Power/Ground Stud Replacement Kit (1370090014) – (If Required) ............................................................ 26

Main Wire Harness.......................................................................................................................................27

OK1 Harness Installation..............................................................................................................................28

OK2 Harness Installation..............................................................................................................................29

Heat Exchanger Replacement for OK1/OK2 ................................................................................................ 30

Shroud Replacement for OK1/OK2 ..............................................................................................................31

Fluid Thermistor ...........................................................................................................................................32

Service Tool Interface ..................................................................................................................................32

Appendix A – Wiring Schematics.....................................................................................................................33

3170029067.................................................................................................................................................34

3170029068.................................................................................................................................................35

3170029068, Rev D and Later ..................................................................................................................... 36

Appendix B – Operation Manual μTMC System Controller .............................................................................. 37

Product Warranty Registration Form................................................................................................................ 38