Emtron DX-2 User manual

OPERATING MANUAL

EMTRON DX-2

HF LINEAR AMPLIFIER

Emtron North America

Distributed Exclusively in North America By:

Emtron North America

6531 Boundary Run Drive

DX-2, Serial No…………

INITIAL SETTINGS FOR PLATE AND LOAD CAPACITORS

TEST

FREQUENCY

BAND FACTORY SETTINGS

50 OHM LOAD

USER SETTING

ANTENNA

PLATE LOAD PLATE LOAD

21.200 MHz 15m

18.100 MHz 17m

14.200 MHz 20m

7.070 MHz 40m

3.600 MHz 80m

1.800MHz 160m

1.850 MHz 160m

1.900 MHz 160m

TABLE 1

TABLE OF CONTENTS

1GENERAL DESCRIPTION.................................................................................................................................1

1.1 DX-2 –INTERNAL VIEW............................................................................................................................. 2

2TECHNICAL SPECIFICATIONS ......................................................................................................................3

3UNPACKING.........................................................................................................................................................3

3.1 OPENING THE CARTON................................................................................................................................4

3.2 OPENING THE DX-2 COVER ........................................................................................................................4

4INSTALLATION I ENVIRONMENT.................................................................................................................4

4.1 REQUIRED ENVIRONMENT ..........................................................................................................................4

4.2 POWER REQUIREMENTS ..............................................................................................................................4

5REAR PANEL .......................................................................................................................................................4

5.1 POWER /EARTH CONNECTIONS...................................................................................................................4

5.2 RF CONNECTIONS .......................................................................................................................................4

5.3 TRANSCEIVER CONTROL .............................................................................................................................4

6FRONT PANEL.....................................................................................................................................................5

6.1 CONTROLS..................................................................................................................................................5

6.2 DISPLAYS ...................................................................................................................................................5

7ELECTRICAL CONNECTIONS ........................................................................................................................6

7.1 CONNECTIONS TO TRANSCEIVER /EXCITER ............................................................................................... 6

7.2 EARTH AND MAINS CONNECTIONS ..............................................................................................................6

7.3 TERMINATING THE POWER CABLE (EXPORT VERSION) ................................................................................7

7.4 OPERATION AT 230V, 220V AND 200V (EXPORT VERSION)........................................................................ 7

8DX-2 DESCRIPTION............................................................................................................................................7

8.1 RF SECTION................................................................................................................................................7

8.2 MAINS TRANSFORMER ................................................................................................................................8

8.3 H. V. POWER SUPPLY .................................................................................................................................8

8.4 SOFT START MODULE.................................................................................................................................. 8

8.5 SENSOR MODULE ........................................................................................................................................8

8.6 ANTENNA RELAY /QSK MODULE...............................................................................................................8

8.7 DISPLAY BOARD .........................................................................................................................................8

8.8 CONTROLLER BOARD..................................................................................................................................8

9POWERING UP ....................................................................................................................................................9

10 OPERATION .........................................................................................................................................................9

10.1 TUNNING PROCEDURE - ......................................................................................................................9

10.1.1 General........................................................................................................................................................9

10.1.2 Preliminary tuning ......................................................................................................................................9

10.1.3 Final tuning...............................................................................................................................................10

10.1.4 Potential problems during tuning..............................................................................................................10

10.2 ALC ADJUSTMENT ..............................................................................................................................10

10.3 USING YOUR DX-2 ...............................................................................................................................11

10.3.1 CW / RTTY and all digital modes..............................................................................................................11

10.3.2 Voice modes (SSB) ....................................................................................................................................11

10.3.3 Hints on good linearity and efficiency.......................................................................................................11

11 SWITCHING THE POWER OFF .....................................................................................................................11

12 TROUBLESHOOTING - IF SOMETHING GOES WRONG ........................................................................ 12

12.1 NO POWER ................................................................................................................................................12

12.2 FAN GOES TO HIGH SPEED .........................................................................................................................12

12.3 FAN NOT WORKING ...................................................................................................................................12

12.4 IF THE FAULT LIGHT TURNS ON............................................................................................................... 12

12.5 OVER-TEMPERATURE CUT-OFF .................................................................................................................12

12.6 OVER-CURRENT CUT-OFF .........................................................................................................................12

12.7 IG2BLINKS FAST -NO PLATE VOLTAGE ....................................................................................................12

12.8

S

PARKS

/

D

ISCHAR

GES IN

RF

AREA

................................

................................

................................

..........

13

14 GLOSSARY .........................................................................................................................................................13

15 SERVICE .............................................................................................................................................................14

15.1 GENERAL..................................................................................................................................................14

15.1.1 CONTROL BOARD...................................................................................................................................14

15.1.2 DISPLAY BOARD ADJUSTMENTS .........................................................................................................18

15.1.3 RF SENSOR ADJUSTMENT.....................................................................................................................19

16 DIAGRAMS AND SCHEMATICS....................................................................................................................21

16.1 DX-2 BLOCK DIAGRAM ...........................................................................................................................21

16.2 CONTROL BOARD CONNECTIONS AND ADJUSTMENT POINTS ...................................................................22

16.3 DISPLAY BOARD ADJUSTMENT POINTS ....................................................................................................23

16.4 CIRCUIT DIAGRAM –HIGH VOLTAGE POWER SUPPLY ....................................................................24

16.5 CIRCUIT DIAGRAM –AC INPUT AND SOFT START WIRING –U.S. VERSION .....................................25

16.6 CIRCUIT DIAGRAM –RF MODULE .........................................................................................................26

16.7 CIRCUIT DIAGRAM –DISPLAY BOARD ................................................................................................27

16.8 CIRCUIT DIAGRAM –SOFT START –240 VOLT VERSION.......................................................................28

16.9 CIRCUIT DIAGRAM –QSK........................................................................................................................29

16.10 CIRCUIT DIAGRAM –CONTROL BOARD ..............................................................................................30

16.11 CONTROL BOARD –COMPONENT LEGEND ...............................................................................................31

16.12 CONTROL BOARD –SOLDER SIDE TRACK WORK ......................................................................................32

DX-2 LINEAR AMPLIFIER

Serial No …………

OPERATING MANUAL

January 2003

CAUTION

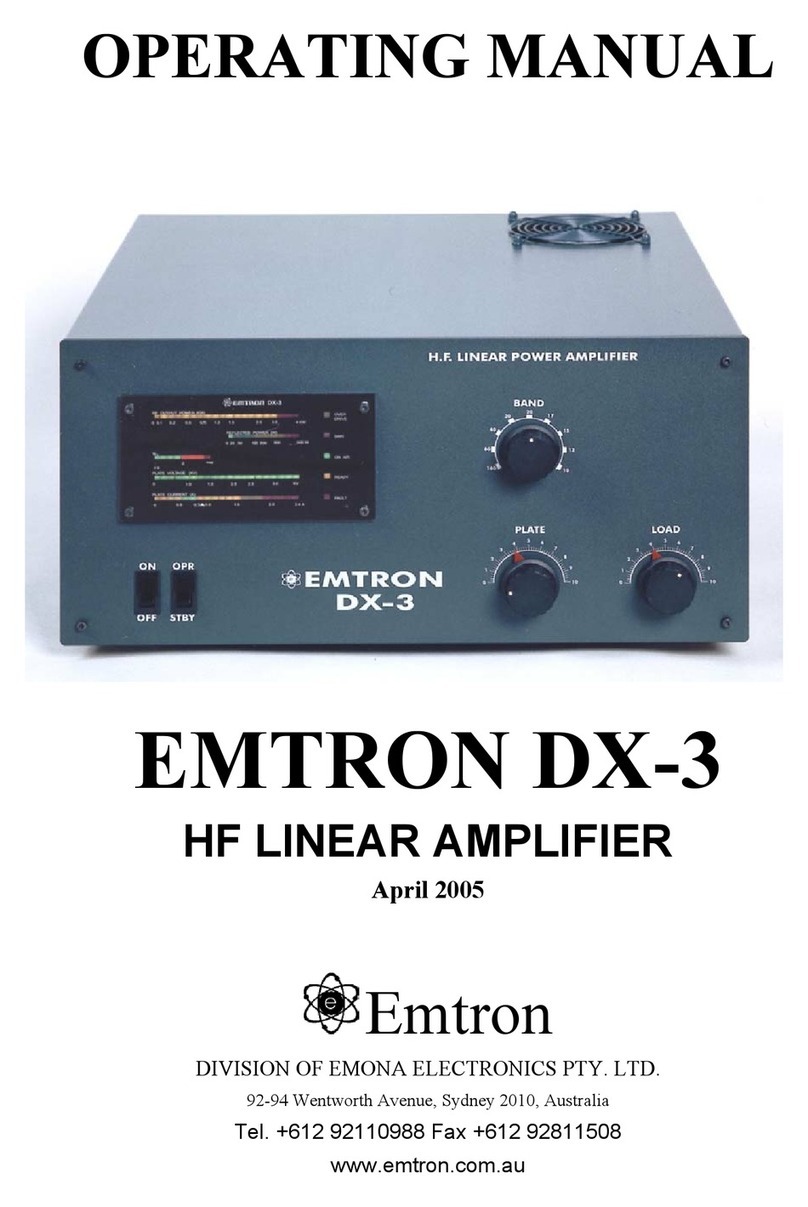

1 GENERAL DESCRIPTION

The Emtron DX-2 Linear Amplifier is a 1500 watt carrier output power, for the 160m through 15m amateur bands (7 bands), housed in a desk-top

cabinet with self-contained power supply and cooling system.

It utilises a single high performance tetrode, type GU84B (4CX2500), a ceramic metal tube with a plate dissipation of 2500W. The tube is air cooled by

a commercial grade forced air turbine blower system with 2 speeds, controlled by a temperature sensor. Tetrodes offer exceptionally stable operation

and levels of quality performance far exceeding that which can be expected from triodes. The harmonic output and intermodulation distortion achieved

with this tube are exceptionally low. This is especially important when dealing with a high output power.

The Emtron DX-2 is supplied as standard with a host of features including solid state metering, comprehensive protection systems and extremely long

duty cycle. In addition, a unique Emtron QSK module is available as an option. With this installed, extremely rapid switching times between transmit

and receive are possible, with consequent advantages when using the digital modes.

Operation of the DX-2 is greatly simplified by the absence of meter switching, mechanical displays and front panel level setting controls. The front

panel moving LED display systems indicate plate voltage, plate current, output power, reflected power, screen grid current, ready, overdrive warning,

and high SWR cut-off indication.

The Emtron Electronic Bias Switch (EBS) automatically switches the standing current (typically 0.37 A) off when there is no modulation. This reduces

the average tube dissipation. On initial switch on, the unique Emtron "soft start" circuitry ensures that no damaging AC surge currents are generated.

Professional, fine output tuning adjustment is possible, due to the 6: 1 reduction mechanism fitted.

The DX-2 has been designed for 100% safe operation and long life.

Interlocking sensing circuitry constantly monitors conditions inside the

amplifier. It must be noted however, that the high voltages present inside

the DX-2 are EXTREMELY DANGEROUS. Do not remove the top cover

under any circumstances if any leads are still plugged into the rear of the

amplifier - especially if the AC lead is plugged in the power outlet. Before

any component inside the high voltage, power supply or output section is

touched, unplug all rear panel leads and allow at least 5 minutes of 'off

time'. After that, you should further check thisby momentarily shorting the

tube anode to the chassis with a suitable insulated lead.

1.1 DX-2 – Internal View

The main components of a DX-2 amplifier are shown in the picture below.

3

2 TECHNICAL SPECIFICATIONS

FREQUENCY COVERAGE: Complete (manually tuned) coverage of the seven HF amateur bands:

1.800 – 1.900 MHz

3.500 – 4.000 MHz

7.000 – 7.500 MHz

14.000 – 14.350 MHz

18.000 – 18.500 MHz

21.000 – 21.500 MHz

TRANSMITTING MODES: Both continuous and low duty cycle modes are supported. That is, the DX-2 supports SSB, CW, AM,

FM, RTTY and SSTV.

OUTPUT POWER: Typical 1500 watts PEP

DRIVE POWER: Nominal 50-60 watts for full rated output.

INPUT IMPEDANCE: Nominal 50 ohm passive impedance, unbalanced. VSWR 1.4:1 or less.

OUTPUT IMPEDANCE: Tuned circuit, nominal 50 ohm load, VSWR maximum 2.6:1 set by protection circuit.

DISTORTION: Third order intermodulation products are more than 35 dB below rated output.

HARMONICS: Harmonic output is better than 47dB below the rated output.

FAULT PROTECTION: The extremely comprehensive fault protection systems include circuitry to monitor:

•plate current: should the plate current exceed a safe value, the amplifier goes to standby mode for 2 minutes.

•screen grid over-current: Absolute tube protection is offered with visual warning and a reduced power level being enabled if

the screen current exceeds a pre-set limit.

•temperature: Should the tube's temperature exceed a specific level, amplifier operation is suspended until the temperature

drops to a safe level.

OPERATIONAL PROTECTION

•Overdrive protection: Should the DX-2 be overdriven, a LED warning indictor will light up when the linearity limit is

reached. If the drive is increased further, a 2 second cut off (by-pass) will follow.

•SWR protection: Should the DX-2 sense a load impedance with SWR exceeding 2.6:1, an LED warning indicator will light

up, simultaneously with a 3 second cut off (by-pass).

METERING: The front panel moving LED display systems indicate:

•plate voltage

•plate current

•output power

•reflected power

•screen grid current

•ready and fault conditions

•overdrive warning

•SWR cut-off indicator

ALC: Negative going, adjustable output level.

EBS: Electronic Bias Switch - automatically switches the standing current (about 0.37 A) to a lower ("pre-bias") value - when there is

no input drive.

PRE-BIAS: A small current will flow in the tube when the amplifier is keyed on, but there is no modulation. This will prevent a harsh

sound at the beginning of each word, when the EBS is activated and the tube goes through a non-linear zone, before reaching the

correct initial bias.

QSK: is an option that makes possible the antenna switching at very fast rate - typically 3ms switching time in each direction.

FACTORY INSTALLED ONLY.

SOFT START: when switched on, the mains power is gradually applied to the transformer, over a period of about 5 seconds, to avoid

the high in-rush current typical for such high loads (transformer “Bang” and filament over-current).

COOLING: the cooling fan has 2 speeds, with electronic temperature control. Most of the time the fan runs at low speed, for reduced

noise.

OPERATING TEMPERATURE: 0 to 40° Celsius

FUSING: Two 20A fast acting fuses on the rear panel

DIMENSIONS: 435mm wide, 190mm high, 465mm deep WEIGHT: 4lkg (90 lb) unpacked

3 UNPACKING

The DX-2 is packed in a heavy duty package easily sufficient to protect the amplifier during transportation, even in case of fairly rough

handling. The weight of the commercially rated mains transformer does mean, however, that dropping the amplifier would without

doubt result in some damage.

4

3.1 Opening the carton

Save the packing material for possible further re-use. Shipment of your DX -2 in other than factory packing may result in non-warranty

damage.

3.2 Opening the DX-2 cover

An inspection of the interior of the amplifier should reveal no damage or adversely affected components. Remove the 4 screws on each

side and remove the cover. Should there be any form of problem, notify your supplier immediately.

4 INSTALLATION I ENVIRONMENT

4.1 Required environment

The DX-2 amplifier can be operated at an ambient temperature between 0 and 40° Celsius. It should be installed in a place with a good

ventilation and protected from the direct sunlight. At least 5 cm (2 inches) of free space must be left at the rear and left and right, for

ventilation. Do not place any object on top of the amplifier, especially above the ventilation opening.

An environment free of dust, smoke and high humidity is required, as for any high powered RF amplifier. Dust, or particles resulting

from burning fire wood or coal could be responsible for sparks or electrical discharges between the capacitor plates, or in other parts of

the RF section.

4.2 Power requirements

When operating at full power, up to 16A from the 240 VAC mains is required. Ensure that the AC supply you intend to use is fully

rated and properly fused. The Emtron "soft start" circuitry ensures that there are no momentary surges of current at power-up, therefore

the fuse does not need to be over-rated. However, the wiring of the mains supply for the amplifier should be able to handle the power at

full load with minimal drop in the voltage, to insure the performance of your DX-2 does not suffer.

5 REAR PANEL

The following connectors and controls are present on the rear panel

5.1 Power / Earth connections

A wing-nut Earth connection is provided at the rear of DX-2. A good Earth link must be provided here. Connect this first, before

making any other connection to the amplifier. The AC power input is protected by two 20A fuses.

5.2 RF connections

RF INPUT

The RF input is an SO-239 female connector. A 50 ohm coaxial cable line of good quality terminated with a PL-259 coaxial

connector is required to connect the transceiver or exciter output to the input connector of your DX-2 amplifier.

RF OUTPUT

The RF output is also a female SO-239 connector. The use of a high quality RG-8A/U, RG-213 or similar 50 ohm coaxial

cable line terminated with a ‘VHF’ type PL-259 connector is essential. Similarly, a VSWR of 2: 1 or better is

mandatory. Remember too, that the EMTRON DX-2 amplifier can deliver 1.5 kW continuously in the SSB mode. Not all antennas can

handle such power.

5.3 Transceiver control

ALC

The ALC output is via a black female RCA connector.

This is an ALC system for use with transceivers or transmitters having a negative-going ALC system and possessing an external ALC

input jack. A shielded patch lead with an appropriate connector at one end and a male RCA connector for the DX-2 at the other end is

required. Check the specifications of your transceiver for a suitable connection.

PTT

The PTT input is a female RCA connector (red). This line controls the transmit/receive switching system. This jack must be connected

to transceiver or exciter relay contacts which are open on RECEIVE and closed on TRANSMIT. In the standard version (DX-2 fitted

with a l2V antenna relay), the PTT input presents an open circuit voltage of + l2V with respect to the chassis, with an impedance of

about 70 ohm. Therefore, a current of typically 0.17 A must be switched by the transceiver or exciter.

In the QSK version, the voltage at the PTT input is typically 28V (and up to 36V unloaded), with an impedance of about 240 ohm. A

current of about 0.12 A has to be switched in this case.

ALC CONTROL

This is a user-accessible control for setting the negative voltage at the ALC output. Further details are given in section 10.2

5

6 FRONT PANEL

The following controls and indicators are present on the front panel:

6.1 Controls

BAND SWITCH

A nine position switch selects the desired frequency range. The 7 operating bands are indicated in metres. The last two switch positions

are not used in the U.S. version of DX-2. If a special licence is produced, the amplifier can be delivered with all 9 bands operational.

PLATE TUNE

Tunes the amplifier operating frequency. A chart of approximate starting settings is given in Table-1

LOAD TUNE

Tunes the amplifier output loading. A chart of approximate starting settings is given in Table-1

ON/OFF

Switches the AC power on and off. On initial switch on, the standby mode is enabled. Note also the appropriate switch down sequence,

given in Section 11.

OPR/STBY

Enables the amplifier once it has warmed up. In STANDBY mode, the screen voltage is removed and any RF power applied to the

input, is bypassed to the output. If this switch is changed to OPERATE before the READY light comes on, the FAULT light will turn

on. This is not a fault, but it is better to leave the switch in STBY position until the amplifier is ready to operate.

6.2 Displays

All the DX-2 indicators are concentrated in a single, solid state, "moving LEDs" display (See drawing). The following parameters are

displayed (top to bottom):

Output Power - Scale up to 2kW. Yellow LEDs, with red indicating power over 1.5kW.

Reflected Power - Scale up to 250W. The colour is green, yellow and red, indicating progressively higher reflected power and possibly

problems with your antenna.

Ig2 - Zero-centred display. The left (green) side has a full scale of about 25 mA of negative screen current. The right (red) side has a

full scale of about 50 mA of positive screen current. Above this value, the red LEDs will flash, warning you to increase the loading, or

reduce the drive. At about 60 mA, the protective current limiting will cut in.

Plate Voltage - Scale up to 3.3kV, green.

Plate Current - Scale up to 2.0A. Yellow, with a green zone indicating the standing current bias (when EBS is disabled only. NOTE:

the factory adjustment could be slightly different from the green zone indication). The area above 1.8A is red. It indicates excessive

plate current, due to high drive level and improper tuning (especially plate tuning - see "Tuning" chapter, Section 10.1).

ON Air - single LED, green. When pressing PTT, this LED turns on (while in OPERATE)

READY - single LED, yellow. Turns on at the end of warm-up period, when the mains power to DX-2 is switched on. It turns off for

about 2 minutes if the plate current protection is triggered. In this case, the FAULT light also turns on (if switch on OPR).

FAULT - single LED, red. Turns on in 3 situations:

when the over-temperature protection is triggered, the FAULT turns on until the tube cools to a safe level. During this time,

the operation of the amplifier is disabled, the screen voltage is off and any RF power applied to the input is bypassed directly to

the output.

when the over-current protection is triggered, FAULT turns on for 2 minutes, while READY turns off

at DX-2 power up, if the OPR/STBY switch on the front panel is left in OPR position. The FAULT light will go off when

the DX-2 is ready for operation, after warm-up.

SWR - single LED, red. A three second cut-off will happen if your antenna has a SWR worse than 2:1 (typical 2.6:1) at the operating

frequency. During the cut-off, the RF from the input is directly by-passed to the output.

OVER-DRIVE - single LED, yellow. Flashes when the input drive is exceeding the linear operation level. If even more drive is

applied, the overdrive protection will cut off (by-pass) the operation for about 2 seconds.

6

Figure 1. DX-2 Front Panel Display

7 ELECTRICAL CONNECTIONS

7.1 Connections to Transceiver / Exciter

Signal connections

Before making any connections, ensure that DX-2 is not connected to AC power, and the transceiver is not transmitting. Connect the

antenna first to the DX-2 output. Then connect the transceiver output to the DX-2 RF input. Plug the PTT lead into the RCA socket

marked PTT on the rear panel. If required, connect the ALC.

The most appropriate interconnection layout is shown in Figure 1 below. In this set-up, the transmit/receive relays in the DX-2 are

controlled directly by the transceiver or exciter.

Figure 2. Connections between DX-2 and station transceiver

7.2 Earth and mains connections

Power connections

Before connecting any power to the amplifier, make a good Earth connection to the screw with wing nut at the rear of DX-2. Make sure

the POWER switch on the front panel is in the OFF position. Then plug the power cable into the power point.

RF OUTPUT POWER

(

kW

)

REFLECTED POWER

(

W

)

PLATE VOLTAGE

(

kV

)

PLATE CURRENT

(

A

)

I

g

2

OVE

R

DRIVE

ON AIR

READY

SWR

FAULT

EMTRON

DX-2

STATION

TRANSCEIVER

RF IN RF

OUT

TO

ANTENNA

ALC ALC

PTT

Relay

In

p

ut

PTT

Relay

Out

p

ut

7

7.3 Terminating the power cable (export version)

As different countries have different standards for their power connections, all DX-2 amplifiers exported from Australia are supplied

with un-terminated power cables.

The green/yellow wire is connected to the amplifier chassis and MUST be connected to the safety ground of the AC mains supply. It

must NEVER be connected to one of the AC 'hot' wires. The brown and blue wires connect to the mains transformer input. The brown

wire is the "active", or "live". The blue wire is the mains neutral. Both wires are fused.

7.4 Operation at 230V, 220V and 200V (export version)

The Emtron DX-2 will normally arrive pre-set for the power source of the country the amplifier has been sold to. However if operation

to another mains voltage is required, the appropriate connection changes will be needed.

Figure 2 shows the transformer connections for 200V, 220V, 230V and 240V operation. If a change is required, this should be done

only by a qualified technician, after taking all the necessary safety precautions. See CAUTION on page 1.

PLEASE NOTE: The DX-2 should not be connected to a mains supply of less than 200V AC !

Figure 3. DX-2 Transformer AC Input Connections

8 DX-2 DESCRIPTION

8.1 RF Section

The RF section occupies the right hand side of the DX-2 (looking from the top - front). See picture in 1.1.

RF Switch and tuned circuits

At the front of the amplifier are two variable capacitors, for plate and load tuning and a band switch. Next to the switch is the “Pi” coil.

The “L” coil is wound on a ferrite torroid.

RF Sub-chassis

The GU84B tube is positioned on a separate RF sub-chassis. All the connections to the tube, except for the plate, are under this sub-

chassis. A 9-way heavy duty connector is used for inter-connections. The fan blows air into this sub-chassis, which is forced out

through the ventilation fins of the tube. The air temperature is sensed by two sensors placed above the tube. The sensors must stay in a

position close to horizontal. Make sure you are not pushing them down, too close to the tube, as high voltage exists between them. The

plate is connected to the RF network and to the choke supplying the 2500VDC voltage to the plate of the GU84B tube.

0

0

0

0

240

230

220

200

FAN

FAN

FAN

FAN

240

240

240

230

230

230

220

220

220

200

200

200

240 volt:

230 volt:

220 volt:

200 volt:

8

8.2 Mains transformer

The transformer is the heart of the amplifier, a high performance type, designed to reduce the size and weight. It is built with a

generous reserve of power, handling easily the DX-2 requirements in continuous operation. The primary can be wired for 200VAC,

220VAC, 230VAC or 240VAC operation. See Figure 2. There are several secondary windings, as follows:

Filament supply

Low voltage supply to the controller board

QSK module supply

Bias supply

Screen grid supply

High voltage supply

8.3 H. V. Power Supply

A full wave bridge rectifier and filter converts the high voltage AC into high voltage DC with a huge reserve capacity of 58

microfarads.

8.4 Soft start module

At power up, the mains power is gradually applied to the transformer by the soft start module. The power is gradually applied over a

time of about 5 seconds, avoiding the high inrush current typical for such big loads.

8.5 Sensor module

A small metal box positioned at the output of the DX-2. It detects the forward and reverse power, for measurement and display, as well

as for SWR monitoring and to activate the protection, when needed.

8.6 Antenna relay / QSK module

In the standard DX-2, the antenna relay is controlled by the transceiver, via the control board. It switches the antenna between the

transceiver, during reception, and amplifier, during transmission. It is also used to bypass the RF from the transceiver, directly into the

antenna, when the amplifier is in standby mode, or during special conditions like overdrive, bad SWR or other error conditions.

When the QSK option is installed, this is a module with two very fast, high power vacuum relays, and the control circuitry. The

purpose of QSK is to allow very fast switching between transmit and receive, during digital communications. See Annex 1 showing

oscilloscope displays of fast switching times and contact bounce-free operation of the QSK module.

8.7 Display board

This board has a number of inputs where various voltages are connected. The board converts these voltages into a "moving LED" type

of display. Two of these displays have flashing light indication (Ig2 and plate current).

8.8 Controller board

The brain of the amplifier is the Controller Board. The following circuitry is part of this board:

Bias voltage regulator, also incorporating a sensitive grid current detector for overdrive detection . Adjustable pre-bias,

removes the distortion at the beginning of the word, when EBS is activated.

Screen voltage regulator, with adjustable voltage and adjustable current limiting, for tube protection.

Overdrive protection and timer - based on detecting grid current, it initially gives visual warning and, at higher level of

overdrive, it cuts off the amplifier for 2 seconds. It ensures a clean signal, making it virtually impossible to overdrive the DX-

2

SWR detector and timer - switches the amplifier to bypass mode for about 3 seconds when high SWR is detected.

Adjustable SWR level. Factory adjusted to about 2.6: 1

EBS - the Electronic Bias Switch - senses the presence of RF input power and turns on the bias to start transmission.

Factory adjusted for about 0.5W. When the input power exceeds this limit, the plate current starts flowing. When there is no

speech, even for a very short time, the tube dissipation is cut to a low value, as set by the pre-bias adjustment.

Interlocking, timer for filament warm-up

Relay control: ready relay, SWR relay, over-drive relay, antenna relay

QSK switching control

Display control: Ig2 measurement and display, SWR cut-off display, overdrive warning display, READY display, FAULT

display

Logic circuitry, low voltage supply to the various electronic circuits

9

9 POWERING UP

Before switching the power on, check all the necessary connections: Earth, Antenna, Transceiver, PTT, ALC (if used). Make sure the 2

switches on the front panel are in the positions: OFF, STBY.

Switch now the mains power ON (The power switch to ON position). The "soft start" system will take about 5 seconds to fully turn the

power on. After 5 seconds, the display will indicate the plate voltage, typically 2450 V. The FAULT light will turn on briefly, then off.

Wait for the DX-2 to warm up, until the READY light turns on.

This takes about 2 - 3 minutes. This is a minimum required. If you are not in a hurry, give it another minute or two before transmitting.

WARNING!

WHEN YOU SWITCH THE POWER ON, YOU MUST HEAR AIR FLOW NOISE.

IF THERE IS NO AIR FLOW NOISE, SWITCH THE POWER OFF IMMEDIATELY

AND CONTACT YOUR SUPPLIER

10 OPERATION

10.1 TUNNING PROCEDURE -

10.1.1 General

For each band and operating frequency, the transceiver settings must match the position of the BAND switch on the front panel of the

DX-2, while the PLATE and LOAD knobs must be adjusted for optimum operation which gives – in conjunction with the input drive

level, the maximum output power that can be obtained for that input power. When the tuning is correct, this will also result in a

minimum plate current, minimum plate dissipation and good linearity.

10.1.2 Preliminary tuning

•Turn the BAND switch to the same band setting as the transceiver. (Also, make sure the right antenna is used).

•Put LOAD and PLATE knobs in the initial positions given in Table 1.

•DX-2 must be powered ON and "Ready", with the OPR/STBY switch in OPR position.

•Start with the transmitter at minimum power, in a "carrier" mode e.g. RTTY or CW - key down.

•Key the transceiver ON and gradually apply power to the DX-2. When 0.5 to l W of drive is reached, the EBS is activated and

the plate current jumps from zero to about 0.3 - 0.4A

•Increase the drive until there is some output power indicated. If the current plate Ip reaches about l A and there is still no

output indication, turn PTT off and check the connections, the band and the initial settings.

•As soon as there is any power indication, tune PLATE for maximum output (and minimum plate current).

•Apply more drive and adjust PLATE again for maximum output. Keep PTT ON for short time only (about 10 seconds). Go

gradually, in several steps. When about 700 - 1000W output is reached, adjust LOAD for maximum output. If there is no red

Ig2 indication, it is likely that LOAD needs to be turned clockwise, towards higher numbers on the dial.

•Apply more drive and adjust both knobs again. When screen current appears (red Ig2 indication), increase loading by turning

anti-clockwise the loading capacitor. (LOAD towards lower numbers on dial) until Ig2 drops almost to zero. Then adjust

PLATE for maximum output power and maximum Ig2. At this point, Ig2 is the most sensitive indicator of resonance on

the working frequency. If Ig2 goes too high (e.g. starts blinking), increase the loading again, then tune PLATE.

•Repeat the above steps, while gradually increasing the input drive power, until the overdrive indicator just starts turning on.

Now the DX-2 is tuned for operation at full power on that particular operating frequency.

NOTES:

1. The maximum power is obtained from a DX-2 when:

onset of the overdrive indication

PLATE is tuned for maximum output power, maximum screen current Ig2 and minimum plate current, Ip

Ig2 indicator shows 2 or 3 red LEDs.

2. The above conditions will also give the best linearity.

3. During the preliminary tuning, switch PTT on and off several times, to allow time for tube cooling. The tube dissipation (at a given

drive level) is minimum when tuning is optimum. In short, be brief, with tuning "bursts".

4. Preliminary tuning, as described above, is only necessary when operating for the first time in a certain band. When the final settings

for PLATE and LOAD have been found for the particular working conditions - especially the antenna used, note your settings on

Table 1. The new settings will normally differ to some extent from the ones indicated, depending on the "purity" of your antenna load.

Note that the settings (especially LOAD) will be different at lower output power – See “Tuning for less than full power”.

10

10.1.3 Final tuning

Once the preliminary tuning has been done for each band / antenna combination, the values found for PLATE and LOAD can be used

for final tuning, with no need to repeat the preliminary tuning every time.

Tuning for full power

•Start with low drive level and the PLATE and LOAD knobs in the known initial positions

•Put PTT ON and increase the power (fairly quickly), to the onset of the overdrive indication. If the screen current (red Ig2)

goes too high, adjust LOAD, by turning the knob to the left (increasing the load).

•Adjust the drive level and LOAD until the overdrive indicator is just about to turn ON, and at the same time Ig2 shows two or

three red LED's ON.

•Fine tune PLATE for maximum output and maximum Ig2.

•Repeat the last two steps above if required.

Tuning for less than full power

•Start at low power, with the initial values for PLATE and LOAD

•Put PTT ON and apply drive until the output is about 1/2 of the desired power.

•Adjust LOAD for maximum output. Most likely, the knob will have to be rotated to the right, towards higher numbers on the

dial.

•Adjust PLATE for maximum output

•Apply more power

•Repeat the 3 steps above until the required power is achieved. If screen current is indicated by Ig2, is should, display two or

three red LED's. Maximise this Ig2 indication (and the output power at the same time), by tuning PLATE

•If the output goes higher then desired, reduce the drive and re-tune. Never reduce the output by de-tuning the amplifier!

NOTE: If the output is low (say, less than about 700W), Ig2 will never show any screen current at all. Ig2 might even indicate a

negative current, in green - this is normal and is no cause for concern).

However, if there (green) negative current indication, usually this will go away with better tuning of the PLATE control.

If there is no Ig2 red indication., simply rotate LOAD to the right in small steps, and each time maximise the output by turning PLATE,

until the highest possible maximum in the output power is achieved.

10.1.4 Potential problems during tuning

The tuning operation. should be completed fairly quickly. If the tuning process takes a longer time, it should be done by switching the

transmission on and off several times, to allow the tube time to cool.

•If the fan changes to high speed, the operation can continue, as there is ample reserve of cooling power. However, it is the best

to make a pause (about 1 minute will be sufficient) and wait for the tube to cool.

•If the FAULT light comes on, it is possible that the plate current has reached too high values due to incorrect plate tuning. In

this case, reduce the excitation power, wait for the FAULT light to turn off (about 2 minutes) and resume tuning.

•If the overdrive protection is activated, by cutting off the amplifier for 2 seconds. It is likely in this case that you are applying

too much power at the input. Reduce the power and watch the "overdrive" LED. Increase the power only until this light starts

flashing.

•If the SWR protection cuts in - it is likely that your antenna is not a good 50 ohm match at the operating frequency. In

principle, the SWR protection level in DX-2 is adjustable, but it is far preferable for you to fix your antenna.

10.2 ALC ADJUSTMENT

The DX-2 can be operated without any ALC connection. However, if you wish to use it, and your transceiver has an ALC input, then

the potentiometer on the rear panel must be adjusted. This adjustment is not critical, since its voltage output is zero under normal

operation and it increases sharply (towards a negative value - up to -11 V), when the overdrive limit is approached. The ALC in DX-2

amplifier is not a conventional design, this circuit operates for only one reason - to prevent overdriving and to keep the signal clean.

To adjust the ALC potentiometer:

•Turn the potentiometer initially all the way to the right (minimum ALC voltage)

•In CW mode, after tuning, apply increasingly higher drive, until the "overdrive" LED just starts to turn on

•Increase the drive slightly more, to have the light fully on, but make sure the DX-2 overdrive protection does not cut you off.

At this power level, adjust the ALC potentiometer to the left, until the transceiver drops its power output.

Alternatively, in voice mode, increase the RF gain or the microphone gain until the overdrive led is flashing at peak of modulation.

Then, increase ALC (rotate potentiometer to the left) until the transceiver begins to limit the drive to DX-2.

NOTE: Some types of transceivers (e.g. YAESU FTI00MP, FT920 and others) are not compatible with this type of ALC. They require

an ALC signal proportional with the output power. DX-2' s ALC is zero until the drive reaches the over-drive limit, when the negative

voltage increases sharply. YAESU operating manual indicates that this type of ALC might not work well with their transceivers, since

grid current could be generated by amplifier mis-tuning not related to excessive drive conditions. If this is the case, simply do not

connect it.

11

10.3 USING YOUR DX-2

While tuning and adjusting the amplifier, a CW mode is normally used. When these operations are finished, you can change to the

operating mode you wish to use and start operating.

10.3.1 CW / RTTY and all digital modes

In CW, the setting up of the amplifier is similar to that of the tuning mode. After adjusting the input power level to the amplifier,

according to the desired output level, and tuning the plate and load capacitors, you can simply start operating by applying the same

carrier level as during tuning. If the amplifier is set to deliver full output power, or close to, then screen current will be present. As in

the case of tuning, the best operation is achieved when there is a certain amount of screen current flowing, corresponding to two or

three red LED's turning on in the Ig2 display.

10.3.2 Voice modes (SSB)

When a voice modulation is applied to the amplifier, the drive level is not precisely defined, as in the case of tuning with continuous

carrier. If there is screen current flowing, or an input overdrive, they will be indicated only at peak of modulation, by the respective

indicators flashing. You will have to adjust the microphone gain, or the RF drive, or both, in an attempt to achieve input driving

conditions similar to those you have used while tuning. Occasional flashing of the overdrive indicator is acceptable. If the over-driving

is severe, a momentary cut-off will occur.

10.3.3 Hints on good linearity and efficiency

Operating with good efficiency: If you are watching the plate current indicator, you must be aware that the total power the amplifier is

drawing from the mains is proportional to the plate current. Power that is not sent to antenna, is dissipated by the tube. As explained in

the Tuning section, the best tuning achieves a maximum power output at the same time with a minimum plate current, drastically

minimising the tube dissipation. Be aware that at a low power level, slightly different tuning is required than is for full power.

Achieving the best linearity: The amplifier must be tuned and operated all the time in the linear mode. This is important because a non-

linear operation will generate harmonics which will disturb RF communications in other bands and frequencies.

We must distinguish two situations:

Less than full power.

With less then full power (say 1000W or less), correct tuning, no screen current and no input overdrive indication, you will always

have your DX-2 operating with a good linearity and clean signal.

Full power operation.

At full power, there are two things that must be watched to see when you reach the limit of linear operation: the screen current, Ig2, and

the grid current, indicated by the "Over-drive" LED.

In this case a good linearity is maintained up to the moment when the screen current is approaching the full scale value of the Ig2

indicator and it starts flashing, or when the overdrive indicator begins to turn on.

A high screen current, indicated by 4 LED's on in the Ig2 display, will create a moderate level of distortion.

Even a small amount of grid current will cause severe distortion. When the "Over-drive" indicator just begins to turn on, there is

already a small amount of distortion, created by a grid current of about 100 microamperes.

With this indicator flashing, you are at the limit of the RF carrier clipping. This is probably more acceptable in a voice mode of

operation. In CW or digital modes, the best is to slightly reduce the drive, just below this level. A severe level of over-driving is not

possible anyway, due to the cut-off protection. The cut-off will happen at about 400 microamperes of grid current.

See the Appendix 2 and the Troubleshooting section for oscilloscope displays showing examples of a two tone generator driving the

DX-2 in linear mode, and an overdrive situation, when a DX-2 with the overdrive protection disabled is being overdriven by the two-

tone generator.

The Ig2 indicator should have two to four LED's flashing on at peak of modulation. This (combined with a correct plate tuning),

indicates an optimum loading, good efficiency and good linearity. A lower screen current, due to excessive loading, will reduce the

output power, with an equal amount of extra power dissipated by the tube. A higher screen current, making all four LED's in the Ig2

flashing, will increase the distortion.

11 SWITCHING THE POWER OFF

When you have finished using the amplifier and you want to switch it off, the following procedure is recommended:

Stop transmitting.

Put the switch on STBY.

Leave the DX-2 running idle for a few minutes, to cool the tube, then switch the power off.

12

12 TROUBLESHOOTING - If something goes wrong

12.1 No power

•When you switch on a DX-2, it takes about 3 - 5 seconds for the lights on the front panel display to come on. This is due to the

"soft start" circuit. If nothing happens after turning the power on, switch off at the front panel, then check the following:

•make sure the power outlet has power

•make sure the power plug is fully pushed in into the power outlet.

If it is still not working, unplug the power cord from the mains, then remove the fuses from the fuse holders on the rear panel of DX-2

and check them with an ohmmeter.

•If a fuse is blown, replace it with a fuse of the same type and try again.

•If the fuse blows again, or if the fuses were not blown in the first place, contact your supplier.

12.2 Fan goes to high speed

This could happen especially during tuning, or when the ambient temperature is high. It could also happen when the ventilation is

restricted, for example by blocking the openings at the back, sides or on the top of the amplifier. In normal operation, with correct

tuning, the DX-2 should be able to handle the maximum power with the fan still running at low speed. Usually driving the amplifier

with high power and bad tuning can make the fan to go high speed. When this happens, the tube temperature is nominally 120° Celsius.

This offers a margin of 30°C before a temperature cut-off occurs, and way below the tube rating, of 200°C. That means you can

continue to operate the amplifier with the fan at high speed, but the best is to let it idle until the fan drops back to low speed. This

usually takes less than one minute.

12.3 Fan not working

As soon as you switch the power on, you should notice two things about your DX-2: the display should indicate about 2500V of plate

voltage, and you should be able to hear the fan running. The amplifier is not supposed to be powered without the fan, even in idling

mode. If the fan does not operate when you power up, or if it stops while using the amplifier, switch the mains power off immediately

and contact your supplier.

12.4 If the FAULT light turns on

The FAULT (red) light turns on in two situations:

•Over-current in the plate circuit

This could happen due to a flash-over in the tube, or as a result of a momentary high plate current during tuning. This completely

disables the amplifier for about 2 minutes. The same timer is activated as when the amplifier is switched on, causing the READY light

to turn off. If the OPR/STBY switch on the front panel is put on STBY, the FAULT will turn off, but the READY will be also off.

When the READY comes on again, the FAULT will disappear (if the amplifier was left in OPR), and the DX-2 is ready to operate

again.

•Over-temperature cut-off. See below.

12.5 Over-temperature cut-off

This would normally happen after a change of the fan to high speed. The operation of the amplifier is disabled, but the timer is not

activated. The FAULT light turns on.. When the tube cools down, the FAULT turns off and the operation can resume. This type of

fault should never happen. DX-2 has a very efficient air cooling system. When the ventilation is not restricted, in normal ambient

conditions, when properly tuned, a DX-2 can operate at full power for extended periods of time, with the fan not even going to high

speed. The temperature cut-off happens when the tube reaches 150ºCelsius, with ample safety margin to the specified limit of 200ºC

for the GU84B tube.

12.6 Over-current cut-off

If the plate current exceeds even for a brief time a pre-set safe limit, an over-current detector will activate the power up timer, disabling

the amplifier for about 2 minutes. During this time the READY light is off, and the FAULT light is on, if the amplifier is left in OPR

mode, as explained under 12.4, "If the FAULT light turns on".

12.7 Ig2 blinks fast - No plate voltage

If the high voltage is lost due to a fault in the amplifier, the screen current tends to reach very high values. This is an unlikely situation,

but if did happen, this would normally guarantee a tube failure in unprotected amplifiers that do not have a current limiting circuit. The

screen current limiting in DX-2 is so efficient, that the tube is fully protected even in such a situation and test bench DX-2's have been

extensively run with no plate voltage and maximum screen voltage, with no effect on the tube. If this loss of high voltage should

happen to your DX-2, the Ig2 display will have the red LEDs flashing, due to the screen current exceeding the pre-set limit, with no

input power applied to the amplifier, while switched to OPR.

In such a case, it is possible that the high voltage is still shown on the display, but it does not reach the tube. In any case, this is a major

fault. Put the amplifier on STBY and the flashing will stop. Then switch the power off and contact your supplier.

13

12.8 Sparks / Discharges in RF area

Very high RF voltages are present in the amplifier during the operation at high power. Incursion of dust or even suicidal insects can

cause such temporary problems.

12.9 SWR cut-off

The factory adjustment for SWR protection is about 2.6: 1. This adjustment can be changed, but the best is to operate with a properly

matched antenna. Should your DX-2 'see' bad SWR, it will shut down for 3 seconds (in bypass mode).

12.10 Frequent over-drive protection cut-off

As previously described in the tuning and operation sections, there is a protection acting on DX-2 input overdrive. When the drive

reaches the limit where signal distortion begins to occur, the overdrive indicator on the front panel will warn you to reduce the drive. If

you increase the drive even further, a cut-off protection is activated.

After about 2 seconds of amplifier bypass, the operation is resumed, but if you have not reduced the drive, the protection will be

activated again. To stop it, you must reduce the input power drive. This protection is not adjustable, you must not exceed the limit. If

this happens too often, you obviously do not have a fine control over the transmit level of your transceiver. In this case, try using the

ALC, See section 10.2.

12.11 Tube replacement

It is very unlikely that you will ever need to replace the GU84B. If there is a need for that, the tube is easy to replace, but a bias

adjustment is required for the new tube. See the service section of this manual.

13 WARRANTY I SERVICE

The full FOUR YEARS warranty for DX-2 amplifiers covers all parts and labour, except for the tube. The tube is under a limited

warranty, also for FOUR YEARS.

14 GLOSSARY

AC Alternating Current

ALC Automatic Level Control

AM Amplitude Modulation

CW Continuous Wave

DC Direct Current

EBS Electronic Bias Switch

FM Frequency Modulation

HF High Frequency

LED Light Emitting Diode

PEP Peak Envelope Power

RF Radio Frequency

RTTY Radio Tele Type

SSB Single Side Band

SSTV Slow Scan Tele Vision

SWR Standing Wave Ratio

VAC Volts, Alternating Current

VDC Volts, Direct Current

WARC World Administrative Radio-communications Conference

VSWR Voltage Standing Wave Ratio

14

15 SERVICE

15.1 General

All Emtron amplifiers are built in a modular for. Most modules are common for the entire DX-n range.

This makes it easier to service the amplifier. However, this should only be attempted by suitable qualified people, with proper tools and

test equipment. Apart from the damaged that could be caused to the amplifier by unqualified intervention, the high voltages and

high RF power present in these amplifiers makes them extremely dangerous. Extreme care is recommended event to those very

experienced in this area.

The following pages describe the main adjustments required on the DX-2 linear amplifier.

15.1.1 CONTROL BOARD

This procedure refers to adjustments made to the board already installed in the amplifier.

This would be required, for example, after replacing the tube or after certain repairs.

After a tube replacement only one or two adjustments are required: BIAS and (if EBS used): PRE-BIAS

15.1.1.1 PRE-BIAS ADJUSTMENT (Adjustment: POT7, marked PRE_BIAS)

The pre-bias is required when the Electronic Bias Switching (EBS) is used. If the EBS link is kept in OFF position, the pre-

bias does not need to be adjusted. PRE-BIAS must be adjusted before BIAS.

When EBS is activated (the default situation), keying the amplifier causes the plate current to stay cut off (as if the PTT

was off), until a small amount of drive is applied. The “Pre-bias” establishes a small plate current as soon as PTT is on.

The transition to full on is then less abrupt, while the tube dissipation is still reduced by using EBS.

PTT Off: Ip = 0

PTT On (no drive) and EBS on: Ip = Ipb (pre-bias current)

PTT On (no drive) and EBS off: Ip = Ip0 (standing current)

PROCEDURE:

Remove the cover and connect a voltmeter (+) to the test point TP2 (top corner). (-) to the chassis.

Make sure the EBS link is in the lower position (EBS ON).

With the amplifier running, wait the warm-up time. When READY, put OPR switch on and key the amplifier with NO

INPUT DRIVE. Read the voltage at TP2. Adjust POT7 (PRE-BIAS) to obtain the desired pre-bias current.

Recommended pre-bias currents (POT 7, PRE_BIAS):

DX1b: 10 to 30 mA 10 to 30 mV on the voltmeter Clockwise to reduce current

DX2 and

DX2SP:

15 to 40 mA 15 to 40 mV on the voltmeter Clockwise to reduce current

DX3: 20 to 60 mA 10 to 30 mV on the voltmeter Clockwise to increase

current

NOTE: the pre-bias current is not critical.

15.1.1.2 BIAS ADJUSTMENT (Adjustment: POT3, marked BIAS)

Adjust Pre-Bias before adjusting Bias.

This adjusts the plate standing current, with the EBS Off and the amplifier keyed with NO INPUT DRIVE.

PROCEDURE:

Remove the cover and connect a voltmeter to the test point TP2 (top corner).

Put the EBS link is in the upper position (EBS Off).

With the amplifier running, wait the warm-up time. When READY, put OPR switch on and key the amplifier with NO INPUT

DRIVE. Read the voltage at TP2. Adjust POT3 (BIAS) to obtain the desired bias current.

CAUTION: With a new tube, start at a low plate current. Rotate POT3 for minimum current before keying the amplifier.

With the adjustment in the wrong position, the plate current could reach very high values.

During this adjustment there is no output power. All the power taken from the high voltage supply is dissipated by the tube.

Be brief and quick. Put PTT on for a few seconds, then on. Repeat several times until the desired standing current is

achieved.

15

Recommended bias currents (POT3, BIAS):

DX1b: 290 to 310 mA 290 to 310 mV on the voltmeter Clockwise to reduce current

DX2 and

DX2SP:

370 to 380 mA 370 to 380 mV on the voltmeter Clockwise to reduce current

DX3: 740 to 760 mA 370 to 380 mV on the voltmeter Clockwise to increase

current

NOTE: After adjustment, move the EBS link back in the ON position (default) if EBS is desired.

The above 2 adjustments are required when changing the tube or when changing the control board.

The remaining following adjustments are pre-adjusted with a new control board and normally there is no need to change

them. A possible exception could be the SWR protection which might require some fine tuning after changing the control

board or the RF sensor module, but usually the factory pre-adjustment is close enough. Also EBS might need adjustment

depending on the personal preference of the operator.

15.1.1.3 SWR Protection adjustment

Adjustment: POT5, marked SWR.

This adjustment require a special jig with a load made of 2 non-inductive, high power resistors (at least 300W).

They can be switched between 130 ohm and 140 ohm. With a 50 ohm output these 2 loads give an SWR of 2.6:1 and

2.8:1 respectively. The adjustment is nominally for a ratio of 2.7:1 to trigger the protection in the form of antenna by-pass.

Usually this adjustment is performed on 20m (14.200 MHz) at full power.

With a 50 ohm dummy load, transmit and adjust for full power (or close to full power).

Stop transmitting and replace the 50 ohm dummy load with the special dummy load described above.

Switch the dummy load to 140 ohm and key the amplifier for just one second.

If the protection wasn’t activated immediately, increase the sensitivity (Rotate clockwise for DX-1, DX-2, and DX-2SP and

anti-clockwise for DX-3).

Repeat applying power for a short time only, until the protection is triggered.

Switch the special dummy load to 130 ohm and repeat. This time the protection should not trigger. If it triggers, reduce the

sensitivity. Try several times using 130 and 140 ohm load. The protection threshold should be between these 2 values

(135 ohm, corresponding to 2.7:1 SWR).

15.1.1.4 EBS ADJUSTMENT (Adjustment: POT4, marked EBS).

Usually this adjustment is performed on 20m (14.200 MHz), but it can be done on any band.

Transmit into a dummy load or antenna.

Apply very low input drive.

With the EBS activated (with the EBS jumper in the lower position, or ON):

Checking the existing adjustment: increase slowly the input drive, starting from zero, until the EBS system activates the

amplifier. This can be checked by watching the plate current or the RF output power or the current or power taken from the

AC mains. Any one of these can be monitored and a jump in reading happens when EBS switches.

Check that this happens for an input drive between 0.5 – 1 Watt.

Adjusting EBS: if the adjustment is not correct or you prefer a lower or higher setting, apply the desired amount of power

and then adjust POT6 until you find the limit where the EBS activates.

NOTE 1: a higher threshold is likely to give reports of the beginning of the words being cut off. If this is the case, a lower

threshold (higher sensitivity) can be used.

A low threshold can make the EBS activate erratically, for example due to the ambient noise of in the room, or even due to

the noise generated by the fan. This is not a problem in itself, except that the tube will dissipate extra power during the

times when you hold the key down but do not speak (eg between the words, while speaking). However, these moment are

usually brief and it won’t make much difference.

NOTE 2: for factory adjustment, a negative voltage with the value of 1.6 V is applied to the RFIN pin on the control board

when this board is checked, then the adjustment is only checked with RF when the amplifier is tested.

16

15.1.1.5 SCREEN VOLTAGE ADJUSTMENT (Adjustment: POT2, marked SCREEN)

The screen voltage can be measured on the pin marked EG2 on the control board (close to the jumper EBS, this pin has a

blue wire connected to it; in DX-3 it is easier to measure on either side of R18).

The nominal adjustment is 356V unloaded.

NOTE: the screen voltage does not need adjustment unless the value was altered by somebody.

15.1.1.6 SCREEN CURRENT LIMIT ADJUSTMENT (Adjustment: POT1, marked IG2LIMIT)

Do not adjust this potentiometer, it has been factory adjusted and there is no need to change.

With the amplifier switched off or on STANDBY, remove the blue wire on pin EG2.

Connect an analogue mA-meter with a 100 mA full scale range (+ to the control board) and then (-) to an adjustable

resistive load with a range from 3-5 kohm to about 20 kohm (this jig is also required for the display board adjustment, it is

convenient to adjust the ig2 indicator at the same time). The other end of the resistor goes to the chassis.

The power rating must be 20 – 25 W (short time loading only).

Connect also a voltmeter to measure the screen voltage.

Put the front panel switch on OPR.

Start with a higher value (20 kohm) of the resistor and reduce the resistance gradually. At 10 kohm the reading will be

about 35 mA.

Continue reducing the resistance until the current reaches about 60 – 70 mA. The screen voltage must drop to about 300

V or less under this load.

If not, adjust POT1.

NOTE 1: While adjusting ig2 limit, the ig2 indicator on the display board can also be checked / adjusted at the same time.

NOTE 2: IG2 LIMIT can be checked / adjusted also by simply putting a mA-meter in series with the blue wire connected to

the EG2 pin on the control board. While operating the amplifier at full load, by rotating the LOAD knob, IG2 can be varied

and the screen voltage can be measured. This way the current limit of the screen regulator and the ig2 indicator on the

front panel can be checked quickly, without the need for a special load.

However, the amplifier has to be opened and wires used to extend the screen voltage connection to the blue wire to an

external current meter and volt meter.

15.1.1.7 7. IPTRIP ADJUSTMENT (Adjustment: POT6, marking: IP TRIP)

This is the sensitivity of the high plate current protection (cut-off).

When the plate current exceeds the adjusted limit, even for a very short time, the start-up timer is reset. The screen

voltage is cut off and the FAULT light turns on. To make FAULT light go off, the amplifier must be put on STANDBY. If left

on OPR, the operation will resume automatically at the end of the (about) 2 minutes warm-up time. During this time, any

RF power applied to the input is bypassed into antenna.

Connect a DC supply to pin TP2 on the control board (in the top corner).

With the amplifier powered and the READY light on, put the front panel switch on OPR.

Apply a current gradually increasing from zero and check that the protection is triggered at about 1.85 A of current. When

this happens, the FAULT light will turn on.

If the current value found is much different from 1.85 A, adjust POT6.

To repeat the adjustment or checking, you need to wait every time for the READY light to turn on again (about 2 minutes).

To speed up, the resistor R20 (5.6 Mohm) can be paralleled briefly with a lower value resistor (1k – 100k). Touch R20 with,

say 10 kohm in parallel and the Ready light will turn on immediately.

Table of contents

Other Emtron Amplifier manuals

Popular Amplifier manuals by other brands

Chord

Chord ULTIMA PRE user manual

Prolude Amplification

Prolude Amplification D750 The Little Brick user manual

Kingray

Kingray MHV34 installation manual

RF Concepts

RF Concepts 9500 user manual

Sony

Sony XM-754HX Operating Instructions (English operating instructions

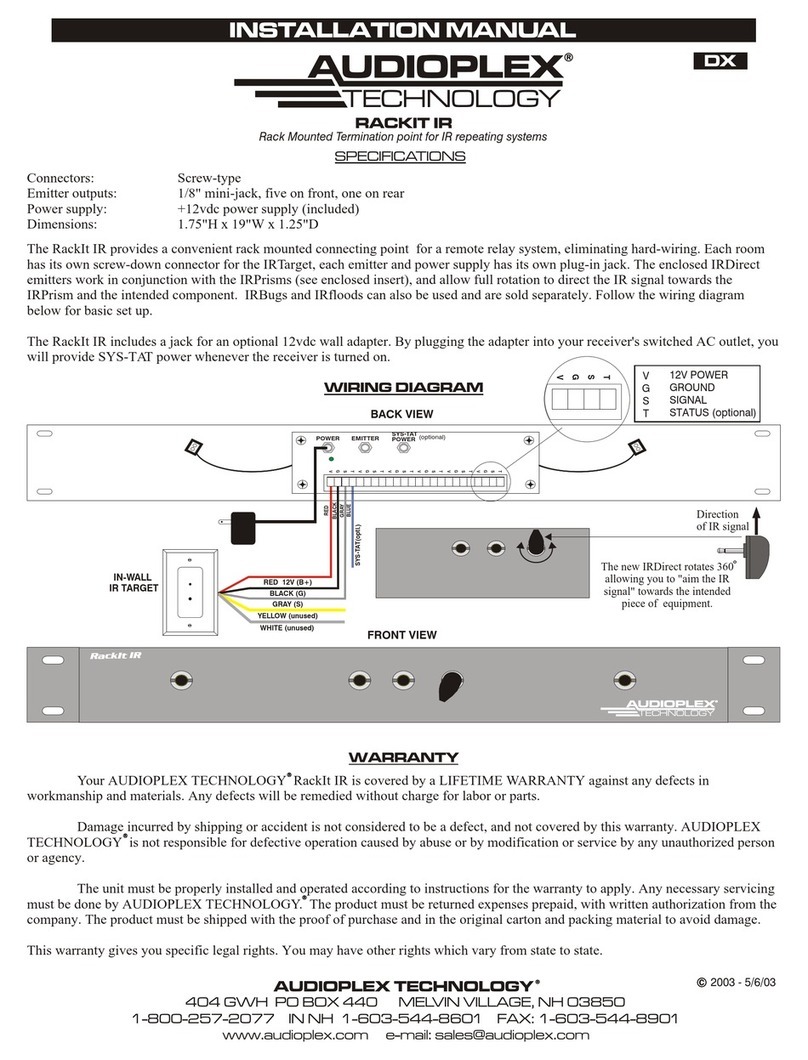

Audioplex

Audioplex RackIt IR installation manual