EMUGE FRANKEN HE 2-IKZZ User manual

HE 2 - IKZZ

HE 2 - IKZ

HE 2 - MK

HE 3

HE 3 - MK

Quick-change adapters HE

Operating instruction

HE

2 Operating instruction edition: 01.02.2017

Contents:

1Application range, safety instructions and technical data...........4

1.1 Application range, determined use ....................................................................4

1.2 Safety instructions and hints..............................................................................5

1.3 Proprietary rights ...............................................................................................5

1.4 Dimensions and technical data..........................................................................6

1.4.1 Type HE, HE-IKZZ, HE-IKZ, for taps/cold-forming taps.......................... 6

1.4.2 Type HE-MK, for drill and countersink .................................................... 7

2Putting the quick-change adapters into operation........................8

2.1 Unpacking..........................................................................................................8

2.2 Insert tool...........................................................................................................8

2.2.1 Insert tap / cold-forming tap .................................................................... 8

2.2.2 Insert drill or countersink......................................................................... 9

2.3 Detach tool ......................................................................................................10

2.3.1 Detach tap / cold-forming tap................................................................ 10

2.3.2 Detach drill or countersink .................................................................... 10

3Maintenance...................................................................................11

3.1 Maintenance schedule.....................................................................................11

3.2 External cleaning.............................................................................................11

4Storage when not in use ...............................................................11

HE

Operating instruction edition: 01.02.2017 3

Warning signs, symbols

This operating instruction uses the following symbols:

Attention

Marks special instructions, rules and prohibitions which are important in order to avoid

any damage.

Please observe these instructions!

Instruction

Marks application instructions and other useful information.

Sectional view:

Quick-change adapter HE

HE

4 Operating instruction edition: 01.02.2017

1 Application range, safety instructions and technical data

1.1 Application range, determined use

Application of the adapters:

Adaptation of taps/cold-forming taps acc. to:

DIN or ISO or ASME dimensions

These adapters are designed to be used in all quick-change tap holders, EMUGE

types:

HF 20 HF20/HD/Spezial Softsynchro®6 HF 30

Production of right-hand and left-hand threads

Possible use in vertical and horizontal machining level

Locking and centering of the taps/cold-forming taps with quick-change adapters type

HE is executed via three screws. The torque arising during the thread producing

cycle is transferred via the square in the quick-change adapter.

In quick-change adapters type HE-MK, drill or countersink are adapted by form-fitting

via the inner taper of the quick-change adapters (acc. to DIN 228B).

Owing to the clamping principle, each shank diameter requires a separate quick-

change adapter.

Following adapter types are available:

Type HE:

For holders without internal coolant-lubricant supply, e.g. quick-change tap

holder HF.

Type HE/IKZZ:

For holders with internal coolant-lubricant supply e.g. quick-change tap holder

Softsynchro®6 and HF20/HD/Spezial and taps/cold-forming taps with coolant-

lubricant bore hole.

The maximum coolant-lubricant pressure is determined by the used quick-change

tap holder, but not more than 50 bar.

Type HE/IKZ:

For adapters with internal coolant-lubricant supply, e.g. quick-change tap holder

Softsynchro®6 and HF20/HD/Spezial and taps/cold-forming taps without coolant-

lubricant bore hole. The coolant-lubricant supply goes along the tool shank.

The maximum coolant-lubricant pressure is determined by the used quick-change

tap holder, but not more than 50 bar.

Type HE/MK:

Adaptation of drills and countersinks with taper shank according to DIN 228 B.

The non-determined use exempts the manufacturer from any liability.

HE

Operating instruction edition: 01.02.2017 5

1.2 Safety instructions and hints

For all works, i.e. putting into operation, production and maintenance, please observe

the details given in the operating instructions.

All relevant safety regulations as well as local instructions are to be observed when

working.

Below please find some basic rules:

Attention

Please wear gloves during tool change to avoid injury.

Basically change the tool yourself to avoid the sudden start of the spindle

caused by mis-operating.

Hold the tool when loosening the tool clamping to avoid it falling down and

damaging the tool and the work piece.

There are maximum values for cutting speeds and feeds for every kind of

machining. Please observe such data.

Please observe the maximum tool dimensions.

Furthermore, the instructions of the tool manufacturers are valid!

1.3 Proprietary rights

The entire contents of these operating instructions are subject to German proprietary

rights legislation.

Any form of multiplication, processing, broadcasting, passing on to third parties - also

in the form of extracts - and any kind of use outside the boundaries of proprietary

rights requires the written consent of EMUGE GmbH&Co.KG.

HE

6 Operating instruction edition: 01.02.2017

1.4 Dimensions and technical data

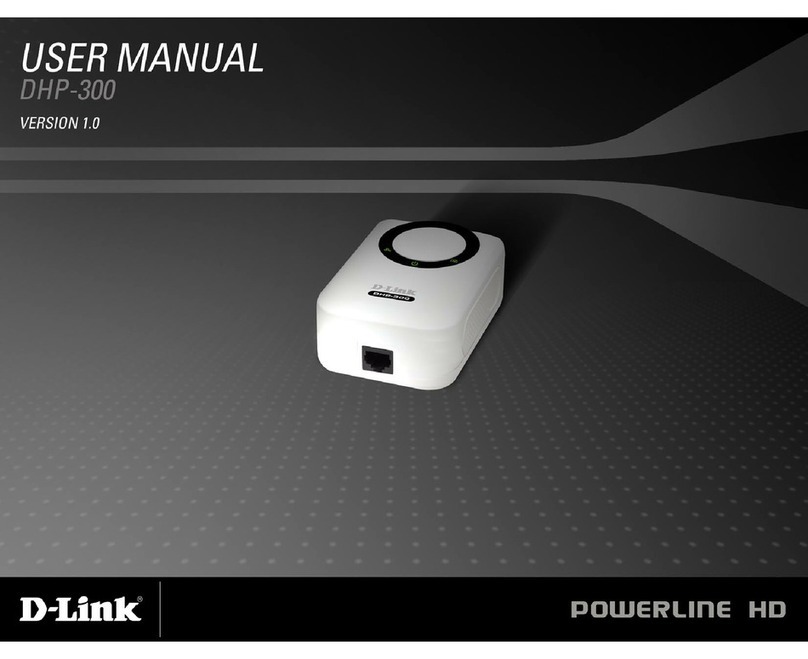

1.4.1 Type HE, HE-IKZZ, HE-IKZ, for taps/cold-forming taps

Type HE:

Without internal coolant-lubricant supply

Type HE-IKZZ:

With internal coolant-lubricant supply through

the tap/cold-forming tap axis

Type HE-IKZ:

With internal coolant-lubricant supply along the

tap/cold-forming tap shank

Picture 1: Dimensions of the quick-change adapters HE, HE-IKZZ, HE-IKZ

Table 1: Technical data of the quick-change adapters HE, HE-IKZZ, HE-IKZ

Type

Cutting

range

D

[mm]

D1

[mm]

D2

[mm]

[inch]

L1

[mm]

L2

[mm]

L31

[mm]

GB

Typ2

HE 2

M24 - M76 *

98

75

18-56

75

12

53-66

DIN

M24 - M76 **

18-56

53-66

ISO

1“–2 1/2

0,80–2,25“

43-66

ASME

HE 3

M36 - M160

128

90

28-70

110

15

76-98

DIN

M39 - M100

28-56

76-98

ISO

13/8 –3 1/2

1,11-2,81“

37-92

ASME

* Fine threads until M120x4 possible

** Fine threads until M100 possible

1

Plug-in depth is defined by the clamping diameter

2

Tool dimensions acc. to DIN or ISO or ASME

HE

Operating instruction edition: 01.02.2017 7

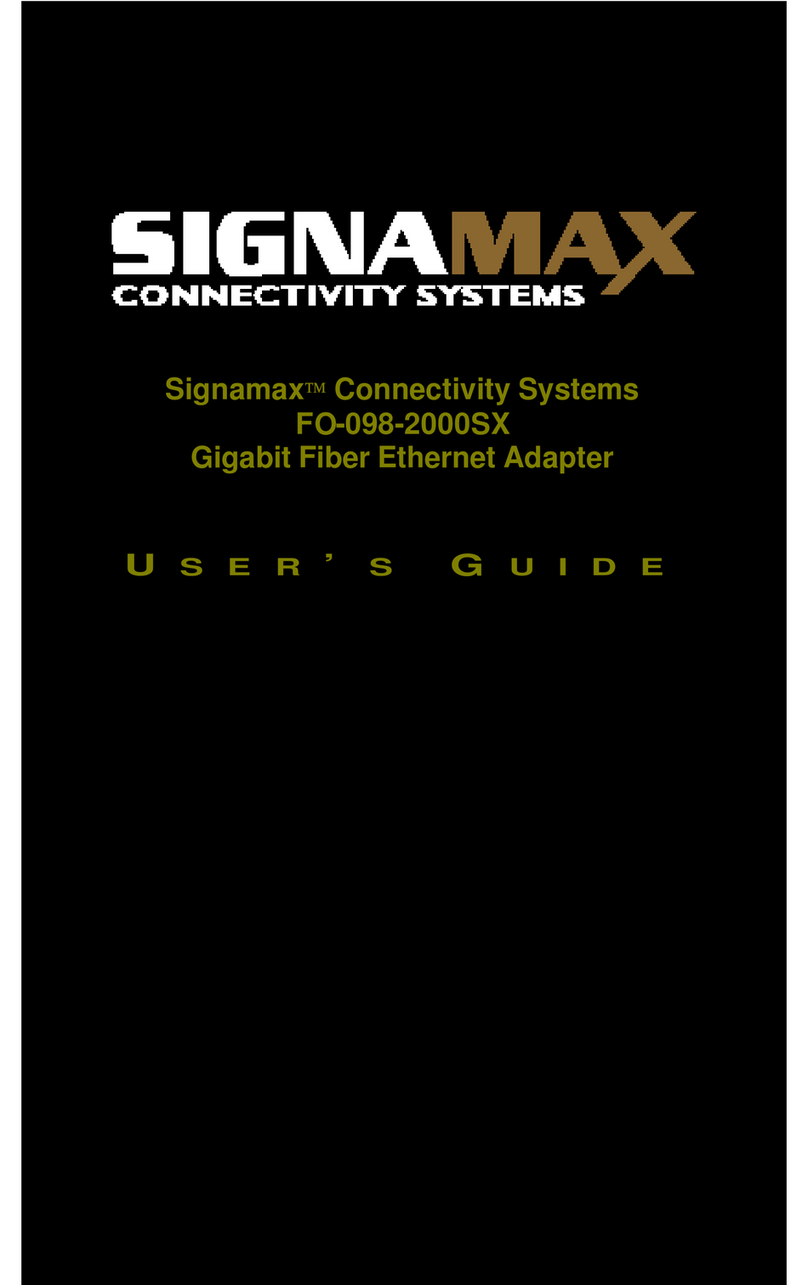

1.4.2 Type HE-MK, for drill and countersink

Picture 2: Dimensions of quick-change adapters HE-MK

Table 2: Technical data of quick-change adapters HE-MK

Type

For holders:

D

[mm]

D1

[mm]

Internal taper

acc.

DIN 228 B

L1

[mm]

L2

[mm]

L3

[mm]

HE 2–MK

HF 20

98

75

MK 3

75

20

25

MK 4

48

MK 5

80

HE 3-MK

HF 30

128

90

MK 4

110

15

20

MK 5

50

MK 6

115

For further dimensions please refer to the EMUGE main catalogue.

Internal taper according to

DIN 228 B

HE

8 Operating instruction edition: 01.02.2017

2 Putting the quick-change adapters into operation

2.1 Unpacking

- Take the quick-change adapter from the plastic case.

- Clean the quick-change adapter with a duster to remove any conservation oil.

Note

Do not use any aggressive solvents.

Do not use fibrous materials i.e. steel wool.

The quick-change adapter is now ready for operation

2.2 Insert tool

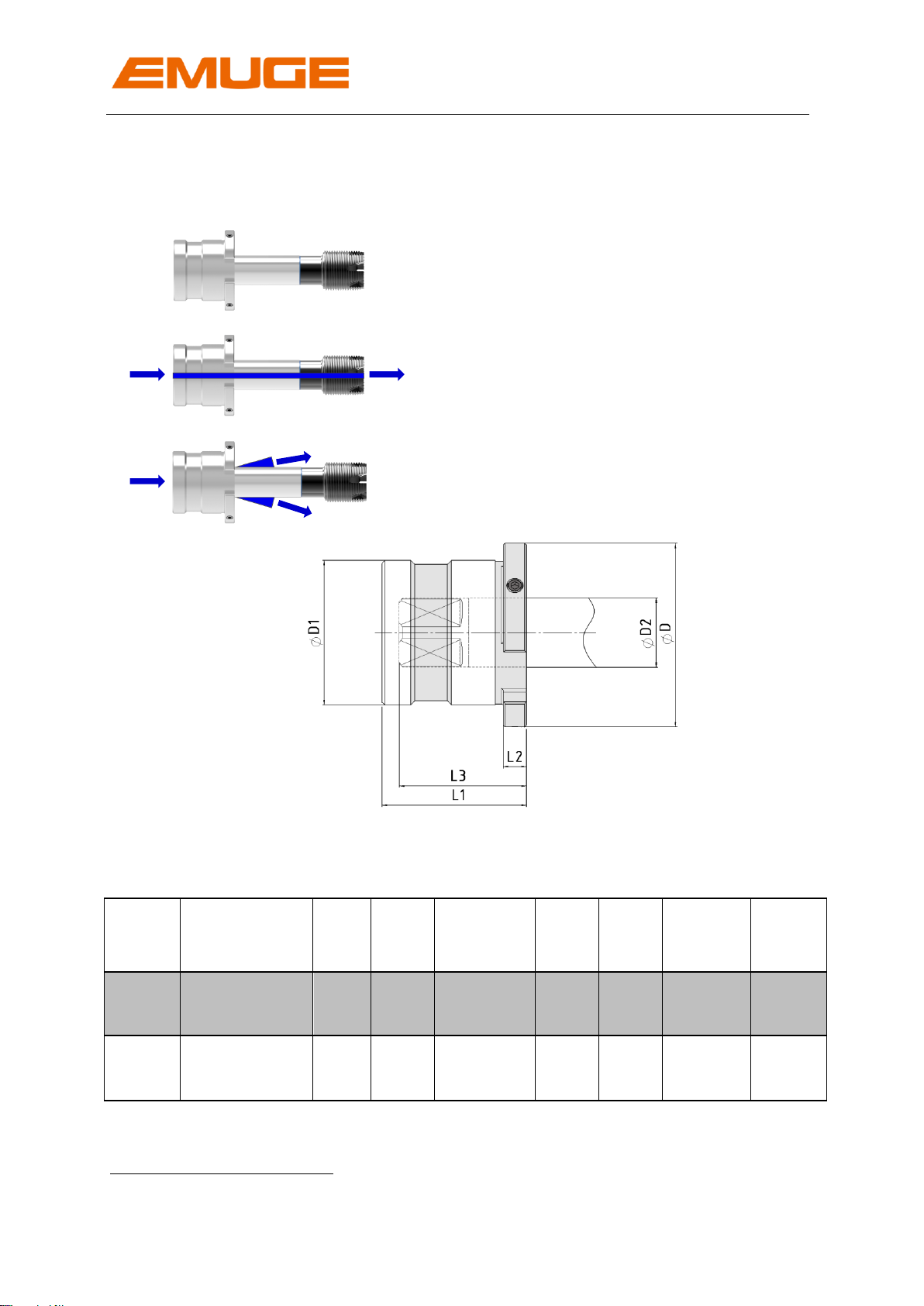

2.2.1 Insert tap / cold-forming tap

Attention

Choose the appropriate quick-change adapter for the required tap/cold-forming tap!

Note

Required tool: Type HE 2: Hexagon socket wrench: width across flats 4

Type HE 3: Hexagon socket wrench: width across flats 5

1. Push tap/cold-forming tap

into the quick-change

adapter.

Note

Bring the square into the

correct position by

turning the tap/cold-

forming tap.

√

Tap/cold-forming tap

Screws for tightening the tap/cold-forming tap

Quick-change adapter

HE

Operating instruction edition: 01.02.2017 9

2. Tighten all three screws

equally.

tap/cold-forming tap is

locked at the shank

Insert the quick-change adapter into the quick-change tap holder as described in the

operating instruction of the used quick-change tap holder.

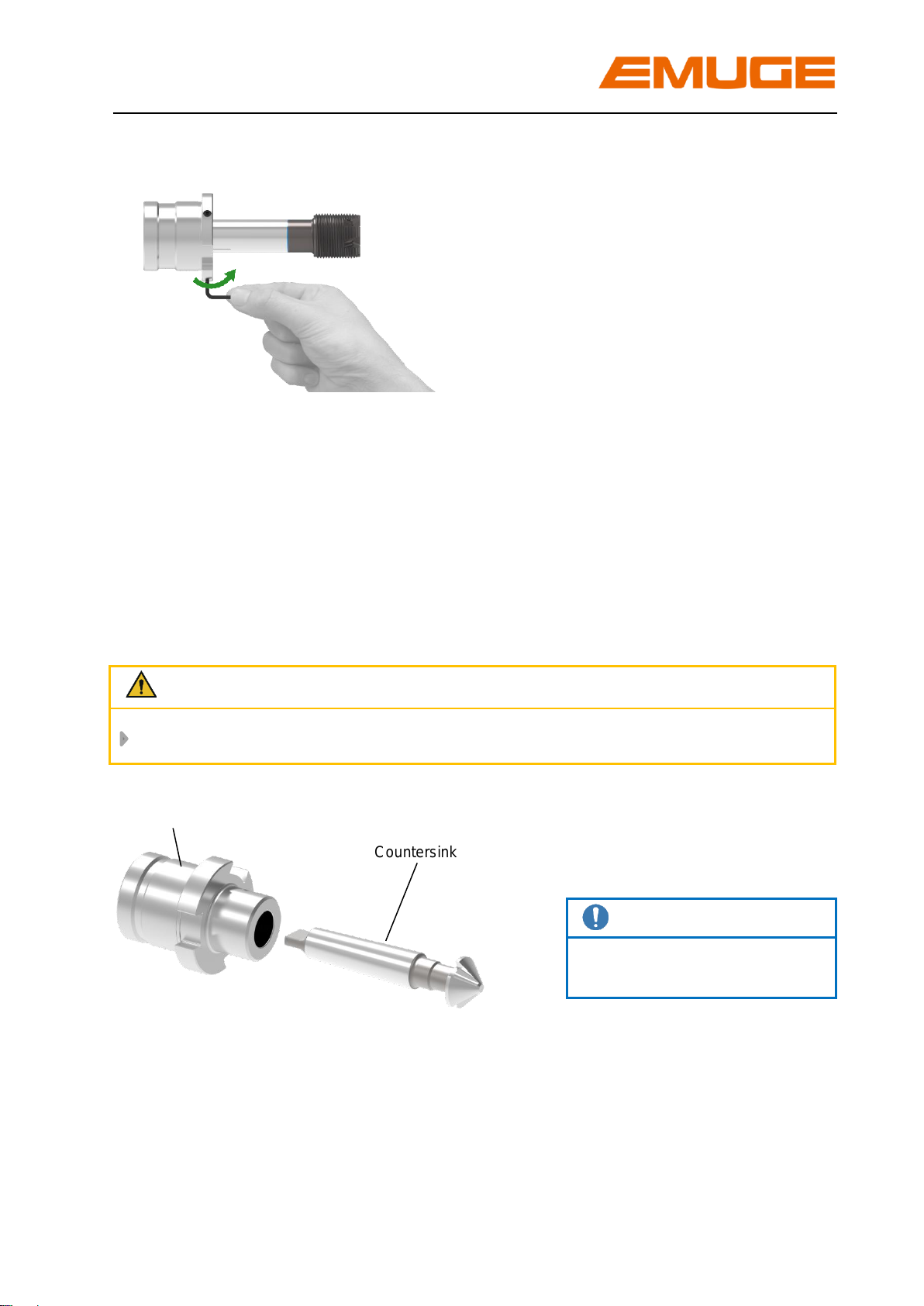

2.2.2 Insert drill or countersink

Attention

Choose appropriate quick-change adapter for required drill or countersink!

Strongly push in drill or

countersink.

Note

Watch position of the tang!

Now insert the quick-change adapter into the quick-change tap holder as described

in the operating instruction of the used quick-change tap holder.

Countersink

Quick-change adapter

HE

10 Operating instruction edition: 01.02.2017

2.3 Detach tool

2.3.1 Detach tap / cold-forming tap

Note

Required tool: Type HE 2: Hexagon socket wrench: width across flats 4

Type HE 3: Hexagon socket wrench: width across flats 5

1. Loosen all three

screws

2. Pull out tap/cold-

forming tap

2.3.2 Detach drill or countersink

Note

Required tool: Drift punch

Hammer

Use hammer and

drift punch to drive

out drill or

countersink

Tap/cold-forming tap

Quick-change adapter

Screws for tightening the tap/cold-forming tap

Hammer

Countersink

Drift punch

drift

Quick-change adapter

HE

Operating instruction edition: 01.02.2017 11

3 Maintenance

3.1 Maintenance schedule

What?

When?

Who?

External cleaning

Periodically, depending on the degree of

dirt.

Operator

3.2 External cleaning

Clean the quick-change adapter at periodic intervals depending on how dirty the

adapter is.

Note

Do not use any aggressive solvents.

Do not use fibrous materials i.e. steel wool.

4 Storage when not in use

If the quick-change adapter is taken out of service, please go through the following

working steps:

1. Clean the quick-change adapter with a duster, see chapter 3.2

2. Spray the quick-change adapter with a preservation oil to avoid rusting and to

preserve the easy running of the adapter

Attention

Before storage all evidence of coolant-lubricant and machining residues must be

removed!

EMUGE quick-change adapter HE

Operating instruction

Article number: ZB10011.GB 10575177

Original in German, Edition: 4, last change: 01.02.2017, change stage: 3

Please keep this for future use!

EMUGE-Werk Richard Glimpel GmbH & Co. KG

Fabrik für Präzisionswerkzeuge

Nürnberger Straße 96-100

91207 Lauf

GERMANY

+49 9123 186-0

+49 9123 186-230

info@emuge-franken.com www.emuge-franken.com

This manual suits for next models

4

Table of contents