EMX WEL-200T User manual

COMMONLY USED 5FETY SENSORS

Installation Steps:

=

I

NOTE: DO NOT

Photocell (Reector)

CSING Direction

IMPORTANT: Photocell MUST be in alignment with

reflector or fault will occur.

OK to

use

12VDC

Photocell (Reector)

CSING Direction

IMPORTANT: Photocell MUST be powered by

MATRIX Ill or it will NOT be MONITORED.

Installation Steps:

23

Photocell (Thru-Beam) CLOSING Direction

Single Gate Operator

Transmitter

(TX) Receiver

(RX)

Single

Operator

CLOSING direction Thru-Beam

Gate Closed

emx irb-mon

IMPORTANT: Photocells MUST be powered

by Matrix III or they will NOT be MONITORED.12VDC OUT

Polarity does NOT matter

NC

NO NCCOM

COM NO

RX

POWER

INPUT

JUMPER EARTH

GND

SENSITIVITY

TX

POWER INPUT

TRANSMITTER

BOARD (TX)

ON DIP

1 2 3 4

RECEIVER

BOARD (RX)

Sensitivity Adjustment:

If the photocell does not

respond to an obstruction,

lower the sensitivity by

turning adjustment

counter-clockwise.

Transmitter (TX) Receiver (RX)

PHOTO CLS NC - Normally Closed

GND - Common

NO ComNC

Green

LED

To PHOTO CLS NC

and 12VDC OUT Input

To Matrix III

12VDC OUT Input

TX

RX

Jumper

Green

LED

NOTE: To meet the UL 325 2018standard, Type B1

Non-Contact sensor entrapment protection device

MUST be MONITORED by the gate operator.

Installation Steps:

1. Set DIP-switches on receiver.

2. Install jumper on receiver.

3. Wire Matrix III 12VDC OUT

power to receiver.

4. Wire PHOTO CLS NC

to receiver photocell NC.

Wire Matrix III GND to

receiver photocell COM.

5. Wire 12V Matrix III

power to transmitter.

6. Align photocells.

7. Adjust sensitivity on receiver. Jumper MUST be on Com-NC.

DIP-switches:

1, 2, 3 are OFF.

Switch 4 is ON

If trouble occurs, try

turning switch 4 OFF.

NOTE: Power must be

cycled when switches

are changed.

IMPORTANT: Photocells MUST be

in alignment or fault will occur.

Green LED will remain ON receiver

when in proper alignment.

OPEN ONLY NC

OPEN ONLY 10K

PHOTO CLS NC

OPEN/CLS NC

GND

12VDC OUT

GND

CLS ONLY 10K

OPEN/CLS 10K

12VDC OUT

UL SENSOR N.C.UL SENSOR 10K

P

NSOR N.C

P

NSOR N.C

P

SOR N.

P

SOR N

SOR N

SOR N

OR N

OR N

OR

UL SEN

N

UL SEN

UL SEN

UL SEN

UL SE

UL SE

UL SE

L SE

L S

NOTE:

IMPORTANT:

DO NOT use 10K Resistor included with photocell.

4 5 6

C-1 NO1 NC1

LIGHT ON

SENSITIVITY

Min Max

DARK ON

Power

Set switch to

“LIGHT ON”

24 to 240 VAC

24 to 240 VDC

1

C-1

2

NO1

3

Sensitivity Adjustment:

If the photocell does not respond to an

obstruction, lower the sensitivity by

turning adjustment counter-clockwise.

OK to

use

12VDC

PHOTO CLS NC

GND

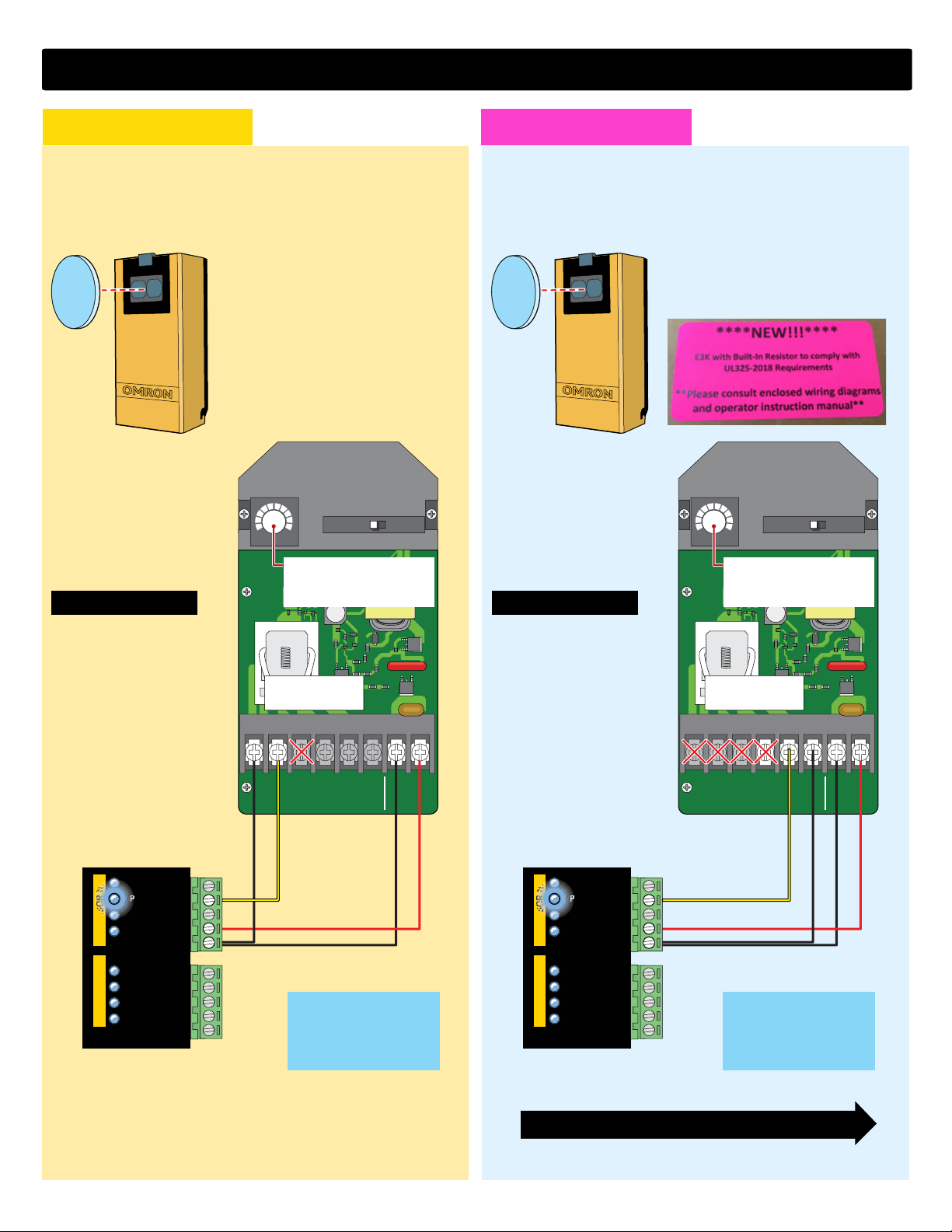

Photocell (Reflector)

CLOSING Direction

NOTE: To meet the UL 325 2016 standard,

Type B1 Non-Contact sensor entrapment

protection device MUST be MONITORED

by the gate operator.

Installation Steps:

1. Set switch to “LIGHT ON”

2. Wire 12V power to photocell

3. Wire PHOTO CLS NC

to photocell NO1

Wire GND to photocell C-1

4. Align photocell to reflector

5. Adjust sensitivity

omron E3K-R10K4 wiring for max pro

DO NOT connect

to NC1 #3.

OPEN ONLY NC

OPEN ONLY 10K

PHOTO CLS NC

OPEN/CLS NC

GND

12VDC OUT

GND

CLS ONLY 10K

OPEN/CLS 10K

12VDC OUT

UL SENSOR N.C.UL SENSOR 10K

NSOR N.C

P

NSOR N.C

P

SOR N.

P

SOR N

P

SOR N

SOR N

OR N

OR N

OR

Polarity doesNOT matter

12VDC Out Monitored

Polarity doesNOT matter

12VDC Out Monitored

45 6

C-1 NO1 NC1

LIGHT ON

SENSITIVITY

Min Max

DARK ON

Power

Set switch to

“LIGHT ON”

24 to 240 VAC

24 to 240 VDC

1 2

N02 C2

3

Sensitivity Adjustment:

If the photocell does not respond to an

obstruction, lower the sensitivity by

turning adjustment counter-clockwise.

OK to

use

12VDC

PHOTO CLS NC

GND

Photocell (Reflector)

CLOSING Direction

NOTE: To meet the UL 325 2018 standard,

Type B1 Non-Contact sensor entrapment

protection device MUST be MONITORED

by the gate operator.

Installation Steps:

1. Set switch to “LIGHT ON”

2. Wire 12V power to photocell

3. Wire PHOTO CLS NC

to photocell NO2

Wire GND to photocell C2

4. Align photocell to reflector

5. Adjust sensitivity

NORMALLY CLOSED (NC)

UL325-2018

Wiring to E3K Photocell

NORMALLY CLOSED (NC)

UL325-2016

Wiring to E3K Photocell

DO NOT connect

to NC2 #4.

OPEN ONLY NC

OPEN ONLY 10K

PHOTO CLS NC

OPEN/CLS NC

GND

12VDC OUT

GND

CLS ONLY 10K

OPEN/CLS 10K

12VDC OUT

UL SENSOR N.C.UL SENSOR 10K

NSOR N.C

P

NSOR N.C

P

SOR N.

P

SOR N

P

SOR N

SOR N

OR N

OR N

OR

NC2 N02 C2

Photocell MUST be powered

by 12VDC OUT Monitored or

it will NOT be MONITORED.

IMPORTANT:

Photocell MUST be powered

by 12VDC OUT Monitored or

it will NOT be MONITORED.

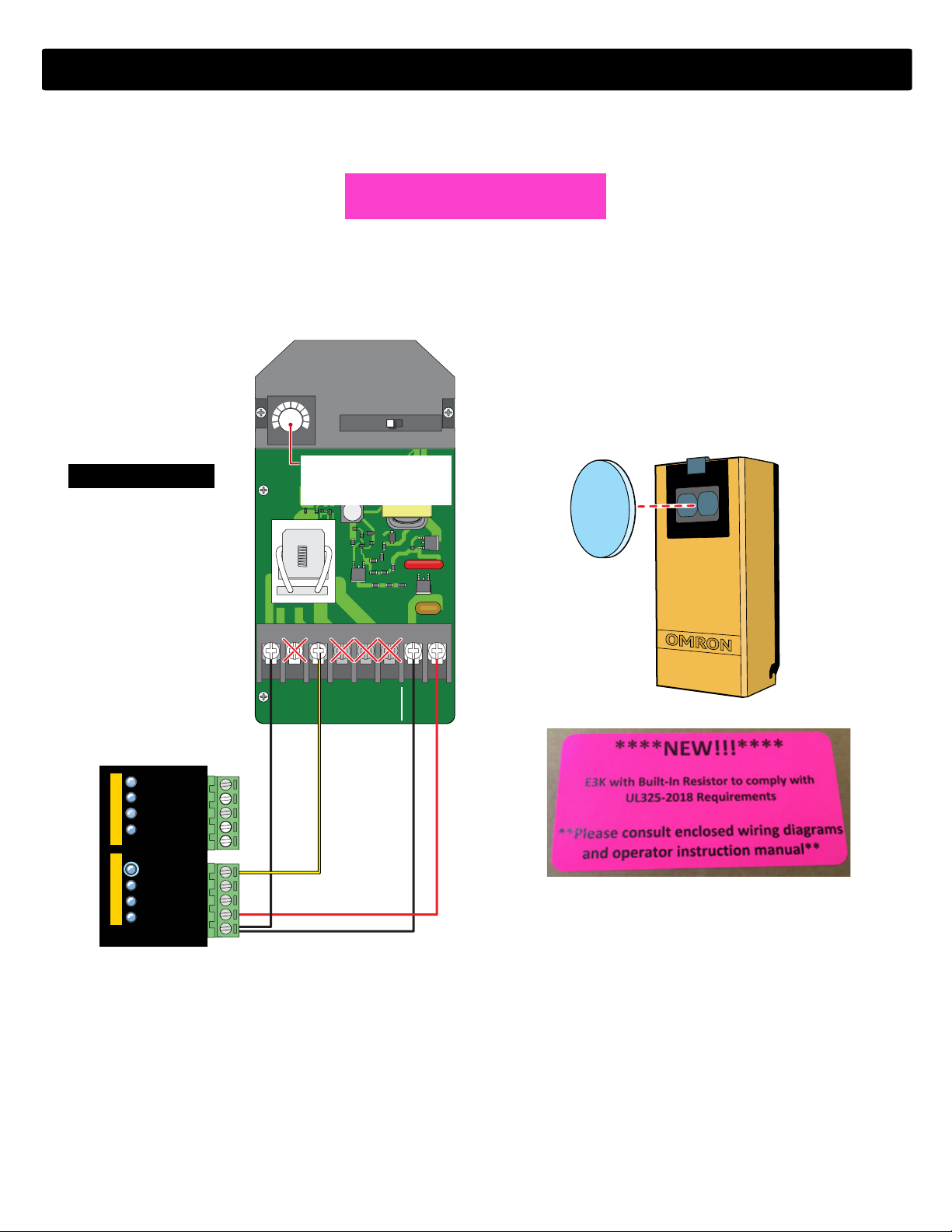

For 10K Resistor E3K Photocell wiring see next page

UL 2018 Label on packaging

Polarity doesNOT matter

4 5 6

C-1 NO1 NC1

LIGHT ON

SENSITIVITY

Min Max

DARK ON

Power

Set switch to

“LIGHT ON”

24 to 240 VAC

24 to 240 VDC

1

C-1

23

NC1

Sensitivity Adjustment:

If the photocell does not respond to an

obstruction, lower the sensitivity by

turning adjustment counter-clockwise.

OK to

use

12VDC

GND

Photocell (Reflector)

OPENING Direction

NOTE: To meet the UL 325 2018 standard,

Type B1 Non-Contact sensor entrapment

protection device MUST be MONITORED

by the gate operator.

Installation Steps:

1. Set switch to “LIGHT ON”

2. Wire 12V power to photocell

3. Wire OPEN ONLY 10K

to photocell NC1

Wire GND to photocell C-1

4. Align photocell to reflector

5. Adjust sensitivity

10K Resistor wiring to E3K Photocell

UL325-2018

OPEN ONLY NC

OPEN ONLY 10K

PHOTO CLS NC

OPEN/CLS NC

GND

12VDC OUT

GND

CLS ONLY 10K

OPEN/CLS 10K

12VDC OUT

UL SENSOR N.C.

UL SENSOR 10K

P

P

P

P

12VDC OUT

NC2 N02 C2

omron E3K-R10K4 wiring for max pro

UL 2018 Label on packaging

OPENING

TRANSMITTER

WEL-200T WEL-200T

WEL-200R

WEL-200R

EMX

CLOSING

TRANSMITTER

RECEIVER

GND

OPEN ONLY NC

OPEN ONLY 10K

PHOTO CLS NC

OPEN/CLS NC

GND

12VDC OUT

GND

CLS ONLY 10K

OPEN/CLS 10K

12VDC OUT

UL SENSOR N.C.

UL SENSOR 10K

P

P

P

P

JP-2

10K

Jumper

JP-1

10K

Jumper

EXIT PWR

ALARM

POWER /

SOLAR IN

BATTERY

INPUT

OPENING CLOSING

CLOSINGOPENING

ERD

OBD PORT

BLACK BOX

PROGRAMMING

SOLAR MODE

PROGRAM

MOTOR

OVER

LOAD

ERD

MOTOR

OVER

LOAD MAX

OFF

MAX

SENSE MAX

SENSE

BATTERY

BACKUP MODE

ERD SENSITIVITY

MOTION CONTROL

OPEN

GATE SPEED

MAG

LOCK

UL

ENTRAP

PRIMARY/

SECONDARY

LINK

STOP CLOSE

MOTOR

INPUTS

CLOSE

TIMER

MAGLOCK

DELAY

JOG

BATTERY

TEST

INPUT

ERROR

BATTERY

BATTERY

IN USE

REPLACE

BATTERY LEAVE

CLOSED

LEAVE

OPEN

OPEN

1 TIME

BATTERY VOLTAGE

E F1/2

RESET /

MANUAL

RELEASE

ID

PLUG

LINK

OK

MODULE

PORT

MOTOR

POSITION

INPUTS

SLIDER

LIMIT

SWING

LIMIT

GND

OPEN ONLY NC

OPEN ONLY 10K

PHOTO CLS NC

OPEN/CLS NC

GND

12VDC OUT

GND

GND

GND

GND

GND

GND

JOG RIGHT

JOG LEFT

TAMPER IN

TAMPER NO

GATE DISABLE

MANUAL RELEASE

KEYPAD / CARD

GND

(-)

(+)

GND

GND

MAX OPEN

FIRE DEPT

RADIO GND

RADIO SIGNAL

STRIKE

CLOSE

COM

COM

STOP

OPEN

CLS ONLY 10K

OPEN/CLS 10K

12VDC OUT

NO

COM

NC

ID PLUG

ERROR

24VDC OUTPUT

12VDC OUTPUT

GND

GND

GND

LOOP PWR

OFF

PRIMARY

LEFT

ON/OFF

BATTERY

RIGHT

SECONDARY

ON

QUICK

CLOSE

OPEN

LEFT

OPEN

RIGHT

GATE

OFF

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

MIN MIN

MAX MAX

ON

OFF 2.5 sec

1.5 sec

FAULTS

OPERATOR

MATRIX III

OFF

OFF

3

1

14

16

MIN

16

MIN

12

9

7

3

1

14 12

9

7

UL SENSOR N.C.UL SENSOR 10K

POWER

MODE A MODE B

EXIT LOOP

LOOP

LOOP

CENTER

SAFETY

GATE OPEN

COM

GATE CLOSED

MIN

MATRIX III

SWING / SLIDE

www.max.us.com

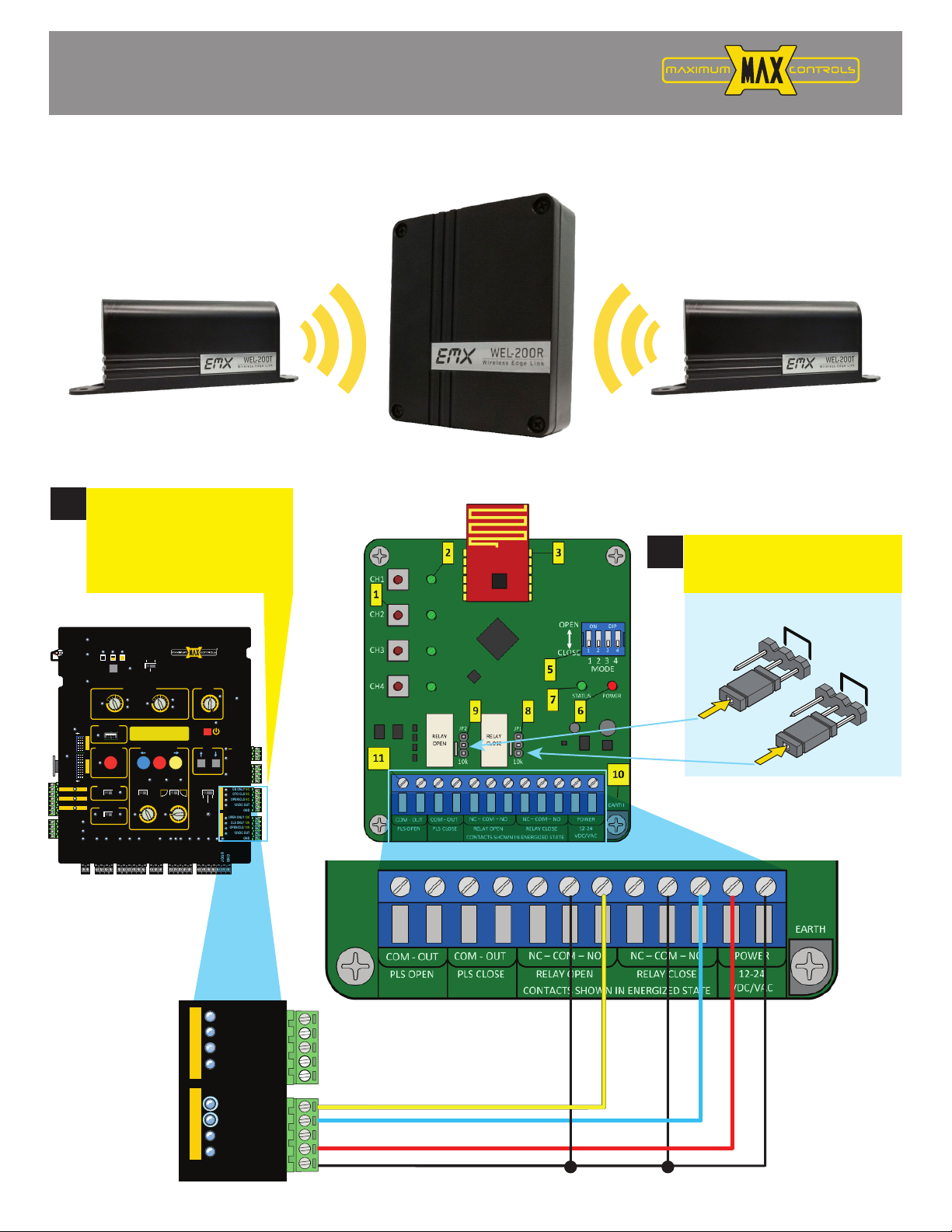

EMX WEL-200 Wiring Guide

FOR MAX PRO SERIES

WIRE WEL-200R

OPEN & CLOSE RELAYS

TO MATRIX III

10K SENSOR INPUTS

WIRE TO ‘NO’ OF RELAY OPEN

WIRE TO ‘NO’ OF RELAY CLOSE

1

INSERT BOTH JUMPERS

IN 10K POSITION

2

Polarity does

NOT matter

for power

Connecting is a two step process. First, on the receiver, press and hold the channel assignment switch until the green status LED

begins rapidly flashing, then release; this will clear any existing assignment for that particular channel. Hold down the

connection switch on the transmitter. If it is not currently connected to a receiver, it will begin flashing rapidly until successfully

connecting. Detailed instructions are given below.

EKdIf there are no existing connections, the receiver’s status LED will blink rapidly

while it is finding a clean operating frequency (this can last a few seconds)

After initialization, the system status LED will flash on/off once every 2 seconds

Set ĞĂĐŚchannel to the desired OPEN/CLOSE direction function using the MODE dip switch

/ĨĂ/WƐǁŝƚĐŚŝƐŝŶƚŚĞKWEƉŽƐŝƚŝŽŶƚŚĞŶƚŚĂƚĐŚĂŶŶĞůǁŝůůƚƌŝŐŐĞƌƚŚĞKWEZĞůĂLJŽŶ

ƌĞĐĞŝǀĞƌKƚŚĞƌǁŝƐĞŝƚǁŝůůƚƌŝŐŐĞƌƚŚĞ>K^ZĞůĂLJ

Install 2 AA Lithium batteries in the WEL-200T (transmitter)

The green LED on the transmitter will quickly flash 2x every two seconds

Install a properly terminated edge to the transmitter (8.2k or 10k termination)

On the receiver, hold down the desired channel assignment switch until all four channel

LED’s activate and the system status LED begins flashing rapidly, then release

the switch.

On the transmitter, hold down the connection switch (next to the terminal block)

The LED on the transmitter will begin flashing rapidly after ~4 seconds

Upon successful connection, the LED will flash once every two seconds

If the transmitter fails to connect, it will return to its initial state, with the

LED flashing twice every two seconds. If this occurs, repeat stepƐĂďŽǀĞ

1

2

3

4

5

WEL-200™ Operating Instructions 11

Document no. 10320104 Revision 2.0 3-1-18

Testing

Without activating the edge, observe the channel status LED, it should be OFF.

When the edge is activated, the receiver channel status LED will turn on and

the corresponding OPEN/CLOSE direction output will activate. The

transmitter status LED will blink once every second when the edge is activated.

If the channel does not exhibit this behavior, double check the edge

wiring/termination and transmitter batteries.

Notes

1. If channel 1 and 4 switches are pressed simultaneously during power up, the receiver will

perform a factory reset and clear all programmed channels.

2. Channel assignment mode will exit under the following conditions:

a. Successful connection to a transmitter

b. 60 second timeout

c. User selected exit

i. Pressing channel 1 and 4 switches simultaneously for more than 2 seconds

3. To remove a connection from the transmitter, hold down the connection button. The

LED will turn on solid for several seconds, and then blink twice every 2 seconds when

disconnected.

CONNECTING RECEIVER (WEL-200R) TO TRANSMITTER (WEL-200T)

STEPS

TESTING

EXIT PWR

ALARM

POWER /

SOLAR IN

BATTERY

INPUT

OPENING CLOSING

CLOSINGOPENING

ERD

OBD PORT

BLACK BOX

PROGRAMMING

SOLAR MODE

PROGRAM

MOTOR

OVER

LOAD

ERD

MOTOR

OVER

LOAD MAX

OFF

MAX

SENSE MAX

SENSE

BATTERY

BACKUP MODE

ERD SENSITIVITY

MOTION CONTROL

OPEN

GATE SPEED

MAG

LOCK

UL

ENTRAP

PRIMARY/

SECONDARY

LINK

STOP CLOSE

MOTOR

INPUTS

CLOSE

TIMER

MAGLOCK

DELAY

JOG

BATTERY

TEST

INPUT

ERROR

BATTERY

BATTERY

IN USE

REPLACE

BATTERY LEAVE

CLOSED

LEAVE

OPEN

OPEN

1 TIME

BATTERY VOLTAGE

EF1/2

RESET /

MANUAL

RELEASE

ID

PLUG

LINK

OK

MODULE

PORT

MOTOR

POSITION

INPUTS

SLIDER

LIMIT

SWING

LIMIT

GND

OPEN ONLY NC

OPEN ONLY 10K

PHOTO CLS NC

OPEN/CLS NC

GND

12VDC OUT

GND

GND

GND

GND

GND

GND

JOG RIGHT

JOG LEFT

TAMPER IN

TAMPER NO

GATE DISABLE

MANUAL RELEASE

KEYPAD / CARD

GND

(-)

(+)

GND

GND

MAX OPEN

FIRE DEPT

RADIO GND

RADIO SIGNAL

STRIKE

CLOSE

COM

COM

STOP

OPEN

CLS ONLY 10K

OPEN/CLS 10K

12VDC OUT

NO

COM

NC

ID PLUG

ERROR

24VDC OUTPUT

12VDC OUTPUT

GND

GND

GND

LOOP PWR

OFF

PRIMARY

LEFT

ON/OFF

BATTERY

RIGHT

SECONDARY

ON

QUICK

CLOSE

OPEN

LEFT

OPEN

RIGHT

GATE

OFF

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

MIN MIN

MAX MAX

ON

OFF 2.5 sec

1.5 sec

FAULTS

OPERATOR

MATRIX III

OFF

OFF

3

1

14

16

MIN

16

MIN

12

9

7

3

1

14 12

9

7

UL SENSOR N.C.UL SENSOR 10K

POWER

MODE A MODE B

EXIT LOOP

LOOP

LOOP

CENTER

SAFETY

GATE OPEN

COM

GATE CLOSED

MIN

MATRIX III

SWING / SLIDE

matrix III led troubleshooting

Table continued on next page

12. ID PLUG ERROR

15. EXIT LOOP

14. PRIMARY/SECONDARY

13. SOLAR MODE

5. POWER

6. ERD

7. MAX SENSE

8. MOTOR OVERLOAD

9. MANUAL RELEASE/RESET

20. CLOSE TIMER

21. SLIDER LIMIT

22. ON/OFF BATTERY

23. QUICK CLOSE

24. OPEN LEFT

25. OPEN RIGHT

26. GATE OPEN

27. GATE CLOSED

29. OPEN ONLY NC

30. PHOTO CLOSE NC

31. OPEN / CLOSE NC

32. 12VDC OUT

28. MAGLOCK

10. OBD PORT

11. PROGRAM

4. REPLACE BATTERY

3. BATTERY VOLTAGE

2. BATTERY IN USE

1. BATTERY INPUT ERROR

16. CENTER LOOP

17. SAFETY LOOP

18. 12 VDC

19. 24 VDC 33. OPEN ONLY 10K

34. CLOSE ONLY 10K

35. OPEN / CLOSE 10K

36. 12VDC OUT

37. UL ENTRAPMENT

42. GATE SPEED 40. LINK OK

41. MANUAL RELEASE

38. GATE TAMPER

39. GATE DISABLE

ID plug MUST be plugged in.

MAX

1500 PRO

MAX

2200 PRO

MAX

F18PRO

MAX 1500

MAX 2200

MAX F18

Matrix III LED

Problem Condition

Solution(s) for

Problem Condition

Normal

LED

“BATTERY IN ERROR” LED is ON.

“BATTERY IN USE” LED is ON

“BATTERY VOLTAGE (E 1/2 F)” LEDs, only “E”

is ON.

“REPLACE BATTERY” LED is ON.

“BATTERY IN USE” and “POWER” LED are

FLASHING

PRIMARY Matrix III “LINK OK” LED is OFF

SECONDARY Matrix III “LINK OK” LED is OFF

“UL Entrap” LED is ON

“ERD” LED is FLASHING

“PHOTO CLS” LED is ON

“CLS ONLY 10K” LED is ON

“PHOTO CLS” LED is flashing

“CLS ONLY 10K” LED is flashing

“OPEN ONLY” LED is ON

“OPEN ONLY” LED is FLASHING

“MAX SENSE” LED is ON

“MANUAL RELEASE/RESET” LED is ON but

manual release is not working

“OBD PORT” LED is FLASHING

“PROGRAM” LED is FLASHING

•“BATTERY Plug” not plugged in to “BATTERY IN” port.

•AC power is lost, operator is in battery back-up mode.

•Check if Toroid box AC POWER ON/OFF SWITCH is ON.

•Measure power input DC voltage on Matrix 1 (“24V/GND” - 2-pin black connector), (expected reading

34 VDC if AC on, 25VDC if on battery back-up).

•Battery is very LOW. Check if AC power ON/OFF switch is ON. If so, check AC power.

•Battery needs to be replaced if BATTERY TEST fails and “REPLACE BATTERY” LED is ON.

•Battery not plugged in to BATTERY INPUT port.

•Check if limit sensors are plugged into PRIMARY MATRIX III “SLIDER LIMIT” input.

•Check wiring between PRIMARY RS485 (+,-, gnd) and SECONDARY RS485 (+,-, gnd) terminals,

connect [(+) to (+)], [(-) to (-)] and [GND to GND].

•Check if limit sensors are plugged into SECONDARY Matrix III “SLIDER LIMIT” input.

•An entrapment event has occurred, check if an entrapment sensor was triggered (see if PHOTO CLS,

OPEN ONLY, or OPEN/CLS LEDs are on).

•An ERD event may have occurred. Check for gate obstruction.

•ERD sensitivity is too high for application. Re-adjust ERD setting, (see ).

•Sensor on PHOTO CLS or CLS ONLY 10K inputs (photocell or edge) may have detected an obstruction

while closing gate.

•Photocell on PHOTO CLS or CLS ONLY 10K inputs is misaligned with reflector.

•

Sensor on PHOTO CLS or CLS ONLY 10k inputs (photocell or edge) may not be wired properly, (see ).

•Sensor is NOT a N.C. monitored sensor that is UL325 2018compliant.

•Sensor might need to be re-learned.

•Sensor is damaged or malfunctioning.

•Sensor on OPEN ONLY input (photocell or edge) may have detected an obstruction while cycling gate.

•Photocell on OPEN ONLY input is misaligned with reflector.

•Sensor on OPEN ONLY input (photocell or edge) may not be wired properly, (see ).

•Sensor is NOT a N.C. monitored sensor that is UL325 2018compliant.

•Sensor on OPEN ONLY is damaged or malfunctioning.

•Sensor might need to be re-learned.

•MOST sensitive setting for ERD entrapment detection. Select a less sensitive setting (recommend level

10 thru 16)

•Connected external device to MANUAL RELEASE input is not working, check wiring. replace device.

•Up to 8000 event history and error codes are being downloaded to connected flash drive. Up to 5 min.

•Program button has been pressed and programming mode is active. Press button again to leave

programming mode.

1

OFF

2

OFF

3

OFF

4

OFF / ON

2 / 5

ON

40

ON

40

ON

37

ON

6

OFF

30 / 34

OFF

30 / 34

OFF

29 / 33

OFF

29 / 33

OFF

7

OFF

9 / 41

OFF

10

OFF

11

8

5

5

matrix III led continued

Matrix III LED

Problem Condition

Solution(s) for

Problem Condition

Normal

LED

“ID PLUG” LED is FLASHING and board beeping

“SOLAR MODE” LED is ON

“OPEN/CLS” LED is ON

“OPEN/CLS” LED is FLASHING

“MOTOR OVERLOAD” LED is ON

“EXIT” LOOP LED is FLASHING or

constantly ON

“SAFETY” LOOP LED is FLASHING or

constantly ON

“GATE DISABLE” LED is ON

“MAG LOCK” LED is FLASHING

“GATE TAMPER” LED is FLASHING

“12VDC” LED is OFF. “24VDC” LED is OFF

“SLIDER LIMIT” LED is ON

“ON/OFF BATTERY” LED is OFF

“QUICK CLOSE” LED is ON

“GATE SPEED” LEDs are ON but gate moves

slowly.

•Insert ID PLUG module that is tethered to chassis into “ID PLUG” connector.

•Operator is being powered by solar panel ONLY.

•Sensor on OPEN/CLS input (photocell or edge) may have detected an obstruction while opening or

closing gate.

•Photocell on OPEN/CLS input is misaligned with reflector.

•Sensor on OPEN/CLS input (photocell or edge) may not be wired properly, (see ).

•Sensor is NOT a N.C. monitored sensor that is UL325 2018compliant.

•Sensor on OPEN/CLS is damaged or malfunctioning.

•Sensor might need to be re-learned.

•Check if gate is binding against catch post or bracket in opened or closed position.

•Check if gate moves manually with low resistance throughout its full range of motion.

•Check if chain is installed inline with idle wheels in both OPEN and CLOSED positions.

•Loop fault condition: Check if EXIT loop wires are connected into to loop input connector properly.

•Check if loop detector is inserted properly in Loop Rack slot.

•Set unique loop detector frequency for each loop detector used.

•Loop Detector might be defective. Replace defective loop detector.

NOTE: RENO loop detector LED’s flash as default, but function normally (ignore the flashing).

•Loop fault condition: check if SAFETY loop wires are connected into to loop input connector properly.

•Check if SAFETY loops are wired in series.

•Check if loop detector is inserted properly in Loop Rack slot.

•Set unique loop detector frequency for each loop detector used.

•Loop Detector might be defective. Replace defective loop detector.

NOTE: RENO loop detector LED’s flash as default, but function normally (ignore the flashing).

•Check if “Gate Shut-off” switch is ON, Turn it OFF. If it is OFF, cycle the switch (ON then OFF).

• Check if the chain is dropped. If so, gate is disabled for safety. Re-install chain and cycle the "Gate

Shut-off" switch (ON then OFF) to enable operator.

•Check if an external device is triggering GATE DISABLE input. Disconnect devices individually to

determine possible false triggering of GATE DISABLE.

•Maglock power is lost. Check if maglock power transformer is wired properly or needs to be replaced.

•Switch is set to delay but no maglock is connected. Set switch to OFF

•Gate was manually moved off of its CLOSED position causing Tamper Relay to trigger for few seconds.

•Check for a short in wiring to connected device. DO NOT power external keypads or telephone entry to

this port (only use for radio receiver / photocell).

•Only ON if factory installed plug is plugged in. Re-install plug into SWING LIMIT connection for swing

gate operator.

•Batteries are turned OFF. Turn toroid box AC POWER switch ON and batteries automatically turn ON.

•Quick Close feature is turned ON. If this feature is not desired, turn quick close OFF.

• Check if OPEN and CLOSE Limits have been learned. Refer to “Learn Gate Positions” (see ).

•ONLY Maximum settings will turn LEDs ON. All other settings, LEDs remain OFF.

OFF

12

OFF

13

OFF

31

OFF

8

OFF

15

OFF

17

OFF

35

OFF

28

OFF

34

ON

18 or 19

OFF

21

ON

22

OFF

23

ON

42

5

7

This manual suits for next models

2

Table of contents

Other EMX Receiver manuals

Popular Receiver manuals by other brands

Daniels Electronics Ltd.

Daniels Electronics Ltd. OST-3H035 instruction manual

Fly Sky

Fly Sky FTr10 quick start guide

W Box Technologies

W Box Technologies HD2s user guide

BOSSCO

BOSSCO Therm RF Series installation instructions

One Forall

One Forall SV-1725 instruction manual

Icom

Icom IC-R8600 Service manual