Encom EN630 Series User manual

Users’Manual

Series Inverter

0.4-1.5KW

Ver.2.0

ISO9001 Quality Management System Authentication

CE Authentication

EN630/EN650A series

SHENZHEN ENCOM ELECTRIC TECHNOLOGIES CO.,LTD.

Version:V2.0-A0

Foreword

Thank you for purchasing EN630/EN650A series inverter developed and produced by

Shenzhen Encom Electric Technologies CO., LTD.

EN630 series mini hi-performance flux vector inverter adopts advanced control mode to

achieve high torque, high precision and wide-range speed regulation drive, and it also supports

speed sensorless torque control and PG control torque. It can meet customer all kinds of

requirement to universal inverter. EN630 inverter is a organic combination for customer’s

universal and industrial control purpose and provides practical main-auxiliary frequency

provision, run channel frequency binding, PID regulator, simple PLC, spinning traverse,

programmable input&output terminal control, pulse frequency provision and inbuilt Modbus, Can

bus, Profibus, RS485 and free protocol and other function and platform. It provides high

integration solution for most manufacturing and automation customer and EN630 inbuilt input

phase loss function, output phase loss function, short circuit to earth grounding function and many

other protective function to improve effectively the system reliability and safety.

EN650A series is a mini multi-function permanent magnet synchronous inverter which

combined market demand for synchronous motor and its supporting system, built-in unique

control algorithm, can achieve high torque, high precision, wide speed range control for

permanent magnet synchronous motor and brushless DC motor, supports PG vector and PG

vector control, and also supports speed and torque mode switching.

This brochure provides the installation and wiring settings, fault check and methods,

maintenance and other relative issues to customer. To make inverter assemble and operate rightly,

and use its high performance to best, please read this brochure carefully before installation usage

and keep them well to the final users of inverter.

Please contact our office or dealer anywhere at any moment when you have any doubts or

special demands in using these inverters, and you can also contact our after service center in our

headquarters directly. We will serve you with all our heart.

We reserve our right to notice you if we change contents of this manual.

Content

Content

1 Safetyinformationandusenoticepoints 1

1.1Safety precautions 1

1.2Usenoticepoints 3

1.3 Usenoticepoints 3

2 InverterTypeandSpecification 5

2.1Incominginverterinspect 5

2.2Typeexplanation 5

2.3Nameplateexplanation 5

2.4Invertertypeexplanation 6

2.5Appearanceandpartsnameexplanation 6

2.6Outersize&grossweight 6

2.7 Outer size of keypad and its fixing box 7

2.8Producttechnicindexandspec 7

3 Installationandwiring 11

3.1 Installationambient 11

3.1.1 Thedemandsforinstallationambient 11

3.1.2 Installation direction and space 11

3.2 Partsdisassemblyandinstallation 12

3.2.1 Keyboarddisassemblyandinstallati 12

3.2.2 Plastic cover disassembly and installation 12

3.3 Wiring notice points 13

3.4 Main loop terminal wiring 13

3.4.1 Connection between inverter and fitting parts 14

3.4.2 Mainloopterminalwiring 15

3.5 Basicrunningwiringdiagram 15

3.6 Control loop collocation and wiring 16

3.6.1Relative location and function for control board terminal and slide

Switch 16

3.6.2 Descriptions for control board terminal 17

目录

3.6.3 Analog input&output terminal wiring 19

3.6.4 Communication terminal wiring 20

3.7 Installation guidance of anti-interference 21

3.7.1 noise interference restraining 21

3.7.2 Field wiring and earth grounding 23

3.7.3 long distance wiring & Leak current and countermeasure 24

3.7.4 Installation demand for electromagnetic on-off electronic

device 25

4 Runandoperationexplanationforinverter 26

4.1Runofinverter 26

4.1.1Runningorderchannels 26

4.1.2Frequency-provisionchannel 26

4.1.3Workstate 27

4.1.4Runmode 28

4.2Operationanduseofkeyboard 30

4.2.1Keypadlayout 30

4.2.2Keypadfunctiondescription 30

4.2.3LEDandindicatorlight 31

4.2.4Keyboarddisplaystatus 31

4.2.5UserManagementParameters 34

4.2.6Methodforoperatingkeypad 34

4.3 Inverter electrification 37

4.3.1 Check before electrification 37

4.3.2Firstelectrification 37

5 FunctionParameterScheduleGraph 38

5.1Symboldescription 38

5.2Functionparameterschedulegraph 38

6 Troubleshooting 77

6.1Failureandcountermeasure 77

6.2Failurerecordlookup 83

6.3Failurereset 84

Content

6.4Alarmreset 84

7 Maintenance 85

7.1Routinemaintenance 85

7.2 Inspection and replacement of damageable parts 86

7.3Repairguarantee 86

7.4Storage 87

Appendix A EN650A Mini multi-function PMSM Inverter 88

AppendixBFree-portCommunicationProtocol 133

AppendixCModbuscommunicationprotocol 152

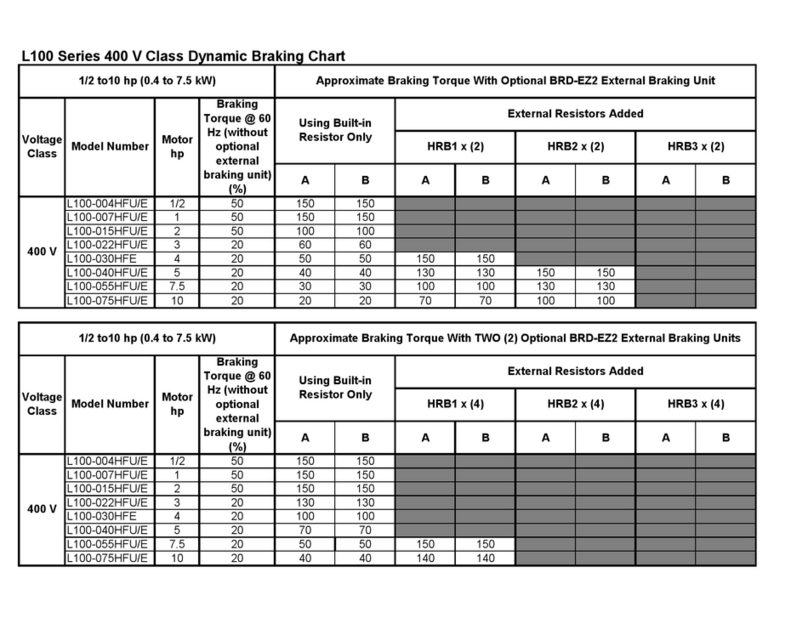

AppendixDBrakingunitandbrakingresistance 167

1 Safety information and use notice points

1

1 Safety information and use notice points

To make ensure personal & equipment safety, this chapter must be read

carefully before the inverter come into use.

1.1 Safety precautions

There are three kinds of safety warnings in this manual as below:

Symbol Symbol description

It may cause human death, serious injury or heavy property loss

with wrong operation.

It may result body or device damage with wrong and timeless

precautions under operation.

Should pay extra cautions when inverter in use under this

symbol

!

Note

!

1 Safety information and use notice points

2

Forbid to cut off the power source directly when inverter under

running, acceleration or deceleration status. Power source could

cut off when inverter completely in halt and standby status.

Otherwise user should be responsible for inverter and device

dama

g

e and human in

j

ur

y

.

!

(1) Forbid to connect AC power source to output terminal U,V,W,

otherwise it could cause inverter completely damage.

(2) Forbid to install inverter on flammable objects, otherwise it

may cause fire.

(3) Do not install inverter in a environment with explosive gas, it

may cause explosion.

(4) Bare connection terminal should be insulation treatment after

main loop connection, otherwise it may cause electric shock.

(5) Do not operate inverter with wet hands when inverter power

on, otherwise it may cause electric shock.

(6) Inverter earth terminal should be well grounding connection.

(7) Do not open the front cover for wiring when inverter power on.

Inverter wiring and check must handle after 10 minutes of

inverter power off.

(8) Wiring connection should handle by qualified person and not

allow to slip any conductive objects inside inverter, otherwise it

may cause a electric shock or inverter damage.

(9) when inverter stocked for more than 6 months, using voltage

regulator to boost voltage up and keep inverter in standy status

for 1 hour, otherwise it may cause electric shock and explosion.

!

(1) Forbid to connect control terminals except TA, TB, TC to AC

220V/380V signal, otherwise it may cause inverter completely

damage.

(2) Do not install and run inverter when inverter damage or spare

part less, otherwise it may cause fire or human injury.

(3) inverter should install in a place where can accept itself weight,

otherwise it may cause inverter drop down or belongings damage.

!

1 Safety information and use notice points

3

1.2 Application range

(1) This kind of inverter apply to 3 phase ac asynchronous motor only for general

industry.

(2) It should handle cautiously and consult with manufacturer when inverter apply

to high reliability required equipment which relevant to life, properties and

safety device.

(3) This kind of inverter is the general motor control device in industry. When

inverter apply to dangerous equipment, safeguard should be considerable in

case of inverter failure.

1.3 Use notice points

(1) EN630/EN650A series inverter belong to voltage type inverter, and it is

normal with up temperature, noise and vibration of motor increasing over

power frequency run slightly.

(2) It is required to match inverter with variable frequency motor running at low

speed with constant torque for long time. When match inverter with general

asynchronous motor running at low speed, it should take measures to make

motor heat dissipation or monitoring motor temperature in avoid of motor

flash.

(3) It is necessary to take measures in advance for the damage caused for the bad

lubrication of the reduction box and wheel gear mechanical devices running at

low speed for long time.

(4) It is necessary to assure at first that the use speed range of motor bearings and

mechanical devices, also the increasing of motor vibration and noise should be

considered, when motor run over rated frequency.

(5) It is necessary to select the suitable brake assembly for hoisting device and big

inertia load to make sure the normal work when inverter stripping from power

grid for the overcurrent or overvoltage failure.

(6) Inverter start and stop control through terminal or other normal command

channel, otherwise it may cause inverter damage via connecting inverter input

terminal to big current switch just like contactor direct to start and stop

inverter frequently.

(7) It is necessary to make sure inverter cut off from operation without output,

when inverter and motor connect through switch components just like

contactor etc. Otherwise it will cause inverter damage.

(8) When inverter output frequency within some range, it may meet mechanical

resonance point of load device, through setting jump frequency to avoid it.

(9) Checking power supply voltage within allowed working range before usage,

1 Safety information and use notice points

4

otherwise, it need to change voltage or custom special voltage inverter.

(10)When inverter usage site altitude over1000 meters,inverter should decrease

current to use, output current decrease about 10% of rated current per 1000

meters increase.

(11)Motor should do insulation check before first usage or reusage after lay aside

for long time. Checking method show as graph 1-1 below with 500V voltage

type megohm meter , insulation resistance should not smaller than 5 MΩ,

otherwise inverter maybe damaged.

(12)Forbid inverter output side to assemble capacitor to improve power factor or

anti-thunder dependent resistor etc, otherwise it may cause inverter fault trip

or component damage show as graph 1-2.

Fig.1-1 motor insulation check Fig.1-2 capacitor at output side forbidden

motor

Ground

megohmm

U

After wiring finish, short-circuit U,V,W

to measure insulation resistance

EN630/EN650A

V

W

EDS1000

U

V

W

M

EN630/EN650A

2 Inverter Type and Specification

5

2 Inverter Type and Specification

2.1 Incoming inverter inspect

(1) Check if there is damage during transportation and inverter itself has damage

or fall-off parts.

(2) Check if parts presented in packing list are all ready.

(3) Please confirm nameplate data of the inverter is in line with your order

requirement.

Our product is guaranteed by strict quality system during manufacturing,

packing, transportation etc., please contact our company or local agent rapidly

if some careless omission or mistake arise, we’ll deal with it as soon as

possible.

2.2 Type explanation

EN630–4T 0015

Fig.2-1Typedescription

2.3 Nameplate explanation

Nameplate presented as figure 2-2 with type and rating data at the bottom of

inverter right side.

Fig.2-2 Nameplate

Code Name

EN630 series

EN650A series

Code Match motor

power (KW)

0004 0.4

0007 0.75

0015 1.5

Code Vo l . g r a d e

2S Single phase 220V

4T Three phase

380V

EN630 INVERTER

TYPE: EN630-4T0015

SOURCE: 3PH 380V 50/60Hz

OUTPUT: 1.5KW 3.7A

Model

Serial No.

Series No.

Manufacturer and origin

Rated input vol. And freq.

Motor power and output current

2 Inverter Type and Specification

6

2.4 Inverter type explanation

Table 2-1 inverter type explanation

Inverter type Rated output

Current(A) Adaptable motor

(KW)

EN630/EN650A-2S0004 2.5 0.4

EN630/EN650A-2S0007 4 0.75

EN630/EN650A-2S0015 7 1.5

EN630/EN650A-4T0007 2.3 0.75

EN630/EN650A-4T0015 3.7 1.5

2.5 Appearance and parts name explanation

Fig.2-3 Parts name sketch

2.6 Outer size & gross weight

Fig.2-4 outer dimension

Up cover plate

Control cable inlet

Input & output power cable inlet

Operation keypad

vent

Open here to connect brake resistor

(

o

p

tional

)

Terminal wiring cover

Digital potentiometer

digital tube

2 Inverter Type and Specification

7

Table 2-2 mounting size

Inverter type W

(mm) H

(mm) D

(mm) D1

(mm) A

(mm) B

(mm) Fix Hole

(mm) GW.

(kg)

EN630/EN650A-2S0004

89 148.5 112.5 124.7 74 138 5

1

EN630/EN650A-2S0007 1.1

EN630/EN650A-2S0015 1.2

EN630/EN650A-4T0007 1.1

EN630/EN650A-4T0015 1.1

2.7 Outer size of keypad and its fixing box(unit:mm)

Fig. 2-5 EN-LED5-D keypad& Hole size of keypad

2.8 Product technic index and spec

Item Item description

Input

Rating volt.

frequency

1 phase 220V Grade:single phase 220V, 50Hz/60Hz;

3 phase 380V Grade:3 phase 380V, 50Hz/60Hz

Allowed volt

range

1 phase 220V Grade:200~260V;

3 phase 380V Grade:320~460V

Output

Vo l t a g e 0 ~380V

Frequency 0~600Hz

Over loading

capacity 150% of rated current for 1 minute

Control

Performance

Control mode vector control, PG vector control, open-loop V/F control, torque

control, PG torque control

Velocity control

precision

±0.5% rated synchronous speed(vector control);

±0.1% rated synchronous speed(PG vector control);

±1% rated synchronous speed(V/F control);

2 Inverter Type and Specification

8

Speed regulation

range

1:2000(PG vector control)

1:100(vector control);

1:50(V/F control);

Start-up torque

1.0Hz:150% rated torque(V/F control);

0.5Hz:150% rated torque (vector control);

0Hz:180% rated torque(PG vector control);

Speed fluctuation ±0.3% rated synchronous speed(vector control);

±0.1% rated synchronous speed(PG vector control);

Torque control

precision

±10% rated torque(vector control,torque control);

±5% rated torque(PG vector control,PG torque control).

Torque response ≤20ms(vector control);

≤10ms(PG vector control);

Frequency

precision

Digital setting:max. frequency×±0.01%;Analog setting:max.

frequency×±0.5%

Freq.

resolut

ion

Analog

setting 0.1% of max. frequency

Digital

setting

p

recision

0.01Hz

Exterior

impulse 0.1% of max. frequency

Torque boost Automatic torque boost;manual torque boost 0.1~12.0%

V/F curve(volt.

Frequency

characteristic)

Setting rated frequency at the range of 5~650Hz,

by

choosin

g

constant torque, degressive torque 1, de

g

ressive torque 2,

degressive torque 3, self-defined V/F total 5 kinds of curve.

Acceleration

Deceleration

curve

Two modes:strai

g

ht line acceleration and deceleration; S curve

acceleration and deceleration; 15 kinds of acceleration and

deceleration time,time unit (0.01s, 0.1s, 1s) for option ,max.

time for 1000 minutes.

brake

Power

consumpt

ion brake

inbuilt brake unit,only add brake resistor between(+)and PB.

DC brake Start, stop action for option, action frequency 0~15Hz,action

current 0~100% of rated current,action time 0~30.0s

jog Jog frequency range:0Hz~up limit frequency;

j

o

g

acceleration

and deceleration time 0.1~6000.0 seconds for setting.

Multi-section

speed run

Realized by inbuilt PLC or control terminal; with 15 section

speed, each section speed with separatel

y

acceleration and

deceleration time; with inbuilt PLC can achieve reserve when

power down.

Inbuilt PID

controller Convenient to make closed-loop control system

Automatic ener

gy

saving run

Optimize V/F curve automaticall

y

to achieve power savin

g

run

according to the load status.

Automatic

voltage

regulate(AVR)

Automaticall

y

keep output volta

g

e constant, when the power

g

rid

voltage fluctuation

2 Inverter Type and Specification

9

Automatic

current limiting

Current limited automatically under run mode in avoid of inverter

over-current frequently to trip.

carrier

modulation

Modulate carrier wave automaticall

y

accordin

g

to the load

characteristic.

Speed tracking

restart Make rotating motor smoothly start without shocking

Running

function

running

command

specified channel

Ke

y

pad specified, control terminal specified, communication

specified can switch through various means.

Running

frequency

specified channel

Main & auxiliar

y

specified to a realize one main ad

j

ustin

g

and one

fine control. Digital specified, analo

g

specified, pulse specified,

p

ulse width specified, communication specified and others, which

can be switched by many means at any time.

Binding function Run command channel and frequenc

y

specified channel can bind

together randomly and switch synchronously

Input output

characteristic

Digital input

channel

Channel 7 for universal di

g

ital input, max. Frequenc

y

1KHz,

channel 1 can be used as pulse input channel, with max. input

50KHz.

Analog input

channel

Channel 2 for analog input channel, AI1 can choose 4~20mA or

0~10V output,AI2 is differential input channel,4~20mA or

-10~10V for option.

Pulse output

channel

0.1 ~20KHz pulse square si

g

nal output to achieve settin

g

frequency, output frequency and other physical quantity output.

Analog output

channel

Channel 1 for analog signal output, AO can choose 4~20mA or

0~10V to achieve settin

g

frequenc

y

, output frequenc

y

and other

physical quantity output.

Unique

function

Rapid current

limit

Limit inverter over current to the greatest point, and make it run

more stably

Monopulse

control

Suitable for workin

g

site where need one button to control

inverter start and stop, first press to start, then press to stop, and

that cycle repeats. Its very simple and reliable.

Fixed length

control Realize fixed length control

Timing control Timing control function: setting time range 0.1Min ~

6500.0Min

Virtual terminal Five

g

roup virtual input & output IO can realize simpl

y

lo

g

ical

control

keypad

Keypad display The parameters as settin

g

frequenc

y

, output frequenc

y

, output

voltage, output current can be displayed

Button Locked Lock all or part of the buttons

2 Inverter Type and Specification

10

Protection function

Motor power on Shot circuit test, input & output phase loss

protection, over-current protection, over volta

g

e protection, under

voltage protection, over heat protection, overload protection,

under load protection, rela

y

absorption protection, terminal

protection and no stop protection under power off.

Envi

ronm

ent

Application site Indoor, not bare to sunlight, no dust, no corrosive

g

as, no

flammable gas, no vapor, no water drop or salt etc.

Altitude

Under 1000 meter.(above 1000 meter require to reduce volume to

use, output current reduce about 10% of rated current

p

er 1000

meter high)

Environment temperature -10℃~+40 ( environment temperature between 40℃℃~50 ,℃

need to reduce volume or strengthen heat sink )

Environment humidity Smaller than 95%RH,no drop condenses

Vibration Smaller than 5.9 M/S²(0.6g)

Storage temperature -40℃~+70℃

struc

ture

Protection grade IP20

Cooling mode Forced air cooling and natural

Installation mode Wall hanging

To get a perfect usage performance of the inverter, Please check and

select right type according to this chapter before wiring.

Note

It is necessary to select right type, otherwise it may cause motor

abnormal run or inverter damage.

!

3 Installation and wiring

11

3 Installation and wiring

3.1 Installation ambient

3.1.1 The demands for installation ambient

(1) Installed in drafty indoor place,the ambient temperature should be within

-10ºC~40ºC,it needs external compulsory heat sink or reduce the volume if

temperature is over than 40ºC.

(2) Avoid installing in places with direct sunlight, much dust, floating fiber and

metal powder.

(3) Don’t install in place with corrosive, explosive gas.

(4) The humidity should be smaller than 95%RH,without condensation water.

(5) Installed in place of plane fixing vibration smaller than 5.9m/s²(0.6g).

(6) Keep away from electromagnetic disturbance source and other electronic

apparatus sensible to electromagnetic disturbance.

3.1.2 Installation direction and space

(1) Normally the inverter should be mounted vertically, horizontal mounting will

seriously affect heat dissipation and the inverter must be used in lower

volume.

(2) Demand for minimum mounting space and distance,please see Fig.3-1.

(3) When installing multiple inverters up and down, leading divider must be

applied between them, see fig. 3-2.

Fig.3-1 mounting space Fig.3-2 mounting of multiple inverters

导流隔板

Leading divider

50mm

above

100mm above

100mm above

50mm

above

Exhaust

fan

3 Installation and wiring

12

3.2 Parts disassembly and installation

3.2.1 Keyboard disassembly and installation

(1) Disassembly

Let the forefinger press finger inlet on the keypad,press fixing flexible plate

on the top lightly,draw it outward, then you can disassemble the keypad.

(2)Assembly

First interface the fixed hook of on the bottom of keyboard with the keyboard

installation claw of inverter, then press the fixed shrapnel on the top of keyboard

to push it assemble well properly (keyboard assemble well when sounding of

crisp).

3.2.2 Plastic cover disassembly and installation

(1) Disassembly

Located the thumbs to the side bayonet,with thumbs press inside and pull

upside at the same time until the bayonet open between cover and whole case,

then pull back cover to make it off the inverter.

3.3 Wiring notice points

Assure power be cut off completely for above 10 m⑴inutes before

wiring, otherwise there is danger of getting electric shock.

Forbid connecting power wire to output U, V, W of the inverter.⑵

If there is current leakage inside inverter, when current leaka⑶ge

greater than 5mA for medium & big power inverter, inverter and motor

must be earth grounding for safety assurance, and the diameter of earth

grounding copper cable is greater than 3.5mm², resistor less than 10Ω.

Before shipment compression resistance⑷test of the inverter is

passed, so users should not conduct compression resistance test again.

Do not add absorbing capacitor or other resistance⑸-capacitor

absorbing device between inverter and motor; also do not add

electromagnetic contact, show as Fig.3-3

To provide inverter over⑹-current protection in output side and

convenient maintenance under power off, it should be connected to

power source through relay.

Relay, input & output circuit wiring (X1⑺~X7、Y1、Y2/DO、TA、

TB、TC、AI1、AI2、AO、485A、485B) should select greater than

0.75mm² stranded wire or shielding wire. One end of the shielding layer

hang in the air, and the other end connect to inverter earth grounding

terminal, connection wire shorter than 20m.

!

3 Installation and wiring

13

、

Fig.3-3 Forbid to use contactor and absorbing capacitor

3.4 Main loop terminal wiring

Fig.3-4 main loop simple wiring

U

inverter V

W

M

(1)Before wiring, assure power supply is cut off completely for 10

minutes and all LED indicator light extinguished.

(2) Wiring can only be done by professional person trained and qualified.

(3) Before power on, check if voltage grade of the inverter is in line with

that of power supply volt., otherwise will cause personnel injured and

device daL1(R)

!

空气开关

W

V

U

M

接触器

R

S

T

三相

交流

电源

(断路器) EN630/

EN650A

Power

source

Air switch

breaker contactor

3 Installation and wiring

14

3.4.1 Connection between inverter and fitting parts

(1) Breaking device like isolation

Switchmustassemble between power

source and inverter to keep persona

safety under repairing and

inverter requirement for compulsory power off.

(2) There must be over-current

protection breaker or fuse in inverter

power supply circuit to avoid failure

expanding because of the second device failure.

(3) AC input reactor

When high harmonics between inverter

and power supply is strong which cannot

meet system requirement or input side

power factor need to improve, ac input reactor

can be added.

(4) Contactor is used to power supply only,

do not use it to control inverter start and stop.

(5) Input side EMI filter

Optionally EMI filter to restrain high frequency

transduction interference and radio-frequency

interference from inverter power line.

(6) Output side EMI filter

Choosing optionally EMI filter to

restrain radio-frequency Interference

and wire leakage current from inverter

output side.

(7) AC output reactor

Installing AC output reactor is suggested

to avoid motor insulation damage, oversize current leakage and inverter

frequent protection when connecting wire between inverter and motor exceeds

50m. While to consider the voltage decrease issue of AC output rector, it can

follow to boost inverter input & output voltage or use smaller power motor to

avoid motor damage.

(8) Safety earth ground wire

Inverter and motor must be earth ground connection, connection wire should

select as shorter and thicker as above 3.5mm² multi-core copper wire, and

earth grounding resistance smaller than10Ω.

Fig.3-5 connection of inverter and

fitting parts

N

T

S

R

UVW

TSR

空气开关

断路器或熔断器

接触器

交流输入电抗器(可选)

输入EMI滤波器(可选)

制动单元(可选)

输出EMI滤波器(可选)

交流输出电抗器(可选)

M

(-)

(+)

EN630/EN650A

Isolation switch

Breaker or fuse

Ac input reactor( In option)

Contactor

Input EMI filter( In option)

Brake unit( In option)

Input EMI filter( In option)

Ac output reactor(Note 1

ion)

AAI2

BrS0~10485A

M

3 Installation and wiring

15

3.4.2 Main loop terminal wiring

Main loop input output terminal show as table 3-1.

Table 3-1 main loop input output terminal description

3.5 Basic running wiring diagram

Fig.3-6 basic wiring diagram

Note 1:When X1~X7 terminal input signal low electric level valid , push SW1 to “L” side.

Note 2:When X1~X7 terminal input signal high electric level valid , push SW1 to “H” side.

Adapted type Main loop terminal Terminal name Function description

EN630/EN650A-2S0004

~

EN630/EN650A-2S0015

L1

L2

U、V、W

Zero line

Live line

Grounding terminal

3 phase AC output terminal

EN630/EN650A-4T0007

~

EN630/EN650A-4T0015

L1(R)、L2(S)、L3(T)

U、V、W

3 phase AC input terminal

Grounding terminal

3 phase AC output terminal

U V W

L1(R) U V 48

L2(S) L3(T)

P+ PB

L2(S)

Breaker

Multifunction select 1

Multifunction select 2

Multifunction select 3

Multifunction select 4

Multifunction select 5

Multifunction select 6

Multifunction selec

t

7

X1

X2

X7

X6

X5

X4

X3

V

W

GND

AO

Y2/DO

Y1

TA

TC

485A

485B

Standard 485

communication

Fault relay output

2 circuit open collector output

frequency meter output 24V

pulse signal

M

0~10V or 4~20mA

-10~10V

Speed command

+10V

AI2

AI1

GND

COM

Power source

Analog meter 4-20mA

current signal or 0~10V

voltage signal

COM

+24V Provide +24V power source outside

+10V

Note 1

Note 2

L3(T)

L1(R)

Brake resistor (external, fitting parts: connect to

right side of inverter)

EN630/EN650A

(Multifunction select 7 can

use as high speed pulse

input)

Internal optocoupler

isolation input

H L

U

TB

SW1

This manual suits for next models

11

Table of contents

Popular Inverter manuals by other brands

Generac Power Systems

Generac Power Systems Guardian 004373-3 owner's manual

CE+T Power

CE+T Power TSI NOVA user manual

YASKAWA

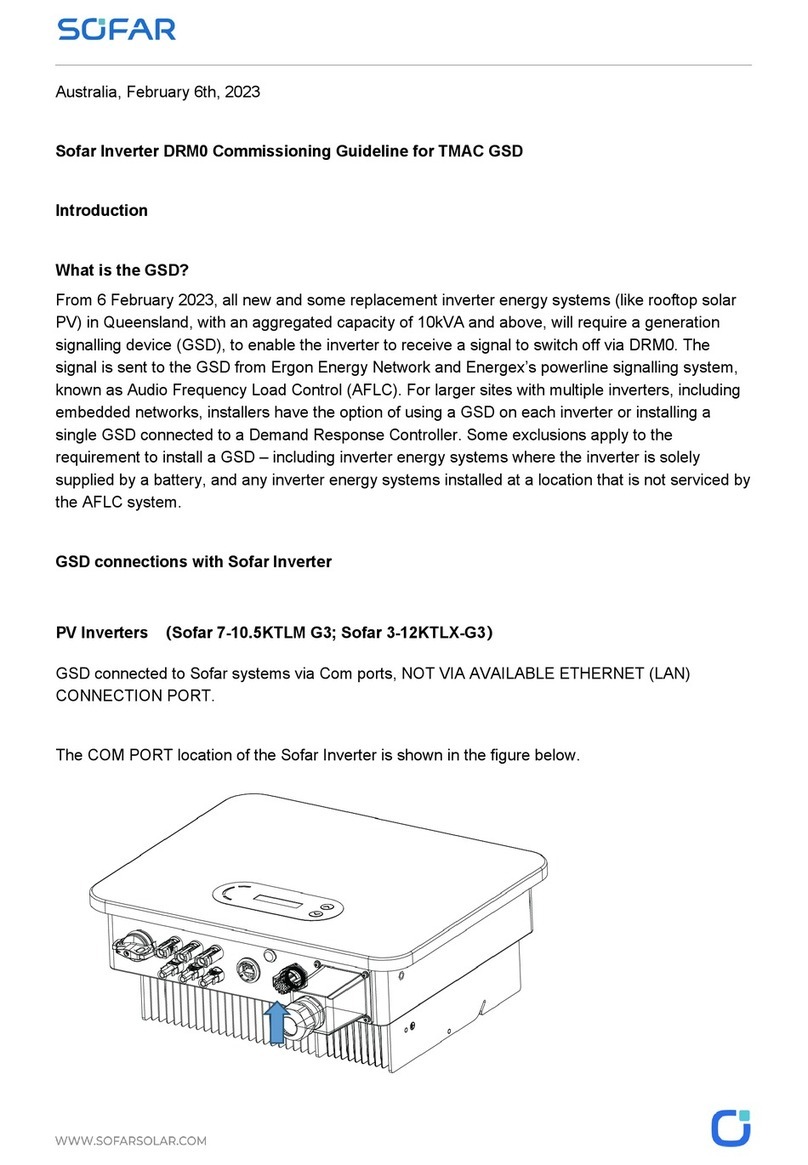

YASKAWA SOLECTRIA XGI 1500 Series Installation and operation guide

Sofar

Sofar DRM0 introduction

PNI

PNI L600W user manual

Schumacher Electric

Schumacher Electric PI-750 owner's manual

enphase

enphase IQ8P Installation and operation manual

Glion

Glion 36500 user manual

Aerpro

Aerpro FTS420 User instruction manual

SolaX Power

SolaX Power X1 Series Quick installation guide

Westinghouse

Westinghouse WGen5300v quick start guide

Solectria Renewables

Solectria Renewables PVI 2500 Installation and operation manual