Encon Safety Products 01104050 User manual

Doc. No: 09900010

Revision: H 1 of 5

Issue Date: 11/05/21

INSTALLATION

•

OPERATION

•

MAINTENANCE MANUAL

SELF-CONTAINED PORTABLE GRAVITY FED EYEWASH

MODEL 01104050 Gravity Fed Eyewash

MODEL 01104055 Gravity Fed Eyewash with Transport Cart & Receptacle

MODEL 01110700 Transport Cart & Receptacle

MODEL 01110302 Transport Cart Only

PRODUCT DESCRIPTION

Portable 14 Gallon Self-Contained Gravity Fed Eyewash units for use in areas where plumbed potable water is not available.

Units are designed for wall mounting or mounting on a transport cart, as well as a stand-alone on a shelf.

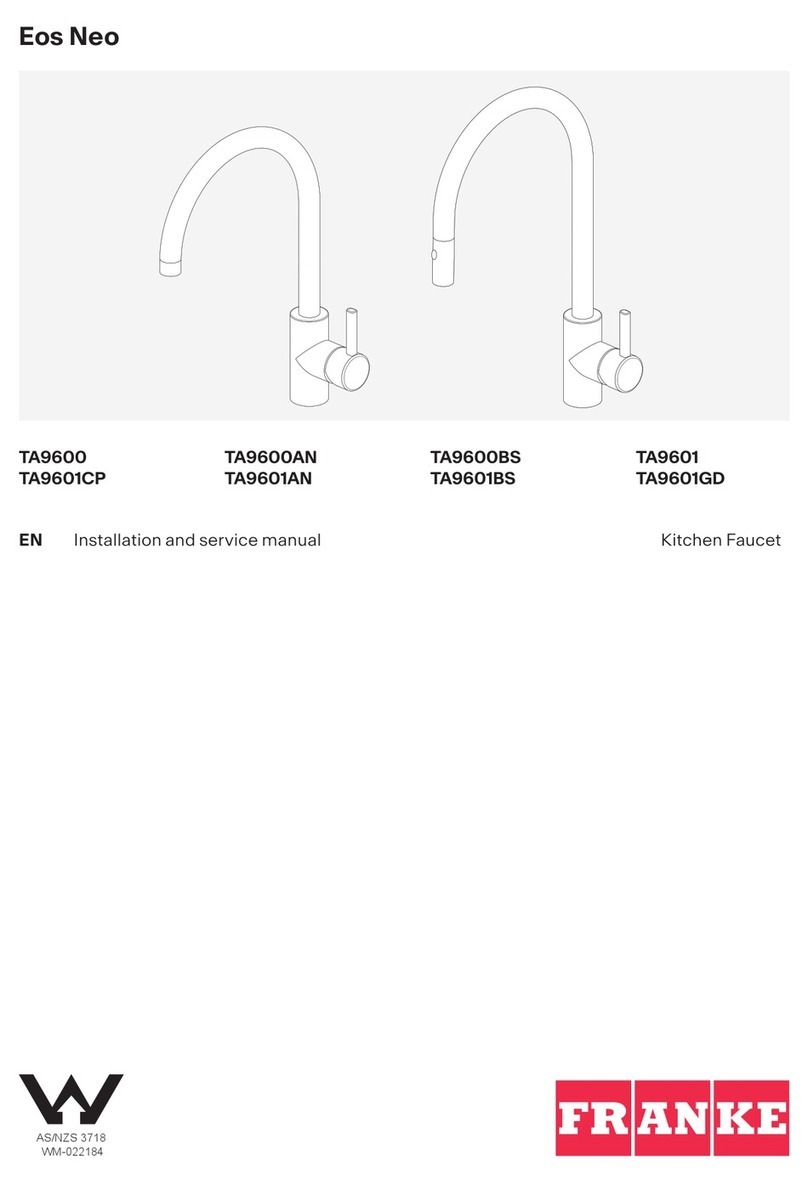

COMPONENT LIST FOR GRAVITY FED

(Ref. Figure 3 below)

A: Gravity Fed Eyewash

B: “J” Hook (1)

C: Hydrosep® Water Preservative (not shown)

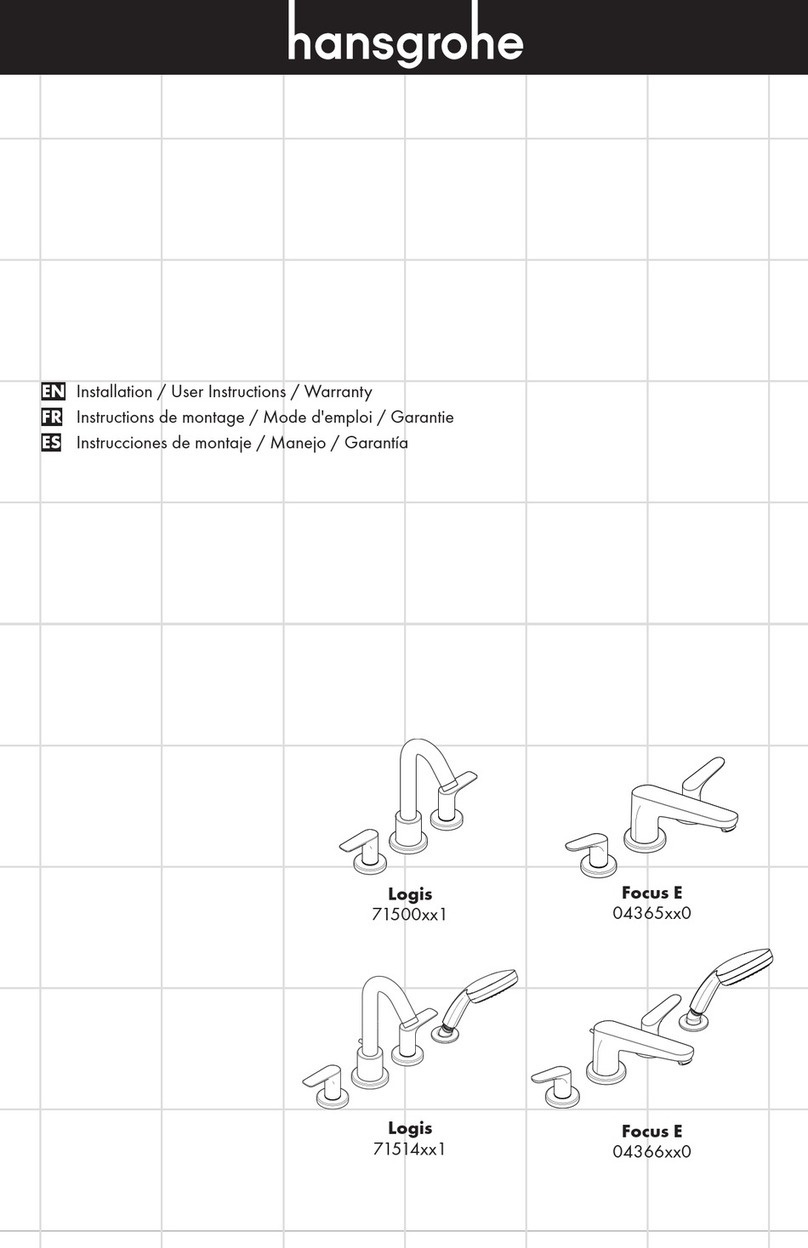

FIGURE 1

MODEL 01104050 SHOWN

(See installation instructions on page 4)

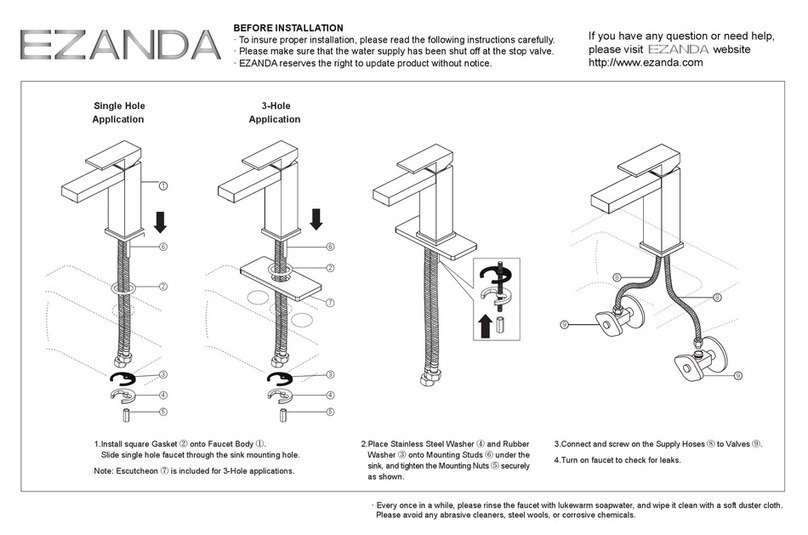

FIGURE 2

MODEL 01104055 SHOWN

(See installation instructions on page)

Doc. No: 09900010

Revision: H 2 of 5

Issue Date: 11/05/21

FIGURE 3

INSTALLATION INSTRUCTIONS FOR GRAVITY FED EYEWASH

CAUTION: Adequate shelf or wall support is recommended.

Unit weighs in excess of 120 lbs (54.4 kg) when filled to capacity.

1. Inspect and rinse vessel, if necessary.

2. The unit may be mounted on a wall, on Encon transport cart, or as a stand-alone unit on a shelf. In both cases, the

eyewash heads should be 33” (83.82cm) to 45” (114.3cm) from the floor when in open position. When operating the top

of the eyewash pattern should reach between 33” (83.8cm) to 53” (134.6cm).

3. When mounting on a shelf, tray should be able to fully open without any obstacles.

4. When wall mounting, install “J” hook to proper support beam 49-61” (124.5-154.9cm) from the floor to the top of the “J”

hook, using proper mounting screws (mounting screws are not included). See Figure 1 on page 1 for reference.

5. When mounting on Encon transport cart, see Installation Instructions for Transport Cart on page 3.

6. Fill the vessel with potable water up to the appropriate fill-line and add Hydrosep® water preservative. Follow directions

on Hydrosep® container.

7. Pull down eyewash tray to activate and test unit for proper flow pattern.

Doc. No: 09900010

Revision: H 3 of 5

Issue Date: 11/05/21

OPERATION AND MAINTENANCE

1. Keep tray closed to protect eyewash heads and shut off flow. Do not lean on tray when in open position.

2. Clean the vessel with mild soap and water as needed. Rinse well and refill with potable water to appropriate fill-line and

add Hydrosep® water preservative.

3. Unit should be drained, flushed, and refilled with clean potable water and Hydrosep® water preservative. Encon

recommends cleaning and replacing the fluid every 90 to 120 days (not to exceed 180 days). Follow the directions

printed on the Hydrosep® bottle.

4. Unit should be activated for 15 seconds to flush lines and inspected annually to verify proper operation. Refill to

appropriate fill-line after each test and add Hydrosep® water preservative if six gallons (cumulative) or more is used

during the testing procedures. Inspection should include examination of hose connecting reservoir and basin, and

reservoir should be free of fungi, algae or other foreign materials.

5. Test records should be maintained verifying compliance with testing procedures.

COMPONENT LIST FOR TRANSPORT CART

1.

Base Plate (1)

11.

Bolt, ¼”-20 x 2½”lg (4)

2.

Front Leg (2)

12.

Bolt, ¼"-20 x 2¾"lg (2)

3.

Upper Support (1)

13.

Bolt, ¼”-20 x 1½”lg (6)

4.

Rear Leg (2)

14.

Bolt, ¼"-20 x 1¾"lg (4)

5.

Upper Frame (1)

15.

Bolt, ¼”-20 x ¾”lg (16)

6.

Lower Support (1)

16.

Lock Nut ¼”-20 (28)

7.

Axle (1)

17.

Flat Washer ⅝” (4)

8.

Locking Caster (2)

18.

Cotter Pin (2)

9.

10” Wheel (2)

19.

Stop Plate (1)

10.

Axle Support (2)

20.

Hand Grip (2)

TOOLS REQUIRED

1.

Hammer

2.

Pliers

3.

7/16” Wrench (2)

INSTALLATION INSTRUCTIONS FOR TRANSPORT CART

1. Attach stop plate to base plate with two ¼”-20 x ¾” bolts and lock nuts.

2. Insert post on locking caster in base plate sockets, until caster locks. Note orientation on base plate. Ensure that the gap

on the tension ring of the locking castor post does not align with the weld seam in the socket. Repeat step on other side.

3. Attach axle support to base plate, using two ¼”-20 x ¾” bolts and lock nuts. Repeat step on other side.

4. Insert axle through two axle supports

5. Place 10” wheel on axle with flat washer on each side on wheel. Repeat step on other side.

6. Install cotter pin through hole on axle to secure 10” wheel. Repeat step on other side.

7. Install front leg to base assembly using two ¼”-20 x ¾” bolts and lock nuts.

8. Install rear leg to base assembly using two ¼”-20 x ¾” bolts and lock nuts. Do not attach front leg to rear leg.

9. Repeat steps 7 and 8 for other side of unit.

10. Insert upper frame into mating hole on front leg. Secure upper frame to front legs using four ¼”-20 x 2½” bolts and lock

nuts.

11. Slip hand grip onto rear leg, two places.

12. Attach upper support to upper frame using four ¼”-20 x 1½” bolts and lock nuts.

13. Attach long surface of lower support to upper frame using two ¼”-20 x 1½” bolts and lock nuts as shown. Note

orientation and location of lower support.

14. Attach J-Hook to hole in upper support using two ¼”-20 x ¾” bolts and lock nuts as shown. J-hook supplied with Gravity

Fed eyewash.

15. Place Gravity Fed Eyewash and receptacle on cart as shown in Figure 4 below.

16. Test for proper operation.

17. Place station in desired location. Lock front wheels by depressing silver tab on wheels.

Doc. No: 09900010

Revision: H 4 of 5

Issue Date: 11/05/21

TRAINING

All employees who might be exposed to hazardous material shall be instructed in the location and proper use of emergency

shower and eye/facewash units. Experiences have shown that initial first-aid treatment for irritants should be to irrigate the

eyes and face for 15 minutes prior to medical treatment. It is important to hold the eyelids open and roll the eyes so water will

flow on all surfaces and in the folds surrounding the eyes.

SPARE PARTS LIST

01110764

Hydrosep® Water Preservative (4 pack 8 oz. bottles)

01110792

Replacement Discharge Hose Kit

01110720

Male Latch

01110721

Female Latch

01110738

“J” Hook

ACCESSORIES

01110729

Drain Tray Kit

01110700

Transport Cart & Receptacle

00015003

Receptacle

01110302

Transport Cart

FIGURE 4 - SIDE VIEW

GRAVITY FED EYEWASH STATION

MODEL 01104055

Doc. No: 09900010

Revision: H 5 of 5

Issue Date: 11/05/21

PROPOSITION 65

WARNING: This product can expose you to BPA, which is known to the State of California to cause birth defects or other

reproductive harm. For more information go to www.P65Warnings.ca.gov.

WARRANTY STATEMENT

ENCON HEREBY DISCLAIMS ALL WARRANTIES EXPRESSED OR IMPLIED INCLUDING BUT NOT LIMITED TO

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, AND NON-INFRINGEMENT OF

THIRD-PARTY RIGHTS, EXCEPT AS HEREINAFTER PROVIDED.

Encon Safety Products warrants that for one year from the date of purchase of any Encon products, the product will be free of

defects in materials and workmanship if properly used and cared for or cleaned under normal conditions in accordance with

Encon’s use and care instructions and properly installed, if applicable, in accordance with Encon’s installation instructions.

With respect to the product, Encon’s only obligation and purchaser’s exclusive remedy under this warranty is to repair or

replace such product; provided that:

1. Encon is notified of the defect within one year of shipment, and

2. the product is determined by Encon to be defective.

Encon requires proof of original ownership as proof of warranty coverage, and Encon must receive any claim under this Limited

Warranty within one year of purchase of the product.

NOTWITHSTANDING ANYTHING TO THE CONTRARY CONTAINED HEREIN, ENCON SHALL NOT BE LIABLE FOR

LOSS, DAMAGE, OR EXPENSE ARISING DIRECTLY OR INDIRECTLY AS A CONSEQUENCE OF USE OF THE

EQUIPMENT WITH OTHER PRODUCTS OR FROM ANY OTHER CAUSE, INCLUDING ANY CONSEQUENTIAL,

INCIDENTAL, SPECIAL OR EXEMPLARY DAMAGES, EXCEPT FOR ENCON’S OBLIGATION TO REPAIR OR REPLACE

DEFECTIVE PRODUCTS AS EXPRESSLY PROVIDED IN THIS STATEMENT.

Replacement parts purchased from Encon are warranted for one year following the shipment of such replacement part, or until

the expiration of the warranty period for the product, whichever is less. No warranty is given in connection with products that

are altered without Encon’s expressed written consent. The same warranty limitations and the obligations of Encon as set out

herein above shall apply to replacement parts.

Encon’s total liability arising out of this warranty (including, but not limited to, warranty claims) regardless of forum and

regardless of whether such action or claim is based on tort, contract or otherwise will not exceed the total purchase price of

the product.

6825 W. Sam Houston Pkwy. N

Houston, TX 77041

1-800-AT-ENCON / 1-800-283-6266

http://www.enconsafety.com

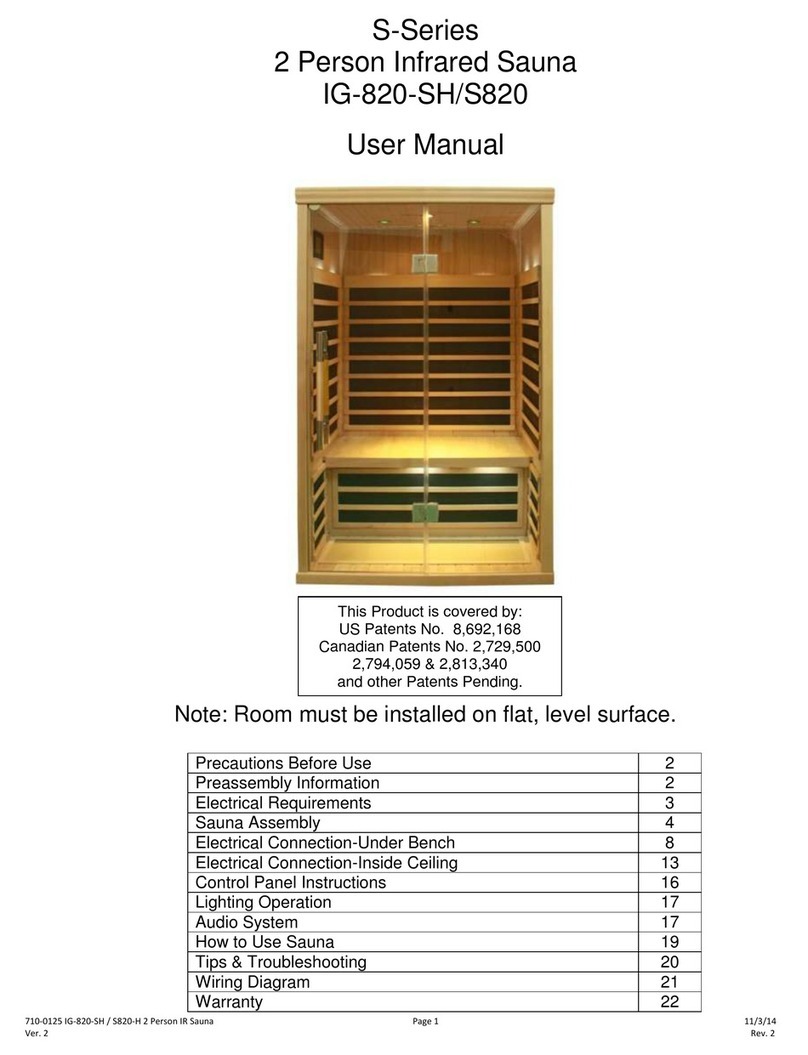

This manual suits for next models

3

Table of contents

Popular Plumbing Product manuals by other brands

Hansgrohe Axor

Hansgrohe Axor Starck 10822000 Instructions for use/assembly instructions

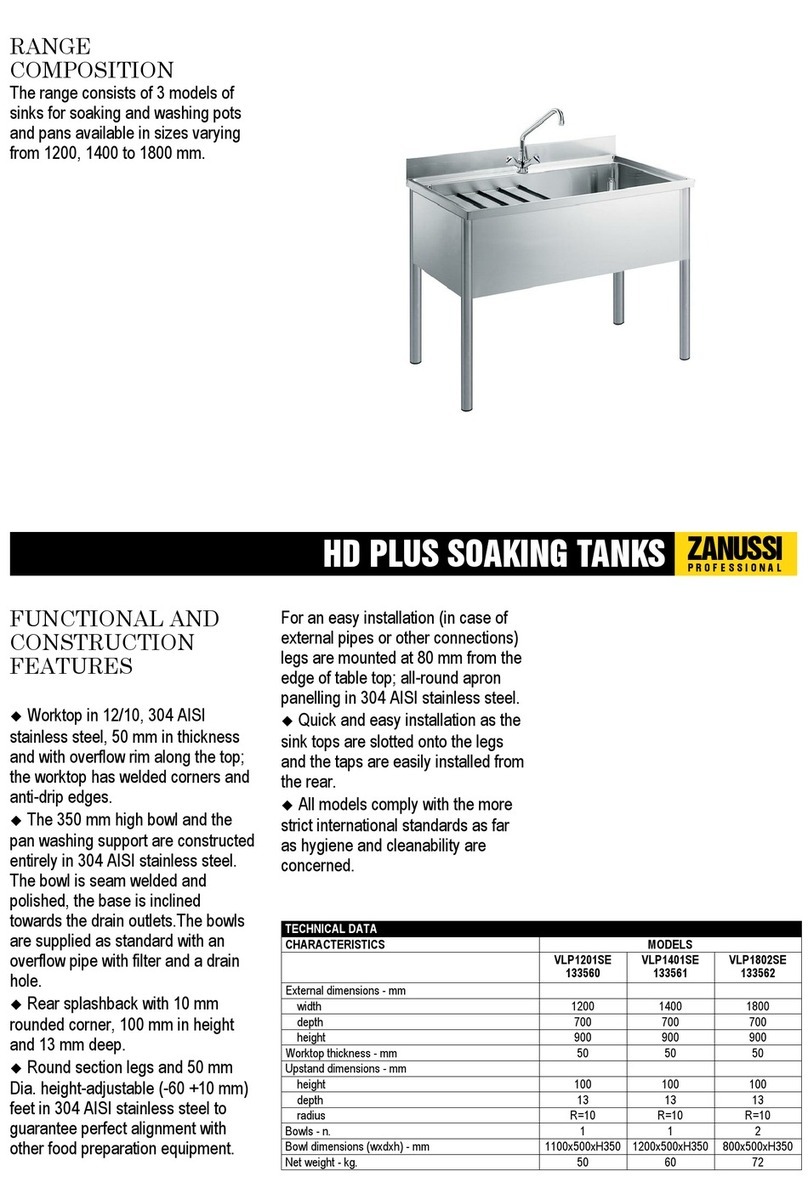

Zanussi

Zanussi 131444 Specifications

Laufen

Laufen CLINIC HF941060100094 manual

Sanela

Sanela SLU 45MD Instructions for use

Nobili

Nobili LIVE LV00713CR quick start guide

Pentair Jung Pumpen

Pentair Jung Pumpen WCFIX 260 instruction manual

American Standard

American Standard Dazzle 6028.201 installation instructions

Bradley

Bradley Terreon TDB3104 Installation

FONTANA SENSOR FAUCETS

FONTANA SENSOR FAUCETS B5081-G installation instructions

MX

MX Douche Bidet Kit user manual

Graff

Graff ME25 2329500 installation instructions

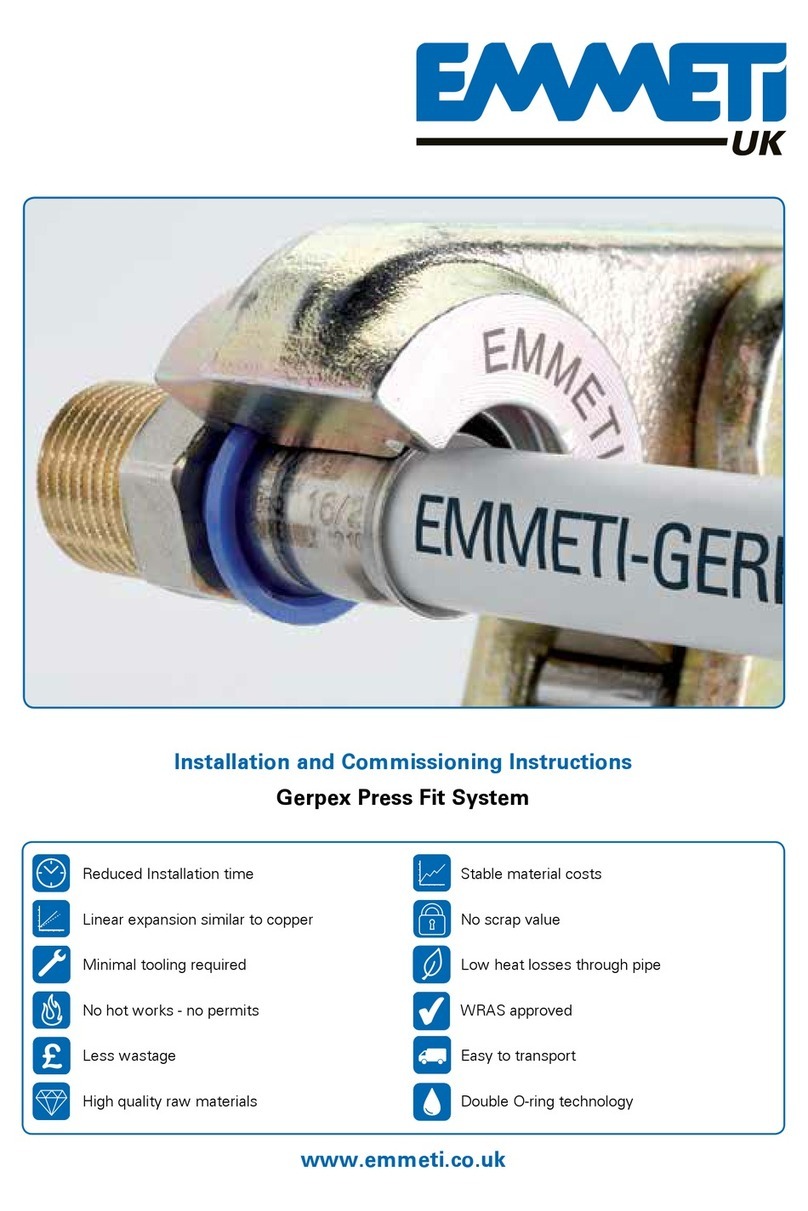

emmeti

emmeti Gerpex Press Fit Installation and commissioning instructions