Endeavour Tools ET8636 User manual

BATTERY

CHECKER

Instruction Manual

ET8636

CONTENTS

Thank you for purchasing "BATTERY CHECKER ET8636". To obtain the maximum

performance of this instrument, read this Instruction Manual carefully, and take safe

measurement.

INTRODUCTION

1 - 3

4

5

6

7 - 8

9

9

10 - 11

11

11

12 - 19

20 - 22

23 - 25

26 - 27

28

29

30 - 31

32

33

33

34

35 - 36

37 - 38

39 - 40

40

40

40

41

SAFETY PRECAUTIONS・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

OPERATING PRECAUTIONS・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

FEATURES・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

UNPACKING AND INSPECTION・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

NAME ILLUSTRATION・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

SPECIFICATIONS

1. General Specifications・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

2. Measurement Specifications・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

BEFORE USE

1. Technical Words・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

2. Language / Date & Time Settings・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

3. Others・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

MEASUREMENT PROCEDURES

1. Battery Test・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

2. Battery System Test・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

3. Print out・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

4. Test Result Saving・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

5. View the Saved Data・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

6. Delete the Saved Data・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

7. Connecting to PC・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

8. Setting of Date and Time・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

9. Setting of Language・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

10. Contrast Adjustment・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

11. Temperature Setting・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

12. CCA Value List for Battery Manufacturers and Their Models・・・・・・・・・・・・・・・・

MAINTENANCE

1. Printing Paper Setup・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

2. Formatting of Removable Disk・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

3. Periodical Check and Calibration・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

4. Software Version Update・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

5. Others・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

TROUBLE SHOOTING & REPAIR・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

1

SAFETY PRECAUTIONS (strict observance is required)

This instruction manual contains the important contents to prevent harm to

user or others and damage of property, and to use the instrument safely and

correctly.

Read this manual carefully and obey the contents after having understand the

following terms and symbols.

■The points where the following symbols are attached in this manual

describe the degree of harm and damage that would be caused by

incorrect usage due to neglect of this description.

WARNING

CAUTION

■The points where the following symbols are attached in this manual

describe the matters which must obey in accordance with the each

meanings. (following symbols are some examples.)

This symbol in this manual advises the user of

an electrical shock hazard that could result in

serious injury or even death.

This symbol in this manual advises the user of

an electrical shock hazard that could cause

injury or material damages.

This symbol shows the warnings and cautions.

This symbol shows the prohibited matters.

This symbol shows the matters that is forced to do.

2

SAFETY PRECAUTIONS (strict observance is required)

Do not place this instrument in any place where it will be subjected to

direct sunlight, high temperatures or the inside of the sun-heated cars.

Fire, electric shock or damage to the instrument may occur.

Make sure that the shift lever is set to "Parking" position (set to "Neutral" for

stick shift car).

The car runs accidentally and could cause unexpected accident, electric shock,

fire or damage to the instrument or the car.

Make sure that the parking brake is applied.

The car runs accidentally and could cause unexpected accident, electric shock,

fire or damage to the instrument or the car.

Keep the instrument away from babies or children.

Important to prevent any accident, injury, or electric shock hazard.

Take the measurement under well-ventilated environment.

The hydrogen gas which stayed around battery catches fire from the spark that

occurred when connecting the Battery Clips and might explode.

Do not drive the car keeping the instrument connected.

Accident, electric shock, fire, or damage to the instrument or the car may occur.

Do not use this instrument with the hands or Battery Clips wetting.

Accident, electric shock, fire, or damage to the instrument or the car may occur.

Do not take the measurement for the battery which does not have enough battery fluid.

It causes combustion and the explosion of the battery.

Do not take the measurement around inflammables such as gasoline or oil.

Fire or explosion may occur.

Do not work in the dark place.

Accident, electric shock, fire, or damage to the instrument or the car may occur.

Do not get the instrument wet.

Fire or electric shock may occur.

Do not use the faulty instrument that can recognize such as display trouble,

switch failure.

Stop using the instrument immediately and consult with your local dealer.

Using the faulty instrument may cause the unexpected accident, fire, or

electric shock.

Do not touch the USB port with finger or insert the foreign objects in the USB port.

Unexpected accident, electric shock, fire, or damage to the instrument may occur.

Do not touch the heated part of the engine such as exhausting parts.

Important to prevent burn injury.

WARNING

3

SAFETY PRECAUTIONS (strict observance is required)

WARNING

Do not use the instrument if it is in the abnormal condition.

Stop using the instrument immediately and consult with your local dealer

when recognizing smoke, strange smell, or abnormal noise.

Using the faulty instrument may cause the unexpected accident, fire, or electric shock.

Do not attempt to disassemble or modify the instrument.

Fire, electric shock, or damage to the instrument may occur.

Do not use the cables with which coating were damaged.

Fire or electric shock may occur.

Be careful about the instrument or the cables not to touch the heated part

of the engine such as exhausting parts.

Important to prevent any accident, or damage to the instrument or the car.

Be careful about the instrument or the cables not to be caught in the engine belt or cooling fan.

Short circuit or wire breaking may occur that could cause unexpected accident,

electric shock, or damage to the instrument or the car.

CAUTION

Be careful not to get the battery fluid into eyes or not to attach it to skin and clothes.

Loss of eyesight or injury may occur. If it gets into eyes, rinse immediately and

submit to medical treatment.

When testing the battery on vehicle, take the measurement after stopping

the engine and turning off the power supply of all in-vehicle apparatuses.

It causes injury or damage to the instrument.

Connect the Battery Clips to the battery with the correct polarity.

Reverse connection causes damage to the instrument.

Disconnect this instrument from battery soon after finishing the test.

It causes consumption of the battery and the ignition.

Do not use the other USB cable except the supplied one.

Damage to the instrument or PC may occur.

Do not hit, thrust and make scratch on the LCD display part.

It causes trouble or damage to the LCD.

Be careful not to jam the fingers in the Battery Clip.

It causes injury.

Be careful about your hands, gloves and clothes not to be caught in

the engine belt or cooling fan.

Important to prevent injury.

4

OPERATING PRECAUTIONS

●Do not apply the engine oil to the metal part of the Battery Clips or USB Plug to

prevent contact failure.

●Do not apply engine oil, gasoline, antifreeze or battery fluid to the instrument to

prevent any damage on its surface.

●Do not polish the case with the fluid that contains alcohol to prevent the cracking.

●Use this instrument under the environment of -10℃to 50℃, 80%RH or less to obtain

the accurate measurement. (Printer is operating at 0℃to 50℃)

●Cables which coating are heat damaged might cause the short circuit. Do not use them

and replace into the new ones.

●Disconnect this instrument from battery soon after finishing the test to prevent trouble

of this instrument and running out of battery power.

●Do not touch the inside of the printer with finger to prevent trouble of this instrument.

●Do not put serious pressure on Printer Lever or Printer Cover to prevent trouble or

damage to this instrument.

●If Date and Time are not able to set, built-in battery for backup is exhausted. Ask

KAISE AUTHORIZED SERVICE AGENCY through your local dealer for repair service.

●Keep this instrument in supplied Carrying Case to avoid malfunction of the printer

trouble by dust penetration.

Cautions for Handling

●Do not apply mechanical shock.

The shock such as dropping or beating might damage the instrument and may cause the

trouble.

●Do not pull cables forcibly.

Pulling the cables forcibly, such as when removing the Battery Clips from the battery or

USB Plugs from USB Port, may cause trouble such as the breaking of wire.

Cautions for Safekeeping

●Keep away the instrument from the following place.

・Dusty area

・The place where has the water splash

・The place where applies the hard shock

・-20℃or less, 60℃or more, 70%RH or more

・The place where has the condensation

・The place where is exposed to direct sunlight

5

FEATURES

■Portable instrument that can operate

with one hand.

■The software is upgradeable by

connecting supplied USB cable with

PC.(※)

■Capable of saving the test results up

to 99 data. Moreover, the test data

can edit on PC as text data by using

the supplied USB cable.

■Batteries for the vehicle equipped

with charge control system or idle

reduction system are testable.

■Test result can be printed on site by

built-in printer. Printing language is

selectable from Japanese, English

and Simplified Chinese.

■ET8636 can test State ofCharge

(SOC), State of Health (SOH), Start

Performance and Charging System

of the car battery.

※PC with Internet access is necessary.

Battery Test Report

Date and Time

2013/5/1515:0 0

Test Result : Good

Test Result : Good

Test Result : Good

Periodical test is

recommended.

Replace to charge controller

battery is recommended for

better gas mileage.

SOC(State of Charge):100%

SOH (State of Health):100%

Store Name

Person in Charge

BATTERY TEST

START PERFORMANCE TEST

CHARGING SYSTEM TEST

Cranking

Start Performance

8.619V

100%

Charging Voltage

Ripple Voltage

14.200V

0.100V

Battery Type

Battery Size

Rated CCA

Measured CCA

Battery Voltage

BatteryTemperature

Testing Mode

JIS

Q-85

530CCA

615CCA

12.780V

24℃

Charge controller / Idle Reduction

File EditViewFavoriteToolHelp

1351501.TXT

TextDocument

1KB

1351502.TXT

TextDocument

1KB

1351503.TXT

TextDocument

1KB

1351504.TXT

TextDocument

1KB

1351505.TXT

TextDocument

1KB

1351601.TXT

TextDocument

1KB

1351602.TXT

TextDocument

1KB

1351603.TXT

TextDocument

1KB

1351701.TXT

TextDocument

1KB

1351702.TXT

TextDocument

1KB

1351703.TXT

TextDocument

1KB

1351704.TXT

TextDocument

1KB

1351705.TXT

TextDocument

1KB

BAD

GOOD CHARGE

MENU

[ バッテリーテスト ]

交換(バッテリー劣化)

JIS規格 95D31

565 CCA

MAX 32V

BATTERY

CHECKER

SK-8530

[ BATTERY TEST ]

Replace

JIS 95D31

565 CCA

BADGOOD CHARGE

MENU

MAX 32V

BATTERY

CHECKER

SK-8530

[ BATTERY TEST ]

Replace

JIS 95D31

565 CCA

■Auxiliary battery for hybrid car is

testable.

1351503.TXT‑Notepad

BatteryTest Report

Date andTime

2013/05/15 15:00:00

------------------------------

BatteryTest

(Aging test mode)

Test Result: Good

BatteryType: JIS

Battery Size: Q-85

Rated CCA: 530CCA

Measured CCA: 615CCA

Battery Voltage: 12.780V

BatteryTemperature: 24℃

Testing Mode

: Charge Controller / Idle Reduction

FileEditFormatViewHelp

BATTERY

CHECKER

SK-8535

CHARGE

BADGOOD

MAX 32V

MENU

BATTERY

CHECKER

SK-8535

CHARGE

BAD

GOOD

MAX 32V

MENU

12V?24V?

12.462V

12VBattery

24VBattery

BATTERY

CHECKER

SK-8535

CHARGE BAD

GOOD

MAX 32V

MENU

(AgingTest Mode)

6

UNPACKING AND INSPECTION (Check before use)

Confirm if the following items are contained in the package in good condition.

If there are any damages or missing items, ask your local dealer for replacement.

①Battery Checker…1 pce.

③Printer Paper…2 rolls

(installed, and spare)

Available Printer Paper (10pcs per set)

Parts number:851

(Paper width:approx. 57mm,

length:approx. 5.8m)

②USB Cable (937)…1 pce.

⑤Instruction Manual…1 pce.

・Use above parts number when ordering.

SILICA

THROW AWAY

"DO NOT EAT"

THROW AWAY

"DO NOT EAT"

DESICCANT

GEL

※The following desiccant is enclosed

in the package for maintenance of

quality. Throw it away after opening

the package.

MENU

BAT TERY

CHECKER

SK-8535

CHARGE BADGOOD

MAX 32V

④Carrying Case…1 pce.

MENU

BAT TERY

CHECKER

SK-8535

CHARGE BADGOOD

MAX 32V

MENU

7

NAME ILLUSTRATION

●LED Indicators

①GOOD (Green LED):

L

ights up when battery test result is

"Good".

②CHARGE (Yellow LED):

Lights up when the battery is weak

and needs re-charging.

③BAD (Red LED):

lights up when battery test result is

"Replace" or needs replacement.

Flashes when battery test result is

"Attention" or "Weak Start Power".

●USB Port

Plug the USB Cable into this port

when connecting to PC.

Connect to the battery.

Red to ○+, black to ○−.

●Battery Clips (Red・Black)

●Printer

●LCD

●△(UP SCROLL) Key

Scrolls up the display / use for

numerical settings.

Press this key to return to the

previous screen.

●(BACK) Key

●(ENTER) Key

Press this key to fix the settings.

● (MENU) Key

Display the Menu screen.

MENU

●▽(DOWN SCROLL) Key

Scrolls down the display / use for

numerical settings.

Front Side

CHARGE BADGOOD

8

NAME ILLUSTRATION

Rear Side

●Serial Number

How to clip :

Open the battery clip widely and clip

it to the holder in the plastic part of

the clip. (Do not clip in the metal

part)

Clip Battery Clips here when not in

use.

●Battery Clip Holder

●Do not clip in the metal part of the Battery clip. To prevent any

damages of the Battery Clip and Clip Holder.

CAUTION

00001

KAISE JAPAN4301-8530-1 1106

TO AVOID ELECTRICAL SHOCK, DO NOT CONNECT

BATTERY WITH WET HAND OR WET BATTERY CLIP.

感電事故防止のため、手やバッテリークリップ等がぬれた

状態で、バッテリーに接続しないでください。

SERIAL No.

WARNING

www.kaise.com

SPECIFICATIONS

Dot presentation, 128×64dots

Japanese, English, Chinese (Default: English)

1 time/second

Green:Lights up when battery test result is "Good"

Yellow:Lights up when battery is weak and needs re-charging

Red:Lights up when battery test result is "Replace"

Flashes when battery test result is "Attention" or

"Weak Start Power"

Built-in

Approx.70cm (Clip and Bush are not included)

Testing battery or USB connection

DC8V to 32V (Testing battery), DC5V (USB Connection)

12V lead batteries ※For 24V battery, only Start-up

PerformanceTest or Charging SystemTest are possible.

JIS, DIN, EN, SAE, BCI, CCA and Industrial Rating

CCA:100 to 1400, Industrial Rating:1.0mΩto 50.0mΩ

12V battery : BatteryTest / Start PerformanceTest and Charging SystemTest

24V battery : Start PerformanceTest and Charging SystemTest

Accuracy at 23°C±5°C×0.01/°C

Test results can be saved to the internal memory up to 99 data.

※The data can be sent to PC via USB connection

From web site via USB connection

0°C to 50°C, less than 80%RH (in non-condensing)

-20°

C

to 60°

C

, less than 70%RH (in non-condensing)

CE marking approved EN61326-1

248

mm

(H)×96

mm

(W)×50

mm

(D) ※

Cable and Bush are not included

Approx. 550g ※Printer paper is not included

1. General Specifications

2. Measurement Specifications (23°C±5°C, <80%RH in non-condensing)

LCD

LANGUAGE

DISPLAY RATE OF

VOLTAGE MEASUREMENT

LED INDICATION

PRINTER

BATTERY CABLE LENGTH

POWER SUPPLY

TESTING VOLTAGE

TESTABLE BATTERIES

TESTABLE BATTERY STANDARDS

TESTABLE BATTERY PERFORMANCE

MEASURABLE TESTS

TEMPERATURE COEFFICIENT

FOR VOLTAGE MEASUREMENT

DATA SAVING

SOFTWARE UPDATE

OPERATINGTEMPERATURE & HUMIDITY

STORAGETEMPERATURE & HUMIDITY

SAFETY LEVEL

DIMENSION

WEIGHT

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

※Specification and appearance are subject to change without notice.

Range

16.000V

32.000V

Resolution

1mV

Maximum Input

Lower than 32V

Accuracy

(8V to 16V):±0.15%±3dgt

(16V〜32V):±0.15%±3dgt

Battery Voltage

※Overload indication:"Over voltage" is displayed.

Range

-20°C to 60°C

Resolution

1°C

Maximum Input

-20°C to 60°C

Accuracy

±3°C

Temperature

※

Accuracy is applied when measuring after leaving under constant temperature more than an hour.

9

10

BEFORE USE

●What is CCA?

CCA stands for Cold Cranking Amperes. It is defined as the current a battery at 0°F

(-18°C) can discharge for 30 seconds and maintain at least 7.2V (for JIS, SAE and

BCI). And it is defined as the current a battery at 0°F (-18°C) can discharge for 10

seconds and maintain at least 7.5V (for EN and DIN). The battery which has the

bigger CCA, the higher ability to start an engine, CCA is one of the criterion for

selection of the battery.

●What is SOH (Stateof Health)?

SOH is the health condition of the battery, the state is expressed in percentage (%).

1.Technical Words

The current discharge at 0°F (-18°C) for 30 seconds

and maintain at least 7.2V.

The current discharge at 0°F (-18°C) for 10 seconds

and maintain at least 7.5V.

CCA definition of various standards

Standards CountriesCCA Definition

JIS

SAE

BCI

EN

DIN

Japan

USA

USA

EU

Germany

●What is SOC (StateofCharge)?

SOC is the charging condition of the battery, the state is expressed in percentage (%).

Definition of SOH in this product:

ET8636 defines SOH 23% as the threshold of the battery replacement recommendation. Test

result shows "Replacement is necessary" when measured SOH is 23% or less and test

result of SOC is not "Charge/Retest".

※SOH(%) is calculated as the ratio of CCA standard value to CCA measured value.

※SOH(%) fluctuates due to the rate of deterioration and charging condition.

Definition of SOC in this product:

ET8636 defines as SOC 100% when the battery voltage is higher than 12.756V. (Higher than

13.056V for the battery for industry)

※ET8636 does not show the exact measurement voltage when testing the battery just after

an engine shutdown or just after charging. Test the battery after reducing the stimulated

condition according to the procedure mentioned in Page 12.

11

BEFORE USE

2. Language / Date & Time Settings

●Set date and time before using this instrument. (Refer to "8. Setting of Date and

Time" on Page 32).

●Language changeable from English (default setting) to Japanese or simplified

Chinese. (Refer to "9. Setting of Language" on Page 33).

●What is Ripple Voltage?

Ripple Voltage is the feeble change of charging voltage which occurs when rectifying

the generated voltage by diode. If diode is damaged, the ripple voltage fluctuated

sharply and adversely affects battery and in-vehicle apparatus.

3. Others

●Protection film is put on the front plate of

the unit before shipment. Tear off the

protection film before using this

instrument.

Tear off the protection film. MENU

B AT TERY

CHECKER

SK-8535

CHARGE BADGOOD

MAX 32V

●Initial display shows the factory default

settings.

12

MEASUREMENT PROCEDURES

1. Battery Test

●This instrument forced to be restarted if the testing battery is extremely

exhausted and cannot afford to supply the workable current.

●Test the battery in the state of the engine shutdown to obtain the accurate

measurement.

●When testing 24V battery, test each 12V battery which is connected in series.

●When testing the battery on vehicle, test the parked car after turning off the power

supply of all in-vehicle apparatuses which are using the electricity from battery

and locking the car door to obtain the accurate measurement.

●Test result may change when testing the same battery repeatedly. Also, test result

may change when testing the weak battery after using the printer.

●Test result may change, even when testing the same battery, depending on the

battery condition or change the storage environment.

●Test results may be higher than usual just after driving. When testing the battery

test of such a car, test it after doing the following procedure.

・Turn on the headlights for approx. 20 seconds.

・Turn off the headlights and test it more than 3 minutes after turning off the

headlights.

In case of the test result is "Charge/Retest" by turning on the headlights, shorten

the time of turning on the headlights after re-charging the battery, and lengthen

the time of intervals before testing.

When you do not perform the procedure mentioned above or testing battery unit

just after charging, test after an interval more than 2 hours.

●This instrument judges the battery condition with testing the basic use of the lead

battery such as charge-discharge characteristics. Test result is not for judging

whether the special control function can use for the vehicle or not.

●This instrument judges the battery condition with testing the basic use of the lead

battery such as charge-discharge characteristics. Test result is not for judging

whether the special control function can use for the vehicle or not.

Special purpose battery such as idling stop battery may not work idling stop

function due to decreasing charge acceptance occurring with long-term use. In

this case ask your car dealer for check and maintenance of the battery.

●The maximum CCA displayed with this unit is up to 1400CCA.

CAUTION

13

MEASUREMENT PROCEDURES

Test the SOC (State of Charge) and SOH (State of Health) of the battery.

①Connect Black clip and Red clip to battery

minus ○− terminal and plus ○+ terminal

respectively.

When you cannot connect battery clips to

battery terminal directly, connect them to

the point from the terminals well as close

as possible.

※In this case a CCA may be measured

lower than a real value.

Red

Black

Battery

●Check the battery visually before connecting Battery Clips to the battery terminals.

●Replace the Battery Terminals if there is corrosion or crack occurs on the

Terminals.

●Connect the Battery Clips to the Battery Terminals tightly without loosening.

●Clean up the Battery Terminals and Battery Clips if there is greasy dirt.

●Replace the battery which is damaged, deformed of the Battery and broken the

Battery Terminals.

●Add the purified water and do auxiliary charge if the level of battery fluid

decreases near to the border of LOWER.

●Replace the battery that the level of battery fluid is lower than the border of

LOWER with discolored battery fluid.

Test Preparation

MENU

BAT TERY

CHECKER

SK-8535

CHARGE BADGOOD

MAX 32V

●Make sure to connect the Battery Clips to Battery Terminals to

obtain the accurate measurement.

●Clean up the Battery Terminals and the Battery Clips before testing

to obtain the accurate measurement.

CAUTION

12V?24V?

12.462V

12VBattery

24VBattery

14

MEASUREMENT PROCEDURES

③Select the battery voltage to be tested.

Choose the battery voltage from 12V or 24V

with using △(UP SCROLL) / ▽(DOWN

SCROLL) Keys, then press (ENTER) Key.

Choose 12V battery:Proceed to the next

step ④.

Choose 24V battery:Proceed to the step of

2. Battery System Test on Page 18.

※Battery voltage is displayed on the LCD.Battery voltage

④Select the battery type to be tested. Choose

the battery type from the choices with using

△(UP SCROLL) / ▽(DOWN SCROLL) Keys

and press (ENTER) Key.

※In case of the measurement voltage is

higher than 13.6V, battery cannot be tested.

WARNING screen is displayed on LCD.

※In case of the measurement voltage is

higher than 16V, "OVER VOLTAGE" is

displayed on LCD.

※Choose "Input CCA" if the CCA is described

on the battery, otherwise choose "Industry"

when testing the battery for Golf cart,

Leisure boat, and Deep-cycle battery.

Press (BACK) Key to go back to the

Battery Voltage Selection screen (Step

③).

②The instrument is powered on automatically and entersTest Battery Selection (step ③)

after showing the following model number / software version number indication.

BATTERY CHECKER

ET8636

Soft Version Number

Ver 2.00

Current version number

BatteryType?

12.462V

JIS

DIN

15

MEASUREMENT PROCEDURES

⑤Choose testing mode with using △(UP

SCROLL) / ▽(DOWN SCROLL) Keys and

press (ENTER) Key. In the case of

battery for the cars with charge controller

or idle reduction systems, choose "Charge

Controller / Idle Reduction". Otherwise

choose "Standard".

※"Industrial Rating" screen in Page 16 is

displayed when choosing "Industry" at

Step ④.

●When choosing "JIS"

Select conformable JIS type with using △(UP

SCROLL) / ▽(DOWN SCROLL) Keys and

press (ENTER) Key. Battery test starts.

⑦The following screen is displayed depending on the selected standards.

Press (BACK) Key to go back to the

Battery Type Selection screen (Step ④

on Page 14).

Press (BACK) Key to go back to the Battery

Type Selection screen (Step ④on Page 14).

SelectJIS

TestStart

95D31 105E41

95E41 110D26

100E41 110E41

105D31 115D26

TestingMode ▲▼

Standard

ChargeController/

IdleReduction

TestingMode ▲▼

ChargeController/

IdleReduction

HybridAuxiliary

WhichTestMode?

AgingTest

UnusedBatteryTest

●If you want to test the auxiliary battery for

hybrid car, choose "Hybrid Auxiliary" with

using △(UP SCROLL) / ▽(DOWN SCROLL)

Keys and press (ENTER) Key. "Select

JIS" screen in step ⑦is displayed.

※"Hybrid Auxiliary" cannot be selected when

choosing EN(DIN), SAE(BCI), CCA Input in

Step ④on Page 14.

⑥Select Test Mode.

Aging Test:

Choose it for deterioration check.

Unused Battery Test:

Choose it for condition check of the

unused battery

Press (BACK) Key to go back to the Battery

Type Selection screen (Step ④on Page 14).

16

MEASUREMENT PROCEDURES

●When choosing "Industry"

Select "YES" for inputting Industrial Rating

with using △(UP SCROLL) / ▽(DOWN

SCROLL) Keys and press (ENTER) Key.

Battery test starts when choosing "NO".

※When choosing "NO", battery condition

(good / bad) is not tested.

●When testing the battery for industry, disconnect the all electric

loads from the battery to obtain the accurate measurement.

●Battery test is effective for only 12V lead battery.

●Generally, industrial battery is recommended to be replaced when

the internal resistance comes up to double of the unused battery.

Based on this, ET8636 judges "Bad" when the test result becomes

double of the input industrial rating.

IndustrialRating?

YES

NO

(TestStart)

CAUTION

※Chosen battery standard is retained.

※If knowing only battery size like B24, D31, etc., select JIS of the greatest specifications

which is replaceable.

InputEN(DIN)Rating

1400CCA

TestStart

Input the Rating with using △(UP SCROLL) /

▽(DOWN SCROLL) Keys and press

(ENTER) Key. Battery test starts.

Input CCA rating

Press (BACK) Key to go back to the Battery

Type Selection screen (Step ④on Page 14).

※Chosen battery standard is retained.

●When choosing "EN(DIN)", "SAE(BCI)" or "CCA input"

Press (BACK) Key to go back to the Battery

Type Selection screen (Step ④on Page 14).

17

MEASUREMENT PROCEDURES

⑧The following screen is displayed during

battery testing.

※LCD backlight turns off during testing.Nowtesting…

InputmΩ

50.0m

Ω

TestStart

(When choosing "YES")

Input mΩvalue with using △(UP SCROLL) /

▽(DOWN SCROLL) Keys and press

(ENTER) Key. Battery test starts.

Input mΩvalue

Press (BACK) Key to go back to the Input

Industrial Rating screen.

Can you find default internal resistance value of the testing

battery which may be written in its body or user's manual?

YES NO

Input that value in this step. Select "NO" in the previous step, and test the unused

(new) battery without inputting rating value to check

the default internal resistance value. Then, input that

value in this step.

When temperature input setting is set

"manual", Battery Temperature Input screen

is displayed as shown in the right, Input

temperature in ℃with using △(UP

SCROLL) / ▽(DOWN SCROLL) Keys and

press (ENTER) Key. Battery test starts.

※Input the temperatures of the battery

fluid or ○+terminal.

●Inputting Battery Temperature(When temperature input setting is set "manual")

(Refer to "11. Temperature Setting" on Page 34)

BatteryTemperature

25 ℃

TestStart

Press (BACK) Key to go back to input

screen of each ratings

18

MEASUREMENT PROCEDURES

※Operating instructions are displayed in the last page of the test result.

Press (ENTER) Key:Enter Battery System Test

Press (MENU) Key:Move to Menu screen (Print / Save Data / Delete Save Data)

(Page 23)

※Make sure to input Industrial Rating when testing battery condition (good / bad) of

industrial battery.

※In case of the test result of the Battery Test is "Replace (Cell Defect)", charge battery

fully, and test it again and judge with observing a state of the battery.

※For the vehicle equipped with higher grade battery, start performance of engine may

have no problem even if the judgment result is "Replace". In this case, battery

replacement is recommended to prevent suddenly battery breakdown.

The battery which is not charged for a long term may be judged "Replace" due to

decreasing CCA by self-discharge even if it is a new battery. Keep the battery with

periodical auxiliary charge to prevent deterioration by leaving with exhausted

condition for a long term.

MENU

⑨When battery test is completed, the test

result screen is displayed as shown in the

right. Confirm test result with using △(UP

SCROLL) / ▽(DOWN SCROLL) Keys.

LED indicator lights up or flashes depending

on a test result as follows.

・Green LED lights up when the test result is

"Good"

・Green & Yellow LED lights up when the

battery is fine but needs re-charging

・Yellow LED lights up when the test result

is "Charge/Retest"

・Yellow LED flashes when the test result is

"Caution"

BADGOOD CHARGE

Green LED lights up when

test result is "Good"

[

BATTERYTEST

]

Good

JIS

55B24

370CCA

※The following results are displayed.

・Battery test result ・Model (JIS only) ・Selected battery type ・SOH (State of Health)

・CCA value (Standard mΩfor Industry) ・Measured CCA (measured mΩfor Industry)

・Temperature ・SOC (State of Charge) ・Battery voltage ・Testing method

・Testing Mode ・Comment

・Red LED lights up when battery test result is "Replace"

Table of contents

Other Endeavour Tools Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

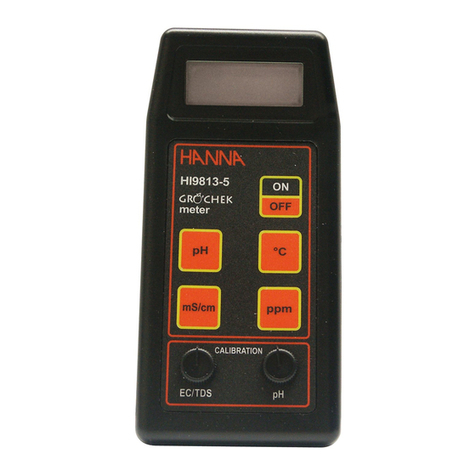

Hanna Instruments

Hanna Instruments Gro Line HI9814 instruction manual

Hanna Instruments

Hanna Instruments HI 9812 instruction manual

BLUM

BLUM TC60 operating instructions

R&S

R&S FSW Series user manual

Bosch

Bosch GIC 120 C Professional Original instructions

socomec

socomec DIRIS Digiware S instruction manual