Meco 3510PHW User manual

3510PHW : 28-09-2012

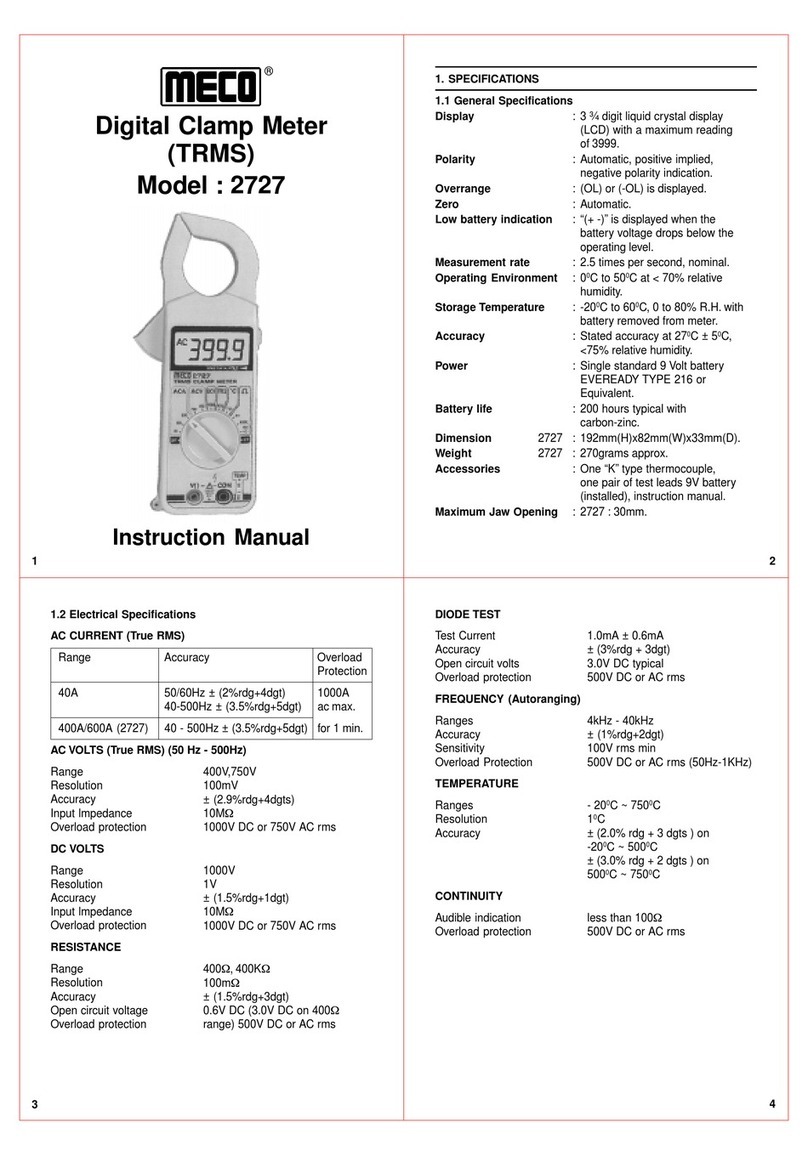

HVAC TRMS CLAMP METER

MODEL : 3510PHW

2

3 4

1

®

INSTRUCTION MANUAL

2.TECHNICALSPECIFICATIONS

2.1 Environment Conditions :

1. Installation category III

2. Pollutiondegree 2

3. Altitude up to 2000 meters

4. Indoor use only

5. Relatively humidity 80% max.

6. Operation ambient 0 ~ 50 0C

2.2 Maintenance :

1. Repairsorservicingisnotcovered in this manual, should

only be performed by qualified personnel.

2. Periodically wipe the case with a dry cloth. Do not use

abrasives or solvents on this instrument.

2.3 Features :

2.3-1 HVAC and Electrical :

1. To check current drawn by motors and compressors.

2. TouseMAX/MIN/Recordingin the temperature mode

to assess the efficiency.

3. To test run / start capacitors.

4. To measure low voltage control signals.

5. To measure flame protection diode current (<200mA)

in a heater control.

6. To analyze temperature and power data with the aid

of the time stamp.

7. Tomeasure highresistance.

8. To capture max. load current.

9. To determine peak power demand periods.

10. To monitor motors and other loads for excess heat.

1.SAFETY INFORMATION

lRead the following safety information carefully before

attempting to operate or service the meter.

lTo avoid damages to the instrument do not exceed the

maximum limits of the input values shown in the technical

specification tables.

lDo not use the meter or test leads if they look damaged.

lUseextremecautionwhenworkingaroundbareconductors

or bus bars. Accidental contact with the conductor could

result in electric shock.

lUse the meter only as specified in this manual; otherwise,

the protection provided by the meter may be impaired.

lRead the operating instructions before use and follow all

safety information.

lCaution when working with voltages above 60VDC or

30VAC RMS. Such voltages cause a shock hazard.

lBeforetakingresistancemeasurementsor testing acoustic

continuity, disconnect circuit from main power supply and

all loads from circuit.

Safety symbols

Caution refer to this manual before using the meter.

Dangerousvoltages.

Meter is protected throughout by double insulation

or reinforced insulation.

When servicing, use only specified replacement

parts.

Complies with EN-61010-1, IEC 1010-2-32

2.3-2 Functions :

1. TrueRMS,ACV,ACA,KW,KVA.

2. 9999 countsdual display LCD with unitsign.

3. DualKW+hp,KW+P.F,KW+KVAR,KVA+ u,A+V

(5 types)

4. Temp. 0C/0F

5. Dual display A + Hz, V + Hz.

6. Dataholdmode/MAX-MINmode

7. Auto PowerOffand to disable AutoPoweroff

function.

2-4 General Specifications :

Maximum voltage between any terminal and earth ground :

600Vrms.

Numericaldualdisplay : Dualdisplay4digitLCD

maximumreading 9999.

(10,000CountReading)

Batterylife : approx.32hr

Lowbatteryindication : The “ ” is displayed when

thebatteryvoltage drops below

theoperatingvoltage.

Autopowerofftime : approx.30minutes.(To disable

AutoPower Off, please refer to

4-9)

Samplingrate : 2.5times / sec (Digital display)

1 times / 6 sec (on KW,KVA)

Jawopeningdiameter : CablesF43mm

Operatingtemperature : 00C to 500C (320F to 1220F)

andhumidity R.H. < 80%non-condensing.

Temperaturecoefficient : 0.1 x (specified accuracy) / 0C

(< 180C or > 280C, < 640F or >

820F)

Storagetemperature : - 100C to 600C (140F to 1400F)

andhumidity R.H. < 70%non-condensing.

3510PHW : 28-09-2012

6

7 8

5

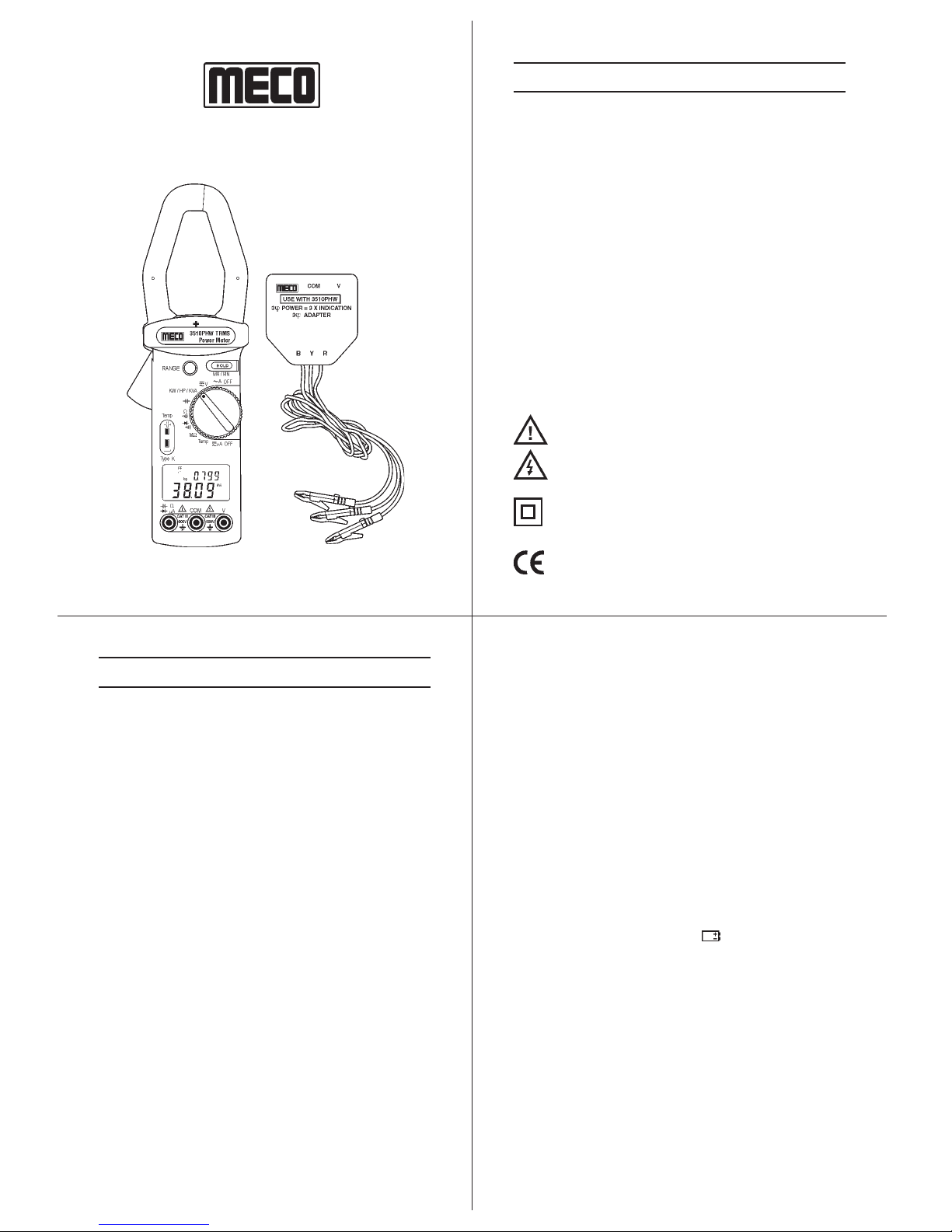

AC Current : (50 to 400Hz) Trms

mATrms :(AC+DC)(Burden Voltage : 5mV/mA)(50to 400Hz)

2-5 Measurement Specifications :

Accuracy : ± (% of reading + number of digits) at 180C to

280C (640F to 820F) with relative humidity to 80%.

AC Voltage : (50 to 400Hz) Trms

Dimensions : 247 x 76 x 39 mm (approx.)

Weight : 465gmsincludingbattery

(approx.)

Accessories : Three phase adapter x 1,

Carrying Case x 1, Test leads

x 1, Battery (installed ) x 1, Pair

ofalligator clip x 1,Instruction

manual x 1

Range Resolution Accuracy Sensitivity Overload

Protection

99.99A 0.01A ±2% ±20dgts (50,60Hz) 0.10A 1000A

999.9A 0.1A ±4% ±20dgts (40-400Hz) 1.0A

Range Resolution Accuracy Sensitivity Overload

Protection

99.99mA 0.01mA±1% ±20dgts 0.20mA600V

999.9mA 0.1mA 2.0mA

Range Resolution Accuracy Sensitivity Overload

Protection

±1% ±20dgts (50,60Hz)

999.9mV 0.1mV ±2% ±20dgts (40-100Hz) 2.0mV

9.999V 0.001V 0.020V 600V

99.99V 0.01V ±1% ±20dgts (50,60Hz) 0.20V

600.0V 0.1V ±2% ±20dgts (40-400Hz) 2V

Input Impedance : 3MV

Resistance (Continuity <40Von the 999.9Vrange) :

Range Resolution Accuracy Overload

Protection

999.9V0.1V

9.999KV0.001KV±1% ±10dgts 600V

99.99KV0.01KV

999.9V0.1KV

MV:

Range Resolution Accuracy Overload

Protection

9.999MV0.001MV

99.99MV0.01MV±5% ±10dgts 600V

Capacitance :

Range Resolution Accuracy Overload

Protection

10.000mF 0.001mF

100.00mF 0.01mF ±1.5% ±5dgts 600V

1000.0mF 0.1mF

7000mF1mF ±2.5% ±15dgts

DCVoltage :

Range Resolution Accuracy Sensitivity Overload

Protection

999.9mV 0.1mV 2.0mV

9.999V 0.001V ±1% ±20dgts 0.020V 600V

99.99V 0.01V 0.20V

600.0V 0.1V 2V

Input Impedance : 3MV

PF & Phase Angle (50Hz, 60Hz) :

Range Resolution Accuracy Sensitivity

-600/ 00/ +6000.10±3.00ACV>100V, ACA>10A

-0.5 / 1 / +0.5

Frequency :

Range Resolution Accuracy Sensitivity

40Hz/1KHz 0.1Hz ±0.5%rdg ±2dgts ACV>1.2V,ACA>6A

Diode (Continuity<40mV) :

Range Resolution Accuracy Overload

Protection

2.000V 0.001V ±2% ±1dgts 600V

TRUE Power : (PF>0.5 or u<600) (1hp = 0.7457kW)

Range Resolution Accuracy Overload

Protection

60.00kW (<100A) 0.01kW ±5% +20 600VAC/

600.0kW (>100A) 0.1kW (50,60Hz) 1000AAC

Temperature (K-Type thermocouple) :

Range Resolution Accuracy Overload

Protection

-500C to 9000C 0.10C ±1% ±10C30VAC or60VDC

-580F to 10000F 0.10F ±1% ±20F

Horse Power : (PF>0.5 or u<600) (1hp = 0.7457kW)

Range Resolution Accuracy Overload

Protection

80.00HP (<100A) 0.01HP ±5% +20 600VAC/

800.0HP (>100A) 0.1HP (50,60Hz) 1000AAC

Apparent Power :

Range Resolution Accuracy Overload

Protection

60.00KVA

(<100A) 0.01KVA ±2.5%±20dgts 600VAC/1000AAC

600.0KVA 0.1KVA

(>100A)

3510PHW : 28-09-2012

10

11 12

9

4. OPERATINGINSTRUCTION

4.1 AC + DC Voltage Measurement

WARNING

Maximum inputis600V.Do notattempttotakeany

voltagemeasurementthatexceedstheselimits.

Exceeding theselimitscould causeelectricalshock

anddamagetotheclampmeter.

1. Set the rotary switchto the “ V ” position.

2. Insert the test leads in to the input jack. (Black to COM

and Red to V)

3. Connect the test leads in PARALLEL to the measured

circuit.

4. The meter will automatically switch to ACV or DCV

display.

5. The meter willautomaticallyselect theappropriaterange.

6. Read the voltage and frequency values displayed on

theLCD. NOTE

Thesensitivityforvoltagefrequencymeasurementis1.2V

and the frequency range is 40 - 1KHz. If the frequency is

less than 40Hz the LCD may show Hz.

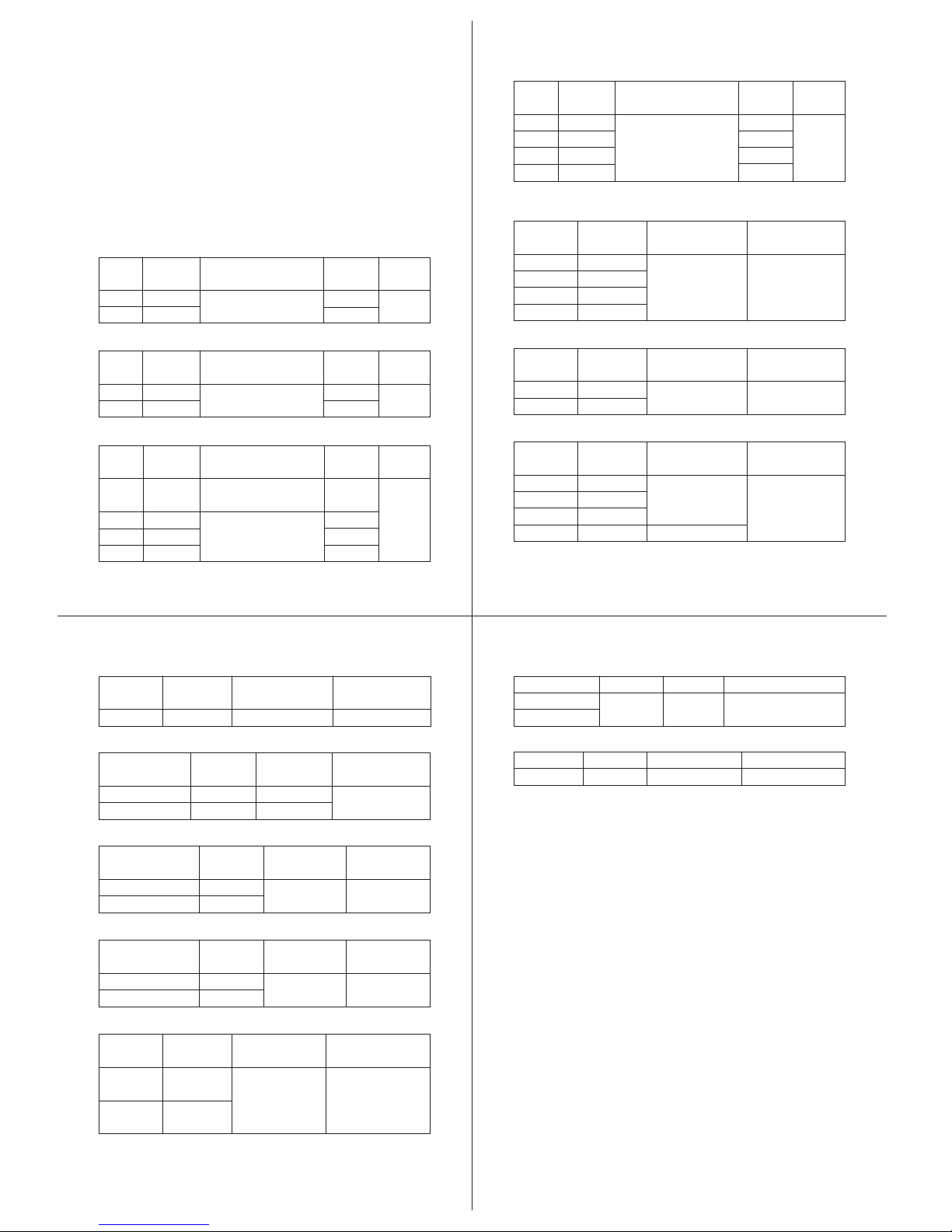

10. “ V mA ”Jack :

Connect red test lead for Capacitance, Resistance,

Diode, Countinuity and Micro ampere measurement

asa positiveterminal.

11. 3 Phase Adapter :

Insert plug in type 3 phase adapter in terminals

“COM”and“V”for3phase3wirepowermeasurement.

3. PARTS&CONTROLS

3.1 Description of Parts & Controls

2

5

4

10 8 9

3

7

6

1

11

Fig.

1

1. Transformerjaws(+marktofacesource):

TopickuptheACcurrentflowingthroughtheconductor.

2. Jawopeningtrigger

3. DataHold(MX/MN)button:

a. DataHoldMode:

Pressit once to hold the measured value and store the

value inmemory.Pressagaintoreleaseholdfunction.

(exceptcapacitancefunction)

b. MaximumandMinimumwithElapsedTimemode

0

1. Select desired ACA, ACV, DCV, C/ F or mA

function and perform the measurement, until the

measuredvalueshowsstablereadingontheLCD.

2. Press “ MX/MN ” button for 2 seconds to enter

recording with Elapsed Time mode, LCD will show

“ ® ” mark to lock the measurement range and

“ MX/MN ” mark to indicate the current measured

value with current elapsed time. The Auto Power

Offfunctionwillbeautomaticallycancelled.

3. Press “ MX/MN ” button one time, LCD will show

“ MX ” mark to indicate the recorded Maximum

valueandmaximumvalueoccurredElapsedTime.

4. Press “ MX/MN ” button one time, LCD will show

“MN ” marktoindicatetherecordedMinimum value

andminimumvalueoccurredElapsedTime.

5. Press “ MX/MN ” button one time, LCD will show

“ MX/MN ” mark to indicate the current value and

currentElapsedTime.

6. Step3,4,5canbecycled.

7. Press “ MX/MN ” button for 2 seconds to exit this

mode.

Note : The Elapsed Time intial setting is “ minute :

second ”, when current Elapsed Time is

over 60 minutes, the Elapsed Time will be

auto setting to “ hour : minute ”. The

maximum Elapsed Time length is 100

hours.

0

4. Functionselector:

Forselectionofdesiredfunction.

5. Rangebutton:

A. In ACA, ACV, DCV, mA, Capacitance and

Resistancefunction.

1. Press it once to enter the manual range select

mode,LCDwillshow®mark.

2. Pressagaintoselectthedesiredrange.

3. Press it 2 seconds to exit the manual range and

entertotheautorange mode, LCD ®markwill be

disappered.

B. InKW/HP/KVAfunction

a. Press RANGE button to select viewing the

KW/hp, KW/PF, KW/KVAR, KVA/uor V/A dual

display.

B1.Press HOLD button keep the measured valued

inmemory.

B2.Press RANGE button to select viewing the

KW/hp, KW/PF, KW/KVAR, KVA/uor V/A dual

display.

B3.PressHOLDbuttontoexitthismode.

C. InTEMPfunction 0 0

1. Press RANGE button to select desired C or F

temperatureunits.

6. Temperatureinputjack:

OnlytypeKthermocoupleinputisaccepted.

7. LCDDisplay:

4digital LCD with indicationsfor measurement values,

unit symbols, decimal point, polarity, over range and

lowbattery;etc.

8. COMJack:

Connect black test lead for voltage, Power,

Capacitance, Resistance, Diode, Countinuity and

Microamperemeasurement.

9. “V”Jack:

Connect red test lead for Voltage and Power

measurementasapositiveterminal.z

3510PHW : 28-09-2012

14

15 16

13

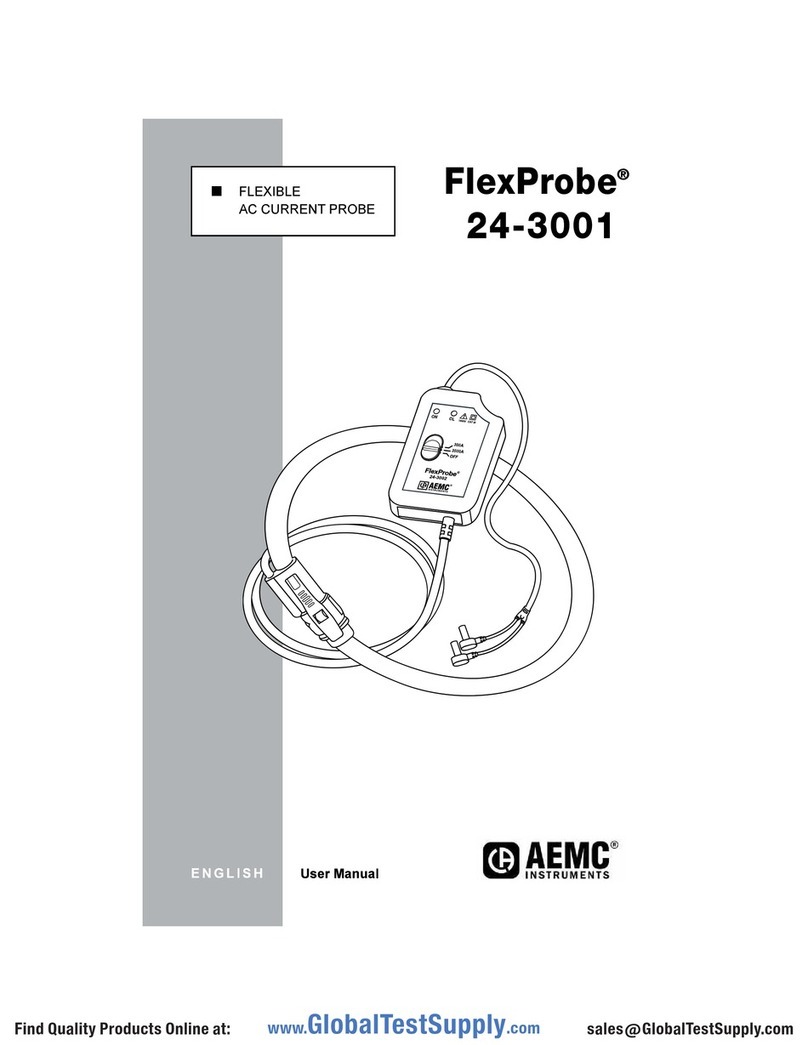

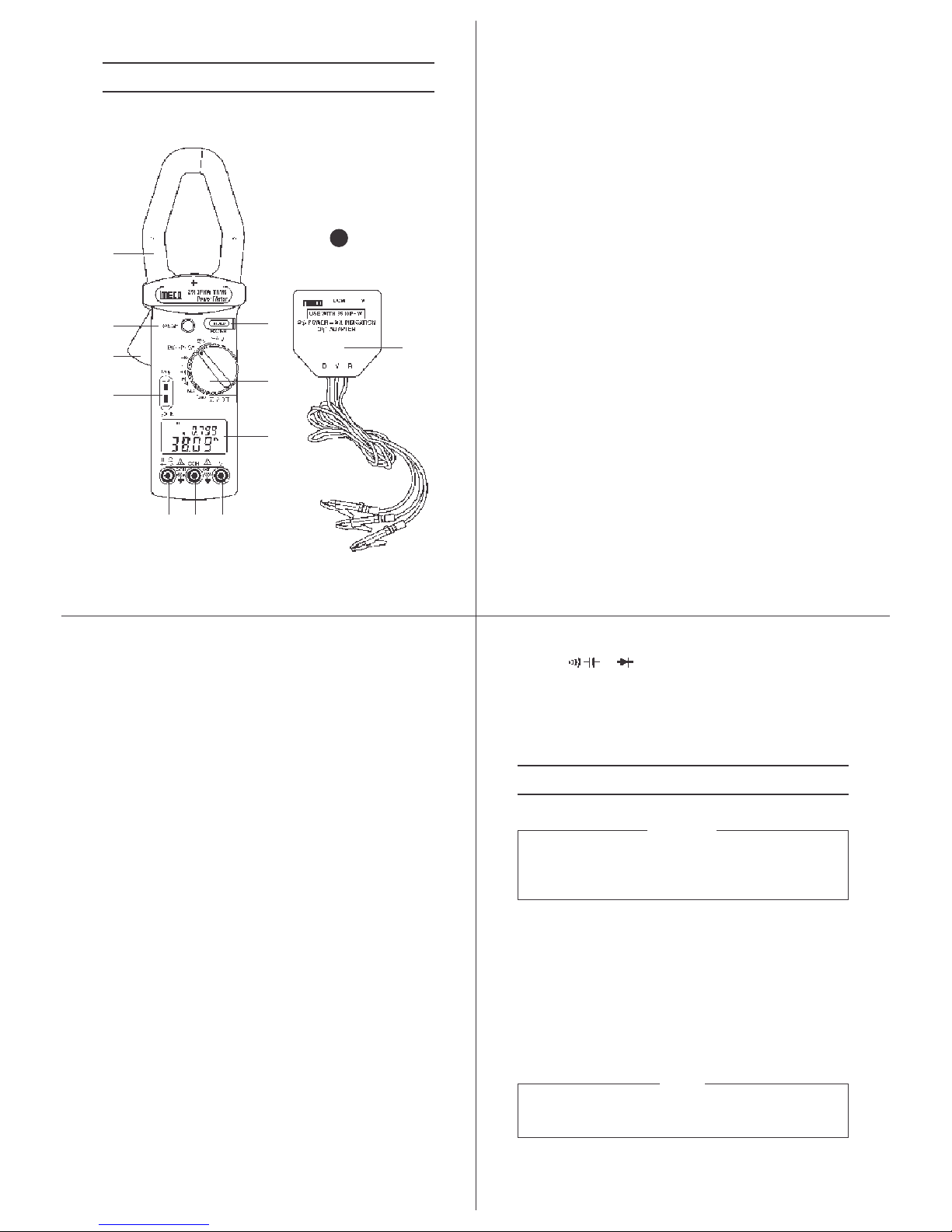

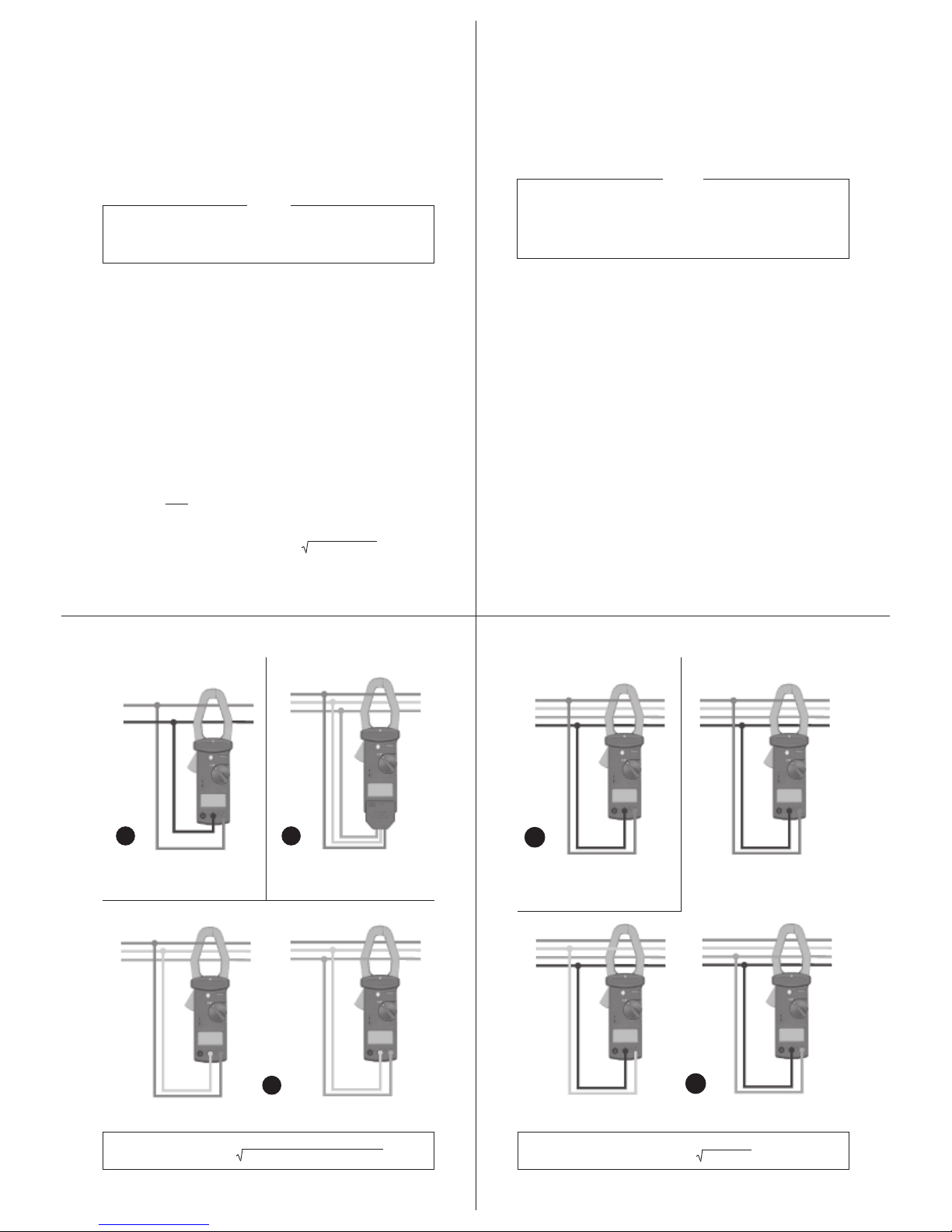

8. For 3 Phase 3 Wire balanced load system, insert 3f

plug in adapter in terminals “ COM ” and “ V ”. Connect

three crocodile clips to appropriate phase (R, Y and B).

Clamp “ R ” Phase conductor. 3f

power = 3 x Meter

indication (Refer fig 3).

9. For measurement in other systems please refer figures

4, 5 and 6.

NOTE

1. The “ + ” sign printed on panel must face the power

source for correct measurement.

2. If the device under test is switching mode power, the

meter KW, PF and

u

reading may be incorrect.

R

Y

B

N

Load

R

Y

B

N

Load

R

Y

B

N

Load

R

Y

B

N

Load

3f 4W Balanced System

Measured Value

= KW1, HP1, KVAR1 & KVA1

3f Values

= 3 x Displayed Value for

KW, HP, KVAR & KVA

Fig.

5

Fig.

6

Measured Value

= KW3, HP3, KVAR3 & KVA3

Measured Value

= KW2, HP2, KVAR2 & KVA2

3

f

Values = (KW1+KW2+KW3) or (HP1+HP2+HP3) or (KVAR1+KVAR2+KVAR3)

or (KVA1+KVA2+KVA3) 3

f

PF = KW

T

/

KW

T

+ KVAR

T

or KW

T

/

KVA

T

22

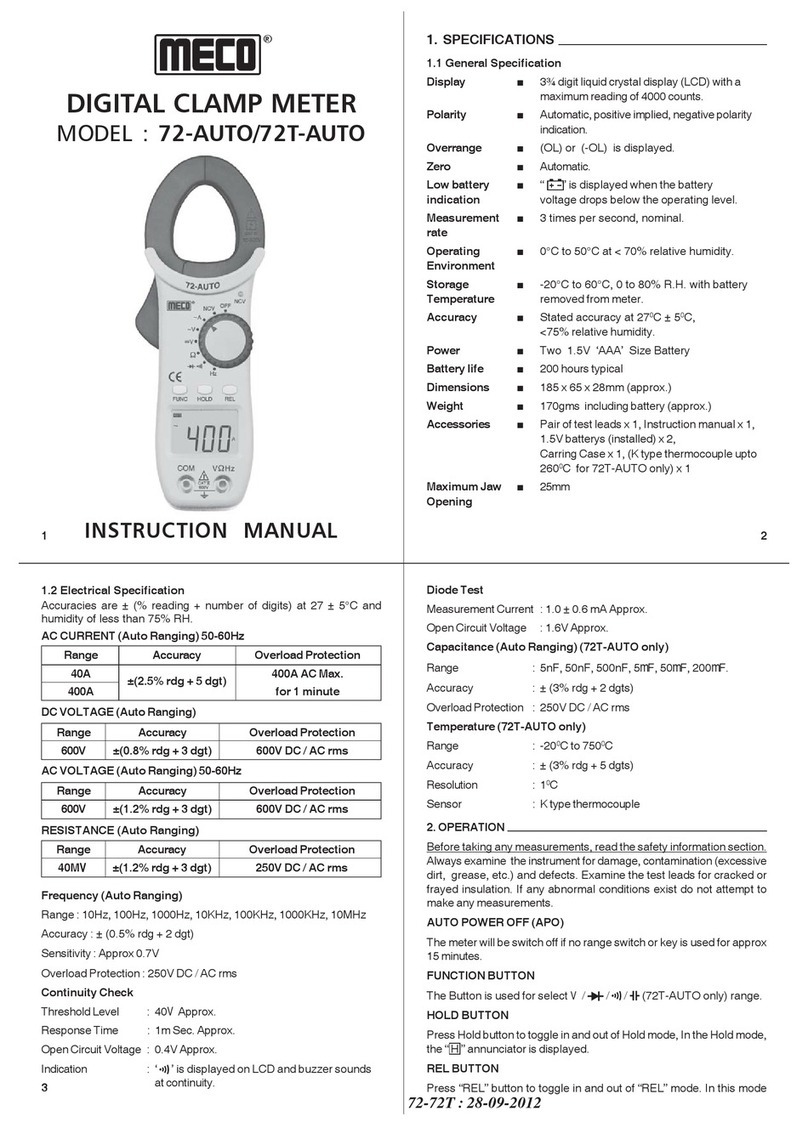

4.2 AC Current Measurement

1. Set the rotary switch to the “ A ” position.

2. Press the trigger to open the jaw and fully enclose the

conductor to be measured. No gap is allowed between

the two half jaws.

3. The clamp will automatically select the appropriate range.

4. Read the current and frequency values displayed on

the LCD.

NOTE

The sensitivity for Current frequency measurement is

6A and the frequency range is 40 ~ 400Hz. If the

frequency is less than 40Hz the LCD may show Hz.

R

N

Load R

Y

B

Load

3f

Adapter

1f 2W System 3f 3W Balanced System

KW, HP, PF,f, KVAR, KVA

3f Values

= 3 x Displayed Value for

KW, HP, KVAR & KVA

Fig.

2

Fig.

3

R

Y

B

Load R

Y

B

Load

Measured Value

= KW1, HP1 & KVAR1

3f Values = (KW1+KW2) or (HP1+HP2) or (KVAR1+KVAR2)

3f PF = Cos[tan-1 3(KW1-KW2) /(KW1+KW2)]

Fig.

4

Measured Value

= KW2, HP2 & KVAR2

3f 3W Unbalanced System

3f4W Unbalanced System

4.3 AC Power KW, KVA, PF (Power Factor) and

uu

uu

u

(Phase

Angle) Measurement

1. Set the rotary switch to the “ KW/KVA ” position (refer to

figure 2).

2. Insert the test leads in to the input jack. (Black to COM

and Red to V)

3. Connect the Black lead COM to the neutral line.

4. Connect the Red lead V to the power line and clamp

the same conductor where V (red) terminal is connected.

5. The power clamp will automatically select the appropriate

range.

6. Read the watt and hp values displayed on the LCD.

7. Press range button to display required parameters.

PF = KW = COS

u

(

u

= Phase Angle)

KVA

KVA (Apparent Power) : KVA = (V*A)/1000

KVAR (Reactive Power) : KVAR = (KV-A)2-(KW)2=KVA*sin

u

HP (Horse Power) = 746W

3510PHW : 28-09-2012

18

19 20

17

CERTIFICATE OF CALIBRATION

Weherebycertifythatthisproducthasbeencalibrated

and found to be in accordance with the applicable

SPECIFICATIONS and MECO STANDARDS.

Accuracies of the standard equipment used in this

calibration are traceable to the National Standards.

MECO METERS PVT. LTD.

Plot No. EL-60, MIDC Electronic Zone,

TTC Industrial Area, Mahape,

Navi Mumbai - 400710 (INDIA)

Tel : 0091-22-27673311-16, 27673300 (Board)

Fax : 0091-22-27673310, 27673330

Web : www.mecoinst.com

SR. NO : __________________________

CHECKED BY : __________________________

DATE : __________________________

MODEL NO : __________________________

®

4.7 Temperature Measurement

1. Set the rotary switch to the “ Temp ” position.

2. Press RANGE button to select desired 0C or 0F

temperature units.

3. Insert the Type K thermocouple to the Temp jack.

4. Use temperature probe to touch the object being

measured and read the displayed value.

4.8 AC + DC Micro-Ampere Measurement

1. Set the rotary switch to the “ mA” position.

2. Insert the test leads into the input jack. (Black to COM

and Red to mA).

3. Connectthetestinserieswiththecircuitbeingmeasured

and read the displayed value.

4.9 To disable Auto Power Off function

The meter will automatically enter sleep mode if no button

is pressed and no function is changed for 30 minutes to

savepower consumption.

1. Set the rotary switch to the “ OFF ” position.

2. Pressandhold“HOLD ” key thensetthe rotary switch to

“~A ”Position,theautopoweroff functionwillbedisabled.

The auto power off mark “ ” will disappear.

Auto power off mode is enabled each time you turn on

the meter and is automatically disabled in the “MX / MN”

mode.

4. BATTERYREPLACEMENT

WARNING

To prevent electrical hazard or shock, turn off clamp meter

and disconnect test leads before removing back cover.

1. As battery power is not sufficient, LCD will display

“ ”. Replacement with one new battery type 9V is

required.

2. Set range switch to OFF position.

3. Use a screwdriver to unscrew the screw secured on

back cover. Take out the batteries and replace with one

newbatteryType9V.

4. Place back cover and secure with the screw.

4.4 Resistance & Continuity Measurement

WARNING

Beforetakingany in circuitresistance measurement,

removePower from the circuit being tested and

dischargeallcapacitors.

1. Before taking resistance measurement, make sure the

circuit is not live and discharge any capacitors present

in the circuit.

2. Set the rotary switch to the “ V, ” or “ MV ” range.

3. Insert the test leads into the input jack. (Black to COM

and Red to V).

4. Connect the test leads to the circuit being measured

and read the displayed value.

5. When the reading is below 40 V, it will be indicated by a

continuousbeeping.

4.5 Capacitance Measurement

1. Fully discharge the capacitor being tested, will speed

test response time.

2. Insert the test leads into the input jack. (Black to COM

and Red to ).

3. Set the rotary switch to the “ ” position.

4. Connect the red test leads to the positive side and black

testlead to thenegativesideofthe capacitor beingtested.

5. Read capacitancevalueon LCD.

4.6 Diode & Continuity Measurement

1. Set the rotary switch to the “ ” range.

2. Insert the test leads into the input jack. (Black to COM

and Red to ).

3. Connect the red test lead to the anode side and black

testleadto the cathode sideof the Diode beingtested.

4. When thereadingis below 40mV, itwillbe indicated by a

continousbeeping.

Table of contents

Other Meco Measuring Instrument manuals