2. Place anempty reelon theleft hand(take-up)

spindle. Make sure that bothreels areproperlyseated

on the reel rests.

3. Reel out a convenient length of tape and hold

a section straight with both hands. Drop this section

into the tape slot and thread the free end of the tape

into one of the slots in the hub of the take-up reel,

Turn the reel by hand until several turns have secured

the tape to the reel and aII slack has been taken up

between reels.

To Turn 0n Amplifier And Motor

Prepare to record or playback by turning

I'Volume-On-Off" Control to the "on" position. On

Model NL-1 this control also turns on the drive Motor,

but on Models NL-2 and NL-3 the motor switch on the

"Tone" control mustalsobe turnedto the "on" position.

Allow the amplifier to warm up for about 30

seconds before proceeding to record or playback.

To Record From Microphone

1. Insert the microphone plug into the "Mic"

jack.

2. Set therecord level. Thiscan bedone before

tape movement is started by holding down the Record

Lock Button and adjusting the Volume control for pro-

per response from the indicator. The proper volume

levels are as follows:

(a) Model NL-1 (Neon Bulb) -- Adjust the

volume level so that the loudest portions of

the signal cause the Iamp to flash inter-

mittently.

(b) Model NL-2 (Magic Eye) - Adjust the

volume level so that the loudest portions of

the signal just cause the eye to close.

(c) Model NL-3 (VtJ Meter) - Adjust the

volume level so that t}re peaks of meter de-

flection do not go past zero, or into the red

area of dial calibration.

3. Hold the Record Lock Button down and turn

the Rotary Control to the right, thus starting the re-

corder in motion. When through recording, turn the

Rotary Control to neutral. The Record Lock Button

will automatically release and deactivate the record

circuit.

To Record From Radio, TV, 0r Phonograph

1. Connect the output signal from the radio,

tuner, TV, or phonograph to the "Radio" input jack of

the recorder.

2. Proceed as under "To Record From Micro-

phone", step 2.

To Play A Recording

1. Depress Rotary Control and turn it to the

right.

2. Adjust "Volume" and "Tone" controls for

desired Iistening quality.

Dual Track Recording

These recorders are designed so that only one-

half the tape width is recorded at a time, thereby re-

sulting in dual-track recording. To make a dual-track

recording proceed as follows:

1. After a reel of tap.e has been recorded, i.e.

all the tape wound onto the take-up reel, place the

Rotary Control in neutral position.

2. Remove the reels from the recorder, turn

the full reeloverand place itonthe right-handspindle.

Place the empty reel on the left-hand spindle.

3. Thread the tape and proceed with the re-

cording.

4. After the second track has beenrecorded the

f ir st track c an be played, without rewinding, by trading

reels on the spindles as in step 2, rethreading thetape

and placing the recorder in Playback operation.

To Erase Recordings

These recorders automatically erase previous

recordings as new recordings are being made. If it

is desired to erase without recording nevr material,

set all controls as if recording but do not plug in the

microphone or other program source, and run the tape

through the machine. For best results, set Volume

Control at zero.

To Use An External Speaker

Plug the external speaker into the jack marked

"SPKR". On Models NIr2 and NL-3 this automatically

disconnects the internal speakers. On Model NL-l

plugging in an external speaker places it in parallel

with the internal speaker.

To Use An External Amplifier

Connect the recorder jack marked"AMP"to the

input of t}te external amplifier. This input should be

one designed to accept a high level signal requiring no

further equalization for flat playbacl{ response.

To Use As A P.A. System

Anyof the Model NL-1, NIr2, or NL-3 recorders

can be used as a public address system by plugging a

microphone into the RADIO input jack.

MECHAN I CAL ADJ U STMENTS

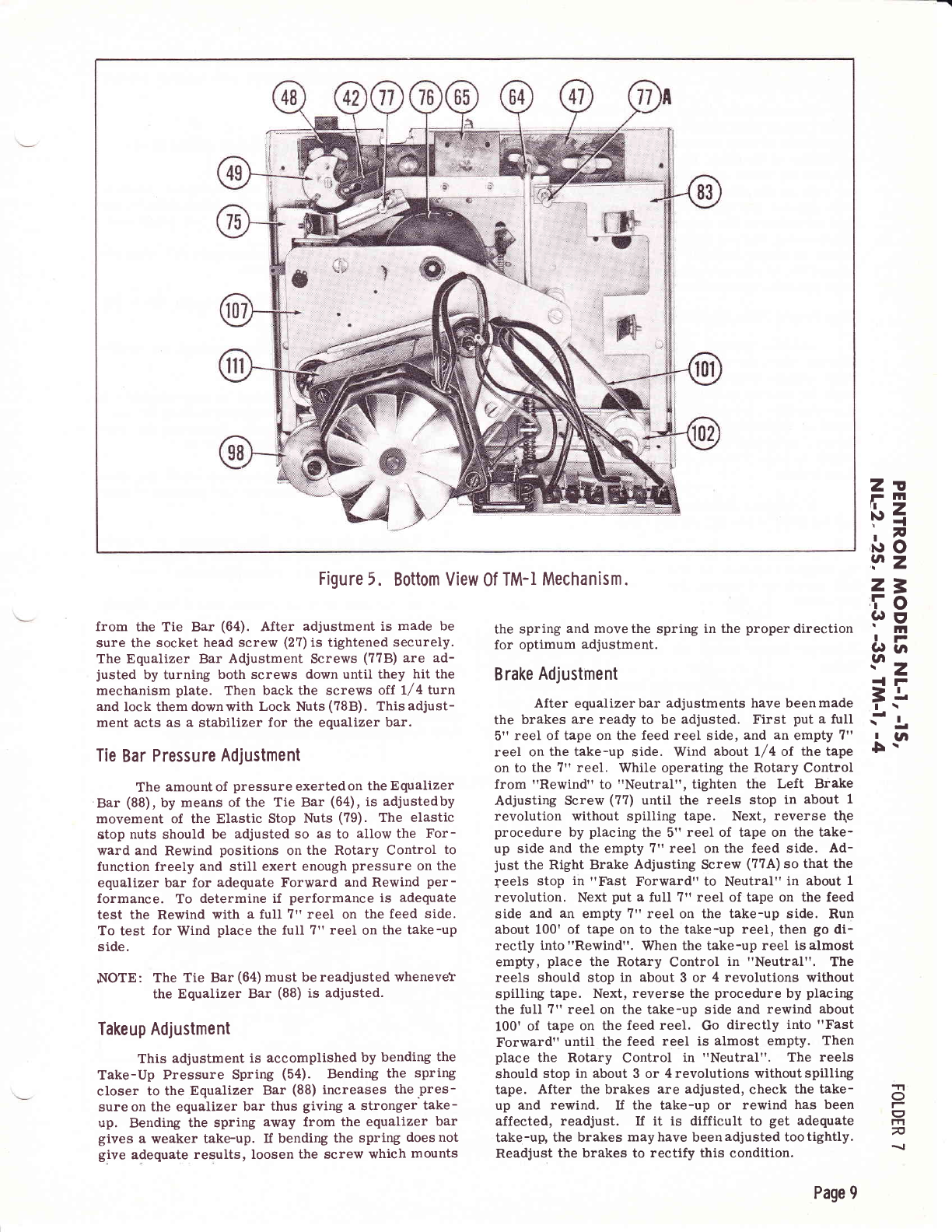

Equal izer Bar Adjustme nt

This adjustment is made by loosening Socket

Head Screw (2?) and shifting the Equalizer Bar (88)

forwardor backward. Make the adjustment as follows:

Page 8

First, remove the Spindle Caps (1) and ReeI Rests

(2). With the Rotary Control (3) in neutral position,

movetlre Equalizer Bar (88) to a position such that the

Take -Up Spindle (93) is on the verge of spinning without

any pressure being exerted on the Equalizer Bar (88)