TMD1000 TMD1 Table of contents

Endress+Hauser 3

Table of contents

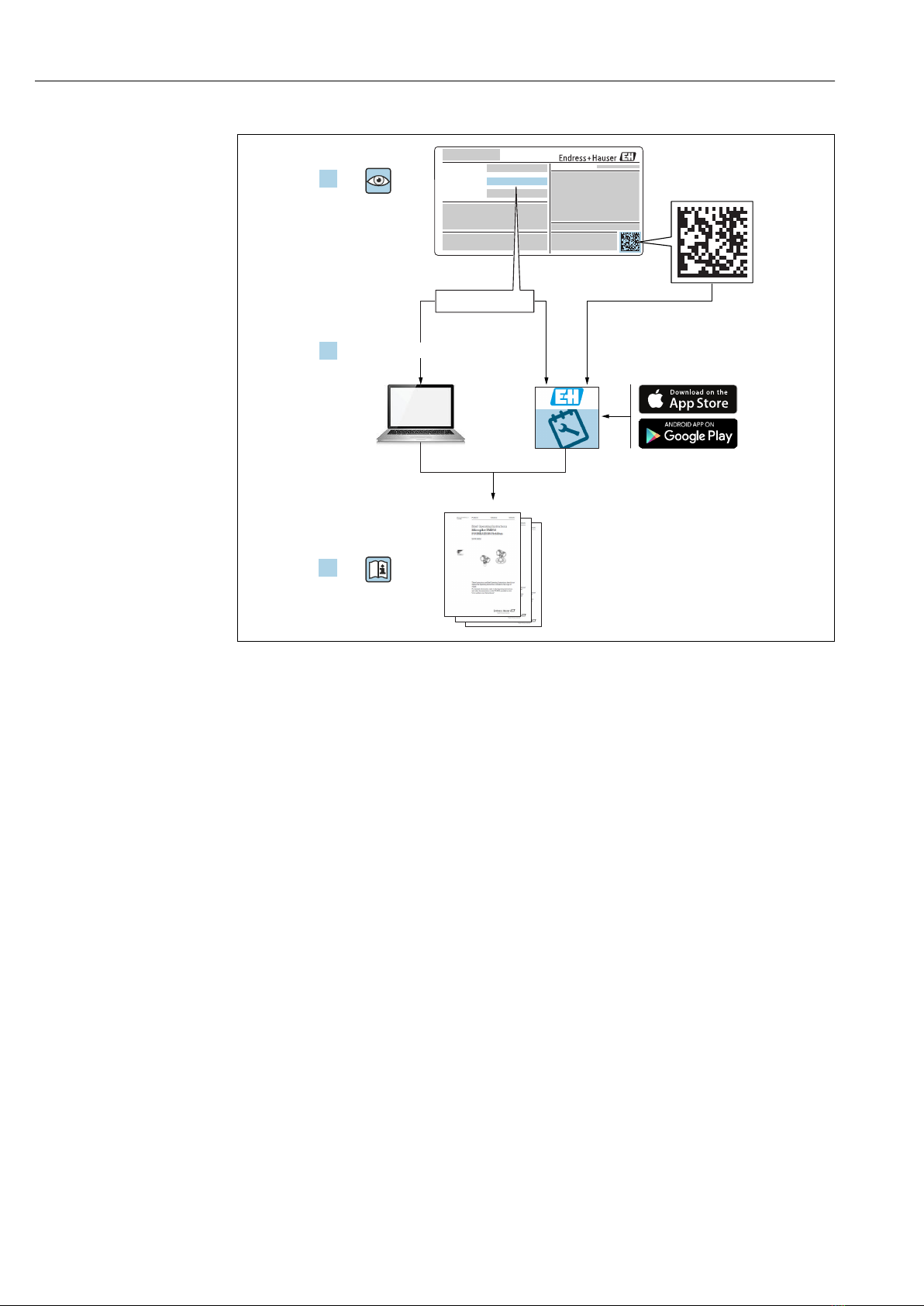

1 About this document ................ 4

1.1 Document function ..................... 4

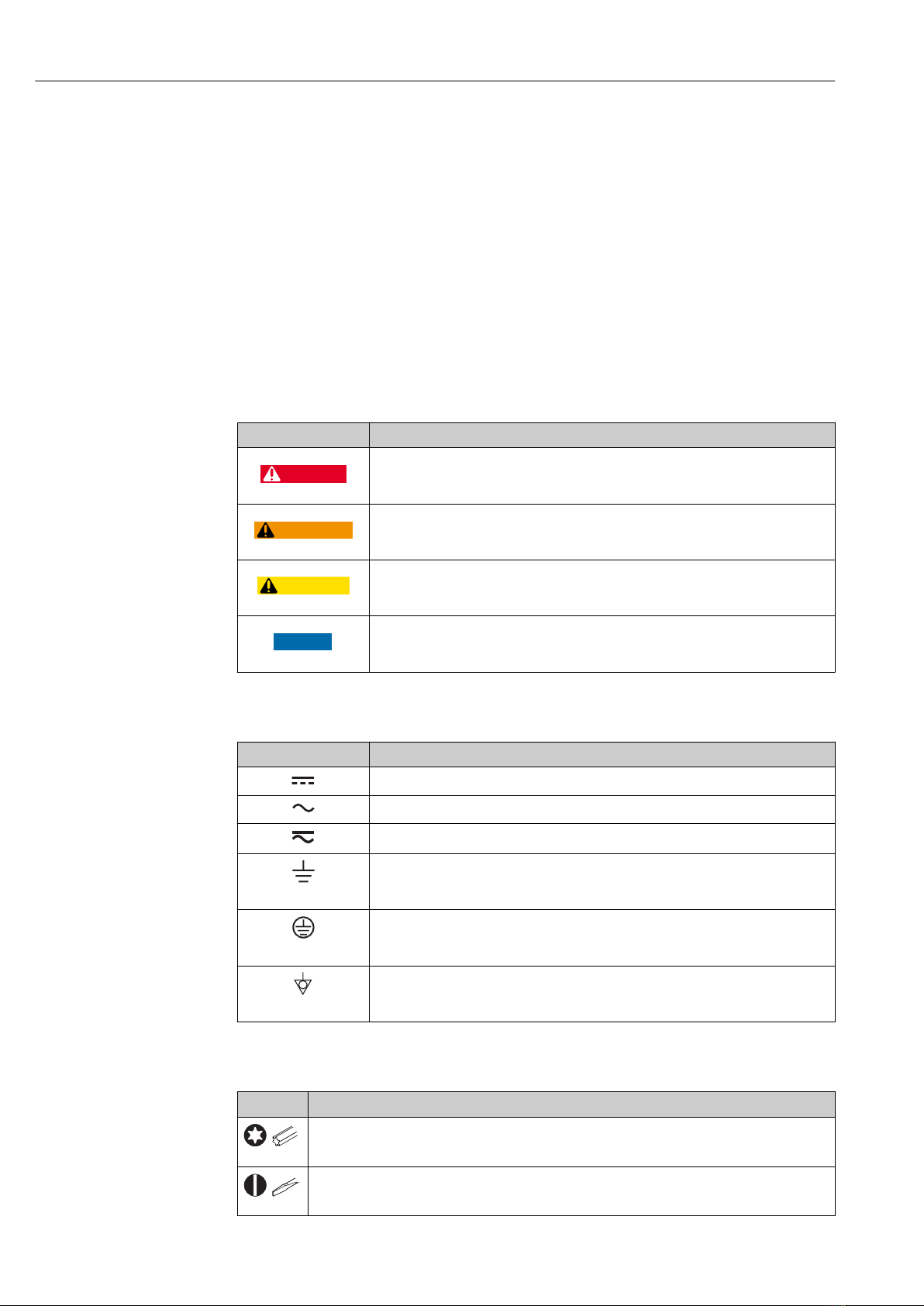

1.2 Symbol .............................. 4

1.3 Documentation ........................ 7

1.4 Registered trademarks ................... 7

2 Basic safety instructions ............ 8

2.1 Requirements for personnel ............... 8

2.2 Designated use ........................ 8

2.3 Workplace safety ....................... 8

2.4 Operational safety ...................... 9

2.5 Product safety ......................... 9

3 Product description ................ 10

3.1 Product design ........................ 10

3.2 Keypad ............................. 10

3.3 Technical data ........................ 11

4 Incoming acceptance and product

identification ..................... 12

4.1 Incoming acceptance ................... 12

4.2 Product identification .................. 12

4.3 Manufacturer contact address ............ 13

4.4 Storage and transport .................. 13

5 Electrical connection .............. 15

5.1 Wiring ............................. 15

6 Operation ......................... 16

6.1 Pre-operation and settings ............... 16

6.2 Power ON ........................... 16

6.3 Device selection ....................... 17

6.4 MODE00 function display and setting

change ............................. 17

6.5 MODE01 Operation and display setting ..... 21

6.6 MODE02 level and status ................ 22

6.7 MODE03 data setting operation for level .... 22

6.8 MODE05 parallel output ................ 23

6.9 MODE06 contact output (Alarm) .......... 23

6.10 MODE07 spot temperature device 1 point

input ............................... 24

6.11 MODE08 spot temperature device 3 point

input ............................... 25

6.12 MODE09 multi-element average temperature

device input .......................... 25

6.13 MODE10 single-element average

temperature ......................... 26

6.14 MODE11 Analog 4 to 20 mA output (No. 1) .. 27

6.15 Analog 4 to 20 mA output No. 2 .......... 28

6.16 MODE13 2-way, 2-wire transmission

output .............................. 29

6.17 MODE14 Analog 4 to 20 mAinput ......... 29

6.18 MODE15 FFi transmission output .......... 30

6.19 MODE21 MIF-4 data setting ............. 30

6.20 MODE30 NMT: V0 (temperature value)

setting .............................. 31

6.21 MODE31 NMT: V1 (Element temperature)

setting .............................. 31

6.22 MODE32 NMT: V2 (Element temperature)

setting .............................. 31

6.23 MODE33 NMT: V3 (element position)

setting .............................. 32

6.24 MODE34 NMT: V4 (element position)

setting .............................. 32

6.25 MODE35 NMT: V5 (water scale temperature)

setting .............................. 33

6.26 MODE36 NMT: V6 (water scale and power

supply) adjustment .................... 34

6.27 MODE37 NMT: V7 (Temperature

adjustment) setting .................... 34

6.28 MODE38 NMT: V8 (Device) setting ........ 36

6.29 MODE39 NMT: V9 (Device) setting ........ 37

7 Diagnostics and troubleshooting ... 38

7.1 General troubleshooting ................. 38

7.2 Maintenance and update ................ 38

7.3 Battery replacement ................... 38

7.4 Firmware history ...................... 40

8 Repair ............................ 41

8.1 General information on repairs ............ 41

8.2 Spare parts .......................... 41

8.3 Endress+Hauser services ................ 41

8.4 Return .............................. 42

8.5 Disposal ............................ 42

Index .................................. 43