ENDURA SPRAY 131004 Service manual

Thin Sprayer

Thin ENDURASPRAY

www.enduraspray.co.u

Product helpline 01778 562810

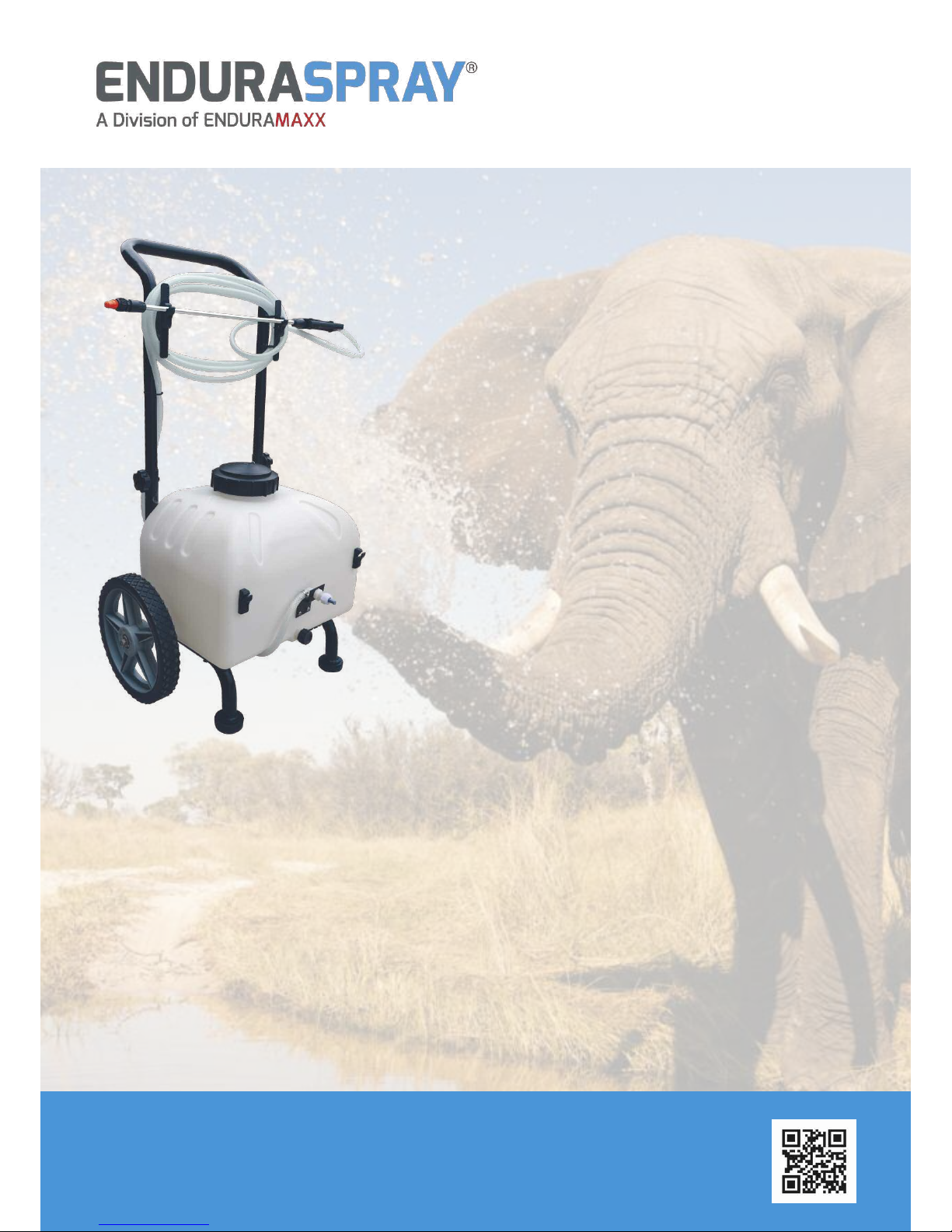

34 Litre Push Along Sprayer

131004

perators Handbook

©

2

Product helpline 01778 562810

INTR DUCTI N

The purpose of this manual is to assist you in the assembly, operation and maintenance of your 34L Push-along Sprayer.

Please read through this manual completely to fully understand how to operate and maintain your equipment.This

product has been manufactured to provide years of dependable service; proper operation and maintenance will ensure

its dependability. Keep your manual in a safe, convenient place for future reference. Always mention the model and part

number in any correspondence.

Thin Sprayer

Thin ENDURASPRAY

Assembly

The 34L Push-along sprayer is assembled at the factory with the exception of a few components to protect them from

shipping damage. Follow the steps below to complete assembly. For photographs showing the wiring and

electrical connections of the unit go to page 7.

Handle Assembly

1. Slide handle (Item 1, figure A) into lower frame (Item 7, figure A). Adjust handle height to a comfortable setting for

the operator. Adjust handle to align the holes in handle and lower frame closest to desired setting.

2. Using the two handle adjustment knobs and bolts (Item 2, figure A) insert bolts through holes in handle and tighten

with knobs.

Front Deflector Nozzle Attachment

1. Locate the bag labelled Nozzle Assembly.

2. Insert Nozzle body fitting (Item 7, figure B), through the nozzle bracket (Item 8, figure B) and hold in place with

nozzle body nut (Item 9, figure B) tightened loosely by hand.

3. Insert nozzle filter (Item 9, figure B) into nozzle body. Place deflector nozzle (Item 11, figure B) into nozzle nut (Item

12, figure B). Thread nozzle nut with nozzle onto nozzle body fitting and tighten slightly.

4. Attach Nozzle bracket to tank (Item 16, figure B) with two screws and washers. Tighten securely.

5. Locate clear vinyl hose from bottom front of tank. Attach hose to nozzle body fitting attached to front of tank with

hose clamp (Item 17, figure B).

6. Tighten all nuts and screws securely ensuring the nozzle is pointing directly down towards the ground.

Using the Push Along Sprayer as a Trailer

If the 34L Push Along Sprayer will be used with a garden tractor, a trailer tongue can be attached to the sprayer for

towing. A “remote switch” is also supplied so the sprayer pump can be remotely operated from the tractor. If the 34L

Push Along Sprayer will be used as a trailer, follow the instructions below:

1. Locate the remote switch wiring harness from the Accessories bag.

2. Locate the wiring harness remote plug in connector. The connector will be protruding from the bottom of the black

pump shield on the back of the sprayer.

The connector will be labeled “remote switch”. Attach the remote switch to the wiring harness on the sprayer.

3. Attach the trailer tongue (Item 8, figure B) to the sprayer frame (Item 7, figure B) aligning the holes and using the pin

and hair pin (Item 3, figure B).

©

34 Litre Push Along Sprayer 131004

3

Visit our website at www.enduraspray.co.uk

Set up

Charging the Battery

1. btain the battery charger (Item 27, figure B) and plug the charger into an AC wall outlet and the other end into the

charging port located on the sprayer.

2. Allow the charger to charge the battery until the light on the charger turns green. A green light indicates the battery

is fully charged. A discharged battery may take as long as 24 hours to recharge.

3. Never allow the battery to discharge completely. Doing so will damage the battery and void warranty.

Testing

Always test the sprayer with clean water prior to spraying with a chemical mixture. This will allow the sprayer to be

inspected for leaks and repaired before expensive chemicals are used.

Using the front Deflector Nozzle

Four things must be considered before spraying with the boom:

1. How much chemical must be mixed in the tank?

Refer to the chemical label to determine the chemical mixture.

2. ate of spray (to be sprayed)?

See the tip chart below to determine the litres per hectare. The chart will also show the speed used when spraying.

3. Speed traveled (K.P.H.) while spraying?

Refer to the tip chart and speed chart below for KPH.

4) Pressure

Determine Litres per Hectare

nce you know how much you are going to spray then determine (from the tip chart) the spraying pressure (Psi) and the

spraying speed (KPH). The pressure is preset by the pump, typically between 30 to 35 Psi, but it will vary depending on

the percentage of charge left in the battery. If precise chemical metering is desired, then the battery should be fully

charged and a flow rate should be measured at the nozzle. After the battery is fully charged, obtain a bucket and place

under the nozzle. Turn the valve on to begin spraying water into the bucket while timing. Allow the sprayer to run for 1

minute and then turn off sprayer. Measure the amount of water within the bucket to obtain the exact LPM of the pump

and nozzle.

Caution

Do not spray on windy days. Protective clothing must be worn in some cases. Be sure to read the chemical label

carefully. After all calibrations have been completed, add water and chemical to the tank. Always follow chemical

manufacturer’s instructions for mixing.

Litres per hectare

Bar L/min 6km/h 8km/h 10km/h 12km/h 14km/h 16km/h 18km/h 20km/h

1 1.39 139 104 83 69 59 52 46 42

2 1.96 196 147 118 98 84 73 65 59

3 2.4 240 180 144 120 103 90 80 72

4 2.77 277 208 166 139 119 104 92 83

Parts List and Boom Assembly 151050

5

Visit our website at www.enduraspray.co.uk 4

Product helpline 01778 562810

Operation, Cleaning and Storage

WA ANTY PA TS SE VICE

Products sold shall be warranted from defects in workmanship and material when used within the service and

scope for which they were designed for a period of one year from date of purchase. Contact your distributor/

dealer for replacements parts or warranty work. Please have your original sales receipt or other proof of

purchase date when requesting any warranty work.

To ensure the correct parts are acquired always provide the model number of your sprayer/attachment and

the part number and description obtained from the illustrated parts breakdown in this manual.

All products are sold in accordance with our terms and conditions of sales of goods. These terms and

conditions can be found on our website. They are also available upon request.

Operation

Ensure battery is fully charged to provide optimum efficiency from the 12 volt pump. Turn the valve located in the back

panel to the off position. This will ensure the nozzle does not begin to spray when the pump is activated. The pump can

be operated with the switch located on the back panel or from the remote harness if connected. Remove the tank lid

and the fill the spray tank with clean water through the basket strainer. Slowly pour in the desired amount of chemical.

Activate the pump by turning on either switch (the pump will run with either switch in the on position. If both switches

are in the on position then both will need to be turned off to disconnect power). The pump when activated will begin to

run until 40 Psi is reached. The built in pressure switch will then shut off the pump.

Your sprayer is now ready.

To spray with the wand, ensure the wand nozzle is pointed in the direction meant to be sprayed and pull the lever

handle. The pump will automatically activate and the wand will disperse the chemical mixture from the tank. To stop

spraying with the wand release the lever handle on the spray wand and the pump will deactivate after reaching

pressure.

To spray with the nozzle located on the front of the tank, ensure the wand is firmly attached to the tank or frame handle.

Turn the valve located on the back panel to the N position. The nozzle on the front of the tank will begin to spray.

Immediately begin to push or pull the sprayer at the desired speed for proper chemical delivery.

To stop spraying with front nozzle, turn off the valve and the pump will deactivate after reaching pressure.

Cleaning and Storage

Most spray materials are highly corrosive. The most important aspect of long dependable service from the sprayer is a

thorough cleaning immediately following each use. In addition, the residue of one type of chemical could cause an

undesirable effect when a different chemical is used for a different purpose.

The most effective cleaning method is to pump several rinses of clean water through the tank, pump, hoses, boom,

spray gun, etc. A neutralising agent such as a solution of Nutra-Sol, a detergent or household ammonia as

recommended by the chemical manufacturer can assist in removal of a persistent chemical. When the system is

thoroughly cleaned drain the tank, suction line, pump, hoses, etc.

The following steps should be followed for the maintenance and storage of your sprayer:

1. Wash and flush out sprayer after completion of each phase of your program. Flush out sprayer when changing

chemicals if there is a possibility of the chemicals being incompatible. Use of a detergent is advisable if the chemical

manufacturer does not make specific cleaning recommendations. Flush system completely, including nozzles. Never

use metal objects to open clogged nozzles.

2. Clean sprayer thoroughly before storing at the end of the spraying season. Permanent type anti-freeze added to the

final rinse will leave a rust inhibiting film in parts of the sprayer.

3. Periodically charge the battery (every 3 months) even if sprayer is not being used.

78

4

3

2

1

5

6

34 Litre Push Along Sprayer 131004

5

Visit our website at www.enduraspray.co.uk

Figure A

Item Description Quantity

1 Frame, Handle (only available as entire frame) 1

2 Handle Adjustment Knobs (pair with bolts) 1

3 Hitch Pin 1

4 Wheel and Tyre 1

5 Axle Nut and Washer (pair) 1

6 Rubber Pad (pair with bolts) 1

7 Frame, Lower (only available as entire frame) 1

8 Hitch, Tongue (only available as entire frame) 1

NEED

MORE HELP?

CALL US ON

01778

562810

Table of contents