Enerdrive Lithium Power Pack Series User manual

Page 2

and created a COMPLETE Lithium Battery & Installation System so your Li-Ion battery bank is fully

protected. Most importantly, our system is designed to give the maximum performance, longevity and

SAFETY in your valuable installations.

Be aware that the market is abuzz with the hot topic of Lithium Ion Batteries; and we can tell you from

our testing to date that all the hype of their performance and capabilities is TRUE. However what we

can also inform you is that all the stories of their ‘Issues’ are unfortunately also true. However the so

called “issues’ of lithium can be avoided with some very basic rules about protection.

• Never go over voltage whilst charging them

• Never let them go ‘Dead’ Flat

• Keep the individual cells ‘Balanced’

What this lesson taught us is if we were to develop our lithium program – IT HAD TO BE DONE RIGHT.

So we developed our own Lithium Power Pack for the Australian market with the emphasis on ‘built

like a tank’; and even to the extent of being a little bit ‘overkill’ on the packaging and protection.

So how does our system actually work?

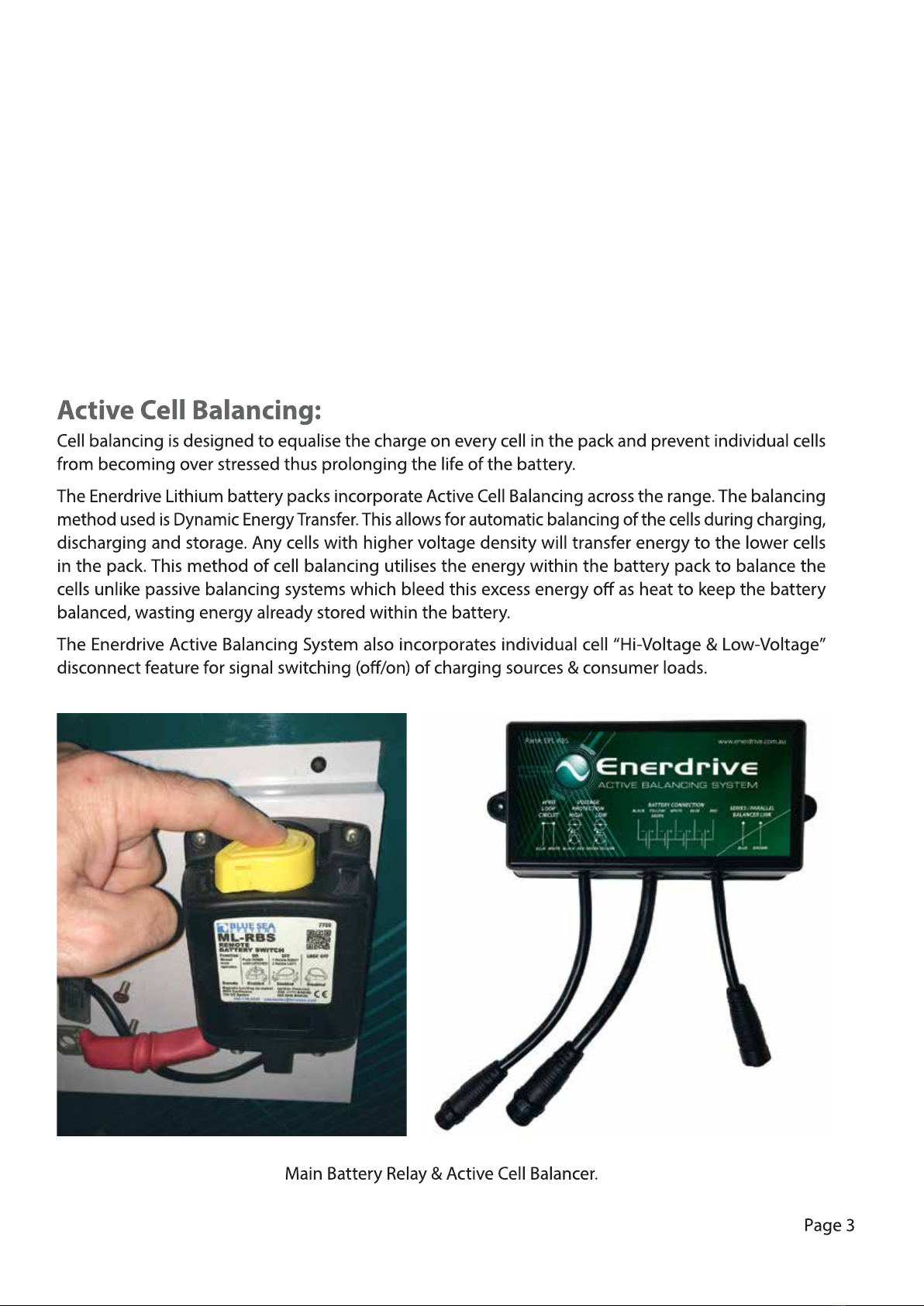

The Advance BMS relay driver is designed to take multiple signal input connections from the ePRO

Plus battery meter for low state of charge (SOC%) & system voltage & Hi/Low Cell voltage from the

batteries Active Cell Balancer unit and control all charging and discharging sources connected to the

lithium battery system.

System Program Selection Switch;

The Enerdrive Advanced BMS Relay Driver has 2 pre-programed settings.

In the event of low SOC% and/or voltage reaches the pre-set level, the program will shut down the

charging sources (solar/vehicle) and the inverter/charger before disengaging the main battery relay,

turning off the whole electrical system to protect the battery. The program will then switch on the

signal for all charging sources. When AC power is applied to the Combi, the AC charger will start once

the main latching relay is re-engaged. To re-engage the main battery relay, press in the Yellow button

on top of the main battery relay.

PROGRAM A:

FOR SYSTEMS INSTALLED WITH ePOWER AC, DC2DC CHARGERS & ePOWER INVERTERS:

This program isolates the charging sources (solar/vehicle/mains charger) in the event of a battery cell

voltage being too high without turning the whole electrical system off. The Enerdrive Advanced BMS

Relay Driver will activate the TOR & output contacts that will cut out all charging sources for 10 minutes.

If the cell has not come back within range before 10 minutes, it will stay active for another 10 minutes and

repeat until the cell/s are within range. This setup allows the system loads to still be powered.

In the event of low SOC% and/or voltage, the main battery relay will disengage to protect the battery. All

charging sources (solar/vehicle/mains charger) will still be active to recharge the battery providing the sun is

up or the chargers are plugged in. To re-engage the main battery relay, press in the Yellow button on top of

the main battery relay. The Enerdrive Advanced BMS Relay Driver will turn the main battery relay OFF every 6

minutes if the SOC% on the battery monitor is still below the set point. So this may need to be reset a few

times before the SOC% set point reaches its re-engagement point.

FOR SYSTEMS INSTALLED WITH COMBI INVERTER/CHARGERS:

After 2 years of research, testing and proving, and a further 6+ years of infield sales, Enerdrive has designed

This program is used if the temperature sensor fails. By selecting Program B, the temperature sensor is

ignored allowing for operation of the system until you can replace the faulty temperature sensor.

Running this program will get you into “Limp-Home Mode” but you will have no temperature control on

the system thus leaving the lithium protection system compromised. Contact Enerdrive to arrange for a

replacement Temperature Sensor.

PROGRAM B:

The Enerdrive Advanced BMS Relay Driver will turn the main battery relay OFF every 6 minutes if the SOC%

on the battery monitor is still below the set point. So this may need to be reset a few times before the SOC%

set point reaches its re-engagement point.

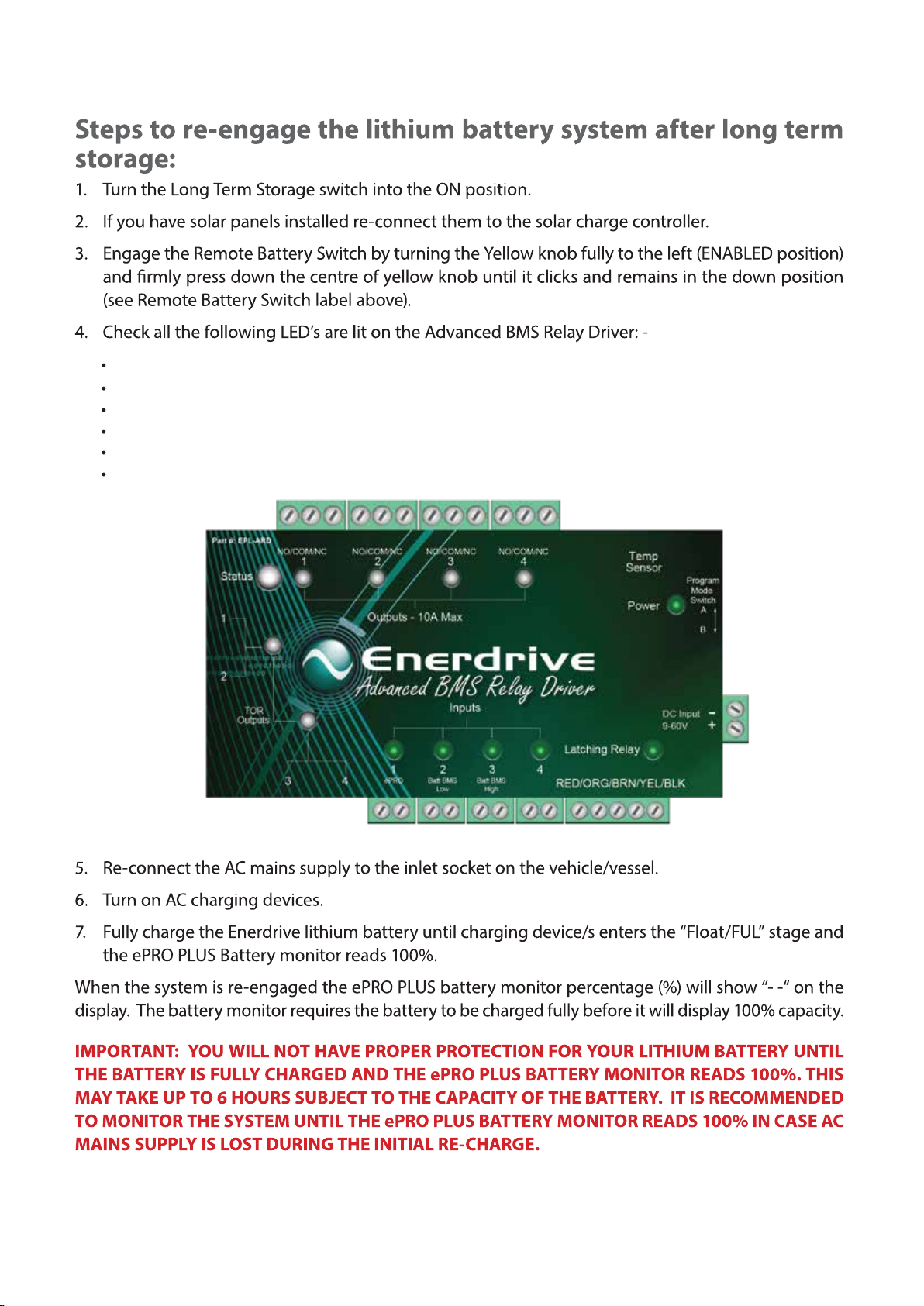

Status LED

The Advanced BMS Relay Driver is equipped with a “Status” LED indicator to respond to certain

conditions that the Relay Driver is experiencing. Status condition is as follows;

No Status LED: All Components are operating under normal conditions

Flashing Green LED: The system has registered an alarm condition from Inputs 1 or 2 and

will activate LOW SOC/Low Cell safety program

Flashing Red LED: The System has registered an alarm condition via high cell voltage

(≥3.80V per cell) shutting down all charging circuits. When voltage drops below 3.60V per

cell, charge circuits will switch back on.

Solid Red LED: The System has registered an alarm condition via a high temperature (≥45˚C)

shutting down all charging circuits. When temperature drops below 45˚C, load circuits will

switch back on.

Flashing Red/Blue LED: The System has registered an alarm condition via a high temperature

(≥ 55˚C, load circuits will switch off.

4 x “TOR” Circuits – Programmed to control Enerdrive ePOWER AC & DC2DC Chargers, &

Morningstar Solar Controllers (Hi/Low Alarm Protection).

4 x Normally Open/Closed/Common Contacts (10 Amps Max) – programmed to switch

trigger contacts/relays connected to Alternators*, Chargers, Solar or DC/AC relays, cabinet cooling

fan and Combi Inverter/Charger Units. (Hi/Low Alarm Protection).

1 x Temperature Sensor input – to control charging/discharging circuits

*Requirements of Alternator must be assessed to determine if suitable for the application.

1 x Latching Rely Output – Used to shut down system loads to protect the battery from over

discharge.

Temperature Sensor

The temp sensor input is monitoring temperature via the connected sensor within the surrounding

space of the sensor. The system is programmed to act on pre-determined temperature readings to

control the output circuits. These programmed parameters are;

At ≥35°C, activates Output No 4 for controlling connected Cabinet Fan cooling.

At ≥45°C, activates TOR Controls 1-4 and Outputs 1-2 to shut down charging sources to protect

battery from overcharge in extreme heat conditions.

At ≥ 55°C, activates Latching Relay to disengage load circuit to protect battery from

overheating in extreme heat conditions. <55˚C this system will re-engage the latching relay to

power the application

At ≤0°C, activates TOR Controls 1-4 and Outputs 1-2 to shut down charging sources to protect

battery from charge input in extreme cold conditions.

Status LED

Flashing GREEN - LOW SOC% <24% or LOW CELL Voltage

<2.8/Cell (Load Shutdown)

Flashing RED - HIGH CELL Voltage >3.8V/Cell - Charger Shutdown

Solid RED - High Temp Charger Shutdown >45˚C

(Charger Shutdown)

Flashing RED/BLUE - Extreme Temp System Shutdown >55˚C

(Charge & Load Shutdown)

When Red LEDs are on, all output circuits

are disabling connected charge sources.

When Red LEDs are off, all output circuits

are within range and operating correctly.

When Red LEDs are on,

all output circuits are disabling

connected charge sources.

When Green LEDs are on, all input

circuits are within range and

operating correctly.

When one or more Green LEDs

are out, the input is receiving an alarm

signal from the connected equipment.

When Green LED is on, the connected

latching relay is engaged and operating

correctly.

When Green LED is off, the connected

latching relay is disengaged shutting

power to all output loads.

When Red LEDs are off,

all output circuits are within

range and operating correctly.

Program

Selector

Switch

(Set To Position A)

Temp Sensor

OUTPUT 4

When Red

ePRO Combi

Inverter

shutdown

(if connected)

Cabinet Cooling

Fan Control

Turns ON >35˚

Power

Input

Reserved

for Future Use

Page 6

What’s in the Enerdrive Lithium System?

To use the Enerdrive Lithium Power Pack you need to use a combination of items together. These are:

• The actual lithium power pack battery box including Active Balancing System.

• The Advance BMS controller board which includes

• The Advance BMS Relay Driver box

•

The ePRO Plus is our latest generation, highly advanced battery monitor. It consists of an intelligent

active shunt and a remote control and display unit (CDU). The shunt has a Grid Optimized footprint

for perfect integration with our DC Modular series of high current busbars and fuse holders.

The ePRO Plus battery monitor can measure DC currents up to 600Amps (500Amp continuous) and

voltages up to 70Vdc. So any lead- or lithium based battery from 12V up to 48V can be monitored.

•

A Blue Sea 500amp main battery latching relay which is activated by the ePRO Plus Battery Monitor

when the low state of charge (percentage is reached).

• A Class T Fuse for system protection.

• 70 - 120mm² Battery cable (depending on system) from the battery to the Connection Kit.

1Left key (<) or Previous value

2Menu or Enter key

3Right key (>) or Next value

4

5Alarm indicator

6Selected battery input indicator

7Value section for SoC (also for Function, Status and History parameter numbers)

8

discharge current (turning counter clockwise). The animation speed will also increase when the charge or discharge

current

clockwise) or a

increases.

Page 7

The ePRO Plus Battery Monitor has been pre-programmed at the factory to suit the selected Lithium

system and is software locked. There is no setup interaction required by the end user. For more user

information on the ePRO Plus Battery Monitor, please refer to the detailed instruction manual included

in your documentation package.

Voltages for Lithium batteries have a very narrow window compared to lead acid batteries. With all of

our testing over the last 6+ years, the Enerdrive Lithium battery standing voltage when fully charged

(with no loads running) will be between 13.35v-13.45v at 100% capacity.

When discharged to near 25% capacity remaining, the standing voltage will be between 12.90v-13.00v

to lead acid batteries where voltage can range from 12.72v at 100% to 11.88v at 20% capacity.

With Lithium, it is better and more accurate to work on the State of Charge Percentage (SOC%) to

determine your remaining battery capacity.

State of charge (%) Volt, Amp, Ah, time remaining,

temperature, Watts, and

maintenance hours.

Status or history readout Alarm activated (low battery

state of charge)

Page 8

BATTERY STORAGE INFORMATION:

IMPORTANT PLEASE READ:

When storing your Enerdrive lithium battery, even with the main Remote Battery Switch disengaged,

the ePRO PLUS Battery Monitor and Advanced BMS Relay Driver will still be powered, producing a small

constant drain on the lithium battery. Therefore, it is essential that you keep your Enerdrive lithium

battery charged when you are not using your vehicle/vessel. It is the responsibility of the end user to

maintain the Enerdrive lithium battery in a charged state.

Your lithium battery should not be left for more than 30 days without checking its charge state. Enerdrive

recommend that your lithium battery should ideally be checked and charged as often as possible to

maintain maximum life expectancy, especially if you leave any DC loads running. Failure to follow these

requirements could see an early failure of the battery, which is not covered under warranty.

When you are not using your Enerdrive lithium system it is strongly recommended that you

have access to AC power then leave your vehicle/vessel in the sun to allow your solar panels

(if installed) to keep the battery charged.

If you store your vehicle/vessel under cover and you don’t have access to AC power, then you must

prevent the battery from being discharged to a critical, potentially non-recoverable, state of charge.

Before your battery state of charge reaches 24% you must either connect your vehicle/vessel to AC

power or move it into the sun and allow the solar (if installed) to bring the battery up to a reasonable

state of charge. In either case, it would make sense to fully charge your lithium battery to 100% in order

to increase the period of time before you have to repeat this procedure.

If your vehicle/vessel is connected to AC power and is being left unattended for longer than 30 days,

and will not be checked by yourself, we recommend that you either ask someone to check on it regularly

while you are away or follow the long term storage procedure in the following pages.

Long Term Storage Switch

------ Failure to correctly store your lithium batteries will result in early battery failure --------

If you are intending to store your vehicle/vessel for more than 30 days,

it is recommended to shut down the entire DC electrical system. You

This switch is designed to completely isolate the Enerdrive lithium

battery from the DC electrical system, including the ePRO PLUS

battery monitor and Advanced BMS Relay Driver and will prevent

any external discharge of the lithium battery.

Page 9

Page 10

Power

Input 1

Input 2

Input 3

Input 4 (if connected)

Latching Relay

Page 11

Troubleshooting the Lithium Battery System

Q: What if the battery monitor reads 24% or less or the battery voltage has reached 12.4v or less, and

the power has gone out?

Q: What if I see red LED’s on the “TOR & Outputs” of the Advanced Relay Driver?

A: If a battery cell goes Hi Voltage and cuts the HI Voltage loop wire then the Advanced BMS Relay

Status LED will flash RED and the Driver will activate the TOR & Output contacts (turning red) and

will drive the installed relay/contacts to cut out all charging sources (solar/vehicle/main charger) for

10 minutes. If the cell voltage has not come back within range before 10min, it will stay active for

another 10 minutes and repeat until the cell/s are within range.

A:

The battery has reached its maximum discharge and the main battery relay has dis-engaged to

protect the battery. Turn off all loads and turn on the charging sources. Once the percentage on

the ePRO Plus Meter reaches 28%, you can push the yellow button on the main battery relay until

it latches down to re-engage the main battery switch and monitor your loads. Keep charging

sources connected until the battery reaches maximum charge 100%.

Q: What if the main battery switch has tripped out, but the LED’s on Inputs 1-3 on the Advanced

BMS Relay Driver are Green and the battery monitor is 26% or higher in capacity?

A: This has happened because the system has registered 1 of 2 faults:

1: A high temperature condition has occurred above 55°C (status LED flashing Red/Blue) and shut

down the main battery relay to protect the system from an extreme high temperature situation.

Once the temperature reduces below 55°C the main battery relay will automatically switch itself back on.

2: The system has registered a low battery SOC ≤24% or low cell voltage ≤ 3.1V condition (Status LED

flashing Green) and shut down the main battery relay to protect the battery from over discharge.

If solar is connected to the system, once the SOC rises above 26% and the cell voltage increases

above 3.1V then inputs 1-3 will register a Green LED. At this point, push the yellow button on the

main battery relay until it latches down to re-engage the main battery switch and monitor your loads.

Switch on additional charging sources until the battery reaches maximum charge 100%

Q: What if the Status light is flashing Blue and the temperature is above 0°C?

A:

The Temperature Sensor has failed or become unplugged and the system has shut down the charge

sources. Check to make sure the sensor is plugged in correctly. If so, remove the Temperature Sensor

from the Advanced BMS Relay Driver and select Program B on the side of the Advanced BMS Relay Driver.

Refer “Program B” on page ##

DC LOADS +

EN3TOR-G2

Set DipSwitch to:

Standard Program

If using Dual Batteries in

Parallel or Series please

refer to:

* Parallel 12v setup drawing

* Series 24v setup drawing

NOTE:

1.Voltage protection circuit must

be connected prior to connecting

the Battery connection Plug.

2. Never disconnect Battery

connection wires from the battery

while the lead is connected to the

EPL-ABS box.

WARNING!

EPL-ABS

14/12/2018

Battery +

Battery -

+

-

RED

BLUE

WHITE

YELLOW/GREEN

BLACK

GREEN

BLUE

BLACK

RED

WHITE

YELLOW

Inverter +

Inverter -

DC LOADS +

COMMON NEG

EPL-ABS

Voltage

Protection

Circuit

Battery

Connection

Balancer

Link N/A

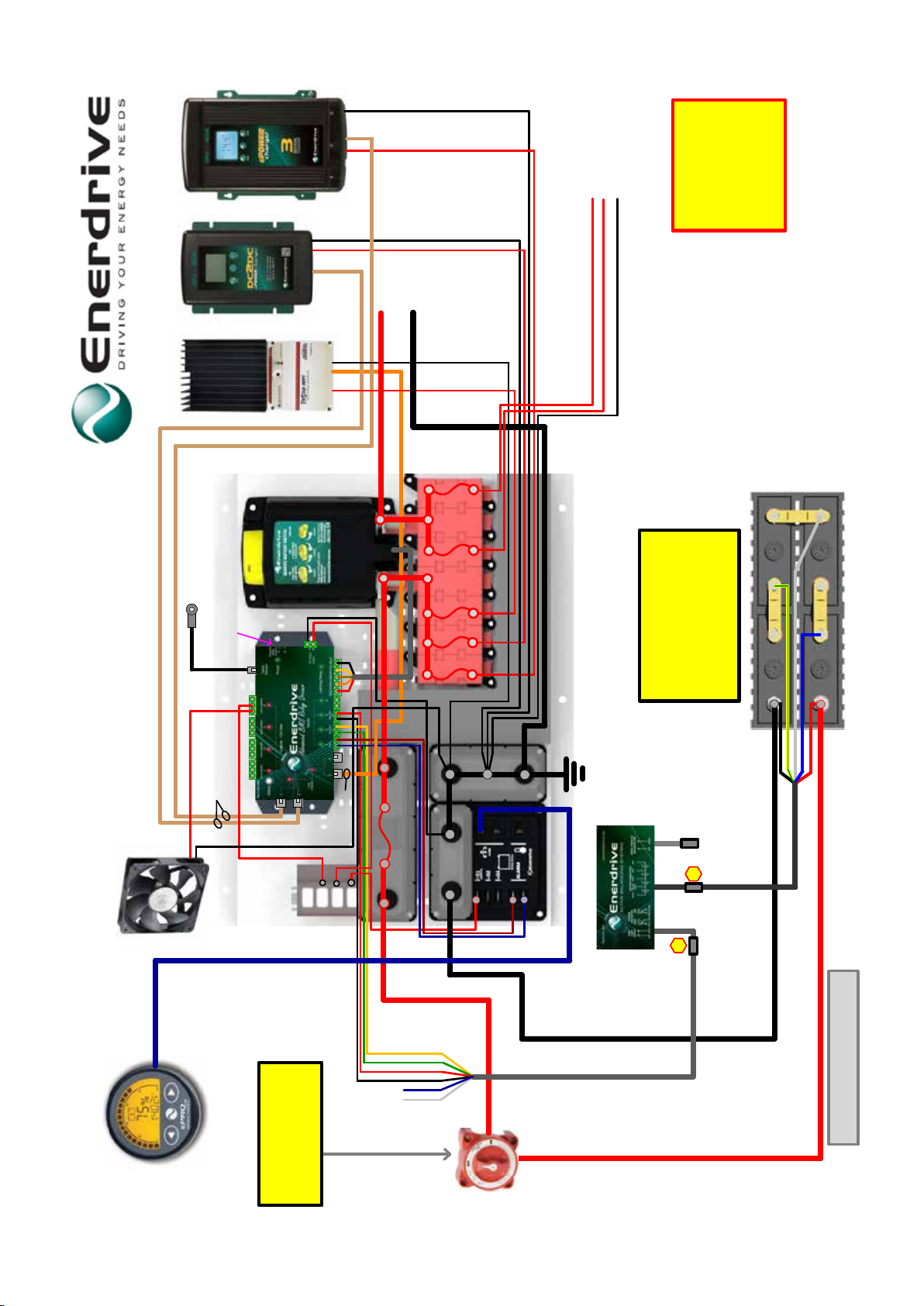

Lithium Setup - ePOWER Single 12v - 2018-G2

SR-TS-TOR-G2

TOR Output SR-TS-TOR-G2

Wire to:

RTS Terminal

2

1

1A

10A

NOTE:

Long term storage switch.

Only turn this switch OFF once the batteries

are fully charged, the Yellow Latching Relay

is disengaged and all charging sources have

been shut down correctly.

Min 95mm Cable with a Max length of

1.5m from Battery to Connection Board.

2

Enerdrive has provided this drawing as a guide only

and installers must ensure the system is installed to the

local requirements for fuse protection and wire sizing.

If you have any questions please call;

Enerdrive on 07 3390 6900

Temp Sensor

5A

Optional Cabinet Fan

Output 4 Turns on when

Temp Sensor >35

°C

EN3TOR-G2

Plug into BTS

EN3TOR-G2

Plug into BTS

DC LOADS +

EN3TOR-G2

Set DipSwitch to:

Standard Program

12/12/2018

GREEN

BLUE

BLACK

RED

WHITE

YELLOW

Inverter +

Inverter -

DC LOADS +

COMMON NEG

Lithium Setup - ePOWER Dual 12v - 2018-G2

SR-TS-TOR-G2

SR-TS-TOR-G2

Wire to:

RTS Terminal

1A

10A

NOTE:

Long term storage switch.

Only turn this switch OFF once the batteries

are fully charged, the Yellow Latching Relay

is disengaged and all charging sources have

been shut down correctly.

Enerdrive has provided this drawing as a guide only

and installers must ensure the system is installed to the

local requirements for fuse protection and wire sizing.

If you have any questions please call;

Enerdrive on 07 3390 6900

Temp Sensor

5A

Optional Cabinet Fan

Output 4 Turns on when

Temp Sensor >35

°C

EN3TOR-G2

Plug into BTS

EN3TOR-G2

Plug into BTS

GREEN

BLUE

BLACK

RED

WHITE

YELLOW

EPL-ABS

Battery +

Battery -

+

-

Battery +

Battery -

RED

BLUE

WHITE

YELLOW/GREEN

BLACK

+

-

RED

BLUE

WHITE

YELLOW/GREEN

BLACK

EPL-ABS

Voltage

Protection

Circuit

Battery

Connection

Balancer

Link N/A

Voltage

Protection

Circuit

Battery

Connection

Balancer

Link N/A

2

12

13

3

Min 95mm Cable with a Max length of

1.5m from Battery to Connection Board.

2

Battery cables must be of equal length and size between

Batteries and busbars to keep the batteries balanced.

1.Voltage protection circuit must

be connected prior to connecting

the Battery connection Plug.

2. Never disconnect Battery

connection wires from the battery

while the lead is connected to the

EPL-ABS box.

3. Only connect Balance wire once

Battery Conection wires and plugs

are connected.

WARNING!

EPL-ABS

6C6P

Splitter

Box

6C6P

Splitter

Box

DC LOADS +

EN3TOR-G2 Set DipSwitch to:

Standard Program

13/12/2018

GREEN

BLUE

BLACK

RED

WHITE

YELLOW

DC LOADS +

COMMON NEG

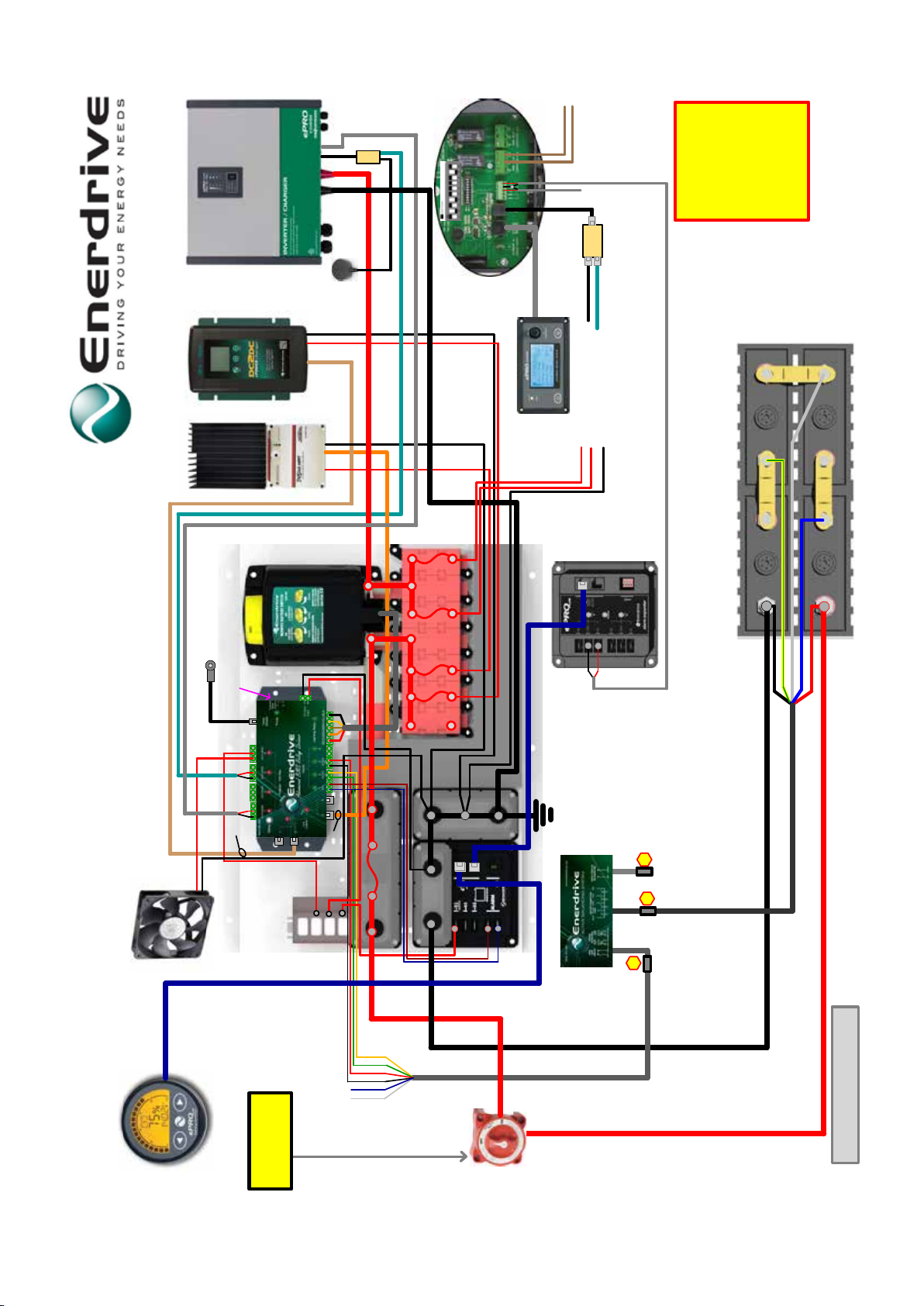

Lithium Setup - ePRO 1600 Single 12v - 2018-G2

SR-TS- TOR-G2

SR-TS-TOR-G2

Wire to:

RTS Terminal

1A

10A

NOTE:

Long term storage switch.

Only turn this switch OFF once the batteries

are fully charged, the Yellow Latching Relay

is disengaged and all charging sources have

been shut down correctly.

Enerdrive has provided this drawing as a guide only

and installers must ensure the system is installed to the

local requirements for fuse protection and wire sizing.

If you have any questions please call;

Enerdrive on 07 3390 6900

Temp Sensor

5A

Optional Cabinet Fan

Output 4 Turns on when

Temp Sensor >35

°C

EN3TOR-G2

Plug into BTS

Battery +

Battery -

+

-

RED

BLUE

WHITE

YELLOW/GREEN

BLACK

EPL-ABS

Voltage

Protection

Circuit

Battery

Connection

Balancer

Link N/A

2

1

3

1.Voltage protection circuit must

be connected prior to connecting

the Battery connection Plug.

2. Never disconnect Battery

connection wires from the battery

while the lead is connected to the

EPL-ABS box.

3. Only connect Balance wire once

Battery Conection wires and plugs

are connected.

WARNING!

EPL-ABS

Min 70mm Cable with a Max length of

1.5m from Battery to Connection Board.

2

Inverter +

Inverter -

EPC-TOR

Twin Core to: Trigger 1/COM

Temp Sensor

(From Output 3) EPC-TOR

Temp Sensor (from Output 1 or 2)

Twin Core to

Trigger 1/COM

Inside Combi

Twin Core

Wire to:

Trigger 1/COM

6C6P

Splitter

Box

6C6P

Splitter

Box

DC LOADS +

EN3TOR-G2 Set DipSwitch to:

Standard Program

13/12/2018

GREEN

BLUE

BLACK

RED

WHITE

YELLOW

DC LOADS +

COMMON NEG

Lithium Setup - ePRO 3000 Single 12v - 2018-G2

SR-TS- TOR-G2

SR-TS-TOR-G2

Wire to:

RTS Terminal

1A

10A

NOTE:

Long term storage switch.

Only turn this switch OFF once the batteries

are fully charged, the Yellow Latching Relay

is disengaged and all charging sources have

been shut down correctly.

Enerdrive has provided this drawing as a guide only

and installers must ensure the system is installed to the

local requirements for fuse protection and wire sizing.

If you have any questions please call;

Enerdrive on 07 3390 6900

Temp Sensor

5A

Optional Cabinet Fan

Output 4 Turns on when

Temp Sensor >35

°C

EN3TOR-G2

Plug into BTS

Battery +

Battery -

+

-

RED

BLUE

WHITE

YELLOW/GREEN

BLACK

EPL-ABS

Voltage

Protection

Circuit

Battery

Connection

Balancer

Link N/A

2

1

3

1.Voltage protection circuit must

be connected prior to connecting

the Battery connection Plug.

2. Never disconnect Battery

connection wires from the battery

while the lead is connected to the

EPL-ABS box.

3. Only connect Balance wire once

Battery Conection wires and plugs

are connected.

WARNING!

EPL-ABS

Inverter +

Inverter -

EPC-TOR

Twin Core to: Trigger 1/COM

Temp Sensor

(From Output 3) EPC-TOR

Temp Sensor

(from Output 1 or 2)

Twin Core to

Trigger 1/COM

Inside Combi

Twin Core

Wire to:

Trigger 1/COM

AC Switch for

Non essental

loads i.e Aircon

AirCon >%

(from Alarm Expander)

Twin Core to

Trigger 2/COM

Optional

Alarm Expander

Min 95mm Cable with a Max length of

1.5m from Battery to Connection Board.

2

6C6P

Splitter

Box

6C6P

Splitter

Box

DC LOADS +

EN3TOR-G2 Set DipSwitch to:

Standard Program

13/12/2018

GREEN

BLUE

BLACK

RED

WHITE

YELLOW

DC LOADS +

COMMON NEG

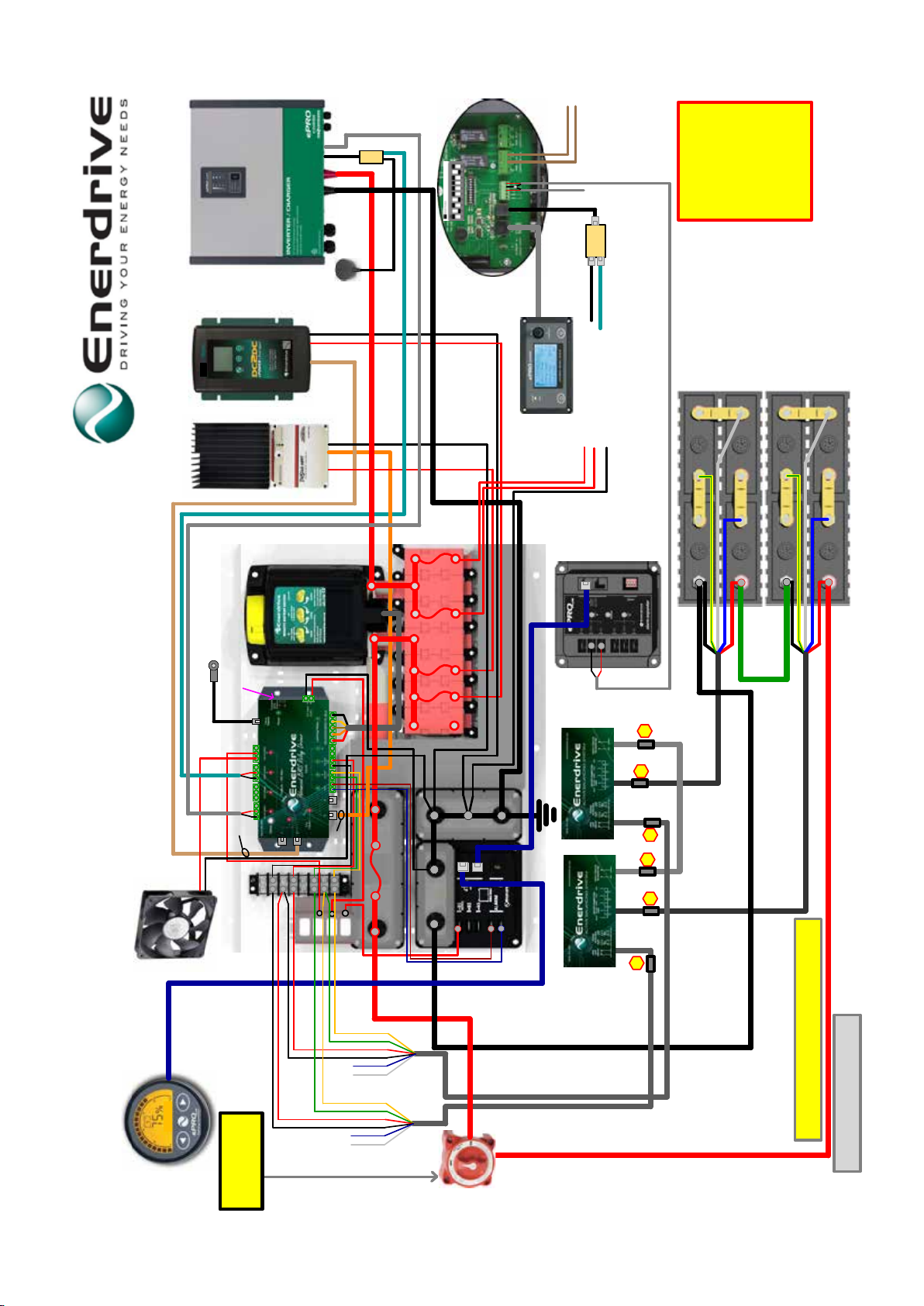

Lithium Setup - ePRO 3000 Dual 12v - 2018-G2

SR-TS- TOR-G2

SR-TS-TOR-G2

Wire to:

RTS Terminal

1A

10A

NOTE:

Long term storage switch.

Only turn this switch OFF once the batteries

are fully charged, the Yellow Latching Relay

is disengaged and all charging sources have

been shut down correctly.

Enerdrive has provided this drawing as a guide only

and installers must ensure the system is installed to the

local requirements for fuse protection and wire sizing.

If you have any questions please call;

Enerdrive on 07 3390 6900

Temp Sensor

5A

Optional Cabinet Fan

Output 4 Turns on when

Temp Sensor >35

°C

EN3TOR-G2

Plug into BTS

GREEN

BLUE

BLACK

RED

WHITE

YELLOW

EPL-ABS

Battery +

Battery -

+

-

Battery +

Battery -

RED

BLUE

WHITE

YELLOW/GREEN

BLACK

+

-

RED

BLUE

WHITE

YELLOW/GREEN

BLACK

EPL-ABS

Voltage

Protection

Circuit

Battery

Connection

Balancer

Link N/A

Voltage

Protection

Circuit

Battery

Connection

Balancer

Link N/A

2

12

13

3

Min 95mm Cable with a Max length of

1.5m from Battery to Connection Board.

2

Battery cables must be of equal length and size between

Batteries and busbars to keep the batteries balanced.

1.Voltage protection circuit must

be connected prior to connecting

the Battery connection Plug.

2. Never disconnect Battery

connection wires from the battery

while the lead is connected to the

EPL-ABS box.

3. Only connect Balance wire once

Battery Conection wires and plugs

are connected.

WARNING!

EPL-ABS

Inverter +

Inverter -

EPC-TOR

Twin Core to: Trigger 1/COM

Temp Sensor

(From Output 3) EPC-TOR

Temp Sensor

(from Output 1 or 2)

Twin Core to

Trigger 1/COM

Inside Combi

Twin Core

Wire to:

Trigger 1/COM

AC Switch for

Non essental

loads i.e Aircon

AirCon >%

(from Alarm Expander)

Twin Core to

Trigger 2/COM

Optional

Alarm Expander

6C6P

Splitter

Box

6C6P

Splitter

Box

DC LOADS +

EN3TOR-G2 Set DipSwitch to:

Standard Program

13/12/2018

GREEN

BLUE

BLACK

RED

WHITE

YELLOW

DC LOADS +

COMMON NEG

Lithium Setup - ePRO 3500 24v - 2018-G2

SR-TS- TOR-G2

SR-TS-TOR-G2

Wire to:

RTS Terminal

1A

10A

NOTE:

Long term storage switch.

Only turn this switch OFF once the batteries

are fully charged, the Yellow Latching Relay

is disengaged and all charging sources have

been shut down correctly.

Enerdrive has provided this drawing as a guide only

and installers must ensure the system is installed to the

local requirements for fuse protection and wire sizing.

If you have any questions please call;

Enerdrive on 07 3390 6900

Temp Sensor

5A

Optional Cabinet Fan

Output 4 Turns on when

Temp Sensor >35

°C

EN3TOR-G2

Plug into BTS

GREEN

BLUE

BLACK

RED

WHITE

YELLOW

EPL-ABS

Battery +

Battery -

+

-

Battery +

Battery -

RED

BLUE

WHITE

YELLOW/GREEN

BLACK

+

-

RED

BLUE

WHITE

YELLOW/GREEN

BLACK

EPL-ABS

Voltage

Protection

Circuit

Battery

Connection

Balancer

Link N/A

Voltage

Protection

Circuit

Battery

Connection

Balancer

Link N/A

2

12

13

3

Min 50mm Cable with a Max length of

1.5m from Battery to Connection Board.

2

Battery cables must be of equal length and size between

Batteries and busbars to keep the batteries balanced.

1.Voltage protection circuit must

be connected prior to connecting

the Battery connection Plug.

2. Never disconnect Battery

connection wires from the battery

while the lead is connected to the

EPL-ABS box.

3. Only connect Balance wire once

Battery Conection wires and plugs

are connected.

WARNING!

EPL-ABS

Inverter +

Inverter -

EPC-TOR

Twin Core to: Trigger 1/COM

Temp Sensor

(From Output 3) EPC-TOR

Temp Sensor

(from Output 1 o 2)

Twin Core to

Trigger 1/COM

Inside Combi

Twin Core

Wire to:

Trigger 1/COM

AC Switch for

Non essental

loads i.e Aircon

AirCon >%

(from Alarm Expander)

Twin Core to

Trigger 2/COM

Optional

Alarm Expander

3500va 24volt 70a

24V

Page 19

Lithium Battery Warranty: Two Year Limited Warranty

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are

entitled to a replacement or refund for a major failure and for compensation for any other reasonably

foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if the goods

fail to be of acceptable quality and the failure does not amount to a major failure.

The limited warranty program is the only one that applies to this unit, and it sets forth all the responsibilities

of Enerdrive. There is no other warranty, other than those described herein. Any implied warranty of

this warranty.

Enerdrive Pty Ltd warrants its Lithium batteries (hereafter referred to as “Battery”) to be free of defects

in material and workmanship for the following Applicable Warranty Period:

• 1 year for Industrial & Commercial Use

•

2 years for marine pleasure vessel and automotive applications in cycling and non-cycling applications.

The battery is warranted, to the original purchaser only, to be free of defects in materials and

workmanship for two years from the date of purchase without additional charge. The warranty

does not extend to subsequent purchasers or users other than OEM applications.

•

An additional 24 months Pro-Rata warranty is included in the battery. The pro-rated price is calculated

as a percentage of the current suggested retail price. Pro-Rata warranty applicable to original end

user only.

Enerdrive does not warrant the battery for use in any residential system sold with the intent or purpose

The Enerdrive ePRO Plus battery monitor that is standard with every Lithium-Ion battery kit is pre-

The warranty does not cover a battery reaching its normal end of life which may occur prior to the

warranty period stated above. Depending on the application a battery can reach its normal end of life

before the end of the warranty period.

to have reached its normal end of life if the application uses up all of these cycles / amp-hours, regardless

claim if it determines the battery to be at its normal end of life, even if the claim is lodged within the

The Applicable Warranty Period begins from the date of purchase with original receipt, or, if no receipt

is available, from Enerdrives invoice / shipping date.

Batteries determined to meet the conditions of this warranty will be replaced free of charge if, at the

sole discretion of Enerdrive, adjustment is necessary due to defect in material or workmanship. Batteries

for warranty replacement consideration are to be returned to the original supplying distributor/dealer.

Batteries replaced under the warranty provisions will be shipped with a replacement warranty sticker

and carry only the remainder of the original Applicable Warranty Period.

The battery is not designed or warranted in the following areas:

• The Battery is NOT to be used in any Aviation aircraft application.

• The Battery is NOT to be used in any lifesaving applications

• The Battery is NOT to be exported to USA/Canada and their territories

•

Lorem ipsum

Page 20

PLEASE NOTE

The battery has a self-discharge rate of 5% per month @ 25°C. When storing the battery with the

main latching relay disengaged, the ePRO Plus Battery Monitor and Advance Relay Driver will still

be powered adding a further drain on the battery.

It is the responsibility of the end user to maintain the battery in a charged state. The battery should

not be left for more than 30 days without checking its charge state. Enerdrive recommend that a

battery left in a “storage state” should be checked and charged every 30 days to maintain maximum

life expectancy of the battery. Failure to follow these requirements will see an early failure of the

battery which is not covered under warranty.

General Provisions:

Enerdrives Pty Ltd has no obligation under the limited warranty herein in the event the battery is

damaged or destroyed as a result of one or more of the following:

• Wilful abuse, misuse, physical damage, neglect or if the decorative cover has been removed.

•

penetration or opening of the battery case in any manner.

•

The supplied Enerdrive ePRO Plus battery monitor is pre-programmed by Enerdrive if and any

•

The battery MUST be installed in an upright position. Installing it upside down or laid on its side

will void warranty.

•

Overcharging, undercharging, charging or installing in reverse polarity, improper maintenance,

allowing the battery to be deeply discharged via a parasitic load or mishandling of the battery such

as but not limited to using the terminals for lifting or carrying the battery.

•

between 13.5V and 14.5V (no lower than 13.0V and no higher than 14.7V) will cause early failure of the

battery. Use of such chargers with the battery will also void the battery’s warranty. For applications

where an alternator is present, the alternator must deliver between 13.5V and 14.2V when measured

at the Battery’s terminals. Alternators that do not have a regulated charge between 13.5V and 14.2V

(no lower than 13.0V and no higher than 14.7V) will cause early failure of the battery. Use of such

alternators with the battery will also void the batteries warranty.

•

All Enerdrive batteries are supplied with an additional battery installation kit. Failure to install or

properly install the battery and its installation kit will void the warranty

•

Repair or attempted repair of the battery by anyone other than an authorized Enerdrive representative

shall void this warranty.

•

Normal or accelerated deterioration in the electrical qualities due to operating or application

conditions.

•

If the battery is used for an application that requires higher cranking power or a greater reserve

rating than the battery is designed to deliver, or the battery capacity is less than the battery capacity

designed.

Lorem ipsum

Page 21

•

Prolonged storage of the battery with either no charge or a parasitic consumption load applied

disconnecting the battery to prevent irreversible damage to the battery.

• A battery with an open circuit voltage (OCV) of equal to or less than 10.0V will be deemed as over

discharged and void warranty due to misuse and/or neglect.

WARNING

Do NOT use any type of oil, organic solvent, alcohol, detergent, strong acids, strong alkalis, petroleum-

cause permanent damage to the battery covers and end plates and will void the warranty.

Return and/or Repair Policy

If you are experiencing any problems with your unit, please contact our customer service department

at support@enerdrive.com.au or Phone 1300 851 535 before returning product to retail store. After

speaking to a customer service representative, if products are deemed nonworking or malfunctioning,

the product may be returned to the purchasing store within 30 days of original purchase. Any defective

unit that is returned to Enerdrive within 30 days of the date of purchase will be replaced free of charge.

If such a unit is returned more than 30 days but less than two years from the purchase date, Enerdrive

will repair the unit or, at its option, replace it, free of charge. If the unit is repaired, new or reconditioned

replacement parts may be used, at manufacturer’s option. A unit may be replaced with a new or

reconditioned unit of the same or comparable design. The repaired or replaced unit will then be

warranted under these terms for the remainder of the warranty period. The customer is responsible

for the shipping charges on all returned items back to Enerdrive.

Limitations

This warranty does not cover damage or defects resulting from normal wear and tear (including chips,

scratches, abrasions, discolouration or fading due to usage or exposure to sunlight), accidents, damage

during shipping to our service facility, alterations, unauthorized use or repair, neglect, misuse, abuse,

If your problem is not covered by this warranty, contact our Support Team at support@enerdrive.com.

au or phone 1300 851 535 for general information if applicable.

Table of contents