ENERDYNE Indigo Xtreme User manual

Revision 1.2. Released on 1

st

of November 2012

™

Indigo Xtreme

Engineered Thermal Interface

for

Socket 1155 & 1156 (Intel Core™ i ,

Core™ i5 and Core™ i7 processors

)

Indigo Xtreme

™

is an Engineered

Thermal Interface (ETI) that fits neatly between

a CPU lid and heat sink or waterblock to keep

CPUs cooler. Unlike

greases, metallic

thermal interface

pads or liquid

metal alloys,

Indigo Xtreme

is a self-contained

and sealed structure,

deploying a Phase Change

Metallic Alloy (PCMA) which reflows and fills

surface defects on the CPU lid and heat sink.

The resultant interfacial layer is void-free and

robust, with low thermal contact and bulk

resistance.

Important: Unlike most thermal

interface products, the Indigo Xtreme

form-factor is optimized for each

application.

Attempting to use Indigo Xtreme with

CPUs or heat sinks other than those

specified may result in degraded

performance or failure of the interface

(See: Supported Hardware).

Supported Hardware

Supported CPUs: Socket 1155 / 1156

• Core™ i

• Core™ i5

• Core™ i7

Supported heat sink/waterblock types:

In general, heat sink/

waterblocks that

contact entire surface

of CPU lid are com-

patible with Indigo

Xtreme.

Unsupported heat sink types:

Heat sinks that do not contact entire surface of

CPU lid, or surfaces with channels between

mounting base and heat pipes, are incompati-

ble with Indigo Xtreme. Please see our compati-

bility document and other application notes for

installation tips specific to your cooler at: http://

w w w . i n d i g o - x t r e m e . c o m /

documentation.html

Prior to the installation and reflow of

Indigo Xtreme, Do ot disable the

Thermal Control feature that pro-

tects your CPU from overheating.

ETI Kit Contents

The Indigo Xtreme ETI is offered as part of an

Engineered Thermal Interface Kit. This kit in-

cludes several cleanroom-grade surface clean-

ing products for (2) complete installations.

The ETI kit includes:

Indigo Xtreme ETIs (2 installations)

Cleanroom-grade dry wiper cloths

Indigo Xtreme Clean™ (sample size)

Pair of powder-free nitrile gloves

Detailed Installation Guide

Check the condition of the ETI kit

before installation; if any problem is

found, contact Enerdyne Solutions

for a replacement.

Installation Steps

Read entire instructions before be-

ginning installation. Computer oper-

ating system and temperature moni-

toring utilities must be installed prior

to use. Contact Enerdyne Solutions if you have

any questions.

1. Motherboard, CPU and Heat Sink/Water

Block Removal:

Remove the motherboard (from the PC case)

and all heat sink clips and support mechanisms

from the motherboard. Remove the CPU from

the motherboard socket and place on a non-

abrasive, lint-free surface for cleaning.

Motherboard and clip support re-

moval will facilitate proper alignment

of the ETI to the CPU lid and heat

sink. It is recommended that all heat

sink mounting hardware be re-installed during

Step #9.

2. Thermal Interface Compound Removal:

Using the supplied dry wiper cloth, apply pres-

sure to thoroughly remove any existing inter-

face grease from the CPU lid and heat sink.

Clean with fresh areas of the wiper cloth until

no visible residue is detected on the wiper.

If removing metal pad or liquid metal

TIM residue, refer to manufacturer’s

specific cleaning methods.

3. Put on Gloves:

Prior to the final degreasing step, the supplied

powder-free nitrile gloves must be worn to pre-

vent any finger oils or contaminants from con-

tacting the CPU lid, heat sink and ETI surfaces

and to prevent skin contact with Indigo Xtreme

Clean™.

4. Degrease CPU lid and Heat Sink/Water

Block Surfaces:

Saturate a dry wiper cloth with Indigo Xtreme

Clean™; use ~1/2 trial size bottle per ETI

installation; thoroughly wipe the CPU lid;

repeat with the heat sink interfacial surfaces.

Continue to wipe each surface with fresh areas

of the wiper until no visible residue is detected

on the wiper. Wipe all surfaces of any visible

lint, fibers, or particulates.

Be prepared to wipe the CPU lid

and heat sink surfaces immediately

upon saturating each dry wiper cloth

as the Xtreme Clean™ solvent will

quickly evaporate. When finished, seal the

used wiper in the ETI kit clear bag. New CPUs

or heat sinks must be degreased as well. Use

only the supplied Indigo Xtreme Clean™ for

the degreasing step.

Use the Xtreme Clean™ solvent

in a well-ventilated area. Avoid

contact with plastics (such as

keyboards, computer cases, cool-

ing fans, some water block housings, coolant

tube fittings, cables, etc.). Also, avoid contact

with elastomers (coolant tubing, gaskets, etc.).

5. CPU Installation:

Install the CPU in the motherboard. Refer to

motherboard or CPU installation instructions.

The ETI can only be applied after

correct installation of the CPU.

6. Indigo Xtreme Handling:

The Indigo Xtreme ETI may be han-

dled on the blue surfaces only. ETI

installation requires a lint-free envi-

ronment.

Do not remove the clear Top and

Bottom liners prior to the specific

installation step. Do not bend, flex or

puncture any portion of the ETI.

Keep all chemical agents (Indigo

Xtreme Clean™, etc.) away from the ETI.

Page 1

Revision 1.2. Released on 1

st

of November 2012

7. Bottom Side Liner Removal:

Remove the “Bottom” side rectangular clear

liner by slowly peeling the liner, beginning from

the corner with the white BOTTOM” label.

Do not touch the exposed adhesive

area after removal of the clear liner.

Once the liner has been removed,

proceed immediately to Step #8:

Alignment and Placement.

8. Alignment and Placement:

Orient the ETI such that the Bottom side is

facing the CPU lid. (Refer to the figures below

for correct placement).

Orientation and alignment of the ETI

to the CPU lid and socket is critical.

Refer to the figures below for correct

placement.

Hold the ETI on the blue edges (with both

hands to prevent any wrinkling or warping) and

carefully lower onto the CPU lid surface. With

moderate, downward finger pressure, com-

pletely press down all ETI surfaces onto the

CPU lid by following the square blue alignment

ring.

Ensure that the ETI is

oriented with CPU

lid /soc ket as

shown. Align

the square

blue ring to the

edge of the

CPU lid

before mak-

ing contact.

It is critical that the square blue

alignment ring is completely on the

CPU lid and all blue ring

surfaces are thoroughly pressed

down.

ETI on CPU lid with correct alignment and

placement

9 .

Heat Sink Mounting Hardware

Installation:

Any heat sink clip supports may now be

mounted over the installed ETI.

The ETI must extend beneath any

heat sink clip support/frame and

must not be bent by the frame.

Temporarily tape the heat sink

clip to the heat sink base to keep

the assembly stable during heat

sink mounting.

10. Top Side Liner Removal:

Remove the “Top” side rectangular clear liner

by slowly peeling the liner, beginning from the

corner with the white “TOP” label.

Do not touch any

of the clear

surfaces

after

removal of the

clear liner. Once

the liner has been

removed, pro-

ceed immedi-

ately to Step

#11: Heat Sink

Mounting.

11. Heat Sink Mounting:

It is imperative that the heat sink is

aligned correctly before it makes

contact with the ETI. Avoid any twist-

ing on the ETI as the heat sink is

bolted/clamped down. Apply a uniform pressure

to the sink (while clamping) to prevent it from

shifting.

For Clip and Bolt mounted sinks:

Initially tighten each bolt to latch

onto the clip support threading.

Apply uniform torque to all of the

bolts (by alternating the tightening of

bolts). Mounting force recommendations for

specific coolers and water blocks can be found

a t : h t t p :/ / w w w. i n di g o - x t r e m e .c o m /

documentation.html

For plastic Push-Pin mounted sinks:

Attach push-pins to the motherboard

by starting with the two push-pins

opposite the socket hinge. Apply

enough force to lock the final two

push-pins.

12. ETI Reflow:

As part of installation, the Indigo Xtreme ETI

must first be heated with the CPU running under

load in order to reflow (melt) the PCMA.

The interface is highly thermally resis-

tive without a complete reflow. Failure

to perform the exact reflow procedure

may result in unacceptable thermal

performance.

A video demonstration of ETI reflow

can be found at: http://www.indigo-

xtreme.com/documentation.html

ETI Reflow Procedure

1. Connect up any liquid lines to the water block.

2. Orient the computer such that the mother-

board and CPU are in a horizontal position.

. Plug in the CPU (heat sink) fan and case

fan(s). For water cooled systems, turn on liquid

pump.

4. Boot the computer. Clock frequency and volt-

age must be set back to default.

5. Open a CPU temperature monitoring program

(such as SpeedFan™) and select the graphing

option to track the profile of all core temperatures

during reflow. Be certain the graph is open with

all core temperatures selected before proceeding

to next the step.

6. Exercise the CPU with a “burn” program (such

as Prime 95™) to generate adequate heat for

reflow. Multi-core CPUs require one copy of the

burn program for each core to be running simul-

taneously. Refer to References for links to burn

utilities.

7. Unplug the CPU (heat sink) fan and case

fan(s). For water cooled systems, turn off liquid

pump.

Intel multi-core processors have built-

in protection (Adaptive Thermal Moni-

tor) that prevents the processor from

exceeding maximum core tempera-

tures, thereby preventing any damage to the

CPU.

Page 2

Revision 1.2. Released on 1

st

of November 2012

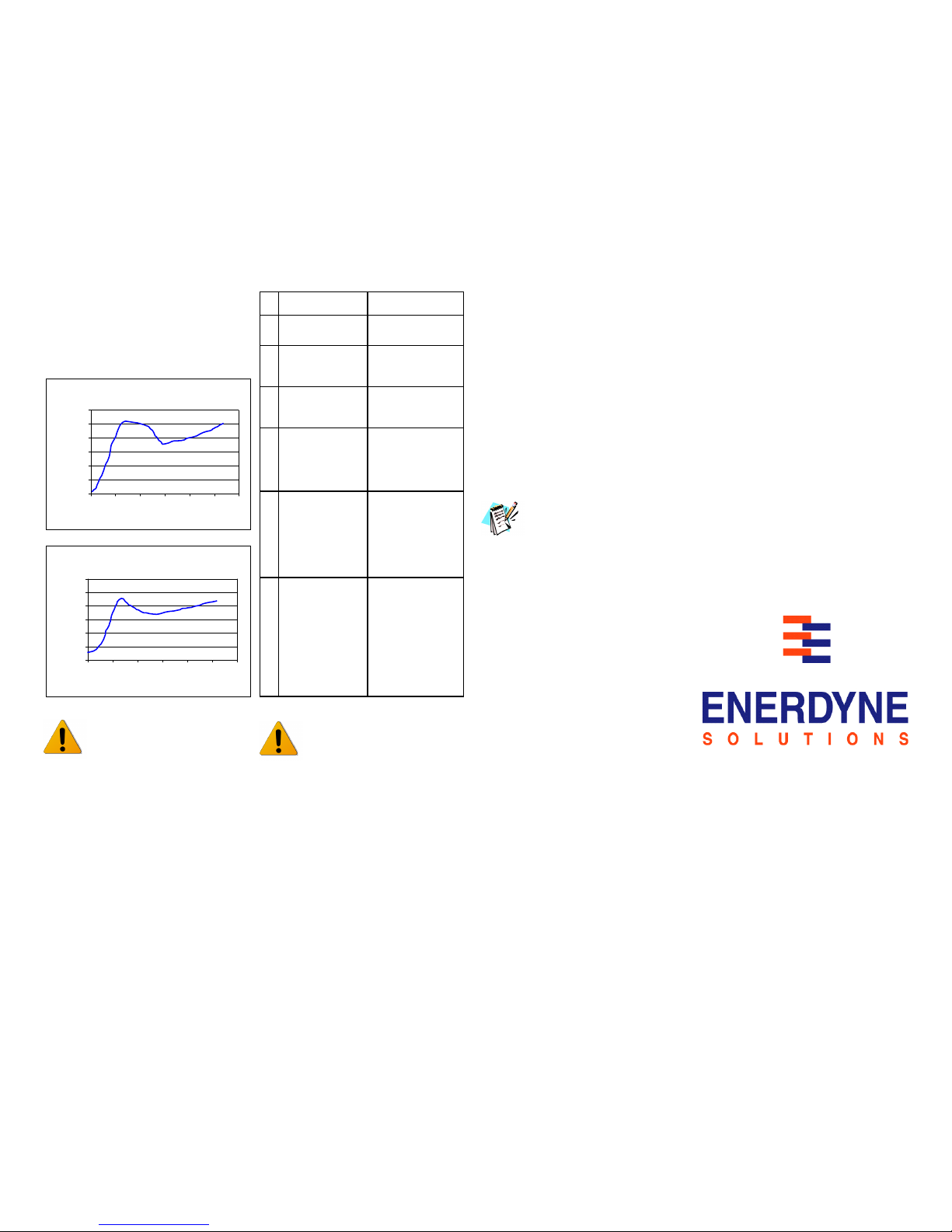

8. Follow the average core temperature profile

(with the temperature monitoring program)

illustrated in the graphics below for your specific

thermal solution: Heat Sink or Water block.

Larger heat sinks and all copper water blocks

will require longer reflow times.

If the average core temperature

does not follow a similar tem-

perature profile as seen in the

previous graphics, then improper

reflow may have occurred. Pro-

ceed to “Removal” and re-install a new

Indigo Xtreme ETI.

Avoid any bumping or excessive

pressure on the heat sink/water

block and keep the computer in

the horizontal position while cool-

ing down.

Removal

To disassemble, release the clamping force

from the heat sink/water block. The ETI may

then be removed (intact) by first slowly peeling

each corner. The ETI is designed to adhesively

capture excess alloy (from differences of CPU

lid/heat sink interfacial roughness and planarity)

on their surfaces.

Any residual adhesive on the CPU or heat sink/

water block may be removed with acetone,

xylene, or Xtreme Clean and a clean wiper or

cotton cleaning swab. Residual alloy is best

removed by wetting a swab with solvent and

gentling rotating the swab to loosen and collect

the alloy particles.

Indigo Xtreme is a single-use inter-

face product and any removal of the

heat sink (pre/post-reflow) will re-

quire a new ETI. All interface mate-

rial and adhesive residue must be removed and

the CPU and heat sink re-cleaned (with the

surface cleaning supplies including in the ETI

kit only) prior to the re-installation of a new ETI.

Storage

Store Indigo Xtreme at room temperature condi-

tions of 72°F (22°C) and 50% R.H., preferably

in the original sealed enclosure and plastic bag.

References

Burn in Program:

http://files.extremeoverclocking.com/file.php?

f=10

Temperature monitors:

SpeedFan is the most popular temperature

monitoring tool. It includes a real-time graphing

mode that will aid in the processor burn-in:

http://www.almico.com/speedfan.php

The Material Safety Data Sheet (MSDS) for

Indigo Xtreme Clean™ can be found at:

h t t p : / / w w w . i n d i g o - x t r e m e . c o m /

documentation.html

Contact us for more information about this or

other Indigo Xtreme applications at our web-

site: http://www.Indigo-Xtreme.com

Disclaimer

Enerdyne Solutions is not responsible for any

damages due to external causes, including but

not limited to, improper use, accident, neglect,

alteration, repair, improper installation, im-

proper testing, or damages caused by

overclocking.

Intel, Intel Core i , Core i5 and Core i7 are

trademarks of the Intel Corporation, USA.

Indigo Xtreme is a trademark of:

Enerdyne Solutions, Inc.,

125 West North Bend Way, PO Box 2660,

North Bend, WA., 98045

Tel:425-888-1880 Fax:425-8 1-077

enerdynesolutions.com

Cool solutions for hot problems

Heat Sinks Water Blocks

1

All burn programs

are now activated.

All burn programs

are now activated.

2

Core temperatures

will initially rise to

peak of ~80-90°C.

Core temperatures

will initially rise to

peak of ~80-85°C.

3

Core temperatures

w i l l s t a b i l i z e

slightly (~85°C).

Core temperatures

will immediately

begin to drop.

4

Within ~2- min-

utes, core tem-

peratures will drop

rapidly to a Bot-

toming Point.

Core temperatures

will drop within sec-

onds of the initial

peak to a Bottoming

Point.

5

Following the Bot-

toming Point, aver-

age core tempera-

tures will slowly

rise again. Allow

core temperatures

to return to ~85°C.

Following the Bot-

toming Point, aver-

age core tempera-

tures will slowly rise

again. Allow core

temperatures to

return to ~90°C.

6

Once core tem-

peratures have

reached ~80-85°C,

de-activate all burn

programs and shut

down computer;

allow to cool for at

least 10 minutes

before booting and

connecting fans.

Once core tempera-

ture have reached

~ 8 5 - 9 0 ° C , d e -

activate all burn

programs and shut

down computer;

allow to cool for at

least 20 minutes

before booting and

plugging in pump.

Page

Heat Sinks

40

50

60

70

80

90

100

0123456

Time (minutes)

Average Core Temperature

(°C)

#1

#2

#3

#4

#5

#6

Water Blocks

40

50

60

70

80

90

100

0 15 30 45 60 75 90

Time (seconds)

Average Core Temperature

(°C)

#1

#2

#3

#4 #5

#6

Table of contents