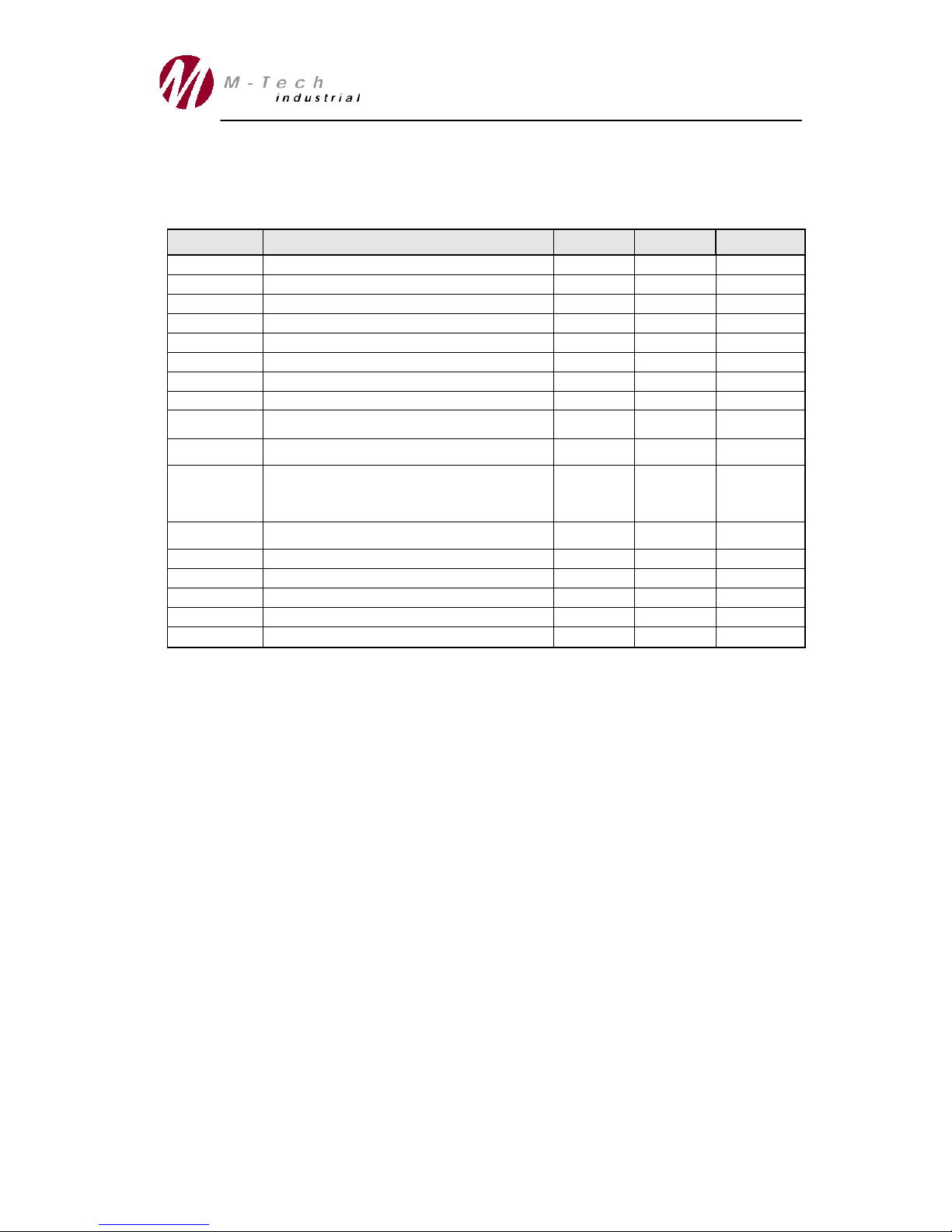

Enerflow Eskom ERHP-SU14 User manual

Residential Heat Pump

User Manual

Please read this manual before operating the heat pump

July 2010

Page 2 of 13

www.mtechindustrial.com

CONFIDENTIAL

Proprietary Class 2

1. Cautions and Warnings

Caution: Installation and maintenance must only be performed by qualified personnel who

are familiar with local codes and regulations.

Warning: Ensure that the electricity/power supply is switched off before any installation

work begins. Note that electric shock is dangerous and can cause death.

Warning: Ensure that the electricity installation complies with local standards and

regulations. This appliance must be installed in accordance with the national wiring

regulations as contained in SANS 10142.

Warning: Do not turn off main power supply to the heat pump during a vacation or if not in

use. The heat pump must have electricity in order to protect itself during cold climate

conditions. It is recommended that the target temperature be set to 25 °C in order to save

electricity.

Warning: Do not turn the unit off and immediately on again. Allow 30 seconds for the

refrigerant pressure to equalize.

Caution: There are some sharp edges within the unit that may cause injury.

Caution: Note that the unit contains a rotating fan that may cause injury if the protective grid

is removed. Ensure not to touch or work on the unit while in operation.

Warning: This appliance is not intended for use by children or other individuals with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge.

Page 3 of 13

www.mtechindustrial.com

CONFIDENTIAL

Proprietary Class 2

2. Heat Pump Controller Functions

2.1 Controller and Button Functions

The heat pump makes use of an intelligent controller and LCD display screen. The LCD screen is

used to change or view different operating parameters. The controller contains the following

interface and keyboard buttons:

Heating with Heat

Pump

Heating with Electric

Element

Water Tank

Temperature

Active Timer

Time

Page 4 of 13

www.mtechindustrial.com

CONFIDENTIAL

Proprietary Class 2

2.2 Heating Mode

Once the system is switched on at the main power, the intelligent controller will go into initialization

mode for a few seconds after which the time will be displayed as 00:00. The unit is now ready for

operation.

1

2

M

Press to turn on and

turn off the unit

Press to change

modes

Press to set operation parameter

during standby status, or check the

operation parameter under running or

standby status

Press to enter

timer setting

Note:

The user can select between two heating modes by simply pressing

1. Normal heating mode (heat pump only)

2. Fast heating mode (heat pump and electric element)

Warning: Do not turn off main power supply to the heat pump during a vacation or if

not in use. The heat pump must have electricity in order to protect itself during cold

climate conditions. It is recommended that the target temperature be set to 25 °C in

order to save electricity in periods of non use.

Page 5 of 13

www.mtechindustrial.com

CONFIDENTIAL

Proprietary Class 2

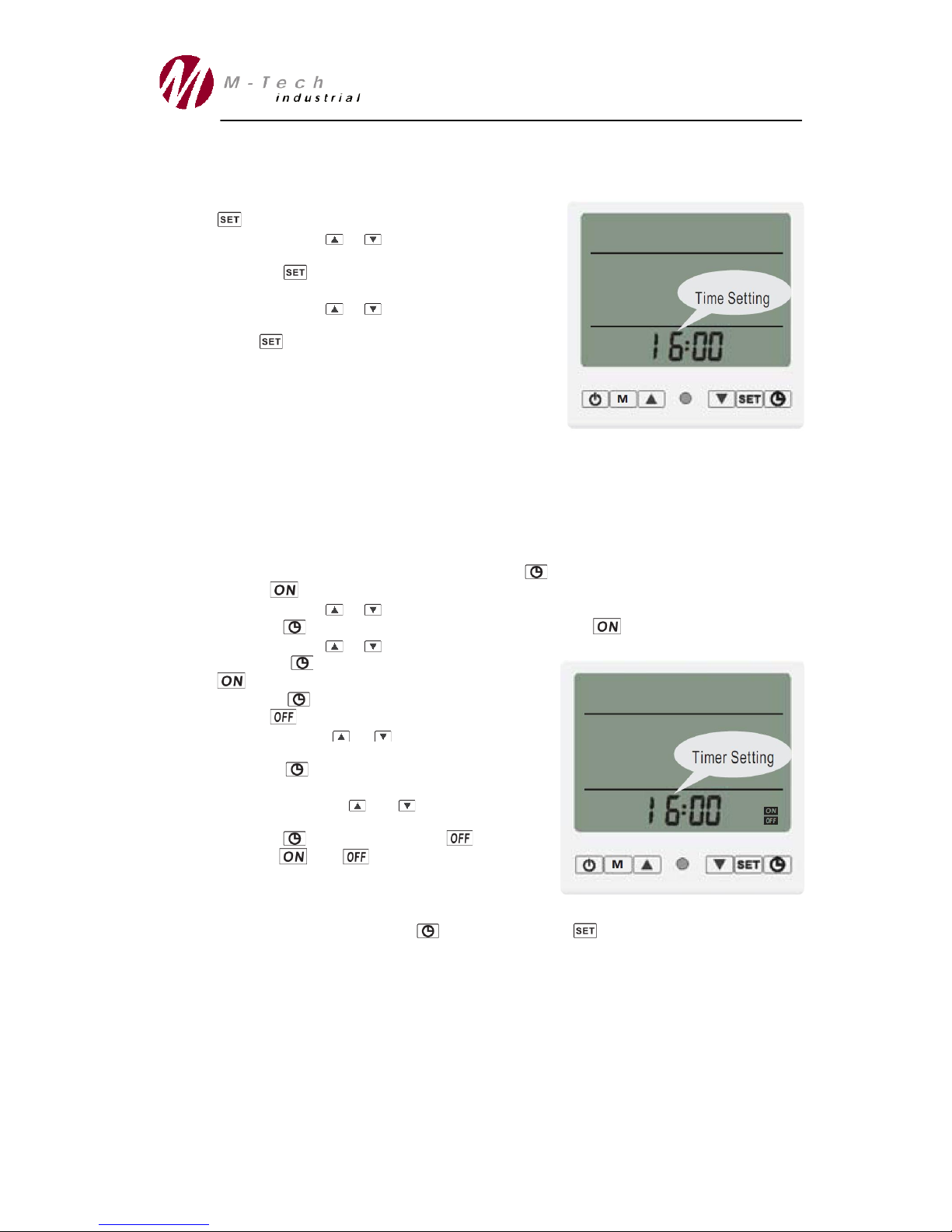

2.3 Time and timer function

In order to set/change the time, use the following procedure:

During the standby or running mode, press the

button once so that the Hour position flashes.

Make use of the or button to change the

Hour parameter.

Press the button so that the Minutes position

flickers.

Make use of the or button to change the

Minutes parameter.

Press to acknowledge the setting. Two beeps

will then sound to confirm the change.

Timer Function:

To select a period when the heat pump should not be in operation, such as during high electricity

demand in the household due to other appliances or during the night, the timer function can be

used to keep the heat pump switched off. In order to set the timer, use the following procedure:

During the standby or running mode, press the button twice so that the hour parameter

and the sign flashes.

Make use of the or button to set the Hour parameter.

Press the button so that the Minutes position and the sign flashes.

Make use of the or button to set the Minutes parameter.

Press the button to confirm the heat pump

time.

Press the button so that the Hour parameter

and the sign will flash.

Make use of the or button to set the Hour

parameter.

Press the button so that the Minutes position

flashes.

Make use of the or button to set the

Minutes parameter.

Press the button to confirm the time.

Both the and signs will be displayed on

the LCD screen, indicating that the timer function

is active.

Note:

To cancel the timer function, press the button and then the button.

Page 6 of 13

www.mtechindustrial.com

CONFIDENTIAL

Proprietary Class 2

2.4 Heat Pump Operating Parameters

Some of the heat pump control system operating parameters can be changed by the user if

required. The function and range of all the parameters are explained in the following table:

Parameter

Description

Range

Default

Remark

0

Return Water Temperature (Control Purposes)

12 °C

Factory Set

1

Target Water Temperature*

25 - 75 °C

40 °C

Adjustable

2

Defrosting Interval

30 - 90 min

40 min

Adjustable

3

Start Temperature for Defrosting Mode

-30 - 0 °C

-7 °C

Adjustable

4

Stop Temperature for Defrosting Mode

2 - 30 °C

13 °C

Adjustable

5

Defrosting Time

1 - 12 min

8 min

Adjustable

6

Installer function

-

10

-

7

Auto Restart Modes (Control Purposes)

-

1

Factory Set

8

Heating Mode (Control Purposes)

-

0

Factory Set

9

Micro Circulation Function (Off = 0; On = 1)

0 - 1

1

Adjustable

A

Set Temperature Difference - Difference

between water temperature and set temperature.

(The smaller the difference, the more frequently the

heat pump restarts)

1 - 5 °C

4

Adjustable

b

Excessive temperature difference between inlet and

outlet water. (Control Purposes)

13

Factory Set

c

Current Water Temperature in Tank

-9 ~ 90 °C

Output value

D

Water Outlet Temperature

-9 ~ 90 °C

Output value

E

Coil Temperature 1 (value for automatic control)

-9 ~ 90 °C

Output value

F

Coil Temperature 2

-9 ~ 90 °C

Output value

10

Ambient Temperature (value for automatic control)

-9 ~ 90 °C

Output value

* A maximum water temperature of 55°C can be reached by the heat pump alone. However, if the target temperature is set

between 55°C and 75°C the electric heater will be activated above 55°C to reach this temperature.

Remarks:

Parameter 1 –It is advised to set the target temperature at 55°C.

Parameter 2 –Interval between two defrosting operations. When ambient temperature is

lower, set this at a shorter interval for better performance.

Parameter 3 –The temperature setting at which the heat pump will start the defrosting

cycle. When ambient temperature is lower, set this temperature higher for complete defrost

of the heat pump evaporator.

Parameter 4 –The temperature setting where the defrost cycle is stopped. When ambient

temperature is lower, set this temperature higher for complete defrost of the heat pump

evaporator.

Parameter 5 –Defrosting time. When ambient temperature is lower, set this temperature

higher for complete defrost of the heat pump evaporator.

Page 7 of 13

www.mtechindustrial.com

CONFIDENTIAL

Proprietary Class 2

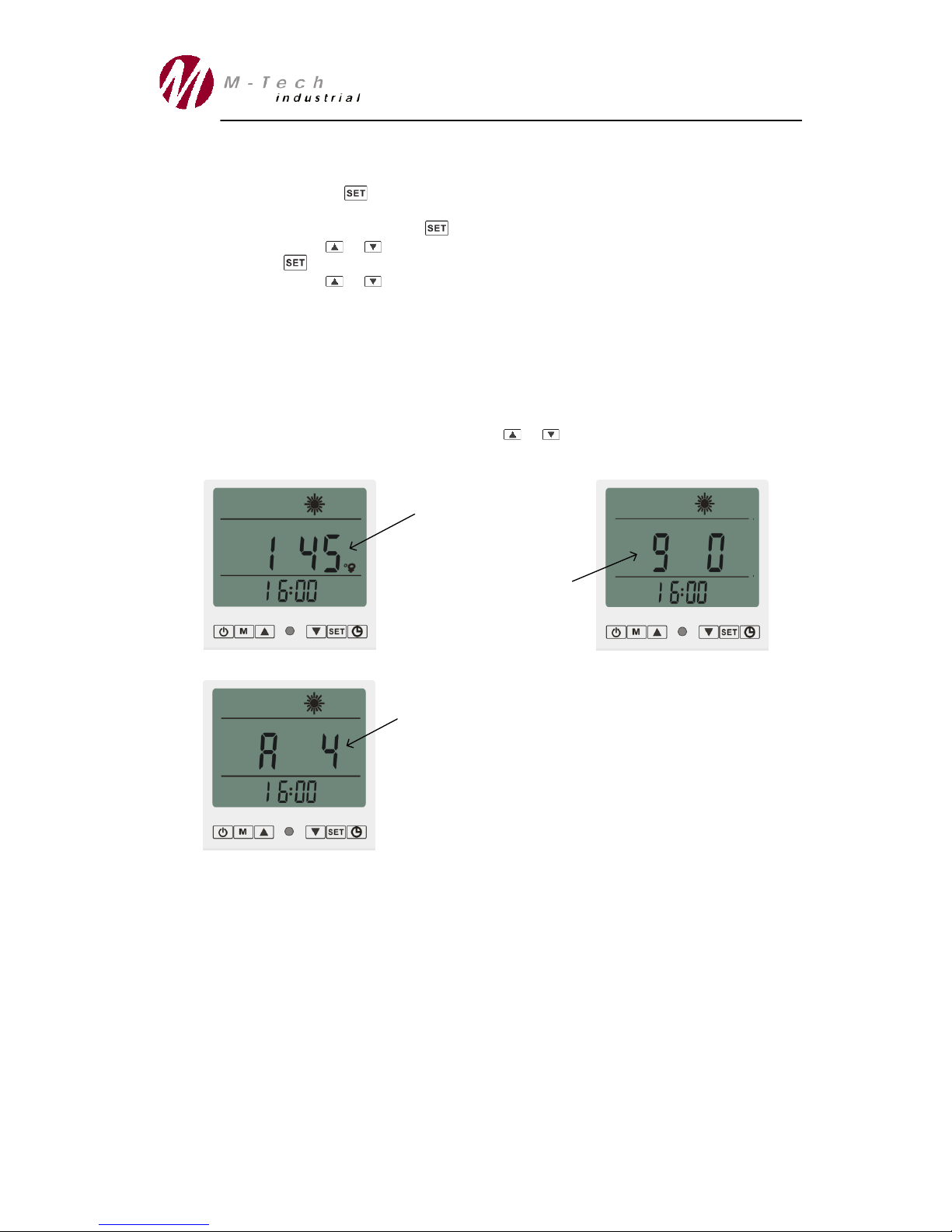

To access and change these parameters follow the steps below:

1. Press and hold the button for a few seconds when the unit is in standby mode (i.e. not

busy heating the water). Parameter 0 will flicker.

2. To change this value, press the button once.

3. Make use of the or button to change the value accordingly.

4. Press the button to confirm the setting.

5. Make use of the or button to select between the different operating parameters.

6. To change the values of these parameters, repeat steps 2 to 4.

7. Wait 5 seconds to exit this mode automatically.

Note:

The water temperature measured near the bottom of the water vessel is displayed on the

LCD screen continuously. The temperature displayed will drop as water is consumed and

cold water fills the vessel from the bottom.

If the target temperature needs to be changed, parameter 1 can be modified as explained

above or else the user can simply press the or button.

Target Water Temperature

Micro Circulation Function

0 = function off; 1 = function on

Temperature Difference between Target Temperature and

Measured Temperature before Heat Pump Start:

1°C = Heat Pump Starts More Frequently

5°C = Heat Pump Starts Less Frequently

Page 8 of 13

www.mtechindustrial.com

CONFIDENTIAL

Proprietary Class 2

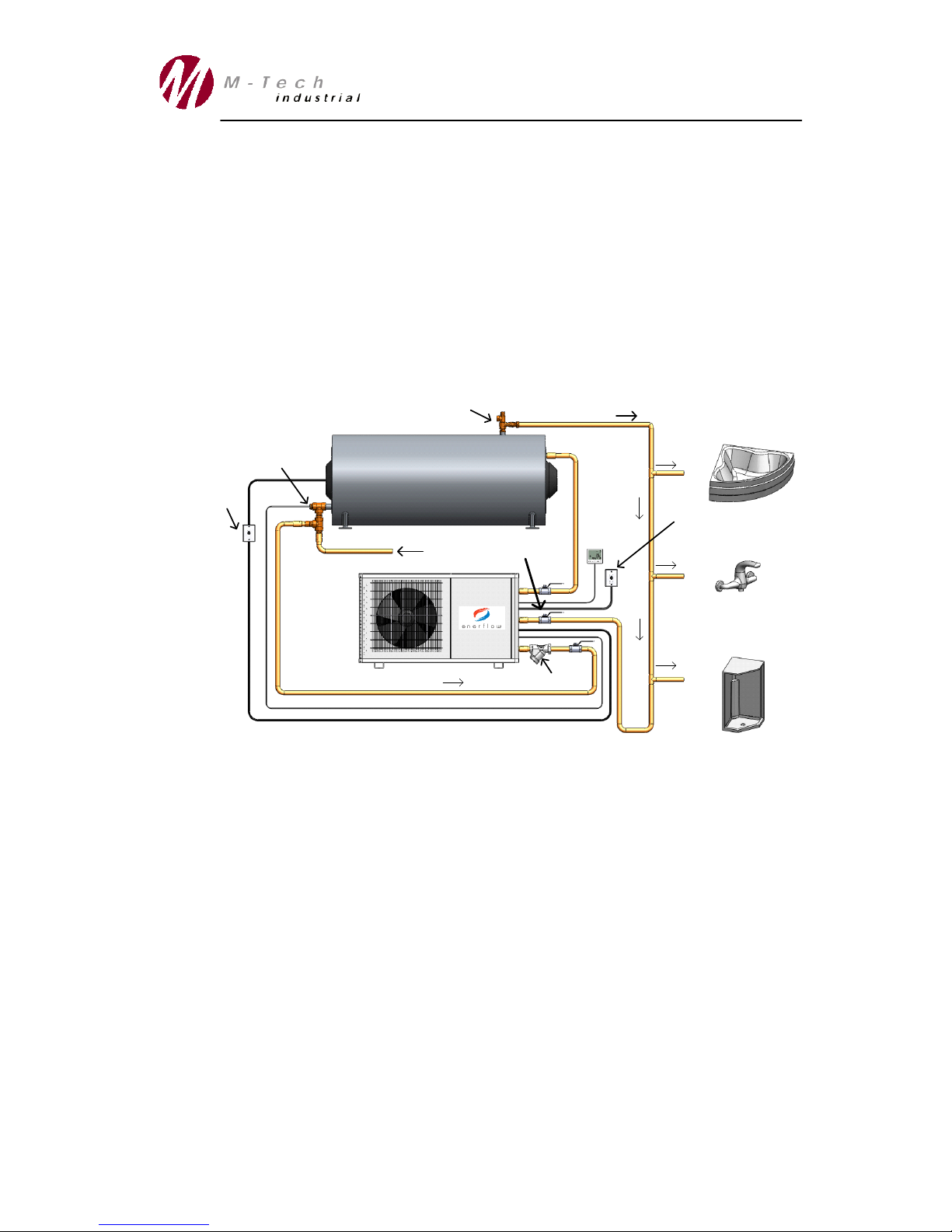

Micro Circulation function:

Note: All plumbing installations must comply with local standards and regulations. Refer to SANS

10254. The drawings below do not show additional components such as pressure control valves,

vacuum breakers and draincocks.

Your Enerflow heat pump has the functionality of heating a central, ring-main water distribution pipe

line. This function is used to ensure that hot water is supplied throughout the residence as an

instant hot-water-on-tap solution. The installer will ensure that the commissioning valve on the

return line is set on 10% bypass. Activate the micro circulation function by changing Parameter 9

to the value of 1 (as described in the previous section) on the intelligent controller. With this

function enabled, the water pump will run for 40 seconds during the period set in Parameter B

(adjustable between 1 and 60 minutes).

Hot Water Outlet

Safety Valve

Cold Water Inlet

Heat Pump

Temperature Probe

Main Power Supply

to Field Isolator

Field Isolator

Strainer

Flow direction

Commissioning Valve

Page 9 of 13

www.mtechindustrial.com

CONFIDENTIAL

Proprietary Class 2

3. Troubleshooting

Note: Please make use of the following table to do troubleshooting if an error or fault occurs. If the

problem persists shut down the system and switch off the main power supply and contact your

installer for assistance.

FAULT/ERROR

POSSIBLE CAUSES

CORRECTION/REMARK

Heat pump does not start

1. Main power supply off

2. Circuit breaker off

3. Heat pump protection imposed

(error message as below)

4. Loose electrical connections

5. Unit failure

1. Check power supply.

2. - Test for a electric leak/short-circuit

- Reset the circuit breakers

- Check that all electric components

have been installed correctly.

(Note: Do not work on electrical

components if you are not qualified.)

3. Identify the protection type and

correct the fault.

4. Check wiring connections and tighten

the terminal screws.

Fan does not work

1. No power supply

2. Fan motor fault

3. Loose connection

4. Obstruction

1. Check power supply.

2. Check if the fan rotates freely and

that no restrictions are present.

Replace if broken.

Heat pump works with

insufficient heating

1. Finned coil is dirty

2. Obstacle blocks air inlet/outlet

3. Insufficient refrigerant in heat

pump gas cycle

1. Clean the finned coil.

2. Remove the obstacle.

3. Add refrigerant (By Technician).

PP1

1. Water inlet temperature sensor

failure

1. Contact installer to check

connections and replace sensor if

required.

PP2

1. Discharge gas temperature sensor

failure

1. Contact installer to check

connections and replace sensor if

required.

.PP3

1. Coil temperature failure

1. Contact installer to check

connections and replace sensor if

required.

PP5

1. Room temperature failure

1. Contact installer to check

connections and replace sensor if

required.

PP6

1. Electricity leakage protection

1. Switch off main power supply to the

heat pump, wait 30 seconds and switch

on again. If the problem persists, please

contact your installer.

PP7

1. Anti-frosting protection in winter

1. Ambient temperature too low .

Page 10 of 13

www.mtechindustrial.com

CONFIDENTIAL

Proprietary Class 2

EE1

1. High or Low pressure protection

2. Possible airlock in the water pump

3. Insufficient water supply

1. Switch off main power supply to the

heat pump, wait 30 seconds and switch

on again. If the problem persists, please

contact your installer.

2. Clean strainer and open a hot water

tap to flush/prime the water lines

3. Ensure that the fan is not restricted

by dirt or leafs.

4. Check main water supply pressure

EE2

1. Over current protection

1. Switch off main power supply to the

heat pump, wait 30 seconds and switch

on again. If the problem persists, please

contact your local installer.

EE3

1. Water switch failure

1. Switch off main power supply to the

heat pump, wait 30 seconds and switch

on again. If the problem persists, please

contact your local installer.

EE8

1. Communication failure

1. Reconnect LCD display unit.

2. Switch off main power supply to the

heat pump, wait 30 seconds and switch

on again. If the problem persists, please

contact your local installer.

Defrosting Sign Indicating

1. Defrosting failure

1. Defrosting sign will show

permanently on LCD screen.

2. Switch off main power supply to the

heat pump, wait 30 seconds and switch

on again. If the problem persists, please

contact your local installer.

Please note the following:

1. Outdoor temperature, water inlet temperature and parameter settings may affect the

performance and power consumption of the heat pump unit.

2. Make sure that the heat pump air duct is not blocked

3. If the ambient temperature is too high, the fan may stop in order to protect the system. The

heat pump will however still provide hot water to the geyser tank. If the temperature

decreases the fan will restart again.

4. If the unit goes into the defrosting mode the fan may stop. Once the coil temperature is

high enough the fan will restart.

5. Make sure that the unit is well ventilated and that no cold air is redirected back into the

evaporator (i.e. do not install the heat pump in small enclosed room where it may re-

circulate the cold air given of).

6. Make sure that all the isolation valves are open before the heat pump is started

Page 11 of 13

www.mtechindustrial.com

CONFIDENTIAL

Proprietary Class 2

4. Service and Maintenance

Service and maintenance operations should be carried out by

qualified personnel who are well trained within the refrigeration

engineering field.

Although your Enerflow heat pump is a self contained and reliable means

of providing eco-friendly hot water, some maintenance and service

needs to be performed. The following items should be checked:

The airway of the fan and the evaporator needs to be cleaned six monthly to ensure effective

airflow and heat transfer. Remove items such as cobwebs, leafs and the like. Do not use a

high pressure water hose to spray down the unit, the heat exchanger fins may be damaged.

The strainer should be checked regularly, especially two days after initial installation. This is

done by removing the bonnet of the strainer with a spanner and removing the strainer element

(sieve). The strainer element can be flushed under running water before reinserting it and

closing the bonnet again.

Bonnet

Strainer Element

Ensure that the water supply is sufficient at all times.

No maintenance needs to be performed on the internal components of your Enerflow heat

pump.

The unit is designed with a close loop gas cycle that does not need short term maintenance or

service under normal operation.

Ensure that the system is drained completely of water if it is not going to be used in the winter

in order to avoid a pipe burst/damage due to freezing.

Page 12 of 13

www.mtechindustrial.com

CONFIDENTIAL

Proprietary Class 2

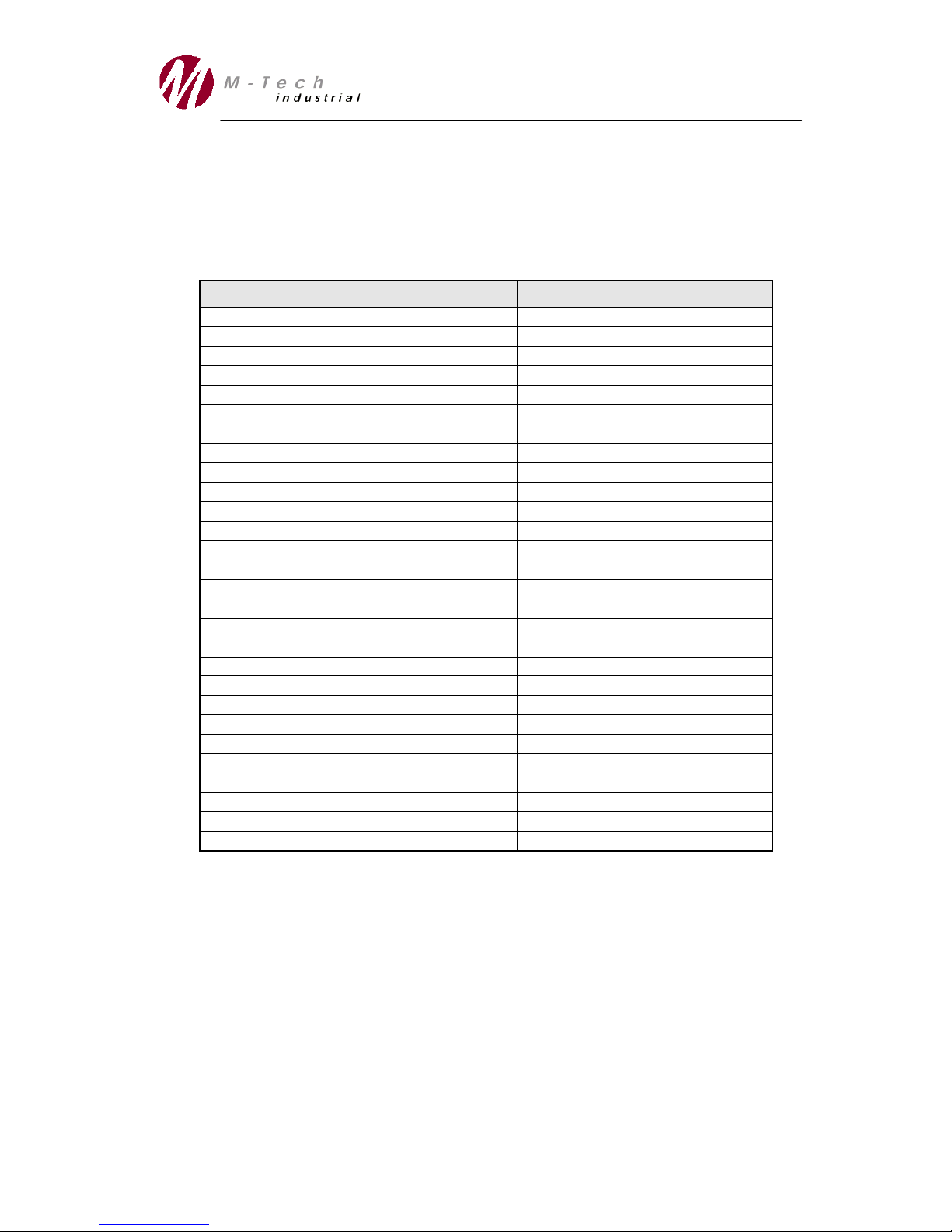

5. Performance Specifications

Unit may be improved or technical data may be modified without prior notice. For

specific technical parameters, please check the plate on the side of the unit.

5.1 Model ERHP-SU14

ITEM

UNIT

VALUE

Model range

ERHP-SU14

Refrigerant

R407C

Mass of Refrigerant

g

1100

Power Supply –Voltage

V

230/1ph

Power Supply –Frequency

Hz

50

Heat Pump Rated Current

A

6.2

Heat Pump Rated Power Supply

kW

1.4

Coefficient of Performance (COP)

W/W

3.5 *

Electric Heater Rated Current

A

9

Electric Heater Rated Power Output

kW

2 **

Water Temperature Setting Range

°C

30 ~ 55 ~ 75 ***

Maximum Water Temperature

°C

75

Highest Ambient Temperature

°C

43

Lowest Ambient Temperature

°C

-5

Water Tank Allowable

L

100 –500

Maximum Water Pressure

MPa

0.7

Discharge Pressure

MPa

2.8

Suction Pressure

MPa

0.5

Inlet and Outlet Water Pipe Diameter

Inch

1/2"

Protection against water class

IPX4

Noise Level

dBA

60 ***

Net Weight

kg

65

Net Dimension

w x d x h

953 x 360 x 555

Packing Dimension

w x d x h

1013 x 380 x 575

Note:

* Testing condition: Ambient Temperature DB 20°C / WB15°C.

Water outlet temperature 55°C.

** Size the electric heater by considering the volume of the water tank.

*** Water temperature can reach 55°C by the heat pump alone. However if the water

temperature needs to reach 75°C the electric heater will be activated.

*** Noise level was tested in ARI Standard Acoustic Room.

Page 13 of 13

www.mtechindustrial.com

CONFIDENTIAL

Proprietary Class 2

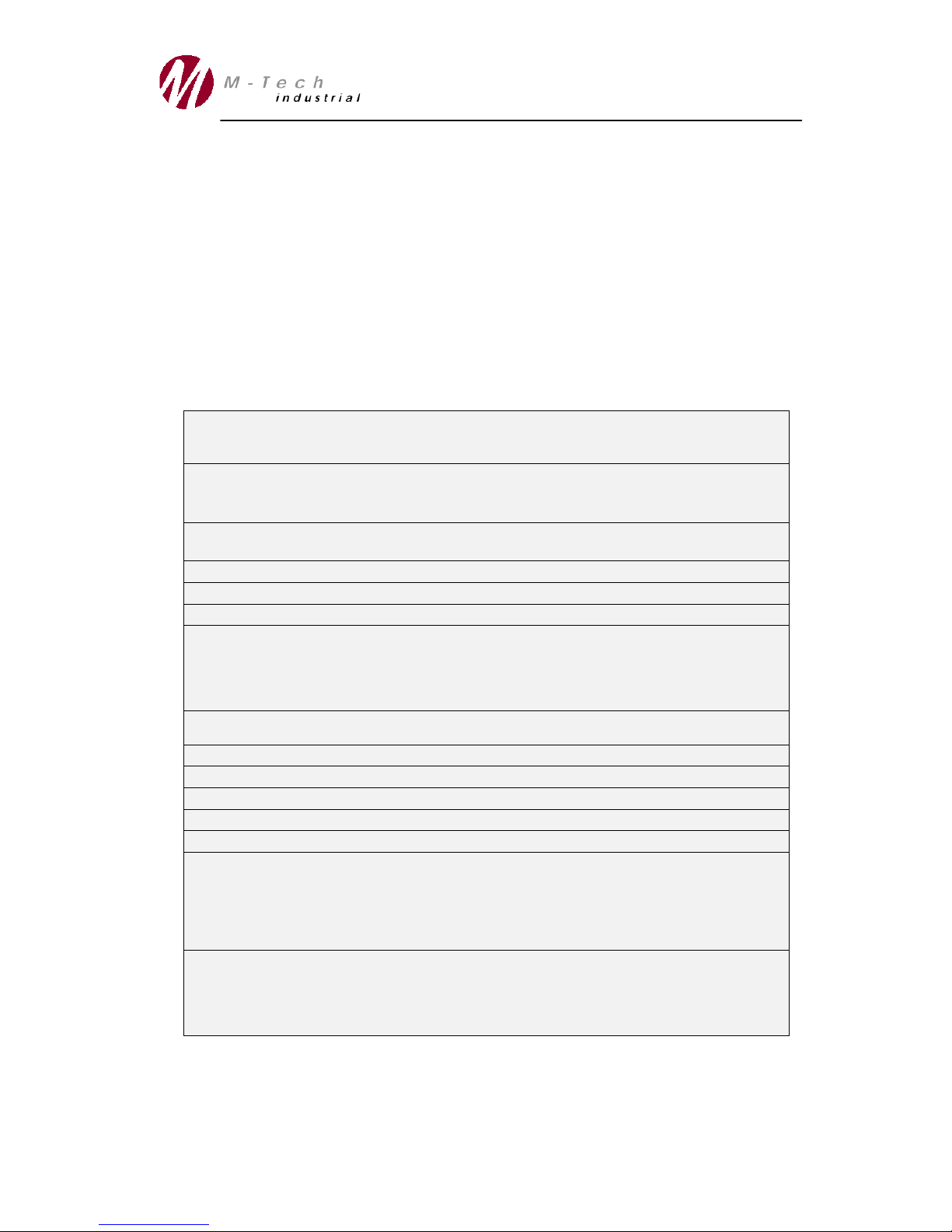

6. Installation Handover

Once the installation is complete and the system tested, make sure that the

client understands the operation and safety requirements of the heat pump.

All repair and service work that needs to be performed to this product must be

done by a qualified person.

Ensure that the details of the certificate below are completed by both the client

and the installer to ensure the warranty on the heat pump unit is valid.

Please keep this certificate safe for warranty purposes.

Residential Heat Pump - Installation Certificate

Date: Heat Pump Serial Number:

Installer Detail

Company Name: Reference Number:

Surname: Name:

Tel:

Signature:

Client Details

Surname: Name:

Address:

Suburb:

City:

Tel:

I (the undersigned) acknowledge that the installation was completed and tested. I confirm

that the installer has shown me the workings and operation of my Enerflow heat pump. I

also understand the operation and safety requirements for this heat pump unit.

Signature:

Table of contents

Other Enerflow Heat Pump manuals

Popular Heat Pump manuals by other brands

REMKO

REMKO WKF Series Electrical Wiring Manual

Nibe

Nibe S1155 Installer manual

Gree

Gree GUD24W2/D-D(U) Service manual

STIEBEL ELTRON

STIEBEL ELTRON WPL 33 HT S Operation and installation

Johnson Controls Unitary Products

Johnson Controls Unitary Products BHZ024-060 installation manual

Mitsubishi Electric

Mitsubishi Electric PUZ-HWM140HA Series installation manual

Ariston

Ariston NIMBUS M NET user manual

Heat Controller

Heat Controller VMH C Series Service manual

Regulus

Regulus CSE2 MIX F W 1F Installation and operation manual

Rheem

Rheem RKNA SERIES installation instructions

GeoSmart

GeoSmart ECO-Y installation manual

Carrier

Carrier 38AH044 38AH044-134 Installation and service instructions