Installation methods

Free from shading

Optimal solar radiation leads to maximum energy yields:

» Set up modules so that they face the sun.

» Avoid shading (e.g. from buildings, chimneys, trees).

» Avoid partial shading (e.g. from overhead lines, dirt,

snow).

» Energetica solar modules can be used up to an altitude of

4000 m.

INSTALLATION METHODS

General information

» To maximize sun exposure, choose an appropriate orien

tation.

» The module must be stored so that the glass faces up.

At the same time, a suitable, water-repellent cover on the

back prevents moisture from penetrating the connector

and creating a security risk.

» To avoid damage, never drop objects on the modules.

Also, never step on the modules, do not subject them

to mechanical stress or deform them through mechanical

stress.

» A suitable distance must be maintained between the

frame of the solar modules and the respective under-

ground, such as roof or floor, in order to avoid damage to

the cabling and to allow air to circulate behind the solar

module. The recommended minimum distance is 100mm.

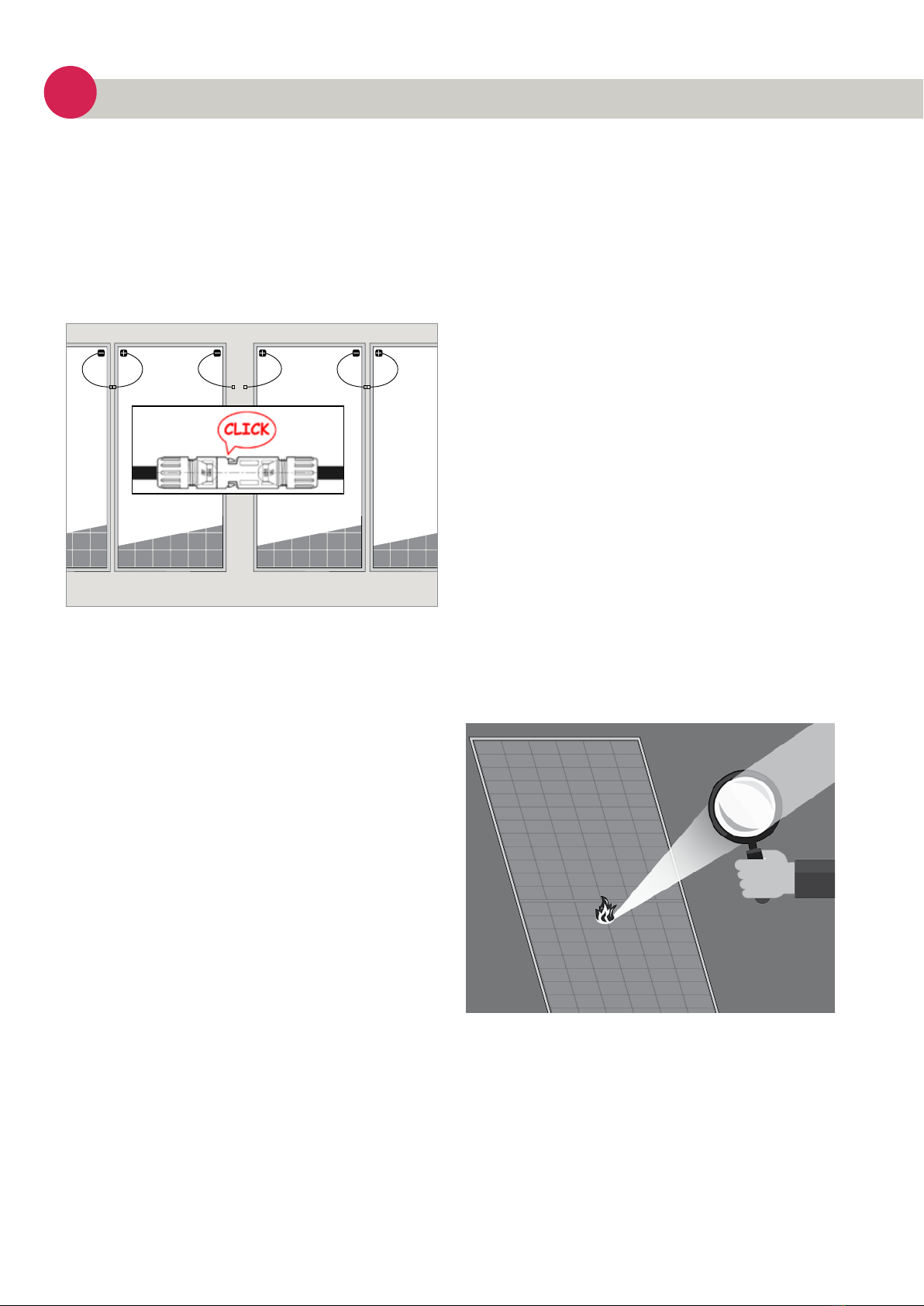

» Modules must never be mounted upside down. Cables

and plugs must always point downwards.

» When installing PV modules in snowy areas, Energetica

Industries recommends taking appropriate measures to

prevent damage to the backside of the frame from sliding

snow. We recommend using corrosion-resistant materials

for such additional structures.

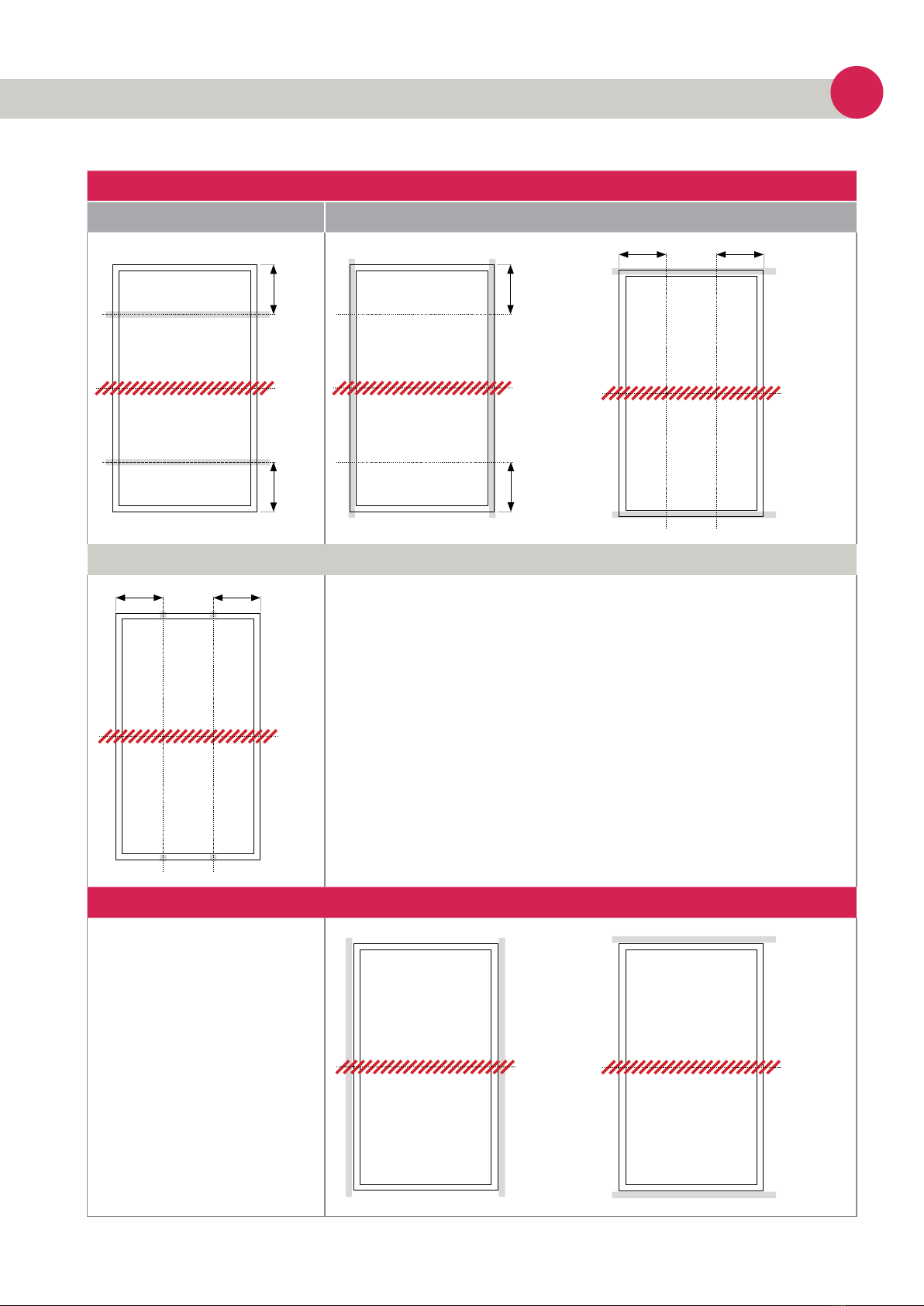

» Each module should be securely fastened at at least four

points on two opposite sides.

» Only use corrosion-resistant parts as installation rails and

fastening material. Use suitable screw or clamp con-

nections as required in the manufacturer's instructions.

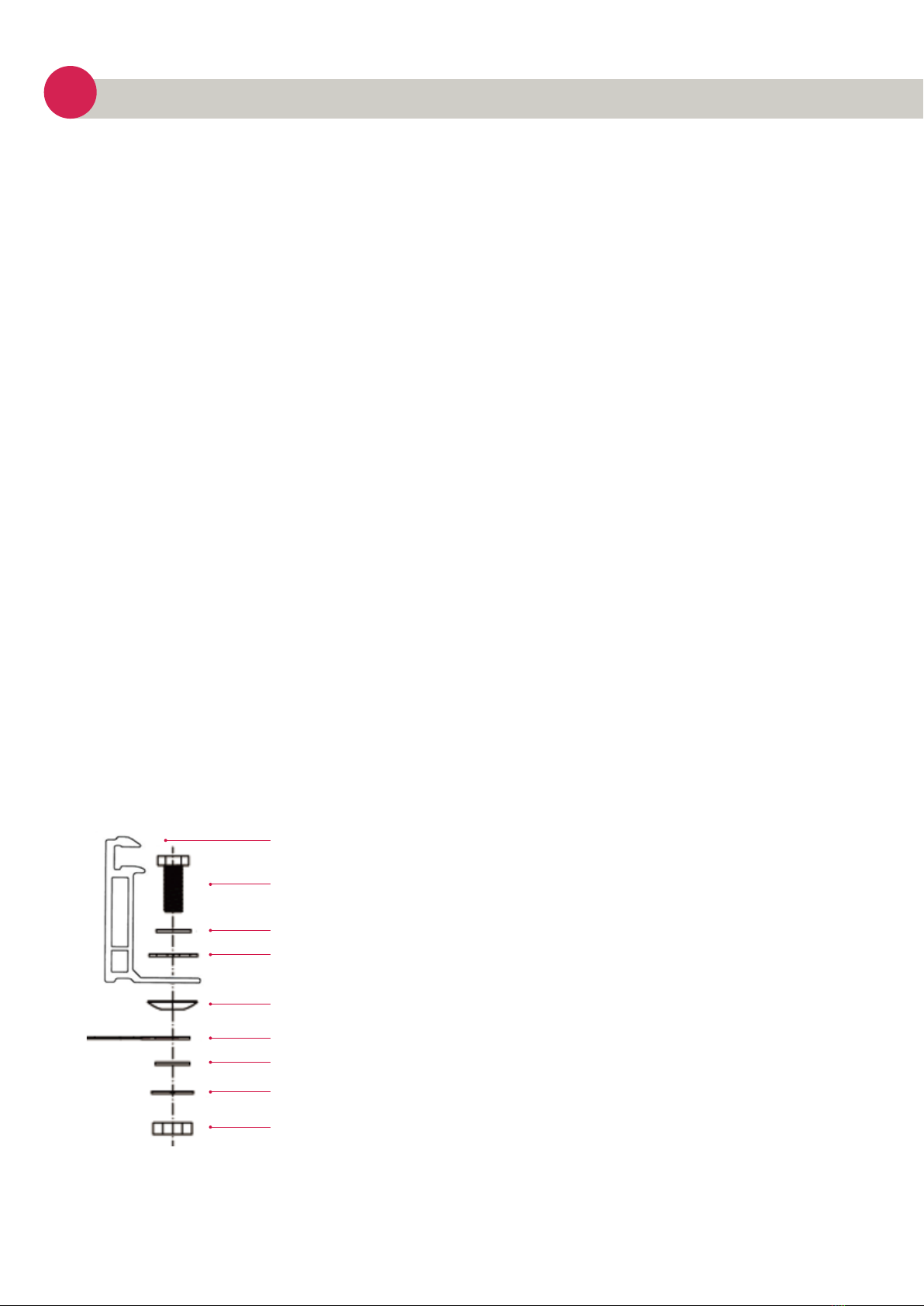

» After installation, there must be no electrical parts (such

as cables) between the laminate and the substructure.

» Make sure that the plug connections are never in the

water.

» Detailed information on the dimensions of the solar

modules and the position of the installation holes can be

found in the “Product Specifications” section.

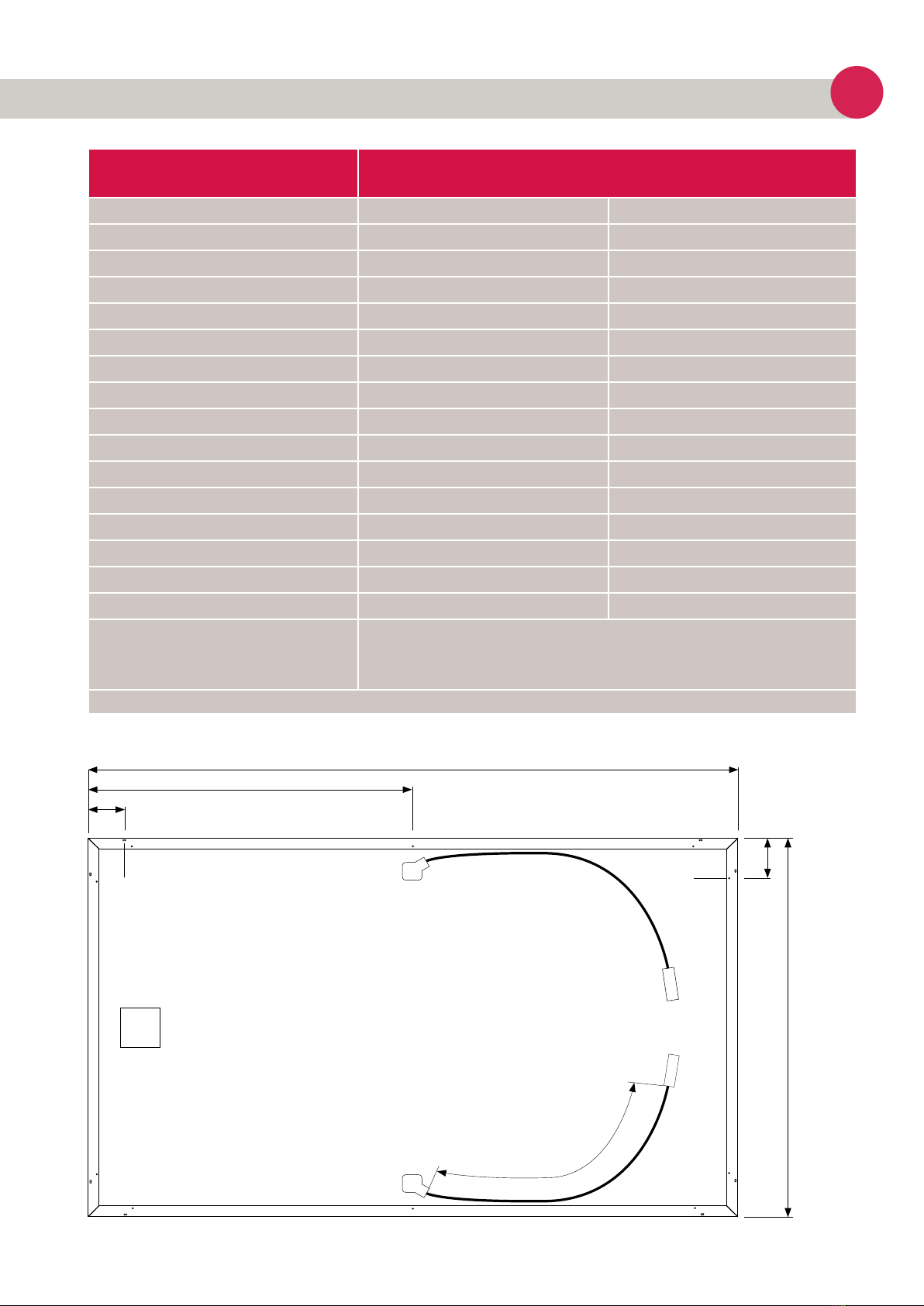

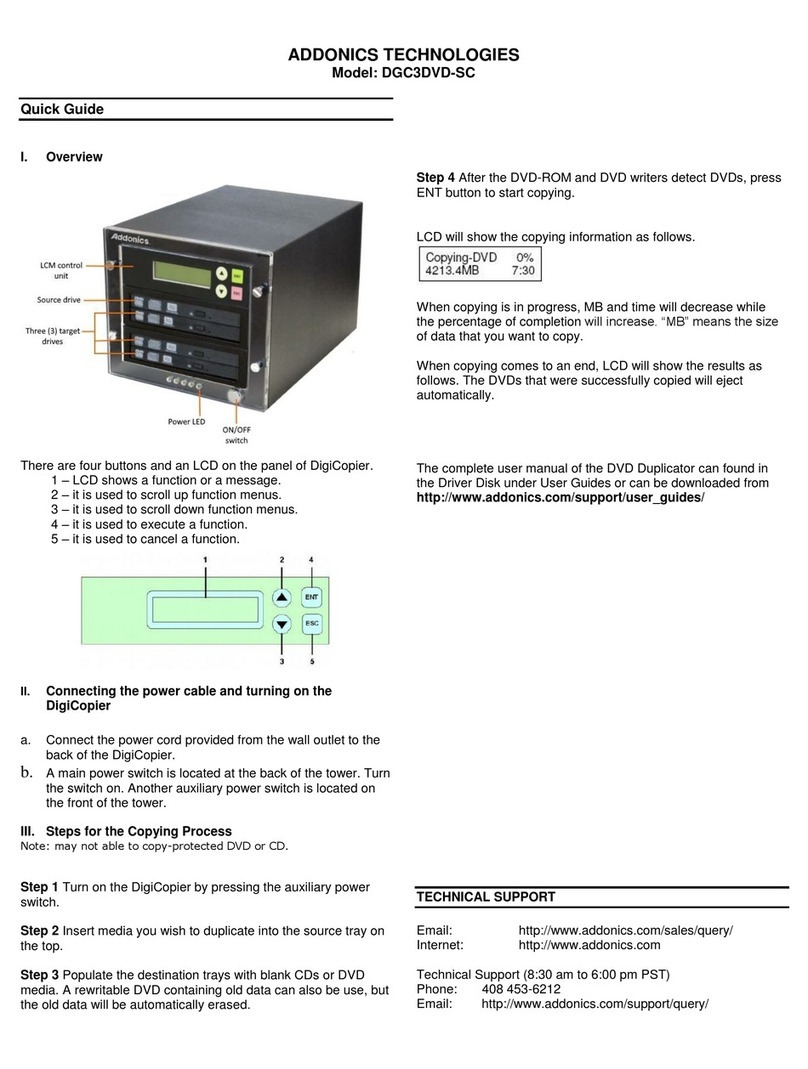

Installation with clamps

» The module can be attached to the substructure on both

the long and the short edge using clamps.

» You can find detailed information about the positioning

of the clamps in the installation options on page 11.

» If you use a special clamp, it must be tested for

compatibility by Energetica Industries.

Planning

Check whether the maximum snow loads of the modules

are suitable for the relevant snow load zone. For zones with

a correspondingly high snow load, we recommend our

e.Prime series with higher mechanical stability.

» Adding additional installation holes can damage the solar

module and affect the stability of the frame.

» We recommend leaving a gap of 10 mm between the

module frames in order to prevent tension due to

thermal expansion.

Disclaimer of liability

» The installer must read and fully understand this

installation manual before beginning the installation

process.

» If you have any questions about the manual or any

concerns, the installer should contact Energetica

Industries and express them.

Recycling

Do not decommission module yourself, but hire a specialist

company. Dispose of the modules in accordance with the

local disposal regulations.

The original foil of the pallet packaging from Energetica

Industries consists of biodegradable and recyclable plastic

and was made from renewable raw materials (corn starch).

Please dispose of the packaging in accordance with the

country-specific disposal regulations.

Page 9

e