Energx Dyna TF6000E User manual

OWNERS MANUAL

60707-023

EA8EL)fiw

-

-

-

-

-

-

-

-

-

-----

--

---

-

--

-

--

---

-

---

-

CORPORATION

READ AND UNDERSTANDALL INSTRUCTIONSIN

THE MANUAL BEFORE STARTING AND OPERATING

THE GENERATOR SET.

USING THIS MANUAL

Congratulations on your choice of an ENERGX gener-

ator set. You have selected

a

high-quality, precision-

engineered generator set designed and tested to give

you years of satisfactory portable service.

To get the best performance from your new engine

generator set, it is important that you carefully read and

follow the operating instruction in this manual.

Should you experience a problem please follow the

"Things To Check" near the end of this manual. The

warranty inthe back of this manualdescribes what you

can expect from ENERGX should you need service

assistance in the future.

PROPER USE AND INSTALLATION

You must be sure your new engine generator set is:

*

Properly serviced before starting

Operated in a well ventilated area

*

Exhaust gases are dispersed safely

Wired by a qualified electrician

Operated only for its designed purposes

*

Used only by operators who understand its

operation

Properly maintained

TABLE

OF CONTENTS

PAGE

INTRO

......................................

I

GUIDE TO PRODUCT SAFETY

................

A1

BASIC INFORMATION

.......................

B1

Specifications..

.........................

B1

Intended Uses

...........................

B1

Restricted Uses

.........................

B1

Unit Capabilities.

........................

B1

Where is Everything Located

..............

82

PREPARING THE UNIT

......................

C1

Unpacking the unit

......................

C1

Oil Requirements

........................

C2

Fuel Requirements.

......................

C2

Battery Installation.

......................

C3

BASIC OPERATION

.........................

Dl

Operating Procedure

.....................

Dl

Connecting the Loads..

..................

D3

Conserver operation

.....................

D3

Low Oil Shutdown Operation

..............

D3

INSTALLATION

.............................

El

Wiring

.................................

El

OPERATOR MAINTENANCE

..................

F1

Engine Care

............................

F1

Generator Care

..........................

F1

Unit Cleaning

...........................

F1

Things to Check before you call for Service

.

F2

.......................

ENERGX WARRANTY

COPY YOUR MODEL AND SERIAL

NUMBER HERE

Noother ENERGX generator has the same serial num-

ber as yours. It is important that you recordthe number

and other vital information here, if you should ever need

to contact us on this unit it will help us to respond to

your needs faster.

MODEL

................

SERIAL NUMBER..

......

DATE PURCHASED

......

DEALER.

...............

GUIDE

TO

PRODUCT SAFETY

This engine generator set has been designed and

manufactured to insure your personal safety. Improper

use can result in potential deadly hazards; from elec-

trical shock, exhaust gas asphyxiation, or fire. Please

read all safety instructionscarefully before installation

or use. Keep these instructions handy for future refer-

ence. Take special note and follow all warnings on the

unit and in the manuals.

CAUTION:

Possible Damage to Equip-

ment.CAUTION notes indicate any con-

[-]

dition or practice, which if not strictly

observed or remedied, could result in

damage or destruction of the equip-

ment.

WARNING:

Personal Danger. WARN-

ING notes indicate any condition or

practice, which

if

not strictly observed,

could result in personal injuryor possi-

ble loss of life.

a

ELECTRIC SHOCK

-

The output voltage pres-

ent in this equipment can cause a fatal electric

shock. This equipment must be operated by a

responsible person.

A. Do not allow anyone to operate the genera-

tor without proper instruction.

B. Guard against electric shock.

C. Avoid contact with live terminals or receptacles.

D. Useextreme care

if

operating this unit inrain or

snow.

E.

Use only three-pronggrounded receptacles and

extension cords.

F. Be sure the unit is properly grounded to an ex-

ternal ground rod driven into the earth.

2.

FIREHAZARD

-

Gasolineandother fuels always pre-

sent a hazard of possible explosion andlor fire.

A. Do not refuel when the engine is running or hot.

Allow the engine to cool at least two minutes

before refueling.

B. Keep fuel containers out of reach of children.

C. Do not smoke or use open flame near the

generator set or fuel tank.

D. Keep afire extinguisher nearbyand know its pro-

per use. Fire extinguishers rated ABC by NFPA

are appropriate.

E. Store fuel only inan approved container, andon-

ly in a well-ventilated area.

3.

DEADLY EXHAUST GAS

-

Exhaust fumes from any

gasoline engine contain carbon monoxide, an odor-

less and deadly gas that must be mixed with fresh

air.

A. Operate only in well ventilated areas.

B

.

Never operate indoors.

C.Never operate the unit in such a way as to allow

exhaust gasesto seep back into closed rooms(i.e.

through windows, walls or floors).

4.

NOISE HAZARD

-

Excessive noiseis not only tir-

ing, but continual exposure can lead to loss of

hearing.

.

A.Use hearing protection equipment when working

around this equipment for long periods of time.

B.Keep your neighbors in mind when permanently

installing this equipment.

5.

CLEANLINESS

-

Keep the generator and surrounding

area clean.

A.Remove all grease, ice,s.now or materials that

create slippery conditions around the unit.

B.Remove any rags or other material that could

create potential fire hazards.

C.Carefully wipe up any gas or oil spills before start-

ing the unit.

D.Never allow leaves or other flammable materialto

build up around the engine exhaust area.

6.

SERVICING EQUIPMENT

-

All service, including the

installation or replacement of service parts, should

be performed only by a qualified technician.

A.Use only factory approved repair parts.

B.Do not work on this equipment when fatigued.

C.Never remove the protective guards, cover or

receptacle panels while the engine is running.

D.Use extreme caution when working on electrical

components. Highoutput voltagesfrom this equip-

ment can cause serious injury or death.

E.When servicing this unit alwaysavoid hot mufflers,

exhaust manifolds,and engine parts.They all can

cause severe burns instantly.

F.Installingand wiring a home-standbygenerator is

not a "do it yourself" project.Consult a qualified,

licensed electricianor contractor. The installation

must comply with all national, state, and local

codes.

SPEClFlCATIONS

*Rating based on gasoline. For LP derate 1O0/0 for

natural gas derate 20%.

**CrankingPerformance at 80 Degree F. 190 CCA.

MODEL

Generator

Continuous Watts'

Volts

AMPs

Receptacles

NEMA 5-15 (120V)

NEMA 5-50 (120V)

N

EMA 6-30 (240V)

Engine

Size

Model

TYpe

Fuel Capacity

Fuel Consumption

Full Load gas

LP

NG

Starting System

Stop System

Low Oil Shutdown

Muffler

Complete Unit

Weight (dry)

Dimensions LxWxH

Dolly Wheels

Owner Must

Provide

Fuel

Oil Type

Oil Capacity

Battery Size

INTENDED USES

1.

These engine generator sets have been designed

primarily for portable use. Receptaclesare provided

inthe control panel on the generator for you to plug

inyour loads (portable appliances and tools). These

generatorsare designedwith full powercapabilities.

See unit capabilities for further explanation.

2. These units require large quantities of fresh air for

coolingof boththe engine and the generator. Fresh

air isdrawn from both the engine end and the gen-

eratorend and isexhaustedat the centerof the unit.

For safety, long life and adequate performance,

these units should never be run in small compart-

ments without positive fresh air flow.

TF4500E TF6000E

4000 5500

1201240 1201240

33.3116.7 45.8122.9

4

4

1 1

1 1

8HP 11HP

195437 254427

See Engine Shroud Above

Recoil For Type

----.--em--m-

41/* GAL

------------.

.87glhr 1.09glhr

6.'/#lhr 7.7#lhr

110CuFtlhr 155CuFtlhr

---------

RecoillElectric---------

--------------

Panel Switch

--------------

-----------------

Standard

-----------------

Super Low Tone with Spark

Arrestor

160 LBS 199 LBS

29x19~24 29x19x24

.----------.----.

Optional

-----------------

Unleaded Gas or LP or NG

10W-30 for Service SF, SE,

SD, SC. See engine manual

for additional info

23/4 Pints

3

Pints

Ul*' Ul*'

RESTRICTED USES

1.

DO NOT removefrom the cradle assembly. Remov-

al of the generator from the cradle assembly may

causeexcessivevibration and damagetothe engine

generator set.

2. DO NOT install and operate these portable genera-

tors in small compartment. (i.e. generator compart-

ment of vehicles, motor homes, or travel trailers)

Thesecompartments will not allow enough free flow

fresh air to reachthe engine generator set for cool-

-

ingandwill allowthe unit tooverheat damagingboth

the engine and the generator. Small compartments

will also develop hot spots where there isvery little

air flow and may cause a fire.

3.

DO

NOT attempt to operate this unit at 50 cycles.

These units are designed and are governedto oper-

ateat 60 Cycles only. Special units are available for

50 cycle operation.

UNIT CAPABILITIES

1. Generator Connections

-

These generators are

equipped with a patented full power feature. This

feature is designed to give the owner full rated

generator output from a SINGLE 120 volt outlet or

a SINGLE 240 volt outlet without the necessity of

having to carefully balance this 120volt load. Con-

ventional generators require splitting the 120 volt

loads and balancing them on two separate power

leads inorder to fully utilize the rated output of the

conventional generator.

FullPowerwindings use extra heavywire sothat

itcan safely carry the entire loadon a single 120volt

circuit. This eliminates the needto split and balance

the 120 volt load to avoid damaging the armature.

The operator usingthis generatorhasthe entire out-

put availablefrom asingle 120volt circuit or a single

240 volt circuit or a combination of 1201240volts cir-

cuits as long as the total load does not exceed the

engine power.

j

,j.

240

VOLTS

!

B!

)

1-

v

v

POWER

WINDING

G3

Fig. B-1

Typical Full Power generator

The followingcurrents(measuredinamps) are pro-

duced at 120volts and 240 volts for Models shown.

AMPS

@

120 VOLT 240 VOLTS

RECEPTACLE ID

MODEL

TF4500E

TF6000E 45.8 22.9

Table B-1

B1

SPECIFICATIONS

(continued)

2.

Starting Electric Motors

-

Electric motors require

much more current (amps)to start them than to run

them. Some moJors,particularly low cost split-phase

motors are very-hardtostart and require5to 7times

as much current to start them as to run them. Ca-

pacitor motors are easierto start and usually require

2to 4times as muchcurrent to start them as to run

them. Repulsion Inductionmotorsare the easiest to

start and usually require 1% to 2% times as much

to start them as to run them.

Most fractional horsepowermotors take about the

same amount of current to run them whether they

are of Repulsion-Induction (RI),Capacitor (Cap), or

Split-Phase(SP) type. The chart below shows the ap-

proximate current required to start and run various

types of sizes of 120 volt 60 cycle electric motors

under average load conditions.

RUNNING Sf

ARTlNG AMPS

HP AMPS SP CAP R

I

116 3.2 16 TO 22 6 TO 13 5 TO 8

114 4.5 22TO32 9TO18 7TO12

113 5.2 26TO35 10TO21 8TO17

112 7.2 NOT MADE 14 TO 29 11 TO 18

1 13.0 NOT MADE 26 TO 52 20 TO 33

and no harm is done. Under these conditions the

motor may revolvea few times when it isfirst turned

on, and then stop.

On the other hand,suppose an electric motor that

requiresjust a little moreoutput than the generator

can produce is connectedto it. It will run but will not

reach a high enough speed for the centrifugal switch

to disconnect the starting winding. The generator

output voltage, instead of being 120, maydrop to 70

or 80 volts. RUNNING THE GENERATOR UNDER

THESE CONDITIONS MAY RESULT IN BURNING

OUT THE GENERATOR ARMATURE AS WELL AS

THE MOTOR WINDINGS.

Because the heavy surge of current required for

starting motors is required for only an instant, the

generator will not be damaged

if

it can bring the

motor up to speed in a few seconds of time. If dif-

ficulty is experienced in starting motors, turn all

other electrical loads off and if possible reduce the

load on the electric motor.

3.

Motor Starting Capacity

-

listed below you will find

the motor starting capability of your engine genera-

tor set.

The figures givenabove are for average loadsuch

as a blower or fan. If the electric motor isconnected

to a hard starting load such as an air compressor,

itwill requiremore starting current. If it isconnected Trying to start a larger motor or a higher code (ie

to a light load, or no load such as a power saw, it

J

or

K)

motor may result indamage to both the gen-

will require less starting current. The exact require- erator and the electric motor, especially 120 volt

ment will also vary with the brand or design of the motors.

motor.

For 240 volt motor, the "running" current is half WHERE IS EVERYTHING LOCATED

as much as shown for the 120 volt motors of the

same size. Some dual voltage 1201240 volt motors

are difficult to start on 240 volts when driven by en-

ginelgeneratorsand can be started more easily when

connectedtooperateon 120volts. This isparticularly

true of "capacitor start-induction run" motors.

Sometimesa 240 volt motor which cannot be started

on the 240 volt circuit of a 1201240volt generatorcan

be started on a 120 volt circuit and then quickly

switched to the 240 volt circuit after it is started.This

can be done in applications where the motor is man-

ually controlled and is started under "no load" con-

ditions.

A self-excited generator responds differently to

severe overloading than atransformer connected to

a power line. To illustrate, suppose that a 240 volt

5

H.P.

"capacitor start-Induction Run" motor iscon-

nectedto a small transformer that would not be able

tosupply enough power to bring the motor up to op-

erating speed. It would be very severely overloaded

and probably would burn out in a short time. The

motor might also be damaged. When this motor is

connected to a self-excited4000 watt generator, its

output voltage drops to practically zero. Thus, there

is virtually no load on the generator or the engine,

1. Starter

2. Battery Positive Connection

3. Battery Negative Connection

4. Fuel Mixture Valve

5.

Vapor Fuel Connection Point

6. Demand Regulator

7. Start Switch

SPEClFlCATlONS

(continued)

PREPARATION INSTRUCTIONS

Gasoline FilllGauge

Muffler

Air Cleaner

Start Switch

Rewind Start Grip

Demand Regulator

Choke

Oil Drain Plug

Oil fill (behind panel)

Control panel

Equipment Damage.

THIS UNIT HAS BEEN SHIPPEDWITH-

-1

OUT OIL. Failure to maintainthe engine

oil at the proper level will result in

serious engine damage.

UNPACKING

-

When you unpack your new ENGINE

GENERATOR be sure to remove all the information

sheets and manualsfrom the carton. Also be sure that

any accessories (suchas battery rack) ordered with the

generators have also been received.

1. This power plant was in good order when shipped.

Inspect the power plant promptly after receiving it.

If damage is noted, notify the transportation company

immediately; request proper procedures for filing a

"concealed damage" claim. Title to the equipment

and responsibility for filing claim rests with you when

a generator is sent F.O.B. shipping point. Only you

the customer, can legally file a claim.

2.

Before proceeding with the preparation of your new

engine generator set for operation, take a few min-

utes to insure that the unit you have received is the

correct model and review the specification pages in

this manual to insure that this unit meets your job

requirements.

3.

After removing the engine generator from the car-

ton locate and remove the shipping strap attached

tothe generator shock mount. See the tag attached

for removal instructions. Fig. C-1showsthe location

of the tag and the shipping strap.

CRADLE

SHIPPING GENERATOR

STRAP MOUNTING

BRACKET

Fig.

C-1

PREPARATION INSTRUCTIONS

(continued)

UNIT PREPARATION

-

Before your engine generator

was shipped from our factory it was fully checked for

performance.The generator was load tested to its full

capacity, and the voltage and frequency were careful-

ly checked and adjusted.

t

1.

Lubrication

-

Beforestarting theengine,fill thecrank-

case to the proper level with a good quality oil. The

recommended grade of oil and quantity of oil re-

,

quired is listed inboththe engine operators manual

and in the specifications section (page B1) of this

manual.

The importance of usingthecorrect oil, and keep-

ing the crankcase full cannot be overemphasized.

Engine failures resulting from inadequate or im-

proper lubricant are considered abuse and are not

covered by Energx or the engine manufacturer's

warranty.

2. Gasoline

fuel

-

When usi,nggasoline always use a

good grade of unleaded fuel. Leaded gasoline may

beuseif unleadedisnot available. Gasolinecontain-

ing alcohol, such as gasohol is not recommended.

Howeverif gasolinewith alcohol isused, it must not

contain more than 10 percent Ethanol and must be

removed from the engine during storage. DO NOT

use gasoline' containing methanol. Always insure

that the fuel is clean and free of all impurities.

FIRE DANGER

Gasoline and its fumes are VERY ex-

plosive when proper precautions are

not taken.

a

Never usegasoline that has been stored for an ex-

tended period of time as the fuel will lose it volatile

properties and you will be left with only the varnish

residue.This varnish likesubstance will clog the car-

buretor and will not burn properly.The useof a fuel

additive, such as STA-BIL,or anequivalent, will mini-

mizethe formation of fuel gumdeposits. If a unit has

beenout of operation for an extended periodof time

itsbest to drain old fuel from the engineand replace

with fresh fuel before attempting to start.

3.

LPlNG

Fuel

-

The information in this section is of-

fered toassist you in providing the propervapor fuel

supply for your engine.This information isonly pro-

vided toadviseyou of the engine's requirementsand

the decisionsyou must make. In no case should this

informationbe interpreted to conflict with any local,

stateor nationalcode. If in doubt, alwaysfollow local

codes.

I

A

Fire Hazard. All fuel lines must be in-

stalled by qualified fuel supplier.

A. LOCATION

The engine-generator models covered in this

manual were designed for portable use. The

manufacturer does not recommend installing or

operatingthis generatorindoors.The unit should

be stored inadry location.Duringa poweroutage

movethe unit outdoors toa flat dry location such

as adriveway, concrete pad or sidewalk for use.

Recommend installing the optiorial dolly kit or

equivalent for ease of handling.

The fuel source' should be close as possible

totheoutdooroperating location.Thiswill reduce

the installation cost of fuel runs. Connect the fuel

supply line to the inlet of the fuel demand regu-

lator on the unit using a locally approved flexi-

blefuel line(seetablefor recommendedlinesize).

The pressuresuppliedtothedemand regulator

MUST BE FOUR TO SIX OUNCES or 7 to 11 IN-

CHESW.C. (watercolumn).The primary regulator

at the fuel supply must be capable of delivering

the proper volume of fuel at this pressure. (See

specification on age A1 for fuel requirements.)

Haveyour local fuel supplier install a protected

fuel connection at the outsideoperating location.

He should also install a lockable fuel shutoff

valve at the connection point.

Have your fuel supplier permanently install a

flexible fuel line to the demand regulator on the

engine generator set.

B. INSTALLINGTHE FUEL LINE

A

PERSONALDANGER. Units that are in-

tended to be run unattended MUST

have an electric fuel solenoid installed.

This solenoid MUST be wired to auto-

matically turn off the fuel anytime the

enginestops. Request instruction sheet

60714-009 from your dealer for addi-

tional information.

Unit location will determinethe size of fuel line

that is required to supply the engine with a con-

stant fuel pressure. Refer to the tables below for

fuel linesize, fuel consumption and recommended

tank size. For distances of 100 feet and over, a

two regulatorfuel systemconsisting of a primary

10-15#regulatorat the tank and a

6

ounce secon-

dary regulator installed close to the engine-gen-

erator set. When a two (2)stage regulator system

is used, a fuel line size of 318 inch is generally

adequate for distances up to 300 feet. The line

size from the table below applies to the distance

from the second regulator to the demand regu-

lator. A positive fuel shut-off device must be in-

stalled in the fuel line close to the engine

generatorset. This may be either a lockableman-

ual shut-off valve available from your local fuel

installer, or a 12volt DC fuel solenoid valve. This

optional 12volt DCvalve isavailablethroughyour

local Energx dealer as part number 42942-000.

A

PERSONAL DANGER. Do not use gal-

vanized pipe in fuel line runs. The gal-

vanized coating will become erroded

and flake off,causing possibleobstruc-

tion in the regulator or fuel valve. The

results could rangefrom an inoperative

I

engine to hazardous fuel leaks.

i

PREPARATION INSTRUCTIONS

(continued)

Size of pipe requiredfor generatorsoperatingon natural

gaslLP gas

I

UD

to

25

feet*

25-100

feet* over

100

feet*

I

I

3h"

pipe

1"

pipe not recommended-

use a two regulator

I

system-

I

*

allow an additional

3

feet for each standardelbow. Do

not use 'street ells' (restrictive)*

Be careful when sealing gas joints. Ex-

cessivesealina compound can bedrawn

into the solenoid, regulatoror carburetor

causing an engine malfunction.

C. FUEL PRESSURE

Correct fuel pressure cannot be stressed

enough.The most common cause for inoperative

systems is an inadequate or incorrect fuel pres-

sure. Power and performanceof the engine is in

direct relation to the correctness of the fuel sys-

tem. Shown below is a block diagram of a typical

L.P. or N.G. installation.

1%

PRl REG

H

2nl

REG

H

SOLENOID

M

REGULATOR

OEMANO

H

GENERATORENGINE.SET

1

2

3

4

5

Two Regulator Fuel System

Single Regulator Fuel System

FIGURE C-1

Reference numbers

1

through

4

inthe blockdia-

grams above are fuel lines supplied by customer.

Referencenumber

5

isalready installedonyour

engine generator set.

Rememberthat whichever fuel delivery system

or typeof vapor fuel used, the fuel pressureat the

demand regulator installed on the engine gener-

ator must be between

4

and

6

oz

(7-11

inches of

water column). Any lower pressure and the unit

will starve for fuel under load. Any higherand the

unit will 'flood' when attempting to start.

TANK SIZING

Once above the minimum acceptable size, the

size of L.P. tank used will generally depend on

how longyou want the unit to runwithout refilling.

The tank sizes shown below are the smallest

recommended tank sizes based on the outside

temperature. Keep in mind the colder it gets the

slower L.P. will vaporize. This is the reason for

the largertanks at low temperature. Minimumsiz-

ing is not based on running time.

7

Tank Size

40

Gal.

50

Gal.

125

Gal.

350

Gal.

Tank

60

F.

32

F.

0

F.

-

20

F.

Temp.

16C. OC.

-18C.

-29C.

See Specification section of the fuel consumption

data on each unit.

E. FLEXIBLE FUEL LINE CONNECTION

The fuel line used to connect the supply line,

previouslyinstalled,to the demand regulator must

be a locally approved flexible fuel line. Products

used will vary in different parts of the country

dependingon localcodes.Consult with your local

fuel supplier for proper compliance.

1.

Remove the pipe from the demand regulator.

2.

Connect the flex fuel line to the demand regu-

lator

4.

Battery InstallationandCare -Allelectric start engine

generatorsets are shipped with abattery rack kit for

customer installation. This kit consists of a battery

rack, batterytie down, battery cables and instruction

sheet for installation.After installing the battery rack,

file the instruction sheet in the back of this manual

for future reference.

If you intendto usethe power plant's electric start

system, you will need to purchase and install a bat-

tery to operate it. Unitsequipped with a recoilor rope

start will operate satisfactorily without a battery. A

twelve volt battery group

U1

rated at

190

CCA or

larger is recommended for this electric start engine

generator set. Follow the battery manufacturers rec-

ommendationsfor servicing and charging prior to use.

Connectthe battery to the electric start systems us-

ing the cables provided.

start engines are NEGATIVEGROUND.

-1

Use extreme caution when connecting

the battery to connect the NEGATIVE

Foryour safety always connect the positive bat-

tery terminal tothe "bat

+

"

terminal first. Then con-

nectthe negativebatteryterminal to the "bat

-"

ter-

minal. Make sure all connections are clean and

tight. Reverse the sequence when disconnecting,

disconnect the negative cable first. These engines

produce enough direct current to keep batteries

charged under normal operating conditions, but

they are not intended to be usedas battery charger.

A

PERSONAL DANGER. Lead acid bat-

teries produce explosive hydrogen gas

when charging. Keep sparks, flames,

and burning cigarettes away from the

battery. Ventilate the area when charg-

ingor using the battery inan enclosed

space. Lead acid batteries contain

sulfuric acid, which causes severe

burns. If acid contacts eyes, skin or

clothing, flush well with water. For con-

tact with eyes, get immediate medical

attention.

PREPARATION INSTRUCTIONS

(continued)

Generators, when installedfor standby purposes,

must be run periodically (at least once a month)for

a minimumof

30

minutesto keepthe batterycharged.

A trickle charger can also be used to keep the bat-

tery fully charged. The trickle charger should be a

taper charger (usually

2

amps max).With a taper style

charge as the battery reaches its maximum charge

capacity, the chargercurrent tapersto nearzero and

maintains the battery in a fully charged condition.

Manual type charges with fixed or constant charg-

-

ing ratesare not recommended, since the batterywill

be overcharged,permanently damaging the battery.

5.

Optional Dolly Kit

-

An optional dolly kit is available

for this engine generator set. The dolly kit comeswith

instructions and parts list. After installing the dolly

kit, file the instructions and parts list in the back of

this manual for future reference.

BASIC OPERATION

INITIALSTART UP

-

Usethe following checklist toverify

the correct preparation of your enginegenerator before

starting.

On All Units Check:

A.

Engine oil, fill as required with correct grade and

quantity.

B. Visually check unit for loose parts.

C.Battery connections clean and tight on the electric

start units.

D.Proper battery voltage and amperage hour ratings.

E.Battery fully charged.

On Gasoline Fueled Units Check:

F.Fuel level and fill as required with clean fresh fuel.

On LPlNG Fueled Units Check:

M.Proper fuel pressure and line size.

N.Fuel line protected.

0

.Shut off valve installed.

P.Automatic fuel shutoff installed on units operated

unattended.

BASIC OPERATING CONTROLS

-

Now that you have

completed the initial start up checklist, you are ready

to start and operate your new engine generator set.

Before starting read through the next section which

details whats on the control panel.

FRONT PANEL CONTROLS

STOP

SWITCH

1

NEMA 5-50 NEMA 6-30

120v

-

50 amp40

8

c'-

240v

-

30 amp

d

NEMA 5-15

DUPLEX

120v

-

15

amp

STARTING AND STOPPING

-

The throttle control on

these generators is preset and locked to operate at

3600

RPM (nominal)with no loadspeed set at

3690

RPM. Only

a trained servicetechnician should be allowed to adjust

this speed setting. See "Operating Speed" section for

additional information. Vapor fuel may be hard to start

manually. Recommend using electric start.

1.

Manualstarting

-

Refer to the engine manual for addi-

tional starting, operating, and stopping instructions.

A. Turn on the fuel supply.

B. Move the choke to the full on position. A warm

engine will require lesschokingthan acold engine.

C. Grasp starter grip and pull slowly until starter

engages, then pull cord rapidly to overcome com-

pression, prevent kickback and start the engine.

Repeat if necessary.

D. When the engine starts, open the chokegradually.

E.

The engine should promptly come up to operating

speed.

2.Electric Starting

-

If engine is cold and stiff or if bat-

tery is not fully charged,starting can be made easier

by slowly handcranking the engine throughthe com-

pressionstroke before pushingthe starter button.This

permits the starter to gain momentum before the

heavy loadof the compressionstroke occurs, minimiz-

ing drain on the battery and ensuring starting under

such adverse conditions. Keep the battery fully

charged, especially during cold weather operation

A. Turn on the fuel supply.

B

.Movethe choketo the full on position. A warm en-

gine will require less choking than a cold engine.

Normallychoking is not requiredwith LPlNG vapor

fuel.

C.Depressthe starter switch. The best starter life is

provided by using short starting cycles of several

seconds. Do not operate the starter more than

15

seconds each minute.

D.When the engine starts, open the choke gradually.

E.The engine should promptly come up to operating

speed.

3.

Starting Hints

A. Cold weather

1.

Be sure to usethe proper oil for the temperature

expected.

2

.A warm battery has much more starting capaci-

ty than a cold battery.

BASIC OPERATION

(continued)

3. Use fresh winter grade fuel. Winter grade

gasoline has higher volatility to improve

starting. Do not use gasoline left over from

summer.

4.

A slightly richer fuel mixturewill usually im-

prove cold starting.

B. Hot weather

1. Besureto usethe proper oil for the temper-

ature expected.

2. Use only summer blended gasoline. Using

gasoline left over from winter may cause the

unit to vapor lock, because of the higher

volatility of the winter fuel.

3. Do not over-choke the unit.

4.

Stopping and Storage

A. For gasoline units depress the stop switch.

B. Close the fuel shui-off valve. Always shut the

fuel off whenever the engine isstopped to pre-

vent fuel leakage from carburetor.

C.

Beforeextended storage (over30 days) certain

precautions must be taken to ensure the fuel

doesn't deteriorate and clog the fuel system.

Note: The use of a fuel additive, such as STA-

BIL, or an equivalent, will minimize the forma-

tion of fuel gum deposits during storage. Such

an additive may be added togasoline inthe fuel

tank of the engine, or to gasoline in a storage

container.

1.

Remove the remaining fuel from the fuel

tank.

2.Start the engine and allow it to run until all

the fuel in the carburetor and the fuel lines

has been used up and the engine stops.

3.While the engine is warm drain oil and refill

with fresh oil.

4.

Remove the spark plug, pour approximately

'/2

ounce(15cc)of engineoil intothe cylinder

and crank slowly to distribute oil. Replace

spark plug.

5.Clean dirt and chaff from cylinder, cylinder

head fins, blower housing, rotating screen

and muffler areas.

6

.Store in a clean and dry area.

5.

Changing

Fuel

Types

These engine generator sets are designed to run

on three different fuels; gasoline, natural gas or LP

vapor. They may be easily changed from one fuel

to another.

'

A. FROM GASOLINE TO LPING

1

.Withthe engine runningturn off the gasoline

fuel valve.

2.Run the engine till it runs out of fud.

3.Remove the pipe plug from the demand

regulator.

4.

Install locally approved flexible fuel line.

5.Connect the LPING vapor fuel line.

6.Turn on the vapor fuel valve.

7

.Start the engine.

8.

Apply the load to the generator.

9.

Adjust the fuel mixture valve to smooth the

engine out.

Note:Operating on LPINGvapor fuel for an extended

period of time without liquid fuel in the carburetor

may damage the carburetor float, and needle and

seat. If you plan to convert back to gasoline, we

recommend the float and needle assembly be re-

moved from the carburetor. (Consult a local engine

supplier for assistance.

B. From LPING to Gasoline

1.

With the engine running turn off the LPING

fuel supply.

2. Run the engine till it runs out of fuel.

3. Remove the flexible fuel line from the de-

mand regulator.

4.

Reinstall the pipe plug inthe regulator. (use

thread sealant sparingly)

5.

Check to be sure the gasoline fuel valve is

off.

6.

Fill the gasoline fuel valve.

7.

Turn on the gasoline fuel valve.

8.

Start the engine.

9.

Adjust the loadjet on the carburetor as re-

quired to smooth the engine out.

OPERATING SPEED

-

The engine-generator must be

run at the correct speed in order to produce the pro-

per electrical voltage and frequency.

The outputvoltage should be checked

to insure the generator is working

A

properly prior toconnecting a load to

the generator. Failure to do so could

result in damage to equipment

plugged into the unit and possible in-

jury to the individual.

1.

All engines have a tendency to slow down when a

load is applied. The governor on the engine is

designed to holdthe speed nearly constant. When

the electrical loadconnected to the generator isin-

creased, the engine ismore heavily loaded, and as

a result the speed drops slightly. This slight

decrease in speed, together with the voltage drop

within the generator itself, results inaslightly lower

voltage when the generator is loaded to its full

capacity than when running no load. The slight

variation inspeed also affectsthe frequency of the

output current. This frequency variation has noap-

preciable effect in the operation of motors, lights

and most appliances. However, electronic equip-

ment and clocks will be affected if correct RPM is

not maintained. (See load vs. Output chart.)

Although individual units and models may vary

slightly, the normal voltage and frequency of the

engine-generators described in this book are ap-

proximately as follows, under varying loads:

BASIC OPERATI0

N

(continued)

LOAD

vs.

OUTPUT

Generator Frequency Generator voltage

Load Speed

(Hz)

120V 240V

Applied* (RPM) Recpt. Recpt.

None

3690 61.5 129V 258V

Half

3600 60.0 120V 240V

Full

3510 58.5 115V 230V

'Portion of plant's rated output current.

2.

The speed of the engine was carefully adjusted at

the factory so that the generator produces the prop-

er voltage and frequency. For normal usage, the

speed setting shouldnot bechanged. If the generator

is being run continuously on a very light load, it is

often advisable to lower the operating speed slight-

ly. Whenever making any speed adjustments check

the unit with a voltmeter or tachometer and be sure

the speed is neither too high or low.

The engine must be run at the specified speed at

all times. Lower voltage may damage both the

generator and any load connecting to it. Runningthe

engine at excessively high speeds results in high

voltage, which may significantly shorten the life of

appliances being used.

3.

Output voltageshould bechecked periodically toen-

sure continued proper operation of the generating

plant and appliances. If the generator is not equip-

ped with a voltmeter, it can be checked with a por-

table meter. Frequency can be checked by using an

electric clock with a sweep second hand. Timed

against a wrist watch or a stop watch the clock

should be correct within

+

1-

2

seconds.

CONNECTING THE LOADS

1

.Applying The Load

-

Allow the engine towarm upfor

two or three minutes before applying any load. This

will allow the engine to reach normaloperatingtemp-

erature and oil to circulatethroughout the engine.A

short warm-up time will permit the engine to work

more efficiently when the load is applied and will

reduce the wear in the engine, extending its life.

A. Receptacles have been provided on the control

panel to connect the loads. The loads should be

applied gradually. If a large motor is beingstarted

or multiple motors are being started, they should

be started individually and the largest should be

started first.

Keep the generatorloadwithin the gen-

rm-]

erator and receptaclenameplaterating.

Overloading may cause damageto the

B.Most electric tools and appliances will have the

voltage and amperage requirements on their in-

dividual nameplates. When in doubt consult the

manufactureror a local electrician. The nameplate

amperage rating for electric motors can be mis-

leading, see Starting Electric Motors insection B.

C.

These engine generator sets are inherently self

regulating based on engine speed. The engine

governor will automatically adjust itself to the

load. No harm to the generator will result if it is

run with no.load connected.

D. Proper utilization of the receptacles located on

the control panelisnecessaryto prevent damage

to either the receptacles or the generator. The

generator is a limitedsource of electrical power,

therefore pay special attention to the receptacle

and generator ratings. The nameplate rating can

be obtainedthrough acombination of receptacles

or a single receptacle as long as the receptacle

amperage rating is not exceeded. Both the

120

and

240

volt receptacles can be utilized at the

same time. See section Bfor proper load separa-

tion.

2.Grounding

-

All units must be grounded.

A. Drivea

314

or

1"

copper pipeor rod into the ground

close to the engine-generatorset. The pipe must

penetrate moist earth. Connect an approved

groundclamp,to the pipe. Run a no.

10

AWG wire

from clamp to the generatorground lug or the bat-

tery negativeterminal. Do not connect to awater

pipe or to a ground used by a radio system.

LOW OIL LEVEL SHUTDOWN SYSTEM

1.

BRIGGS

&

STRAlTON PoweredGenerators

-

These

engine generator sets come equippedstandardwith

the Briggs

&

Stratton OILGARD warning system.

A. This low oil warning system will automatically

stop the engine well beforethe oil level reaches

an operational danger point. This feature is de-

signed to prevent costly repairs and downtime.

B. The OILGARD system uses a float inthe engine

crankcase to sensethe oil level. If a low oil level

condition should occurduring operation, the float

will groundout the magneto impulse, "killing" the

engine. In addition, there is an indicator light

mounted on the engine shroud near the recoil

starter. This light will blink on and off to indicate

a low oil level conditionwhen you are attempting

to start the unit. To get the engine started, you

must add the requiredamount of oil tothe engine

crankcase.

C

.Useof the OILGARD systemon applications that

are subject to shock, bumping or severe angles

of operation (inexcess of

15

degrees)should be

avoided. This isespecially true if an unexpected

shutdown would cause asafety hazardor serious

inconvenience for the operator. To disable the

OILGARD, remove the wire attached to the sen-

sor unit mounted on the engine crankcase. The

wire should be insulated with a connector or

tape.

INSTALLATION

WIRING -Wiringthis unit into a homeor'business elec-

trical system isNOTA SIMPLE DO-IT-YOURSELFJOB.

For your safety all wiring must be done by a qualified

electrician and must conform to the National Electric

Code and comply with all state and local codes and

regulations. Check with local authorities before pro-

ceeding.

A

fully isolated, double pole double

throw manual transfer switch must be

installed any time a generator is being

connected to an existing distribution

The engine-generatormodelscovered inthis manual through a fully isolated manualtransfer switch. The

were designedfor portable use. The manufacturerdoes transfer switch prevents damage to the generator

.

not recommend installing or operating this generator and other circuit components if main line power is

indoors. The unit should be stored in a warm dry loca- restoredwhile the generator isconnected. Installing

tion. Duringa power outage movethe unit outdoors to a transfer switch also permitsthe useof normal fus-

A. These engine generator sets are designed for port-

able use. Thereforethe receptacles on the units are

designed to have the 120 and 240 volt portable ap-

pliance and tools plugged directly intothem. Please

note that the 3 wire 240 volt receptacle(s)on these

unitsare designed to provideonly 240 volts as there

is no neutral connection in the receptacle.Split ser-

vice 1201240volts requires a 4 wire receptacle be in-

stalled. Consult a service center or your dealer for

installation.

To connect one of these units directly to an emer-

gency distribution panel select one of the following

methods:

1. Wire the distribution panel directly to the gener-

ator output brush holders using afine strand(flex-

ible) motor lead wire.

2.Replace the 240 volt receptacle on the unit with

a 1201240 four wire twist-lock receptacle. (Nema

Spec L14-30R)The useof locking receptaclesand

locking plugs will prevent the plug from being ac-

cidentally removed by bumping or vibration, caus-

ing a voltage imbalance or interruption.

.

When installingthe L14-30Rreceptacleinplace

of the current 240 volt receptacle the neutral wire

will have to be routed to the 120 volt receptacle

currently inthe unit. The "hot" leads(GI and G3)

and the ground are already connected to the ex-

isting receptacle.

B. Connect generator to house wiring circuits only

a flat dry location such as a driveway or a sidewalk.

If your home wiring has not been modified and a

manual transfer switch installed (Fig.E-1)you will have

to plugyour appliances such as furnace blower, sump

pump and other items to be powered directly into the

generator receptacles.

Beforebeginning the wiring installation recheckthe

ratingof the generator set. Be certain it can handlethe

intended load and is compatible with the entrance

voltage, phaseand current ratings. These suggestions

are not intended to constitute recommendations or

guarantee of satisfaction or pe,rformance.

To Power L~neMaster Swvlch

Emergency

Power

System

To Range

To

Water

Healer

To Ltghls

TO L~ghls

TO Llghls

-

L-

-

-

-

-

--

J

Figure

E-1

Typical Generator To House Wiring

ing. See figure E-1 for typical wiring examples.

C.Since most homes today are wired with at least a

100 amp service, when operating the generator to

power the homea secondary emergency distribution

panel must be installed. The circuits tobe powered

during the outage are movedto that panel. Keep in

mind that only a limited amount of amperage avail-

able. Some breaks will have to shut off to prevent

an overload on the generator during initial start up

of the unit. See the specification page for the

amperage available on your generator.

EQUIPMENT DAMAGE

Failureto properly limit and balancethe

loadappliedto the generatorwill cause

the generator to produce low voltage

and may damage the engine generator

set. It may also cause severe damage

to the loadsconnectedtothe generator

at that time. Improper loading of the

generator set constitutes abuse and

will not be covered by warranty.

OPERATOR CARE AND MAINTENANCE

ENGINECARE

-

If major engine service.or repair is re-

quired contact an Authorized Engine Service Center.

The manufacturer of these engines hasestablishedan

excellent world-wide engine service organization.

Engine service is very likely available from a nearby

authorizeddealerof distributor. Check the yellow pages

of your local telephone directory under "Engines-

Gasoline" for the closest engine repair center or ask

the dealer from whom you purchased the power plant.

1.

Oil Changes

Changethe oil after the first five hours of operation

and every 50 hoursthereafter under normaloperating

conditions. Changeengine oil every 25 hours of op-

eration if the engine is operated under heavy load,

or in high ambient temperatures.

A. Remove oil drain plug at base of the engine and

drain the oil with the engine warm.

B.

Replace oil drain plug.

C.Remove oilfiller plugand refill with new oil. Refer

to the table in the engine manual for the proper

grade of oil base on your operating temperature.

D.Replace filler plug.

2.Checking the Oil Level. The oil level must always be

checked before the engine is started. Take care to

removeany dirt or debris from around the oilfill plug

before removing. Be sure the oil level ismaintained.

FILLTO POINTOF OVERFLOWING or on units with

the extended oil fill to the "FULL" mark on the

dipstick.

If theengine generatorshould fail to start and run,

check to be sure that the low oil protection system

has not been activated by a low oil condition.

3.

Sewicing Air Cleaners

A.CartridgeAir Cleaner

-

Remove andcleancartridge

yearly or after every 25 hours, whichever occurs

first. Service moreoften if necessary. Cleanbytap-

pinggently on flat surface. If very dirty, replacethe

cartridge usingonly original equipment parts avail-

able at any engine service center.

Do not use petroleum solvents, such as kero-

sene, toattempt toclean the cartridge. They may

cause deterioration of the cartridge. DO NOTOIL

CARTRIDGE, DO NOT USE PRESSURIZEDAIR TO

CLEAN OR DRY CARTRIDGE.

B.Dual Element Air Cleaner

-

Clean and re-oil foam

pre-cleaner at three month intervals or every 25

hours, whichever occurs first. Service more often

under dusty conditions.

1. Remove knob and cover.

2. Remove foam pre-cleaner by sliding it off the

paper cartridge.

3. Wash foam pre-cleanerin keroseneor liquidde-

.

tergent and water

4.

Wrap foam pre-cleanerincloth and squeeze dry.

5.

Saturatefoam pre-cleanerinengineoil. Squeeze

to remove excess oil.

6.

Install foam pre-cleanerover paper cartridge.

Reassemblecover and screw down tight. Re-

placethe cartridgeincludedwith DualElement

Air C1eaner:yearly or every 100 hours. Service

more often if necessary.

4.

Spark Plug

-

Clean and reset gap at .030" every 100

hours of operation. Do not blast clean spark plug.

Cleanby scrapingorwire brushingand washingwith

a commercial solvent. Poor spark will occur if ter-

minal does not fit firmly on spark plug. If this hap-

pens reform the terminal to fit firmly on spark plug

tip.

GENERATOR CARE

-

Propercare and maintenance of

the generatorisnecessaryto insurea longtrouble free

life.

1

.

ExercisingThe Generator

-

The generator should be

operated every three to four weeks. It should be op-

erated for a periodof timesufficient to warm the unit

upandto dry out any moisturethat hasaccumulated

inthe windings. If left this moisturecan cause cor-

rosioninthe winding andon the slip rings. Frequent

operationof the enginegenerator set will also insure

that the set isoperatingproperlyshould it be needed

in an emergency.

2. Generator Maintenance

-

Any major generator ser-

vice including the installation or replacement of

parts should be performed only by a qualified elec-

trical service man. USE ONLY FACTORYAPPROVED

REPAIR PARTS.

A. Bearing

-

The bearing when used in these gener-

ators isa heavy duty double sealed ball bearing.

They require no maintenance or lubrication.

B.

Receptacles

-

Quality receptacles have been util-

ized. If

a

receptacle should become cracked or

otherwisedamaged, replaceit. Usingdamagedor

cracked receptaclescan bedangerous bothtothe

operator and to the equipment.

CLEANING

-

Remove dirt and debris with a cloth or

brush. DO NOTuse high pressurespray tocleaneither

the engine or the generator. This high pressure spray

could contaminate the fuel system and the generator

components.

1. Keep the air inlet screen on both the engine and

generator free of any dirt or debris to insure proper

cooling. At least yearly remove the blower housing

onthe engine andcleanthe chaffand dirt out of the

engine cooling fins and flywheel. Clean more often

if

necessary.Failure to keep these areas clean may

cause overheating and permanent damage to the

unit.

OPERATOR CARE AND MAINTENANCE

(continued)

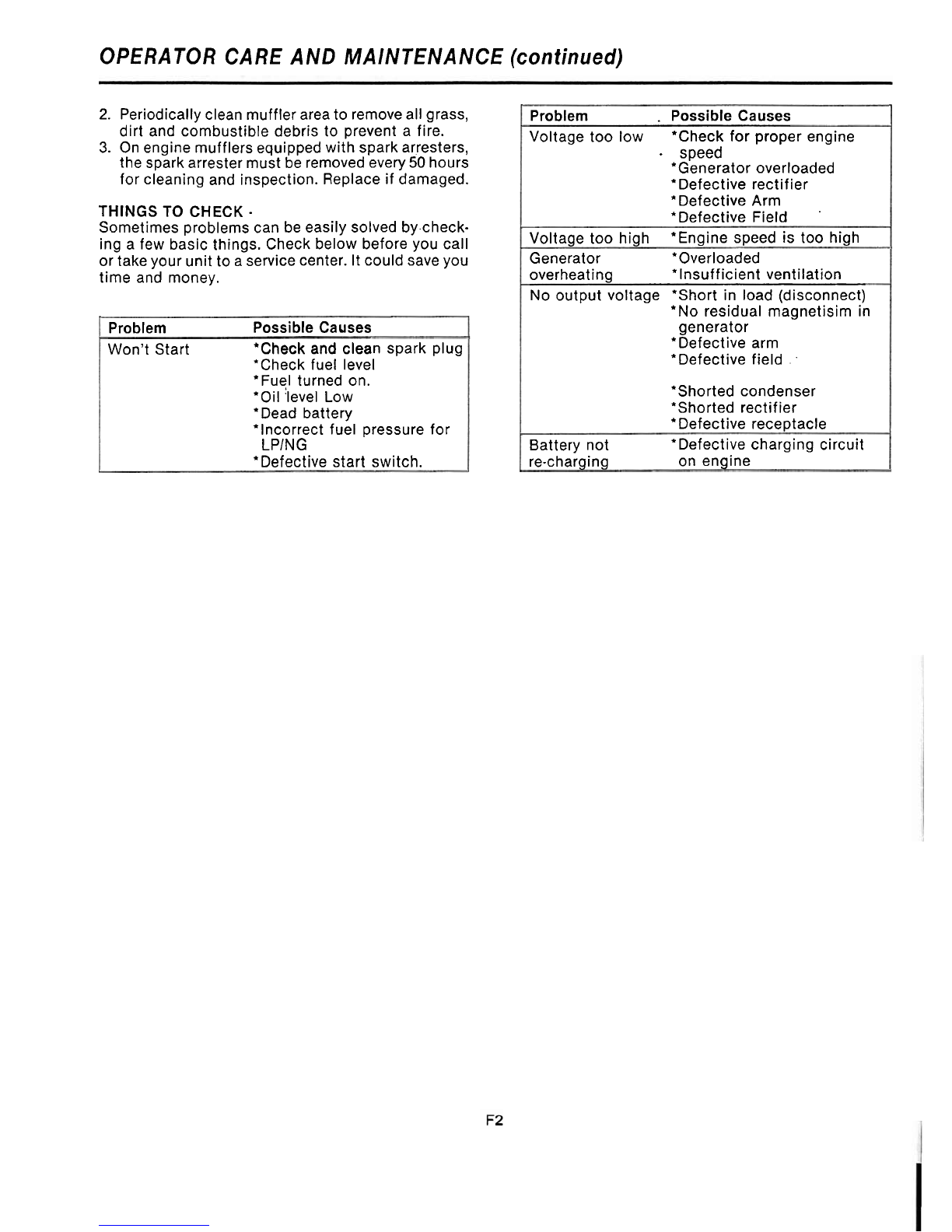

2.

Periodically clean muffler areato removeallgrass,

dirt and combustible debris to prevent a fire.

3.

On engine mufflersequipped with spark arresters,

the spark arrester must beremovedevery 50 hours

for cleaning and inspection. Replace if damaged.

THINGS TO CHECK

-

Sometimes problems can be easily solved by-check-

ing a few basic things. Check below before you call

or take your unit toaservice center. It could save you

time and money.

Problem Possible Causes

Won't Start 'Check and clean spark plug

*Check fuel level

*Fuel turned on.

*Oil'level Low

'Dead battery

*Incorrect fuel pressure for

LPlNG

'Defective start switch.

Problem

.

Possible Causes

Voltage too low 'Check for proper engine

.

speed

*Generator overloaded

*Defective rectifier

'Defective Arm

*Defective Field

.

Voltage too high *Engine speed is too high

Generator Overloaded

overheating *Insufficient ventilation

No output voltage *Short in load (disconnect)

*No residual magnetisim in

generator

'Defective arm

'Defective field

.

.

*Shorted condenser

'Shorted rectifier

'Defective receptacle

Battery not *Defective charging circuit

re-charging on engine

I

Remove

1

EXCITATION

WI.NDING

(STATOR)

FIELD

COILS

(ROTOR)

CAPACITOR

I

EXCITATION

RECTIFIERS

s$

MAIN

STATOR

for

.isolated

AC WINDING

\

CIRCUIT

bb

mC)FAYFC)

I

I.

I

GROUND

TF450016000 SCHEMATIC WIRING DIAGRAM

LIMITED

WARRANTY

r normal use and service.

There isnoother express warranty. To the extent permittedby law,

any andallwarranties, includingthose of merchantabilityandfitness

for a particular purpose, are limited to one year from date of ship-

ment, and liability for incidental or consequential damages or ex-

exclusion or limitationof incidental or consequentialdamages, so

the above limitation or exclusion may not apply to you. This war-

vary from state to state.

ENERGX

does not warrant engines or certain other component parts

of the product since such items are warranted by their manufacturers.

ENERGX

does not warrant

alterations or repairs

which were not

made by the

ENERGX

factory or a factory-authorized service sta-

tion and which affect the stability or reliability of the product.

ENERGX

does not warrant products which have been exposed to

misuse

andlor

negligence

or have been involved in an

accident.

ENERGX

reserves the

right to change or improve

its products

without incurring any obligations to make such changes or im-

provements on products purchased previously.

CAJEDE

W

-

---

----

-----

-----

-

-

-

-

-

-

-

-

-

--

-

---

-

CORPORATION

225

South

Cordova Avenue

Le Center,

MN

56057

(612)357-6821

PRINTED

IN

US.4

3/89

TF4500E/L. TF6000E/L

P/N

60707-023

t

I

This manual suits for next models

1

Popular Inverter manuals by other brands

Delta

Delta RPI M6A Quick installation guide

Go Power

Go Power GP-DC-KIT2 owner's manual

Qcells

Qcells Q.HOME PLUS ESS-G1 3.6 user manual

CanadianSolar

CanadianSolar CSI-50KTL-GS-FLB Installation and operation manual

AlcaPower

AlcaPower IRP3000D-12 user manual

Tripp Lite

Tripp Lite EMS1012UL Features & specifications

KEBCO

KEBCO COMBIVERT F5 instruction manual

Qcells

Qcells Q.PEAK DUO XL-G10 BFG Series Installation and operation manual

KEBCO

KEBCO COMBIVERT F5 INSTALLATION GUIDELINE

OutBack Power

OutBack Power FLEXpower ONE VFX3524 installation manual

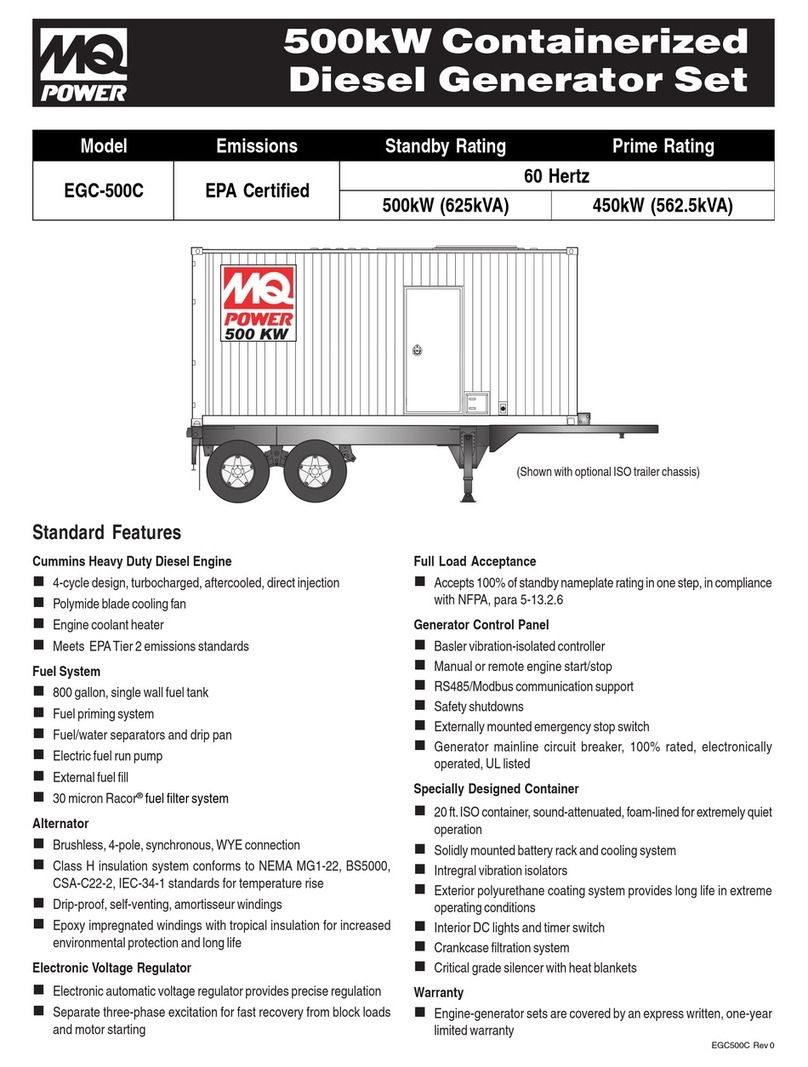

MQ Power

MQ Power EGC-500C Specifications

FRONIUS

FRONIUS Primo 3.8-1 208-240 operating instructions