ENERGY SUPPORT CORPORATION DTF-201 User manual

Manual No.3156E R4

Operation Manual for

DTF-201

Oxygen Analyzer

(% Range)

RX-62230*-A*****

Observe the following cautionary items for safe operation of the device.

Warning

1. When connecting wiring at the terminal of the analyzer, be careful to avoid electric shock.

Be sure to turn the power off before connecting wiring.

2. Connect a grounding cable to avoid electric shock.

Caution

1. To avoid electric shock, check for correct power supply wiring and agreement between the

supply voltage requirement of the device and the supplied voltage before turning on the

power switch of the device.

2. Keep away from the sensor and its periphery during operation and shortly after operation

stop to avoid burns caused by high temperatures. If maintenance is inevitably necessary,

wear heat resistant gloves or the like and be careful to avoid burns.

3. An “electric shock”warning mark shown on the right is attached near the

power supply where there is a danger of electric shock. If the wiring

circuit is unknown, turn the power off even when no electric shock

warning mark is attached.

4. If the sample gas includes toxic contents, there is a danger of gas intoxication. Be sure to

shut off the source gas valve when performing maintenance of the piping system.

5. For safe and correct use of the device, observe the cautions and handling methods

described in this operation manual. If the device is operated without observing description

herein, there is a danger of electric shock, gas intoxication, oxygen deficiency and burns as

well as damage to the device, deterioration of functions or possible damage to the final

product (system, etc.).

Cautionary items for safety

1. Term

The term of guarantee of a single piece of equipment shall be one year since the product

is delivered. However, if the equipment is built in another unit, the term of guarantee shall

be that of the unit. The single unit delivery meant that the receiver, sensor unit, cable are

delivered as single unit whereas the equipment built in another unit meant the equipment

by combining the sampling flow or to combine to another units are delivered as built-in

delivery.

2. Conditions

The delivered product shall be exchanged or repaired free of charge if it fails or any

abnormality is generated due to poor workmanship in design, manufacture or material

attributable to ENERGY SUPPORT CORP. in the above-mentioned term of guarantee

though it is operated properly after it is stored and installed properly after it is delivered to

the client.

The proper operating method includes the following.

①The installation conditions and operation conditions described in the specifications of

this measuring tool and this operation manual are satisfied.

②The analyzer is periodically calibrated and replacement of consumable parts is made.

③Periodic maintenance and inspection are made according to the operating state of the

analyzer.

However, the following cases shall be excluded from the scope of guarantee even if they

occur in the above-mentioned term of guarantee.

1) Failure generated due to operation errors (erroneous operation not described in

operation manual)

2) Failure caused by repairs, remodeling, disassembly, cleaning and so on made by

other than us

3) Failure caused by fire or act of God (including inductive lightning surge)

4) Failure caused by improper storage (storage in a hot and humid site, etc.) or lack of

maintenance (generation of fungi, etc.)

Note) Consumable parts and consumable components are excluded from the scope of

guarantee.

3. Scope

The scope of guarantee shall be limited to the range delivered by us.

4. Indemnity

We will not assume responsibility for any accompanying losses caused by the failure of

our product (losses, lost profits and so on caused by the controlled or recorded results

made under the use of our product, or losses, lost profits and so on caused by the

system in which our product is installed.). Safety units or the like shall be installed under

the responsibility of the client.

5. Term of supply of replacement parts or repair

①Repairs or replacement with alternative product will be made with charge for seven

years after manufacture of the product is stopped.

②We may reject even charged repairs of products passing 10 years or more after

delivery.

Guarantee

Table of Contents

1. Introduction-----------------------------------------------------------------------------------------------------------------1

1-1 Introduction--------------------------------------------------------------------------------------------------------1

1-2 Usage Caution Notices-----------------------------------------------------------------------------------------1

1-3 Product Outline---------------------------------------------------------------------------------------------------1

1-4 Name of each part-----------------------------------------------------------------------------------------------4

2. Opening the Packaging-------------------------------------------------------------------------------------------------5

2-1 Checking the Components and Accessories-------------------------------------------------------------5

2-2 Temporary Product Storage ----------------------------------------------------------------------------------5

3. Installation------------------------------------------------------------------------------------------------------------------5

3-1 Installation Conditions------------------------------------------------------------------------------------------5

3-2 Installation Method ----------------------------------------------------------------------------------------------6

3-3 Piping and Wiring Methods------------------------------------------------------------------------------------6

4. Operation-------------------------------------------------------------------------------------------------------------------8

4-1 Operation Preparation------------------------------------------------------------------------------------------8

4-2 Start-up-------------------------------------------------------------------------------------------------------------9

4-3 Stop Procedure------------------------------------------------------------------------------------------------- 10

4-4 Procedure During Operataio-------------------------------------------------------------------------------- 10

4-5 Operation for when an Error Occurs---------------------------------------------------------------------- 18

4-6 Applied Operations-------------------------------------------------------------------------------------------- 19

5. Maintenance------------------------------------------------------------------------------------------------------------- 22

5-1 Daily and Periodic Inspection------------------------------------------------------------------------------- 22

5-2 Troubleshooting------------------------------------------------------------------------------------------------ 23

6. Reference Material----------------------------------------------------------------------------------------------------- 25

6-1 Standard Specifications-------------------------------------------------------------------------------------- 25

6-2 Drawing name: DTF-201 oxygen analyzer receiver -------------------------------------------------- 26

1

1. Introduction

1-1 Introduction

The DTF-201 Oxygen Analyzer is a product of the latest ceramics production technology,

using a thick film sensor and digital signal processing technology. This Operation Manual

explains how to operate the DTF-201 oxygen analyzer.

Please read this manual thoroughly to ensure long, successful operation of your

SH-201-C Oxygen Analyzer.

1-2 Usage Caution Notices

・Do not install the analyzer in a location subjected to vibration.

・Do not apply water or volatile fluids to the analyzer.

・Do not use sample gas containing corrosive gases (F, HF, CL2, HCL, SO2, H2S, etc.)

or poisonous materials (Si, Pb, P, Zn, Sn, As, etc.). These can shorten the life of the

sensor.

・Do not use sample gas containing inflammable gas. The inclusion of inflammable gas

can cause deviation in the oxygen concentration measurement value.

・The major usage of this oxygen analyzer is for atmospheric oxygen measurement at

boiler, Heating furnace.

・

1-3 Product Outline

The DTF-201 oxygen analyzer has the following features.

・With one calibration of the air sample point is possible.

・Compact size.(Small installation space.)

・Easy maintenance.

・Low power consumption by the sensor.(About 13 W for normal use.)

・Short warm up time.

・No power switch.

2

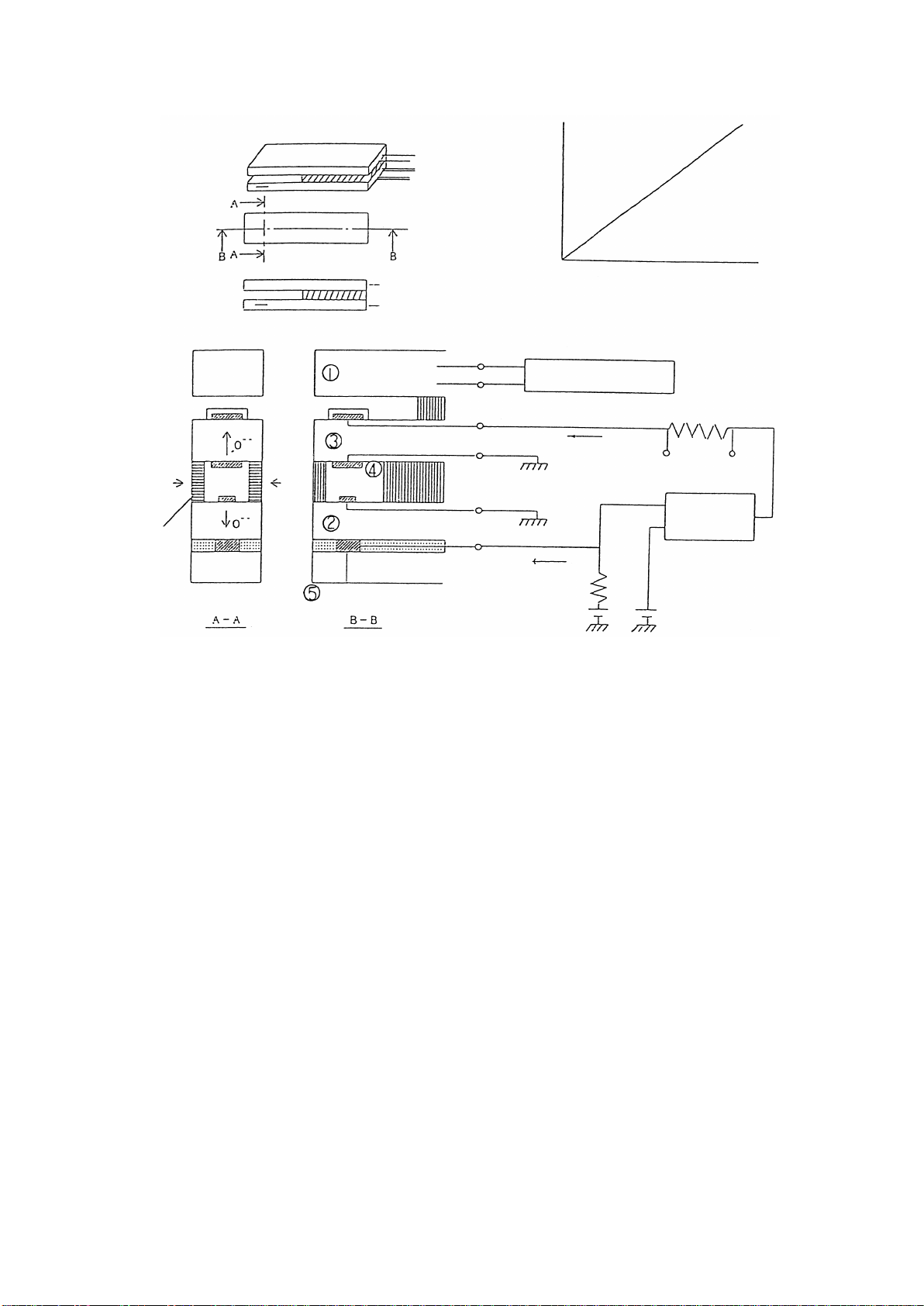

Operating Principles of Zirconia Type Oxygen Analyzer

(1) Configuration and Functions (See diagram at right.)

Heater: Heats the sensor to approximately 800℃.

Sensing cell: Sets the oxygen concentration of the reference oxygen

chamber to 100%, and measures the oxygen

concentration of the gas detection chamber.

(See below for detailed principles.)

Pumping cell: Sets the oxygen concentration of the gas detection

chamber to 0%.

(See below for detailed principles.)

Gas detection chamber: Inducts gas through the gas diffusion holes.

Reference oxygen chamber: The oxygen concentration is set at approximately

100% by the reference oxygen microcurrent.

(2) Detection characteristics resulting from high temperature heating of the sensor:

When a gas with a different oxygen concentration is put between the electrodes,

oxygen ion conductivity occurs and electromotive force is generated. (Oxygen

concentration cell effect)

When current is applied between the electrodes, oxygen ions flow in the opposite

direction in proportion to the current. (Oxygen pumping effect)

The sensing cell uses characteristics and above, and the pumping cell uses

characteristic above.

(3) Sensing Cell Principles

Minute current flows between the electrodes of the sensing cell. When current is

applied between the electrodes, the oxygen inside the gas detection chamber is

transferred to the reference oxygen chamber so that the oxygen concentration in the

reference oxygen chamber is approximately 100%.

Note: The quantity of oxygen transferred from the gas detection chamber to the

reference oxygen chamber is extremely small, so it does not affect the oxygen

concentration in the gas detection chamber.

The electromotive force in the following equation is generated between the

electrodes of the sensing cell by the difference between the oxygen concentration in

the gas detection chamber and the reference oxygen chamber.

The sensing cell measures the electromotive force generated between its electrodes

and sends signals to the pumping cell so that the electromotive force reaches 450

mV (oxygen concentration of 0% in the gas detection chamber).

oxygen concentration in gas detection chamber

oxygen concentration in reference oxygen chamber (100)

X

100

X = approx. 0.003 ppm ≒0%

(4) Pumping Cell Principle

The pumping cell receives the signal from the sensing cell and applies current to the

electrodes so that the oxygenconcentration in the gas detection chamber reaches 0%.

The current applied and the oxygen concentration in the sample gas are proportional, so by

measuring the currenttheoxygen concentrationin the sample gas can be measured.

Electromotive force E = -53.2 X log 10

450 = -53.2 X log10

3

Sensor Element Construction

Heater

Sensor

Pumping current

(mA)

Exhaust gas O2concentration (%)

Gas

Gas diffusion

holes

Gas

Heater

Pumping cell

Gas detection

chamber

Sensing cell

Reference oxygen chamber

Heater temperature

control

Pumping current

Output

signal

Pumping

current

controller

Microcurrent to

generate

reference oxygen

Reference voltage

(450 mV)

4

1-4 Name of each part

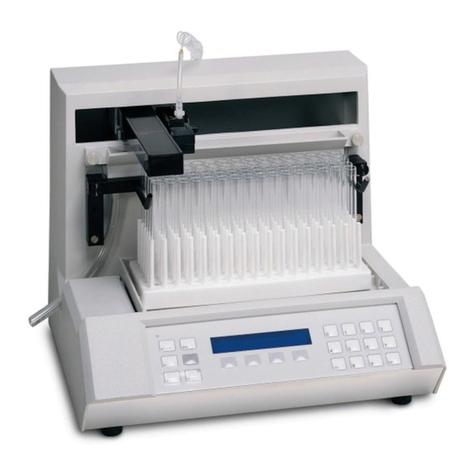

(1)DTF-201 receiver of oxygen analyzer

No.

Name (function)

①

POWER lamp (Lit after the power is turned on.)

②

Display 1 (5 digits, for display of concentration, data and error)

③

Display 2 (3 digits, for display of range, concentration alarm and channel)

④

% range lamp (Lit in % measurement mode.)

⑤

ppm range lamp (Lit in ppm measurement mode.)

⑥

Key (for calibration and data setting)

⑦

Installation fitting (for fixing the panel)

⑧

Connector 1 (for connecting the sensor unit)

⑨

Connector 2 (for RS232C connection; option)

⑩

Terminal block (for input/output wiring)

5

2. Unpacking

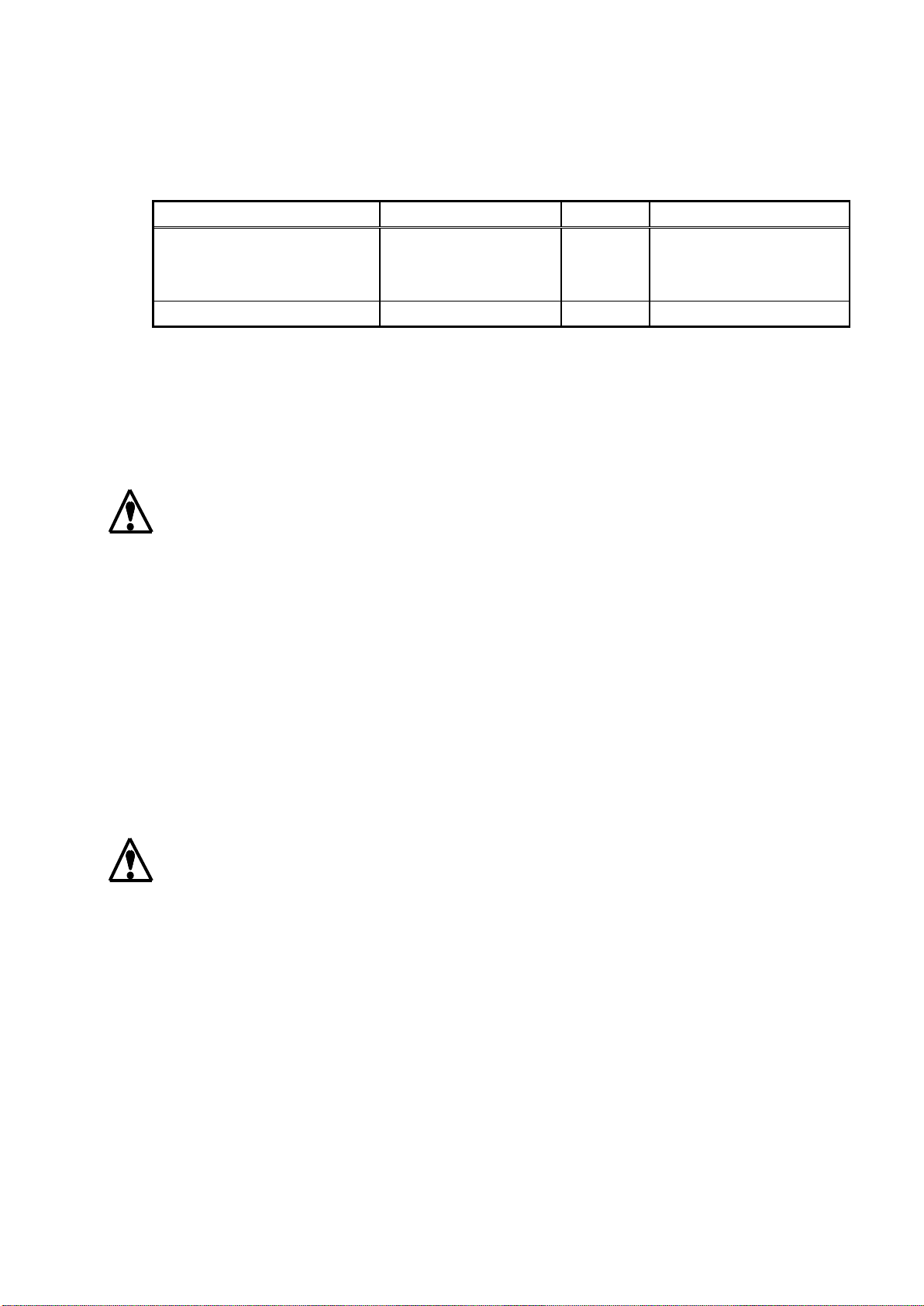

2-1 Checking the Components and Accessories

Part name

Part No.

Q'ty

Remarks

Oxygen analyzer

RX-62230*-A*

1

RX-622300:AC100V

RX-622301:AC200V

RX-622303:DC24V

Installation fitting

CA-1

2

Accessory

NOTE)

※refer to your specifications document. The probe, sensor, relay cables, and others are

different depending on the specifications; check those parts off against the specifications

document.

2-2 Temporary Product Storage

When storing the product temporarily prior to installation, observe the following conditions.

・It is preferable to store the product inside a box, protected by polystyrene, etc.

Store the product in a location with the following features:

・Away from direct sunlight.

・The ambient temperature is between -10℃and 50 ℃, with little variation in temperature.

・There is little humidity and dust.

・The location is not exposed rainfall.

・There is little mechanical vibration.

・There are no corrosive gases or dangerous gases.

3. Installation

3-1 Installation Conditions

This oxygen analyzer must be installed indoors. For safe, correct use of your oxygen

analyzer, install the analyzer in a location with the following conditions to provide the best

possible installation conditions.

・There is little vibration.

・It is not affected by corrosive gases (F, HF, CL2, HCL, SO2, H2S, etc.), and will not

interfere with maintenance personnel.

・Condensation is not caused by sudden temperature fluctuations.

・It is not affected by direct heat radiation.

・It is affected little by noise.

・There is little humidity and dust.

・The ambient temperature is between 0℃and 50℃. (not exposed to direct sunlight)

6

3-2 Installation Method

Installation Cautions

・This oxygen analyzer is a precision instrument. When installing it, avoid large shocks

and applying a load upon it.

・Its terminal block and connector jut out from the panel, so they are easily damaged.

Take care not to knock them during installation.

3-3 Piping and wiring Methods

(1) Piping Arrangement

Piping between the probe generator (sensor) and the air selector unit (for supplying

calibration gas) must be connected.

Pipes consist of the following:

・Calibration gas pipe

・Ejector air pipe

・Purge air pipe

And others

Details differ depending on the specifications. Refer to your specifications document.

(2) Wiring Methods

①Wiring between the probe generator (sensor) and analyzer

Connect the sensor and analyzer with the special relay cable.

Details differ depending on the specifications. Refer to your specifications document.

7

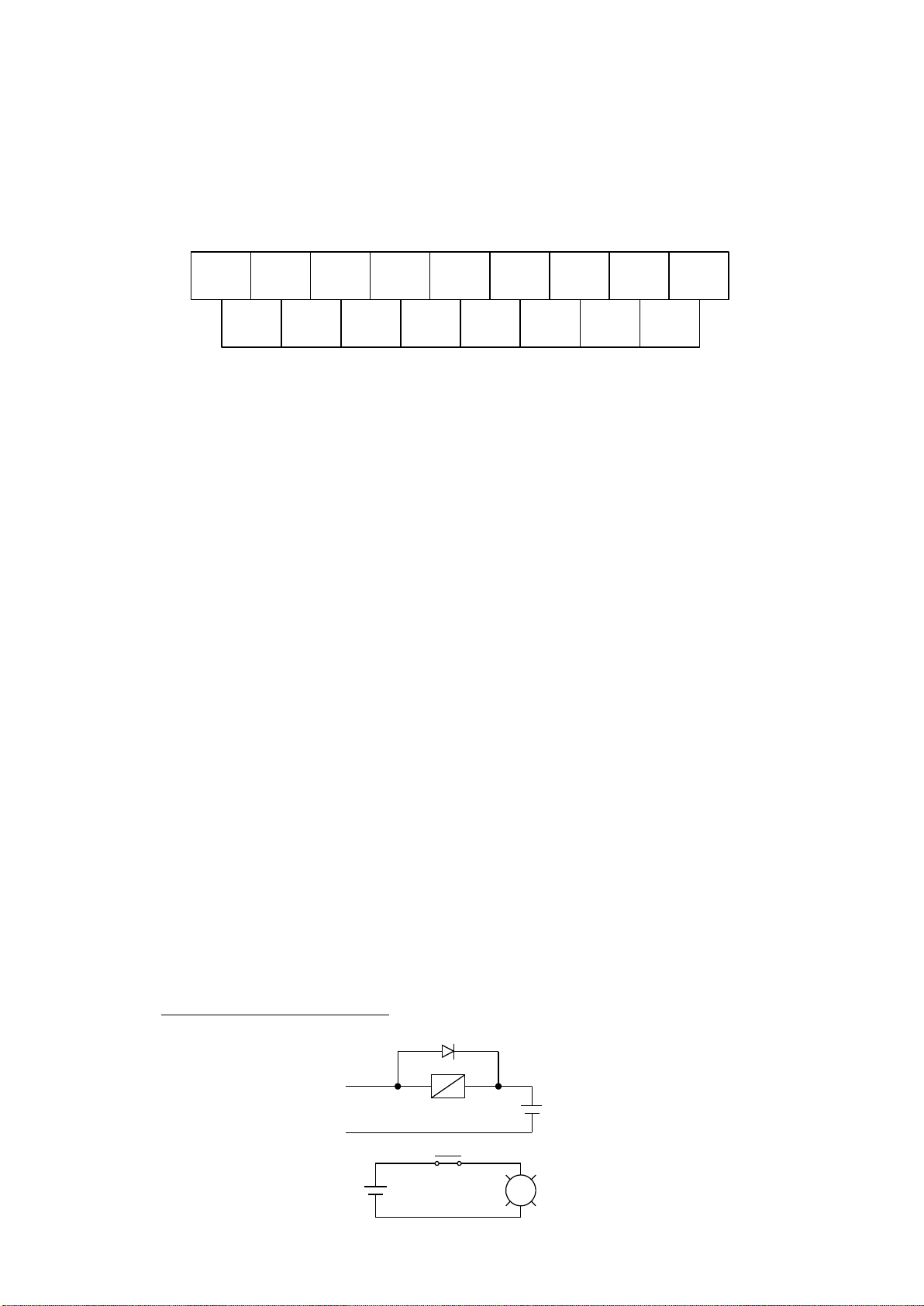

②Wiring to receiver

Connect wiring to the receiver at the terminal block (M3 screws). Take care of the

polarity when wiring.

Layout of terminal block and description

IN1 :NO-voltage contact input terminal 1

IN2 :NO-voltage contact input terminal 2

IN3 :NO-voltage contact input terminal 3

COM1 :Common terminal for IN1 through 3

RY1 :Open co output terminal 1 (permissible rating DC25V, max.50 mA)

RY2 :Open co output terminal 2 (permissible rating DC25V, max.50 mA)

RY3 :Open co output terminal 3 (permissible rating DC25V, max.50 mA)

RY4 :Open co output terminal 4 (permissible rating DC25V, max.50 mA)

COM2 :Common terminal for RY1 through 4

OUT1+,- :4 to 20 ma DC output of oxygen concentration (corresponding to selected

range). Non-insulated output, load resistance 600 Ωor less

OUT2+,- :0 to 5 VDC output of oxygen concentration (corresponding to selected

range). Non-insulated output, load resistance 10 KΩor above

FG :Terminal for connecting shields of OUT1 and 2

POWER :Power terminal (85 to 132 VAC, 50/60 Hz, max.50 VA)

E :Grounding terminal

※1 IN1-2, RY1-4, and OUT2 are different depending on the specifications; check those

parts off against the specifications document.

※2 OUT2 is either one of DC 0-1 V, DC 0-5 V, DC 0-10 V. Refer to your specifications

document.

※3 POWER is either one of AC 85-132 V, AC 170-264 V, DC 24 V. Refer to your

specifications document.

Example of Wiring Circuit to RY

IN1 IN2 IN3 RY1 RY2 RY3 RY4COM1 COM2

OUT1

+

OUT1

-

OUT2

+FG POWER POWER E

OUT2

-

RY

COM2

R1

DC or AC

R1

DC25V 50mA以下

異常ランプ等

DC 25 V,50 mA or less

Error lamp

8

4. Operation

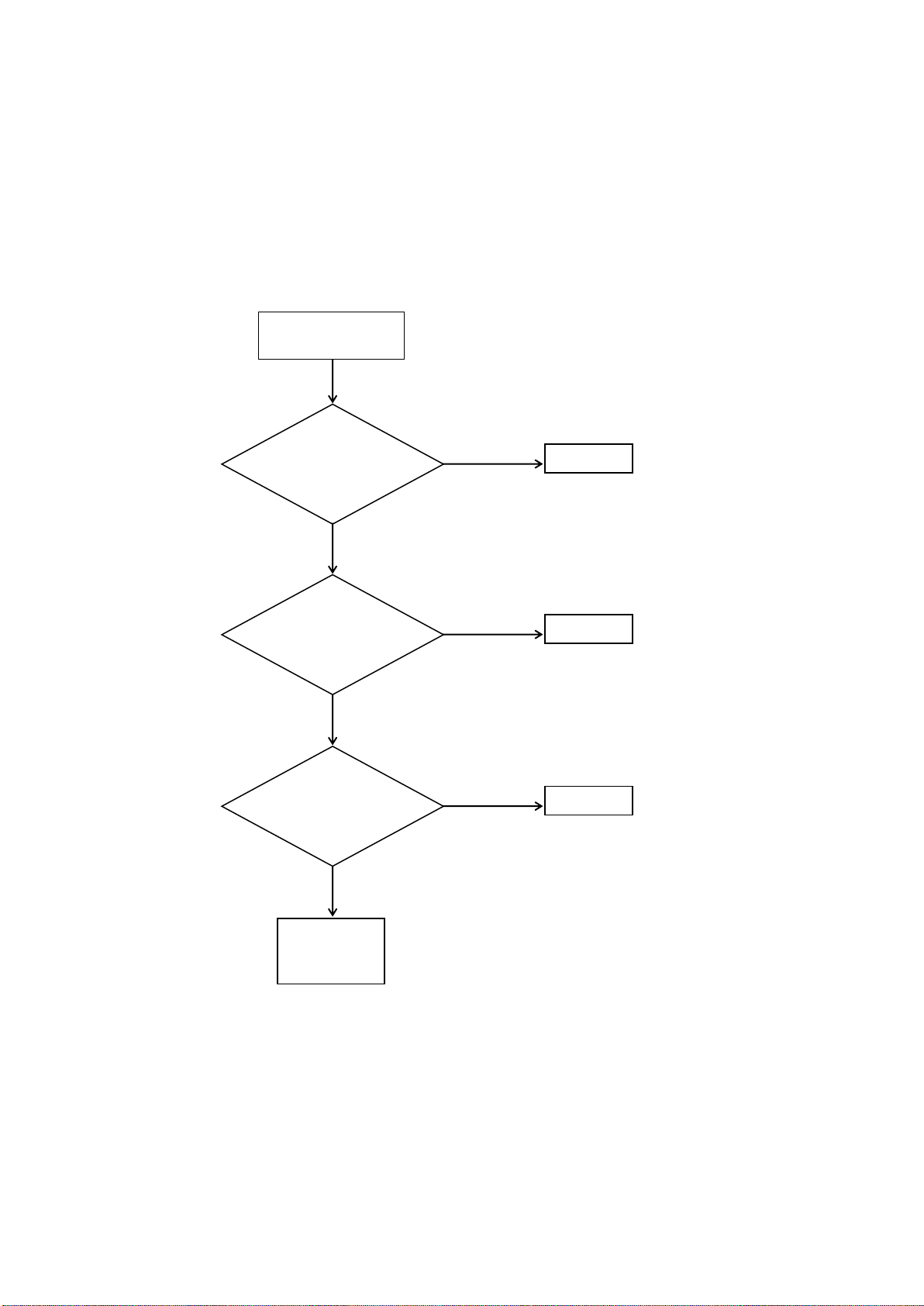

4-1 Operation Preparation

Before you turn the power ON, perform the following inspection.

Start pre-operation

inspection

Connect it.

pre-operation

inspection

completed

Is the power cord

connected properly?

Is the connecting cable

connected properly?

NO

Is the analyzer

input/output wiring

connected properly?

YES

YES

YES

Connect it.

Connect it.

NO

NO

Is the sample gas

piping connected

properly?

9

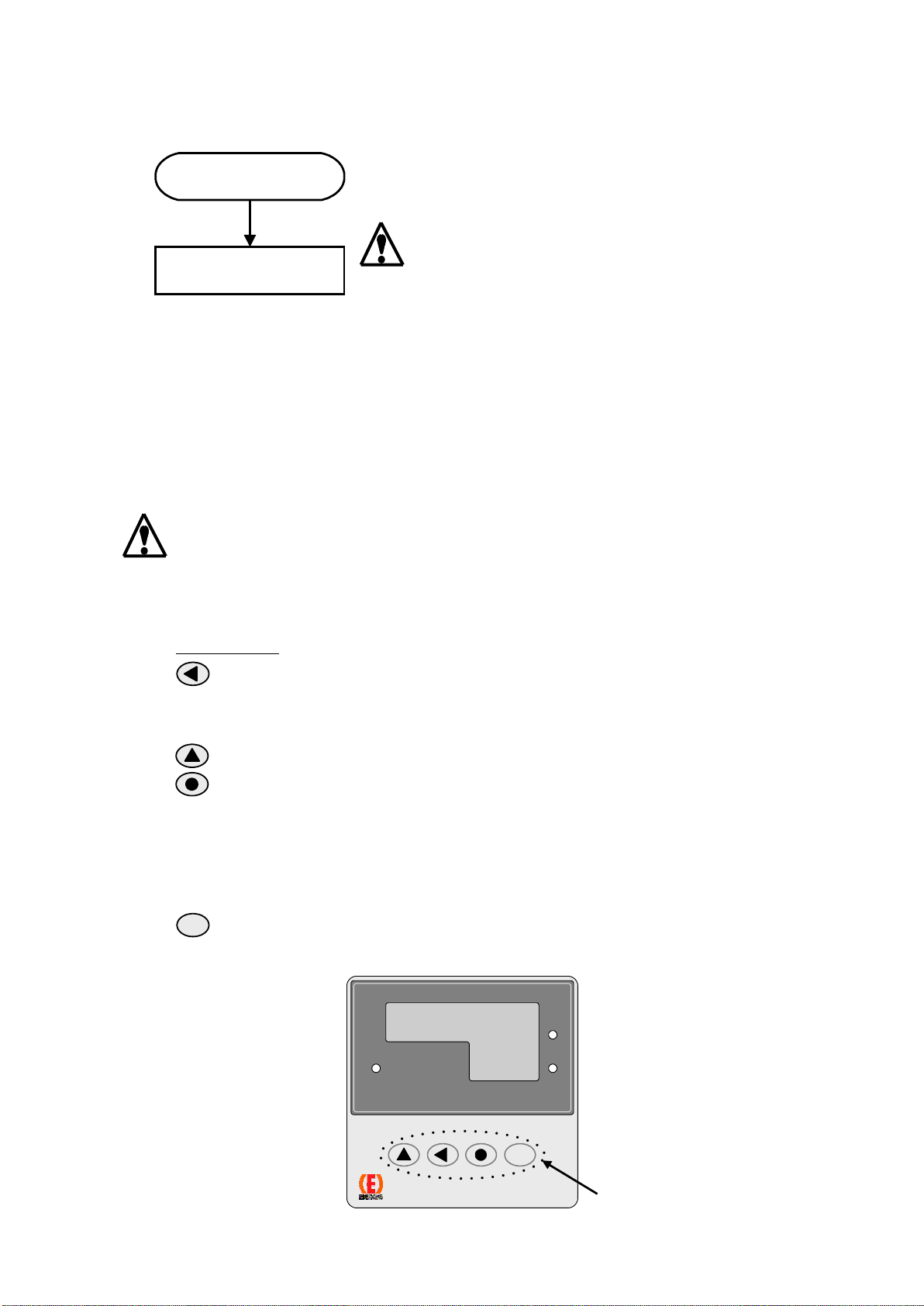

4-2 Start-up

Perform the basic start-up operation as follows.

①When you turn ON the power to the analyzer, the

POWER LED lights up and Display 1 starts the

countdown. After 3 minutes, measurement can start.

Display 1 displays the countdown as follows.

3.00 -> 2.59 -> ... -> 0.01 -> 0.00 ->

Concentration display

The analyzer does not have a power switch, so provide

one externally.

②Display 2 displays the output range No.

When range No. 1 is selected: 1

When range No. 2 is selected: 2

When range No. 3 is selected: 3

When range No. 4 is selected: 4

Checking and changing of each range is performed using

the receiver setting data (CH030 - 037).

If the concentration warning is output, the range No. is

not displayed, and AH (concentration high) or AL

(concentration low) is displayed.

For details, see page 16, 4-4 Procedure During

Operation, (2) Output Range Switching.

③For gas calibration, see page 16, 4-4 Procedure During

Operation, (4) Gas Calibration.

O2 ANALYZER

ppm

%

O2

Vol

POWER

Display 1

Display 2

ENT

RANGE

Start-up operation

Turn power ON.

Check/change

Output range.

Gas calibration

Measurement

10

4-3 Stop Procedure

Turn OFF the power supply to the oxygen analyzer.

There is no power switch on the analyzer, so turn off the

external power supply.

If operation is stopped for a short period such as 1 week or less, do not turn off the power.

If operation is stopped for a longer period, once the sample gas is replaced by ambient air,

then turn off the power.

4-4 Procedure During Operation

(1) Key Operation Method

Key operation is required to change the range and perform gas calibration when starting

up. This operation is very important, so be sure to read these instructions.

Key operation may change the oxygen analyzer output, so when using the oxygen

analyzer output signals for control purposes, always apply the control release device

before operating the keys.

Key Functions

key …Press this key to shift from the O2Concentration display to the data

setting mode, or to move toward the left digit of the setting data. The

currently changeable digit flickers.

key …Press this key to change the value of the set CH and the set data.

key …Press this key in the following cases.

*To insert a decimal point after the flickering digit.

*To switch to the opposite sign when the set data has a plus or minus sign.

*To return to the O2Concentration display mode from the setting mode

*To clear an error when it has occurred.

key …Press this key to save data in the receiver memory after changing the

value of the set CH or set data.

ENT

Stop Procedure

Turn OFF the power

O2 ANALYZER

ppm

%

O2

Vol

POWER

Key

ENT

RANGE

11

Key Operation Method

Display 1 is the O2Concentration display.

Display 2 is the Range or Concentration warning display.

①First, press the key.

Display 2 will display the CH No. and LED 8 will flicker.

Display 1 display the data.

②Press or to set the CH No. of the data you

wish to display on Display 2.

③Press .

LED5 on Display 1 will flicker.

Display 2 will continue to display the CH No.

④Press or to change the data displayed on

Display 1.

⑤Press to save the data in the receiver memory.

⑥Press to return to the O2Concentration display.

Key operation is finished.

Using steps ①- ⑥above, you can change the range and

perform gas calibration.

The following page displays the System Data Table

explaining which data is input to which CH.

Press or

Press

Press

Key Operation Method

During measurement

Press

ENT

Press

ENT

During measurement

Press or

ENT

ENT

O2 ANALYZER

ppm

%

O2

Vol

POWER

LED

1

LED

2

LED

3

LED

4

LED

5

LED

6

LED

7

LED

8

Display 1

Display 2

Keys

ENT

RANGE

12

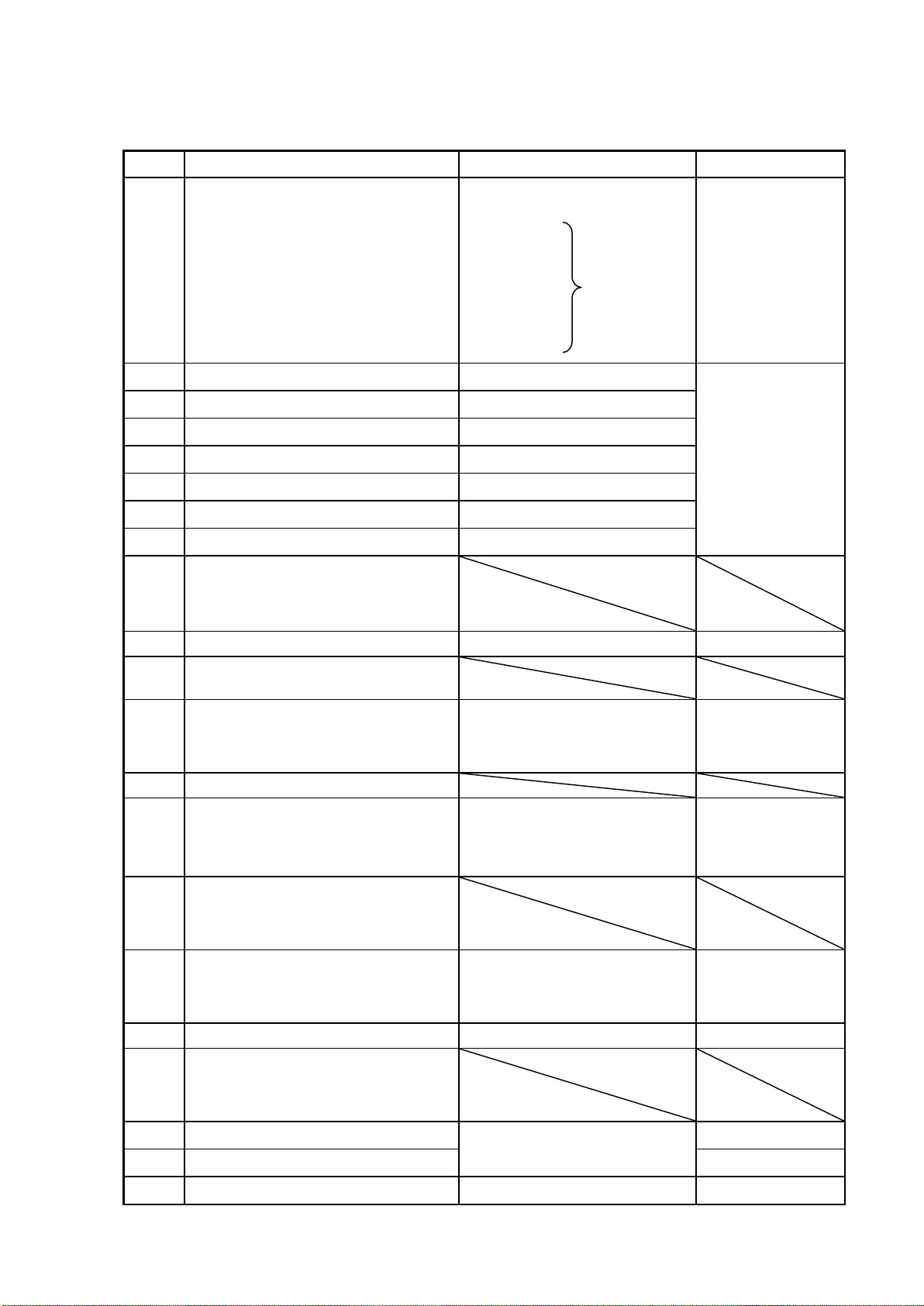

System data Table

CH No.

Function

Setting Data

Default Data

000

Display selection

0: No display (--――)

1: Oxygen concentration

2: Icp

3: Vs

4: Ip1 *2 –9 are for

5: Ip2 checking use

6: Vp by we.

7: Vh

8: Ih

9: CPU Ih

1

001

Sensor output VS monitor (V)

-

Monitor value

002

Sensor output IP monitor (A)

-

003

Sensor output IP monitor (A)

-

004

Sensor output VP monitor (V)

-

005

Sensor heater voltage monitor (V)

-

006

Sensor heater current monitor (A)

-

007

Sensor heater current monitor (A)

-

008

|

015

Data for setting, checking by

ENERGY SUPPORT CORP.

016

Primary delay time (sec)

0 –99

0

017

Data for setting, checking by

ENERGY SUPPORT CORP.

018

WET/DRY operation

0: WET

1: DRY(gas fuel)

2: DRY(solid and liquid fuel)

See

Specifications

Manual.

019

020

Output range switching

1: No. 1 range

2: No. 2 range

3: No. 3 range

4: No. 4 range

Data is supplied

for the current

selected range

021

|

022

Data for setting, checking by

ENERGY SUPPORT CORP.

023

Output hold setting

0: No hold

1: Desired value

2: Value 5 sec. before error

See

Specifications

Manual.

024

Output hold value setting (%FS)

0 - 100

0

025

|

026

Data for setting, checking by

ENERGY SUPPORT CORP.

027

OUT1 output adjustment

When adjusting output ZERO or

SPAN, sets to this CH.

-

028

OUT2 output adjustment

-

029

-

-

-

13

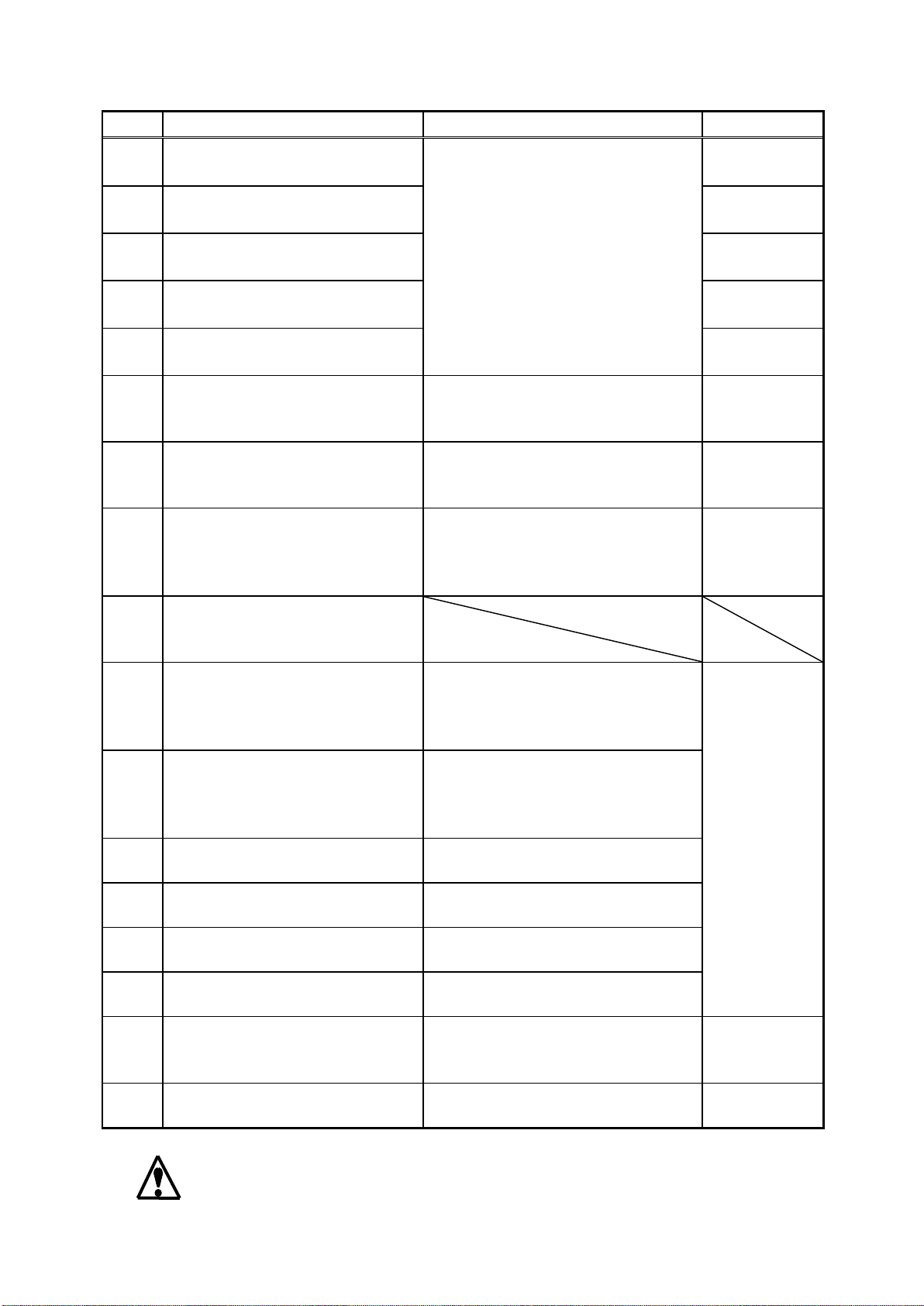

CH No.

Description

Setting data

Initial data

030

Output range No. 1 span value

1 - 99999

* Check the output range unit

using CH034 - 037.

See

Specifications

Manual.

031

Output range No. 2 span value

032

Output range No. 3 span value

033

Output range No. 4 span value

034

Output range No. 1 unit

0: Not in use

1: ppm

2: %

1

035

Output range No. 2 unit

1

036

Output range No. 3 unit

2

037

Output range No. 4 unit

2

038

-

-

-

039

-

-

-

040

|

119

Data for setting, checking by

ENERGY SUPPORT CORP.

120

Zero gas concentration (%)

0.00 - 99.90

See inspection

data

121

Span gas concentration (%)

122

-Span gas concentration (%)

-99.90 - 99.90

123

Air point concentration

0.00 - 99.90

125

to

142

Data for setting, checking by

ENERGY SUPPORT CORP.

143

Linearization table

Specific values for each sensor

See inspection

data

144

|

179

Data for setting, checking by

ENERGY SUPPORT CORP.

180

Calibration point selection

5: Zero point

6: Span point

8: Air point

8

181

Calibration start

0: Default value

1: Calibration start

0

182

|

189

Data for setting, checking by

ENERGY SUPPORT CORP.

190

Heater control mode

0: Heater OFF

1: Constant voltage control

2: Constant resistance control 1

3: Constant resistance control 2

1

(Change not

possible.)

191

Heater voltage setting value (V)

5.00 - 11.00

10.50

(Change not

possible.)

192

Heater resistance at room

temperature (Ω)

Specific values for each sensor

See inspection

data

193

Resistance ratio

Specific values for each sensor

See inspection

data

194

to

199

Data for setting, checking by

ENERGY SUPPORT CORP.

14

CH No.

Description

Setting data

Initial data

200

Contact output RY1 function setting

0: No contact output

1: Analyzer error

2: Range echo (2 range

discrimination)

3: Range echo (discrimination of 3

ranges or more))

4: READY

5: Concentration max. alarm

6: Concentration min. alarm

7: Range echo (3 contacts)

See

Specifications

Manual.

201

Contact output RY2 function setting

202

Contact output RY3 function setting

203

Contact output RY4 function setting

204

Contact output RY1 movement

setting

0: NO

1: NC

See

Specifications

Manual.

205

Contact output RY2 movement

setting

206

Contact output RY3 movement

setting

207

Contact output RY4 movement

setting

208

Contact input RY1 movement

setting

0: Not in use

1: Air 1 point calibration start

See

Specifications

Manual.

209

Contact input RY2,3 movement

setting

0: Local range switching

1: Remote range switching

210

|

219

Data for setting, checking by

ENERGY SUPPORT CORP.

220

O2 concentration max. alarm

setting value

0.0 - 9999.0

If 5 and 6 are set

for CH200 –

203, set your

desired limit

221

O2 concentration max. alarm

setting value

0.0 - 9999.0

222

Oxygen max. alarm unit

0: Not used

1: ppm

2: %

223

Oxygen min. alarm unit

224

Simulation output selection

0: Measurement value output

1: Simulation output

0

225

OUT1

Current simulation output value

0.0 –100.0

0.0

226

OUT2

Voltage Simulation output value

0.0 –100.0

0.0

227

|

229

Data for setting, checking by

ENERGY SUPPORT CORP.

230

Gas fuel CO2 concentration

0.00 –100.00

0.00

231

Gas fuel CO concentration

0.00

232

Gas fuel H2 concentration

0.00

233

Gas fuel CH4 concentration

0.00

234

Gas fuel C2H6 concentration

0.00

235

Gas fuel C3H8 concentration

0.00

236

Gas fuel C4H10 concentration

0.00

237

Gas fuel C5H12 concentration

0.00

238

Gas fuel N2 concentration

0.00

239

Gas fuel H2O concentration

0.00

240

Gas fuel CO2 concentration

0.00

241

Solid and Liquid fuel

C concentration

0.00

15

Caution notices when changing data settings.

Do not make changes to CH190 –191. It will change the heater voltage supplied

to the sensor, which could damage the sensor.

CH No.

Description

Setting data

Initial data

242

Solid and Liquid fuel

H concentration

0.00 –100.00

0.00

243

Solid and Liquid fuel

S concentration

0.00

244

Solid and Liquid fuel

N2 concentration

0.00

245

Solid and Liquid fuel

H2O concentration

0.00

246

Solid and Liquid fuel

O2 concentration

0.00

247

|

269

-

-

-

270

How to calibration

0: Manual

1:Semi Auto

2: Auto

276

Calibration mode

0: Air 1 point calibration

1: Air,Zero 2 point calibration

2: Air,Span 2 point calibration

3: Air,Zero,Span 3 point calibration

See

Specifications

Manual.

271

|

289

Data for setting, checking by

ENERGY SUPPORT CORP.

290

Communication setting

0: Maker setting

1: Maker setting

2: RS-232C

3: Maker setting

Option

291

Bit rate setting

0: 1200

1: 2400

2: 4800

3: 9600

292

Data length setting

0: 8 bit

1: 7 bit

293

Parity setting

0: Even parity

1: Odd parity

294

Parity mode setting

0: No check

1: Check used

295

Stop bit length setting

0: 1 bit

1: 2 bit

296

|

309

-

-

-

310

Data setting change password

0: Data change prohibited

201: Data change possible

201

Table of contents

Popular Analytical Instrument manuals by other brands

Rothenberger Industrial

Rothenberger Industrial RO-LASERMETER 35 operating manual

Digitimer

Digitimer DS4 Operator's manual

Goldanalytix

Goldanalytix GOLDSCREENPEN instruction manual

ennoLogic

ennoLogic eD560L user manual

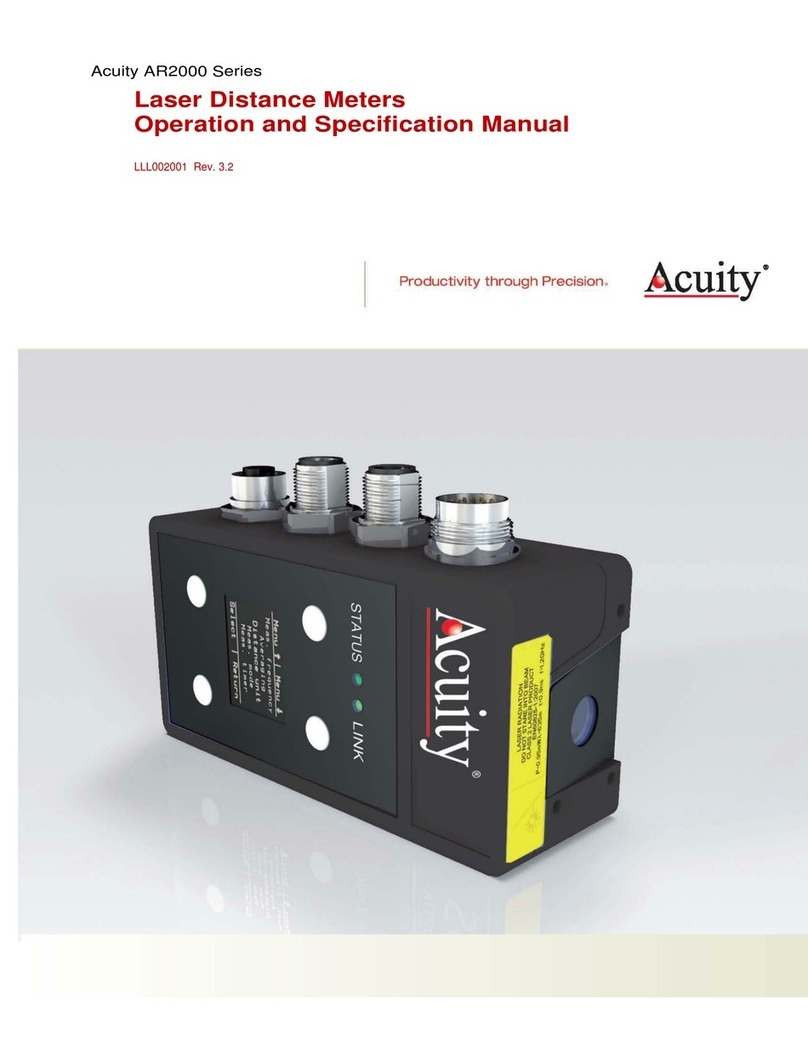

Acuity

Acuity AR2000 Series Installation, operation and specification manual

Powerfix Profi

Powerfix Profi PEK 2.3 A1 User manual and service information