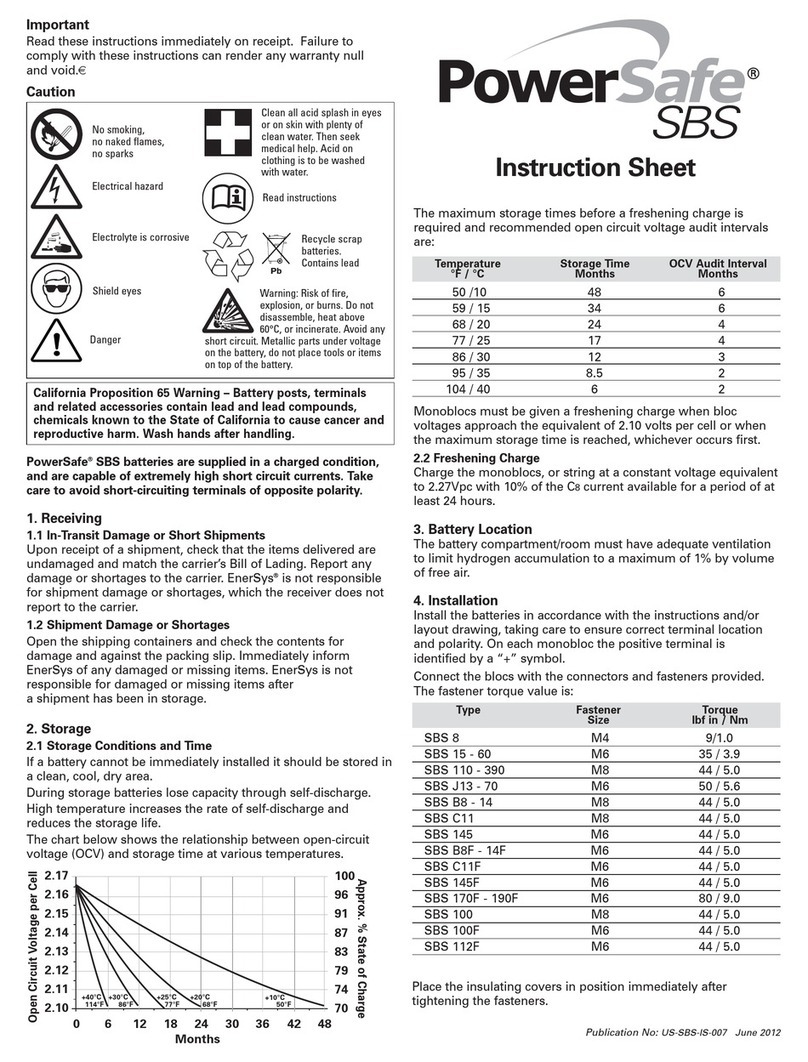

The maximum storage times before a refresh charge is required and

recommended OCV audit intervals are:

Batteries must be given a refresh charge when the OCV approaches the

equivalent of 2.10 Volts per cell (Vpc) or when the maximum storage time is

reached, whichever occurs first.

Temperature °F (°C) Storage Time (Months)

OCV Audit Intervals (Months)

50 (10) 48 12

59 (15) 34 12

68 (20) 24 12

77 (25) 17 6

86 (30) 12 6

95 (35) 8.5 3

104 (40) 6 3

AM-SBSXL-IS AA June 2019 3

2.2. Freshening Charge

Charge the module or string of modules at a constant voltage equivalent to

2.27Vpc with current limited to 10A per 100Ah nominal capacity for a period

of at least 24 hours, but with a maximum of 48 hours. Use temperature

compensation as indicated in Section 5. Start monitoring the charging current

21 hours after initiating the freshening charge. The charge is complete when

the current stabilizes. Current stabilization is defined as three current readings

at least one hour apart within five percent of each other. Do not charge in an air

tight enclosure.

Completing a freshening charge according to the instruction will reset the

storage OCV audit interval and suggested maximum storage time. If voltage

drops below 2.10Vpc contact EnerSys for instruction.

3. Battery Location

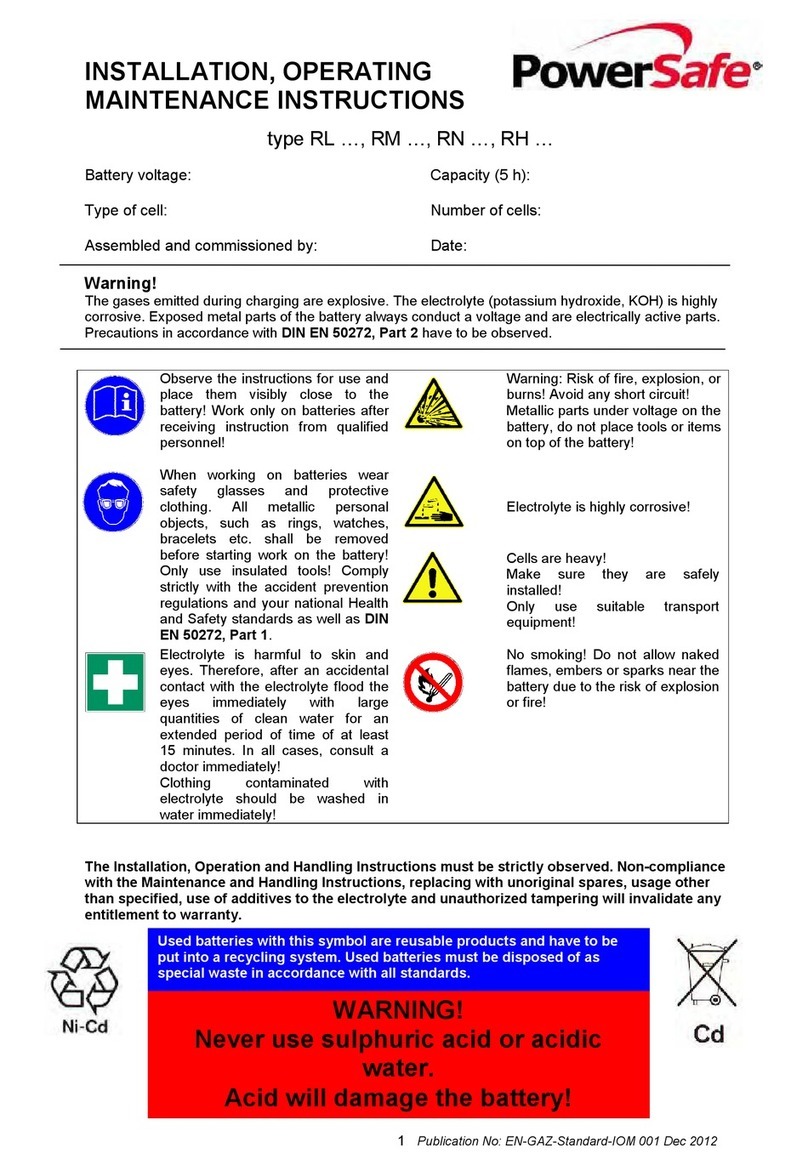

Batteries must be installed in accordance with local/national laws, regulations

and standards. The battery compartment/room must have adequate

ventilation to limit hydrogen accumulation to a maximum of 1% by volume.

Please contact your EnerSys®representative for further advice on this topic.

4. Installation

PowerSafe®SBS XL batteries can be installed on their base or horizontally on

their longest side.

Each monobloc is supplied with the terminal/connector fasteners.

On each monobloc the positive terminal is identified by a “+” symbol. Install

the batteries in accordance with the instructions and/or layout drawing,

taking care to ensure correct terminal location and polarity.

Connect the blocs with the connectors and fasteners provided. Torque the

fasteners to the value indicated on the product label.

Place the insulating covers in position immediately after tightening the

fasteners.

5. Operation

Optimum performance and service life are achieved at a temperature of

68°F (20°C) to 77°F (25°C). The operating temperature range is -40°F (-40°C)

to 131°F (55°C) with short term excursions to 149°F (65°C) permissible.

5.1. Standby / Float Operation

Constant voltage chargers are recommended. The charging voltage should

be set at the equivalent of 2.29Vpc at 68°F (20°C) or 2.27Vpc at 77°F (25°C).

The minimum charging voltage, at any temperature, is 2.21Vpc. The

recommended float voltage temperature compensation is as follows:

5.2. Charging Current

Due to the very low internal resistance PowerSafe SBS XL batteries will accept

unlimited current during recharge but for cost and practical purposes in float

applications where recharge time to repeat duty is not critical, the rectifier

current can be limited to the load plus 0.1C8Amps.

5.3. Discharging

Batteries must not be left in a discharged condition after supplying the load but

must immediately return to recharge mode.

Failure to observe these conditions may result in greatly reduced service life.

5.4. Accidental Deep Discharging

For optimum operation the minimum voltage of the system should be related to

the duty as follows:

In order to protect the battery it is advisable to have system monitoring and low

voltage cut off.

Deep discharge will produce a premature deterioration of the battery and a

noticeable reduction in the life expectancy of the battery.

5.5. Effect of Temperature

The temperature has an effect on the battery capacity. With increased operating

temperature capacity increases, likewise with decreasing temperature the

capacity decreases. Temperatures exceeding 95°F (35°C) will increase the Total

Cost of Ownership (TCO) of this battery.

6. Maintenance

In practice, the user usually specifies the maintenance schedule based on

site criticality, location and manpower. However, the following may be used

as a suggested maintenance schedule. Typically, the maintenance frequency

for standard Valve Regulated Lead Acid (VRLA) batteries is scheduled every

6 months but as a result of the increased design life inherent with the

PowerSafe SBS XL battery range this interval frequency can be extended to

deliver additional TCO benefit, particularly during the early period of service (as

the battery approaches 80% of the intended service it would be beneficial to

increase the frequency of maintenance).

Keep a logbook to record values, power outages, discharge tests, etc.

•Measure the battery string voltage. If necessary, adjust the float voltage to

the correct value.

•Measure individual bloc voltages. After 12 months of operation

blocs should be within stated tolerance of the average voltage value

as specified in the Instruction Manual.

•Check the ambient temperature in the immediate environment.

•Inspect for contamination by dust, loose or corroded connections.

If necessary, isolate the string/bloc and clean with a damp soft cloth.

Warning: Do NOT use any type of oil, solvent, detergent, petroleum-based

solvent or ammonia solution to clean the battery containers or lids. These

materials will cause permanent damage to the battery container and lid and will

void the warranty.

6.1. State of Health Monitoring

A load test should be carried out typically once a year.

Capacity discharge testing is considered as the only true guide to state

of health but can be complimented by the use of Ohmic measurement

trending e.g. Conductance.

•A discharge test should only be carried out on a fully charged battery.

Duty Minimum end voltage

5 min ≤t ≤1h 1.65V

1h ≤t ≤5h 1.70V

5h ≤t ≤8h 1.75V

8h ≤t ≤20h 1.80V

Temperature °F (°C)

50 (10) 59 (15) 68 (20) 77 (25) 86 (30) 95 (35)

104 (40)

Recommended 2.33 2.31 2.29 2.27 2.25 2.23 2.21

Minimum 2.31 2.29 2.27 2.25 2.23 2.21 2.21