Back to the manu acturer!

Batteries with this sign must be recycled.

Batteries wich are not returned or the recycling prozess must be disposed o as hazardous waste!

(deep discharge). A minimum S. . of the electrolyte of 1.13 kg/l is to be

checked at the end of the discharge. Discharged batteries must be

recharged immediately and must not be left in a discharged condition.:

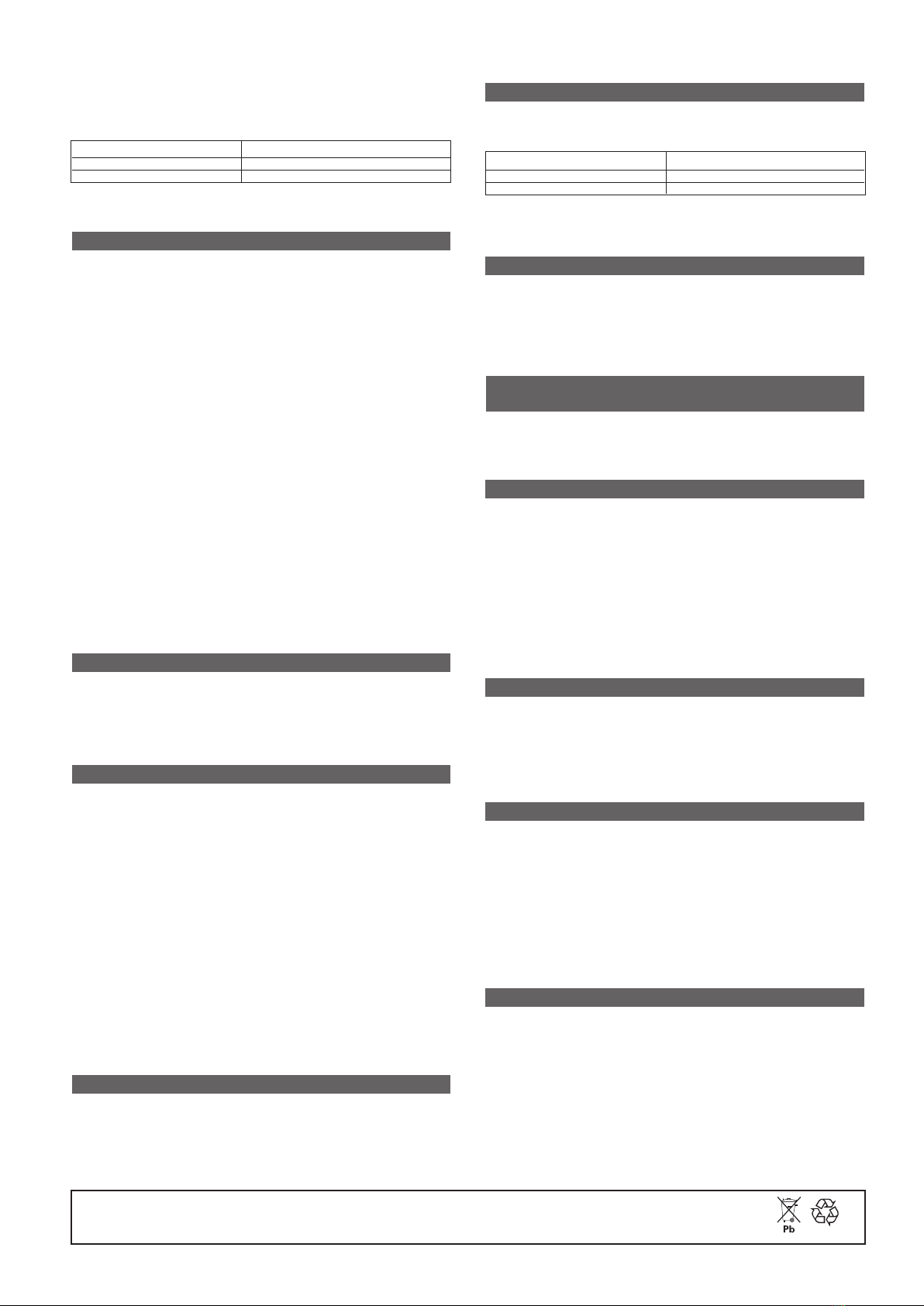

Discharge Recharge

>40% Every day

<40% Every second day

This also applies to partially discharged batteries. Discharged batteries

can freeze.

2.2. Charge

Powerbloc batteries can be recharged with 50 Hz or HF charger. If you wish

to use an existing charger with Wa, WoWa,, IUIa, WUIa…profile, you

should check that the profile is approved by our Technical Department. Only

direct current must be used for charging. Only connect the battery to the

correctly assigned charger, suitable for the battery size in order

to avoid overloading of the electric cables and contacts, electrolyte

overflow and unacceptable gassing of the cells. When gassing the

current limits must not be exceeded according to DIN EN 50272-3.

Before starting the charge, make sure of:

• the presence of the plugs.

•in the case of water refilling system, check the good condition of the

filling up circuit and specific plugs, the water tube connection for the

filling device (fast connection between the battery and the system

with water supply).

When charging, proper provision must be made for venting of the charging

gases. Battery container lids and the covers of battery compartments must

be opened or removed. Keep vent plugs closed. With the charger switched

off, connect the battery ensuring that the polarity is correct (positive to

positive, negative to negative). Now switch on the charger. In the case of

automatic filling up, with manual command, press the push –button of the

electrovalve box to release the supply of demineralized water, at the end

of charge. When charging the temperature of the battery rises by about

10°C, so charging should only begin if the electrolyte temperature is below

45°C. The electrolyte temperature of the battery should be at least +10 °C

before charging, otherwise a full charge will not be achieved without

specific settings of the charger.

The charge is considered as achieved when the electrolyte S. . and the

battery voltage remain constant for 2 hours. During the recharge, the cells

emit hydrogen and oxygen gas. It is necessary to ensure ventilation in the

room, especially during the recharge. All installations must comply with

the current regulations in force in the country of operation.

2.2.1 Normal charge

It is applied further to a « normal » discharge of the battery (up to 80% of

C5), it is not interrupted until the end of charge indication by the charger

display.

It is not necessary to recharge the battery immediately if after a use cycle,

the residual capacity is still more or equal to 60% of its capacity. In that

case it is necessary to recharge the day after, at the latest.

2.2.2. Equalising charge

Equalising charges are used for insuring the service life and to maintain

the capacity. They are necessary after deep discharges and after repeated

uncomplete charges. They allow homogenisation of the specific gravity of

the electrolyte:

• to compensate the self discharge due to the storage period.

• to compensate the eventual lack of charge with normal charges.

• to quickly homogenise the electrolyte, following the addition of

distilled or demineralised water.

• to compensate stratification, following partial charges without

mixing of the electrolyte (not recommended).

To be carried out after a normal charge when a variation (differences more

than 10 grams per litre) of specific gravity is recorded.

It is carried out using a constant current with a low value near C5/30 (C5/20

max) and after a normal charge of the battery (end of charge, see 2.2). The

recommended duration is 8 hours. The equalising charge may be

interrupted if the specific gravities are homogenised. When the nominal

electrolyte specific gravity is not obtained after an equalising charge, and

when this low specific gravity is not the consequence of electrolyte over-

flowing, a recharge in completion with the equalising charge can be

carried out. It must be done with constant current, near C5/60 A, and after

a complete charge for 72 hours. Watch the temperature and a sufficient

ventilation!

2.2.3. Desulphation charge

Should be carried out after a very deep discharge of the battery (> 80% C5)

when the charger does not start the recharge due to an over discharge of

the battery. It must carried out with constant current, near C5/60, for 2

hours minimum. It is followed by a normal charge and equalising charge

(desulphation if necessary). The best result is obtained with the lowest

value of current. In any case, stop the charge if the electrolyte

temperature reaches 45°C.

2.3. Electrolyte

The electrolyte nominal S. . is 1.29 kg/l at 30°C when in fully charged

condition. According to temperature, S. . correction, in respect to 30°C,

will be applied :.

T°C Correction per °C

If T °C > 30°C - 0,0007

If T °C < 30°C + 0,0007

Example : S reading 1.285 at 36°C :

1.285 + (0,0007 X 6) = 1.289 at 30°C

The purity of the electrolyte must correspond to DIN 43530-2.

2.4. Battery check

After a normal charge, measure :

•the total voltage

• the voltage per cell

•the electrolyte specific gravity on several cells or on the whole battery.

NB: measure at the constant intensity of I=0.033 C5or if the charger can

do it, at “equalising charge”. The voltages for a new battery will be

greater than or equal to 2.65 Volts per cell under I=0,033C5.

3. Maintenance

3.1. Daily maintenance

•keep the battery, clean and dry in order to avoid self-discharging and

current leakage.

•check : the condition of the plugs, cables and that all insulation

covers are in place and in good condition.

3.2. Weekly maintenance

If necessary, adjust the electrolyte level of each cell, only use demineralized

or distilled water. The level must never be lower than the minimum level,

in other words, always above the plates. It is carried out:

• at the end of charge and without over exceeding the maximum level

if the battery has standard filling plugs.

• by connection to the water circuit if the battery is equipped with

automatic filling up. The pressure must be between 0.2 and 0.6 bar.

VERY IMPORTANT

In difficult conditions, high room temperature for example, the electrolyte

level must be checked as often as necessary.

If there are traces of electrolyte-overflowing, in general, lead sulphate

trails, wash the battery with clean water at low pressure, with the cells

vent plugs in place and closed.

3.3. Monthly or quarterly maintenance

Carry out an end-of-charge control : measure and record the voltages of

all blocs with the charger switched on. Measure and record the electrolyte

S. . of all blocs.If significant variations to the earlier measurements or big

variations between the blocs or cells are noticed, please contact our

Service. If the battery autonomy is not sufficient, check that the work

required is compatible with the battery capacity, the battery condition

(end of charge S ), and the settings of the charger.

3.4. Annual maintenance

Battery: for bolt on connectors, check the torque settings of the terminal

bolts/screws, the terminals must be covered with grease as protection

against external corrosion. Charger: internal dust removal, check all

connections (plugs, cables and contacts) and charging parameters.

According to DIN EN 1175-1 when necessary, but at least once a year,

the insulation resistance of the truck and of the battery must be checked

by an electrical specialist.

The test on the insulation resistance of the battery must be conducted in

accordance with DIN EN 1987-1. The average insulation resistance of the

battery must not be lower than 50 Ωper Volt nominal voltage.

(DIN EN 50272-3)

For batteries up to 20 V nominal voltage the minimum value is 1000 Ω.

4. Storage and transportation

Batteries must always be stored and transported securely in the vertical

position in order to avoid any electrolyte leakage. Store the battery in a

fully charged condition in a dry, clean and frost free area.

Always disconnect the battery from the electric vehicle before storage. For

easy recharge of the batteries, it is advised not to store without recharge

for more than 3 months at 20°C and 2 months at 30°C.

The storage time is to be considered within the battery life expectancy.

To ensure the battery is always ready for use a choice of charging methods

can be made :

• monthly equalising charge according to 2.2.2.

• float charge with 2.27 V x number of cells.

www.enersys-hawker.com

09.2015 Subject to technical modification without any prior notice.