EnerSys OLDHAM GT User manual

1

G

GT

T

&

&

G

GS

S

C

CA

AP

P

L

LA

AM

MP

P

S

SY

YS

ST

TE

EM

M

WARNING

This manual, including the warnings and cautions inside, must be read and followed carefully by all

persons who use or maintain this product, including those who have any responsibility involving its

selection, application, service, or repair. This cap lamp system will perform as designed only if used and

maintained according to the instructions, otherwise it could fail to perform as designed and persons who

rely on this product could sustain serious personal injury or death.

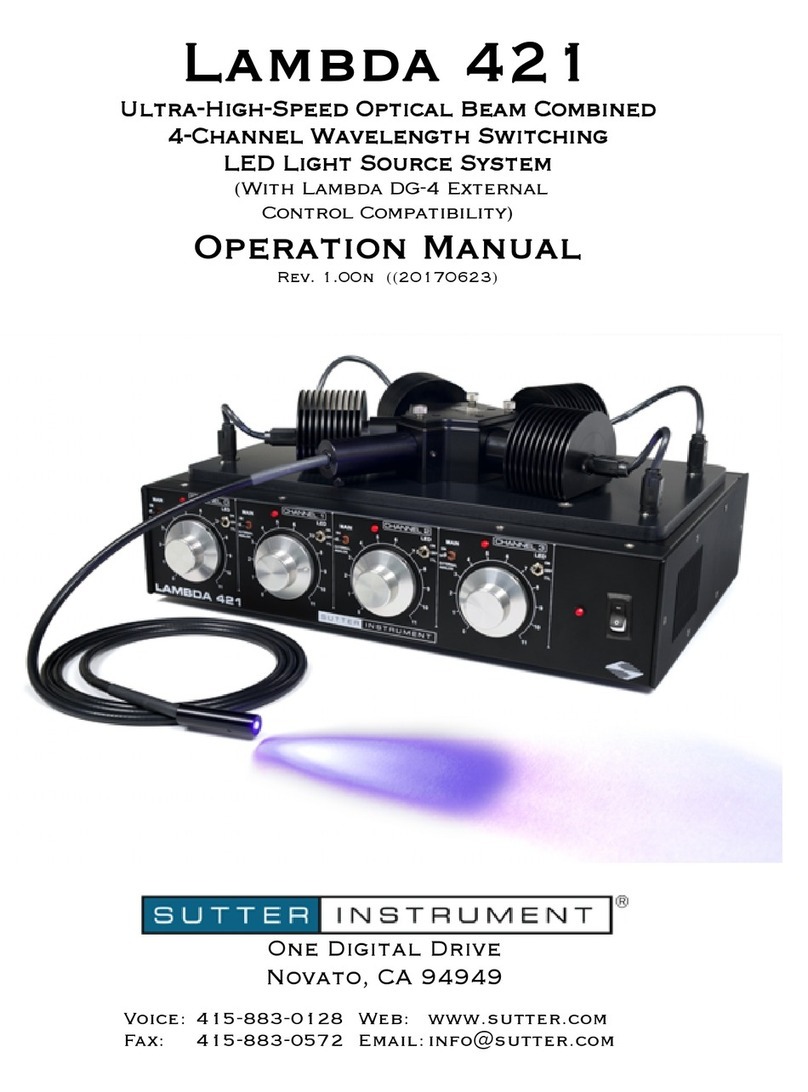

The Powerful Choice

INSTRUCTION

MANUAL

2

G

GT

T

&

&

G

GS

S

C

CA

AP

P

L

LA

AM

MP

P

S

SY

YS

ST

TE

EM

M

TABLE OF CONTENTS

Important p3

General description p3

Preparation for use p3

Battery charging p3

Storage of batteries p3

Filling battery p3

Cap lamp system p4

Replacing battery p4

Removing cable from battery p4

Replacing battery cover (metal) p4

Using GT & GS cap lamp systems p5

Repairing the headpiece p5

Replacing bulbs p5

Removing the bezel ring p5

Replacing main bulb p5

Replacing secondary bulb p6

Replacing the reflector p6

Reassembling the bezel ring p6

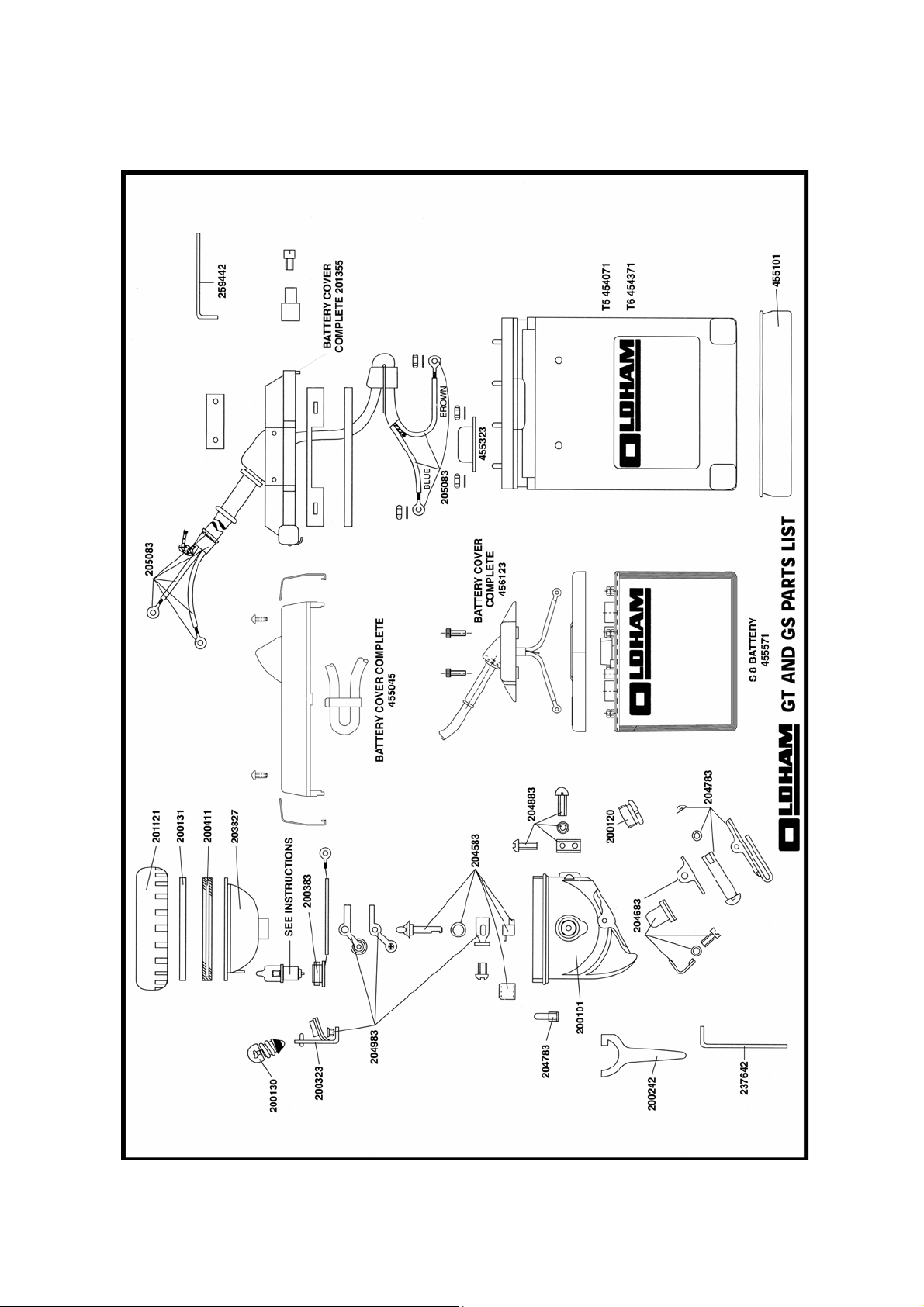

GT & GS diagram – Item list p7

Troubleshooting p8

Certification, equipment marking and instructions for p9

compliance with ATEX standards:-

Use of Equipment p10

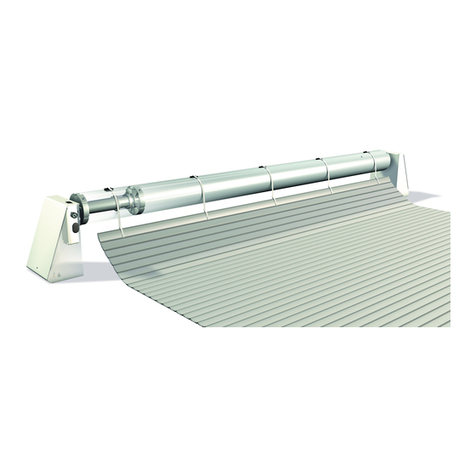

Partsdiagram p11

3

IMPORTANT

Pay close attention to Warnings and Cautions in

this manual. A WARNING describes a condition

that may cause severe personal injury or death if

allowed to happen. A CAUTION describes a

condition that may cause moderate injury or

property damage if allowed to happen.

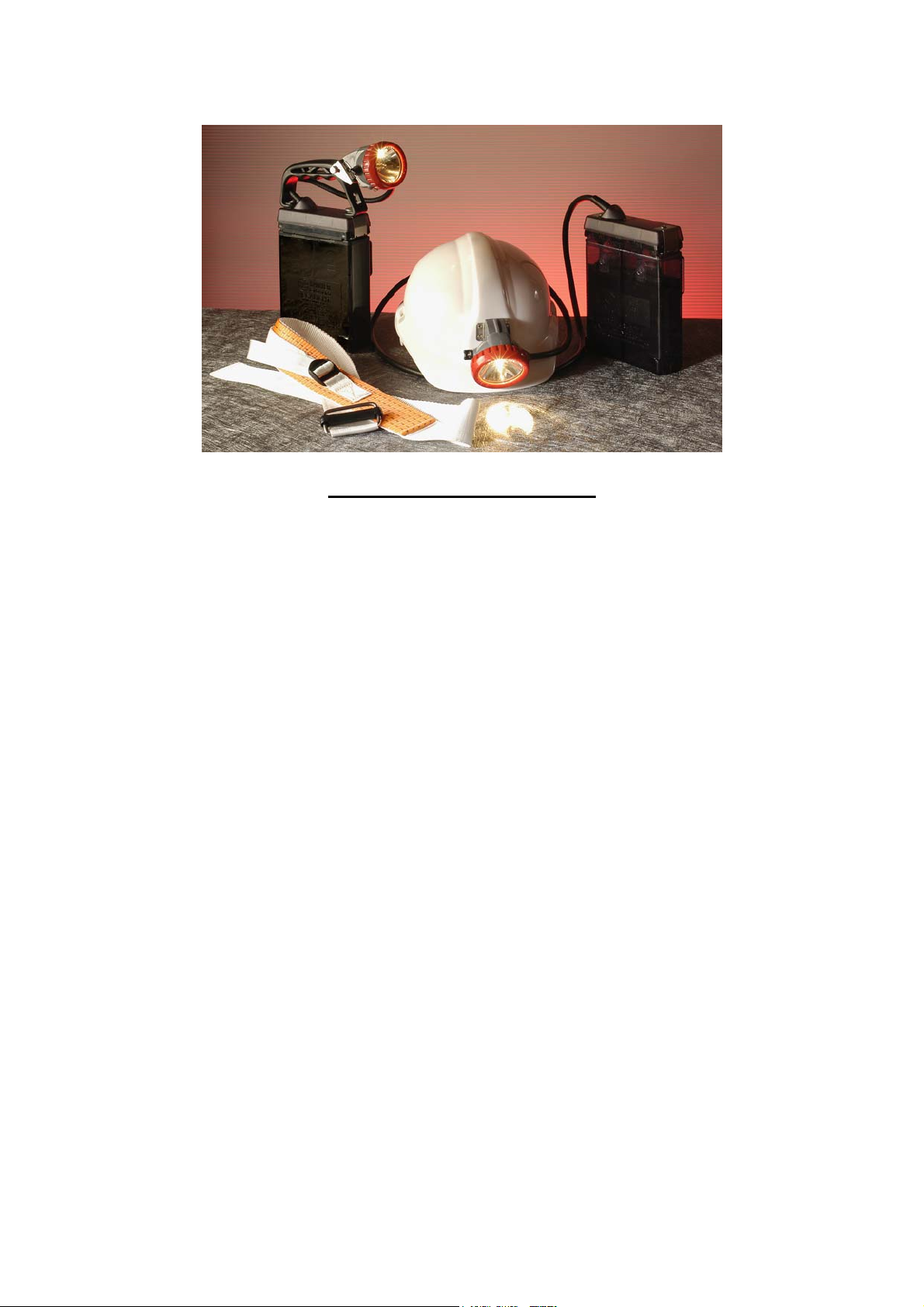

GENERAL DESCRIPTION

The GT & GS cap lamp systems consists of a cap

mounted headpiece powered by a (lead-acid)

battery.

The basis of the headpiece in which some of the

internal connections are integral is as follows. A

selector switch is incorporated, which can switch

on either the large main bulb or the small

secondary bulb. The main bulb is held in the

reflector in a focused position by a screwed bush

from which a lead connects to one of the cable

termination points. The small bulb holder is

positioned at the top of the headpiece, being

connected internally to the cable termination. The

reflector fits over the small bulb and has a rubber

gasket around the rim to seal against the

headpiece lens.

PREPARING THE GT or GS CAP LAMP FOR

FIRST TIME USE

Battery charging

Every battery must be charged before it is used

for the first time.

1. Allow the battery to remain on charge for 24

hours.

2. Top off each cell with distilled water if

necessary (see filling battery). Never fill over

top of fill line.

Note:

Batteries which do not perform satisfactorily,

should be removed from service and cycled-

charged for 16 hours and discharged 8 hours.

Repeat several times until battery responds. If

battery does not respond after three or four

cycles, it should be replaced.

Never discharge completely!

3. After weekly shifts, the battery should be

placed on the charger following the

instructions included with the charger, and left

to charge the remainder of the weekend.

4. If cap lamp needs cleaning, use a mild

detergent and wipe. Do not submerge in

water.

Storage of batteries

All stored batteries with acid should be boost

charged for 24 hours every 3 months, and

immediately before being placed into regular

service.

Recommended storage temperature: 0oC to 27oC.

Filling battery (Type T5 only)

The electrolyte level should be maintained

between the two lines below the filling and venting

hole i.e. slightly above the top of the battery plate.

Normally topping up should not be necessary

more often than once every 4-6 weeks, and

should always be carried out when the battery is

fully charged. Only distilled or de-ionized water

should be used in topping off.

WARNING

The electrolyte level of all batteries should be

checked once each week, and after the battery

is charged (T5 battery only).

Water only when battery is fully charged. If the

battery is overtopped, there is a possibility

that electrolyte may leak out under certain

conditions.

Topping up

1. Fill the plastic bottle (P/N 651901) with

distilled or de-ionized water only.

2. Insert the nozzle of the filling tube into the

small hole provided in the battery window and

squeeze the bottle gently.

3. Fill until the electrolyte level is level with the

bottom one of the two scribed lines below the

cell window. The battery may have to be tilted

back slightly to allow the water to flow.

4. Repeat this procedure in adjacent battery cell.

CAUTION

The electrolyte is corrosive and can cause

burns. Take proper precautions to avoid skin

and eye contact.

4

CAP LAMP SYSTEM

Replacing battery (Stainless steel cover)

1. To remove battery cover, remove the wax

seal (if applicable) from the lock screw hole.

2. Remove locking clamp hex screw with Allen

key (P/N 259442).

3. Remove locking clamp.

4. Lift up locking clamp end of cover and slide

cover back and off battery.

5. Remove fuse.

Replacing battery (Plastic cover)

1. Remove the two M4 button head socket

screws from the two clamp holding the cover.

2. Un-clip the clamps and lift cover to one side.

3. Remove fuse.

S8 plastic cover.

1. Remove the two M5 socket head screws from

the plastic cable clamp.

5

2. Lift the cable clamp to one side.

3. Remove fuse.

Removing cable from battery

1. Loosen nuts from each terminal of battery (do

not lose the nuts).

2. Lift each lead from battery terminal.

Replacing battery cover

1. Attach cable (leads) to battery

2. Connect brown conductor to positive battery

terminal.

3. Connect blue conductor to negative battery

terminal to ensure correct polarity.

4. Tighten cable leads down with terminal nuts

(do not over tighten).

5. Replace fuse.

6. Turn battery so the vent holes are facing you.

7. Replace the battery cover.

Note:

Ensure that the cable leads lie properly on the

battery top without being trapped or pinched.

USING THE GT or GS CAP LAMP SYSTEM

The GT and GS headpiece is made up of the

lamp-housing which contains the following parts:

- Bezel (ring)

- Lens (glass)

- Gasket

- Reflector

- Main bulb

- Secondary bulb

The on-off switch knob is located on the

headpiece. To operate the lamp:

1. Turn the switch knob clockwise to main bulb

or anti-clockwise to secondary bulb.

2. After use turn the switch knob until both bulbs

are off.

Repairing the headpiece

Only the small insulated screwdriver (P/N 201042)

should be used as this allows the screws to be

secured tightly enough without fear of a short-

circuit or other damage. The switch should be

placed in the off position and the battery fuse

removed (see section cap lamp system) before

dis-assembly of the headpiece. When

reassembling the headpiece ensure that the

gasket is correctly fitted around the reflector. The

location of the reflector is by two projections which

fit either side of the pin that rests against the

envelope of the pilot bulb. The bezel ring should

be screwed down firmly and the lock pin placed so

that it fits into one of the recesses of the bezel ring

and firmly screwed tight.

The lock screw can be sealed with wax – if

applicable.

WARNING

It is essential that all contacts in the headpiece

are tight, so that no electrical resistance is

incurred which might increase the time

necessary to obtain an efficient charge or

might reduce the light output of the lamp. In

order to obtain the maximum light possible,

the outside of the lens glass should be

cleaned thoroughly.

REPLACING BULBS (MAIN AND SECONDARY

BULB)

Removing the Bezel ring

1. Remove wax seal (if applicable) from lock

screw.

2. Unscrew lock screw by using special Allen

key P/N 237642

3. Unscrew and remove bezel ring from

headpiece housing.

4. Remove glass (lens) and reflector with sealing

channel from headpiece housing.

Note:

Inspect all parts for cracks or other damage.

6

Replacing the main bulb

1. Lift reflector out of housing, making sure not

to break the bush connection.

2. Unscrew reflector from bush by holding bush

and unscrewing reflector.

3. Remove main bulb.

4. Place the new main bulb in the reflector.

5. Hold the bush and screw the reflector onto it.

Replacing secondary bulb

1. Remove bezel ring (use Remove bezel ring

procedures).

2. Remove reflector from headpiece housing.

3. Unscrew secondary bulb from side socket

assembly of headpiece housing.

4. Thread the new secondary bulb into the

socket assembly (do not over-tighten).

5. Place the hole in the reflector over the

secondary bulb.

6. Reassemble the glass (lens) and bezel to the

headpiece assembly.

Replacing the reflector

1. Remove the bezel ring and lens.

2. Remove the reflector from main bulb bush

connection.

3. Remove gasket around reflector.

4. Place the gasket around the new reflector.

Ensure the gasket is in place all the way

around reflector.

5. Thread the reflector onto the bush connection.

6. Reassemble the lens and bezel ring (see

Reassembling of bezel ring).

Reassembling the bezel ring

When the lens is in position over the reflector, the

bezel ring is locked in position by a hex headed

lock screw that fits into a countersunk hole and

then enters one of the slots in the bezel ring. The

countersunk hole enclosing the lock pin can be

filled with wax if desired.

7

GT & GS DIAGRAM – ITEM LIST

200101. Headpiece shell

201121. Bezel ring

200131. Glass lens

200411. Sealing channel

203827. Reflector

200323. Small bulb socket

259130. Main bulb 4V 48 Lumen Halogen **

200130. Small bulb 4V 0.46A

200383. Prefocus reflector Bush and connection

203456. Cable 1.59m

455101. Plastic protection shoe

** dependant upon lamp type and temperature

classification

204983

HEADPIECE CONTACT KIT

Large bulb/switch connection

Small bulb/switch connection assembly

Switch connection

3/16” B HD screw

204583

SWITCH KNOB KIT

Switch knob

Switch knob sealing washer

Switch blade

Switch blade cowl

Grub Screw

204883

POSITIVE CHARGING SCREW KIT

Positive contact sealing washer

Charging contact screw

Large bulb socket block

Large bulb socket screw

205083

CABLE TERMINAL SPARES KIT

Cable grip

Sealing collar

Small terminal tag

Large terminal tag

Terminal sleeving Brown

Terminal sleeving Blue

Terminal tag (headpiece end)

204683

LOCK CONTACT KIT

Lock spring

Lock barrel

Lock contact

Lock contact screw

Lock contact sealing washer

204783

CAP CLIP KIT

Cap clip

Cap clip screw

Cap clip nut

Spring washer

Cap head lock pin

455045

PLASTIC BATTERY COVER COMPLETE

Clip for standard cover

Screw for plastic cover

Cable gland

Cable tie

614830

TOOL KIT

Small tools and spares kit for GT & GS lamps

comprising :-

Cable outlet gland key

Key for headpiece lock pin

Key for battery lock screw

Insulated screwdriver

Spring screwdriver

Key for battery terminal nuts

Topping up bottle (for T5 battery only)

Two main bulbs 4v / 0.75 amp Halogen

Two secondary bulbs 4v 0.46 amp

Two “T” battery fuses

Note: Only certain replacement items above may

be purchased individually. All others, as noted

above, must be purchased in kit form as this

ensures that other associated parts are also

available for replacement at the same time.

8

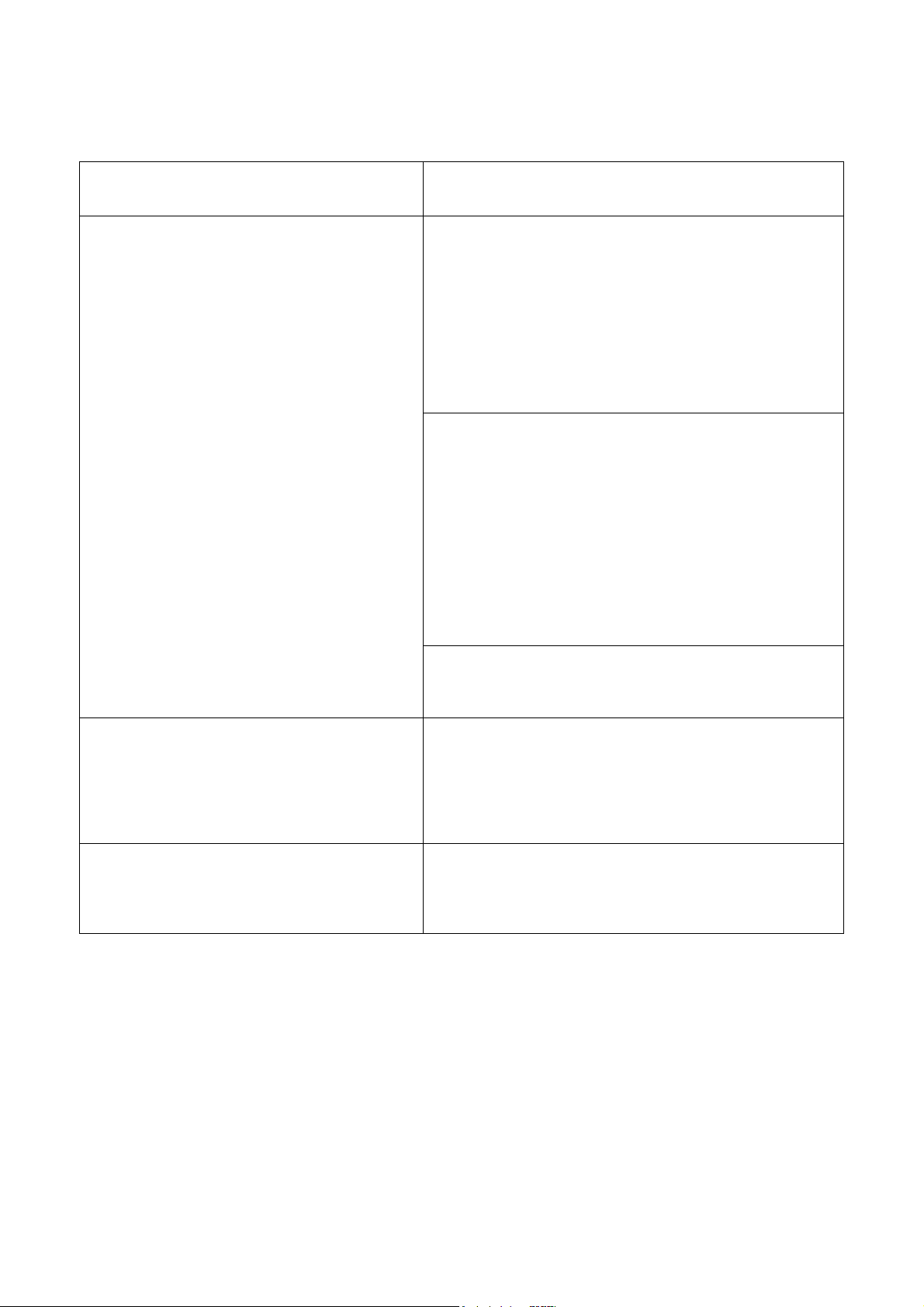

TROUBLESHOOTING

PROBLEM

CAUSE

1. Low battery capacity:

a. Observe the electrolyte level in the cell windows and

make certain level is between the two scribed lines on

the cell windows.

b. Continuous use of battery that has not been fully

charged will cause it to lose its capacity. This may be

corrected by cycling the battery several times

(discharge 8 hours and recharge 16 hours). Repeat

this procedure 3 times. If battery does not respond,

replace with a new one.

c. Battery not charged.

2. Loose connections:

a. Gently wiggle or pry each connection on top of the

battery to make sure it is tight and working properly.

b. Check the cables for broken conductors by twisting or

pulling it at various points along its length.

c. Check the headpiece terminals and the electrical

connections inside the headpiece in the same manner

as those on the battery.

d. Make sure the bulb is secure and making good

contact.

e. If the light flickers or dims when any of the preceding

items are being checked, that item should be repaired

or replaced.

Bulb glows dimly, flickers or fails

3. Electrolyte level:

a. Check at least once each month to see that the

electrolyte level is between the two scribed lines on

the cell window.

Battery not holding a charge during shift a. Make sure charger output is correct.

b. Check electrolyte level after charge

c. Make sure connections between headpiece and

battery are good.

d. Make sure that charging rack connections are good.

e. Make sure stored batteries are boost charged before

placing into service.

Battery capacity a. 13Ah battery recommended for 8-10 hour discharge /

16-14 hour charge, 5 days a week. Use the 16Ah

battery for greater cycle routines.

b. Check charger.

c. Check battery connections.

IMPORTANT : ALWAYS RECHARGE THE LAMP AFTER USE.

9

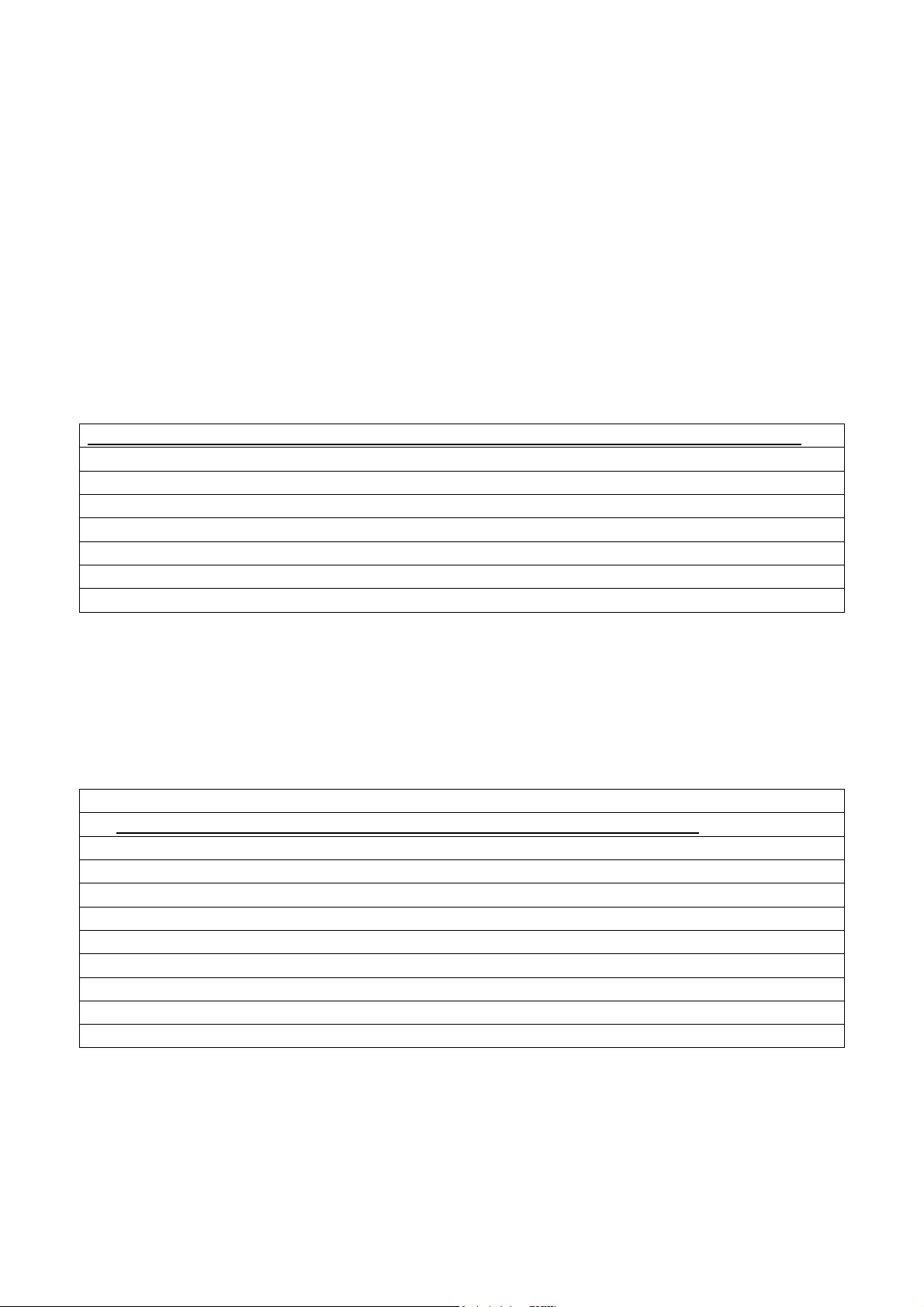

Certification, equipment marking and instructions for

compliance with ATEX standards:-

The GT and GS range of cap lamps are certified for use in Mines (Group I ) and Surface

(Group II ) areas where potentially explosive atmospheres may exist. The lamps are suitable for

M2 (Mining) and Group II 2 applications.

Certification codes are:-

Sira 02ATEX3175

Mining Group I:- EEx I ( Ta = -20oC to +40oC)

Surface Group II:- EEx II (Ta = 0oC to +40oC)

Warning the correct main bulb must be fitted to ensure the correct temperature classification.

Bulb Type Part Number Description Temperature Classification

B2 M259130 Prefocus Halogen Bulb 4.1v 48L T2

B2 M259530 Prefocus Halogen Bulb 4v 1.5A T2

B3 M259230 Prefocus Halogen Bulb 4v 0.75A T3

B4 M201230 Prefocus Krypton Bulb 4v 1A T4

Lamp Type Reference:-

The lamps can be assembled in a variety of combinations to satisfy customer requirements. The

assembly combination is stated on the certification label and this combination should not be

changed without consultation of Enersys Ltd., Swinton, Manchester UK.

The type code sequence is as below:-

1 2 3 4

Lamptop type Bulb type Battery Cover type Battery type

GStandard B2 S Stainless Steel T1 13Ah Low Maintenance

GH i.s. power Take off B3 LHand Lamp T2 16Ah Low Maintenance

B4 CCommunication Cover T3 13Ah Maintenance Free

PPlastic Cover T4 16Ah Maintenance Free

T5 16Ah Low Maintenance

T6 16Ah Maintenance Free

S8 8 Ah MF curved

S16 16Ah MF curved

1 2 3 4

Sample type code:- G B2 P T5

10

Use of equipment:-

The user must ensure that the lamp supplied meets the safety standard required for the Zoned

area:-

1. This equipment must only be used in a Category M2 or 2 / 3 zone. This equipment is not

suitable for a Category M1 or 1 zone.

2. Check the temperature classification and ensure the correct main bulb is fitted.

3. Check that the operating temperature range is in the range –20oC to +40oC for Mining and

0oC to +40oC for surface application.

4. The lamp must not be disassembled in a hazardous area.

5. The lamp must not be charged in a hazardous area.

6. The cap light and battery casings are manufactured from polycarbonate and ABS with

nitrile rubber seals. The performance of these materials, with respect to attack by

aggressive substances that may be present in the hazardous area, shall be taken into

account before the equipment is used.

7. Plastic surfaces may cause propagating brush discharges. Propagating brush discharges

are caused by non-conducting fluid flow over a non-conducting plastic surface. The cap

lights shall not be used in areas where a high fluid flow over the plastic surfaces may occur

(for example in the case of a ruptured process pipe or compressed air pipe).

EnerSys Ltd.,

Rake Lane,

Swinton

Manchester M27 8LR

UK

tel: +44 (0)161 727 3950 - 3955

September 2004

11

This manual suits for next models

1

Table of contents

Other EnerSys Lighting Equipment manuals

Popular Lighting Equipment manuals by other brands

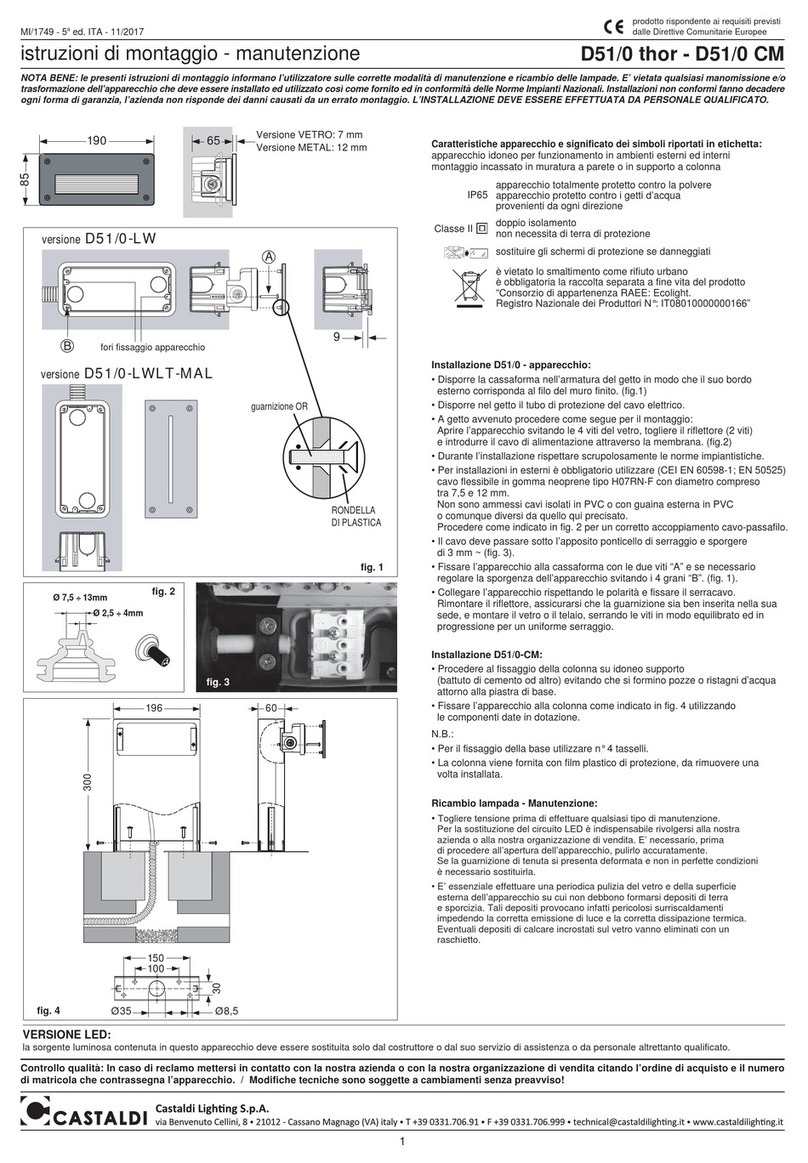

Castaldi Lighting

Castaldi Lighting D51/0 thor Installation and maintenance sheet

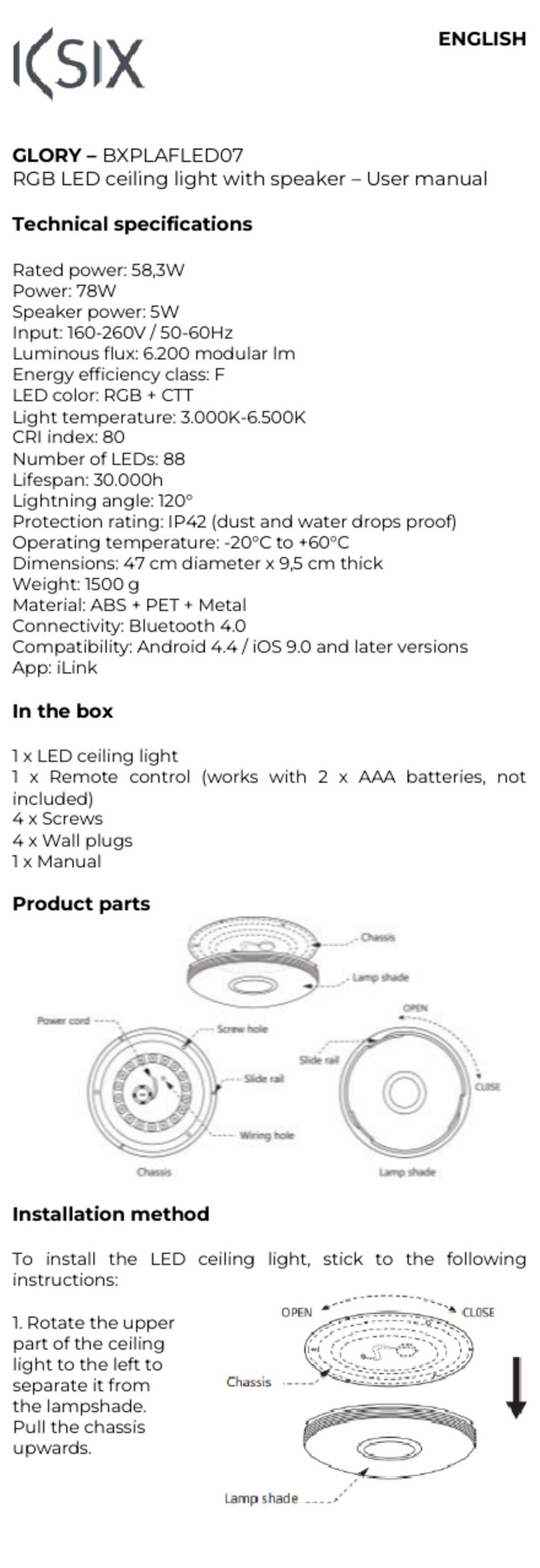

KSIX

KSIX GLORY user manual

Generac Power Systems

Generac Power Systems MLTS owner's manual

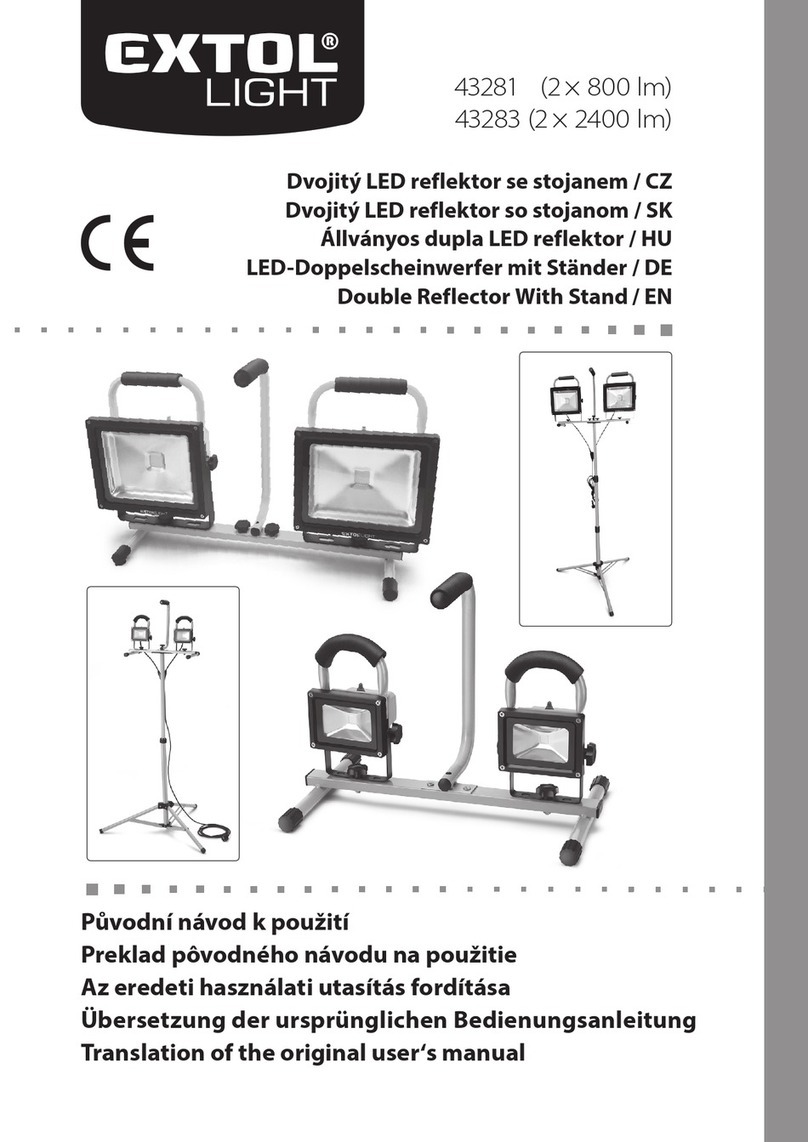

EXTOL LIGHT

EXTOL LIGHT 43281 Translation of the original user manual

Procopi

Procopi AQUADECK EB Installation and maintenance instructions

Anslut

Anslut 005055 operating instructions