ENERVEX VHX-DR Installation instructions

010.4150.0720 08.21 Installation & Operating Manual

ENERVEX

VHX-DR VORTEX HEAT RECOVERY CENTER

ENERVEX Inc.

1685 Bluegrass Lakes

Parkway

Alpharetta, GA 30004

USA

P: 770.587.3238

F: 770.587.4731

T: 800.255.2923

www.enervex.com

READ AND SAVE THESE INSTRUCTIONS!

2

010.4150.0720 08.21

TO: Owners, Operators and/or Maintenance Personnel

This operating manual presents information that will help to properly operate and care for the equipment. Study its contents

carefully. The unit will provide good service and continued operation if proper operating and maintenance instructions are

followed. No attempt should be made to operate the unit until the principles of operation and all of the components are

thoroughly understood. Failure to follow all applicable instructions and warnings may result in severe personal injury or death.

It is the responsibility of the owner to train and advise not only his or her personnel, but the contractors’ personnel who are

servicing, repairing or operating the equipment, in all safety aspects.

ENERVEX equipment is designed and engineered to give long life and excellent service on the job. The electrical and

mechanical devices supplied as part of the unit were chosen because of their known ability to perform; however, proper

operating techniques and maintenance procedures must be followed at all times. Although these components afford a high

degree of protection and safety, operation of equipment is not to be considered free from all dangers and hazards inherent in

handling and firing of fuel.

Any ”automatic” features included in the design do not relieve the attendant of any responsibility. Such features merely free

him of certain repetitive chores and give him more time to devote to the proper upkeep of equipment.

It is solely the operator’s responsibility to properly operate and maintain the equipment. No amount of written instructions

can replace intelligent thinking and reasoning and this manual is not intended to relieve the operating personnel of the

responsibility for proper operation. On the other hand, a thorough understanding of this manual is required before attempting

to operate, maintain, service, or repair this equipment.

Because of state, local, or other applicable codes, there are a variety of electric controls and safety devices which vary

considerably from one boiler to another. This manual contains information designed to show how a basic burner operates.

Operating controls will normally function for long periods of time and we have found that some operators become lax in

their daily or monthly testing, assuming that normal operation will continue indefinitely. Malfunctions of controls lead to

uneconomical operation and damage and, in most cases, these conditions can be traced directly to carelessness and

deficiencies in testing and maintenance.

It is recommended that a boiler room log or record be maintained. Recording of daily, weekly, monthly and yearly

maintenance activities and recording of any unusual operation will serve as a valuable guide to any necessary investigation.

Most instances of major boiler damage are the result of operation with low water. We cannot emphasize too strongly the need

for the operator to periodically check his low water controls and to follow good maintenance and testing practices. Cross-

connecting piping to low water devices must be internally inspected periodically to guard against any stoppages which could

obstruct the free flow of water to the low water devices. Float bowls of these controls must be inspected frequently to check

for the presence of foreign substances that would impede float ball movement.

The waterside condition of the pressure vessel is of extreme importance. Waterside surfaces should be inspected frequently

to check for the presence of any mud, sludge, scale or corrosion.

It is essential to obtain the services of a qualified water treating company or a water consultant to recommend the proper

boiler water treating practices.

The operation of this equipment by the owner and his or her operating personnel must comply with all requirements or

regulations of his insurance company and/or other authority having jurisdiction. In the event of any conflict or inconsistency

between such requirements and the warnings or instructions contained herein, please contact ENERVEX before proceeding.

DO NOT OPERATE, SERVICE, OR REPAIR THIS EQUIPMENT UNLESS YOU FULLY

UNDERSTAND ALL APPLICABLE SECTIONS OF THIS MANUAL.

DO NOT ALLOW OTHERS TO OPERATE, SERVICE, OR REPAIR THIS EQUIPMENT UNLESS

THEY FULLY UNDERSTAND ALL APPLICABLE SECTIONS OF THIS MANUAL.

FAILURE TO FOLLOW ALL APPLICABLE WARNINGS AND INSTRUCTIONS MAY RESULT IN

SEVERE PERSONAL INJURY OR DEATH.

WARNING

3

010.4150.0720 08.21

Content

1. PRODUCT INFORMATION

1.1 Function............................................................4

1.2 Components.....................................................5

1.3 Shipping ...........................................................5

1.4 Warranty ...........................................................5

2. SPECIFICATIONS AND DIMENSIONS

2.1 Dimensions and Capacities...............................6

3. PRE-INSTALLATION INFORMATION...............7

4. MECHANICAL INSTALLATION

4.1 General.............................................................8

4.2 Positioning........................................................8

4.3 Vertical Installation.............................................9

4.4 Horizontal Installation ........................................9

4.5 Connection to Chimney (Bolted Flange)............10

4.6 Modulating Bypass with Flow Control ...............10

5. PLUMBING INSTALLATION

5.1 General.............................................................11

5.2 Connecting Piping ............................................11

5.3 Mounting of Temperature Sensor ......................12

5.4 Safety Relief Valves...........................................12

5.5 Mouting of Flow Meters (if applicable)...............12

5.6 Special Installation Considerations....................12

6. ELECTRICAL INSTALLATION

6.1 General.............................................................14

6.2 Modulating Bypass Damper..............................14

7. STARTUP AND CONFIGURATION

7.1 General.............................................................15

8. MAINTENANCE AND TROUBLESHOOTING

8.1 General.............................................................16

8.2 Removal of Heat Modules.................................16

8.3 Maintenance.....................................................16

8.4 Cleaning...........................................................16

9. APPLICATION EXAMPLES

9.1 Preheating Boiler Return Water .........................18

9.2 Preheating Circulating Feed Water ....................18

9.3 Preheating Boiler Make Up Water .....................19

9.4 Preheating Steam Boiler Feed Water.................19

9.5 Circulating Make Up Water Heating ..................20

9.6 Condensate Return Heating .............................20

9.7 Calorifier Heating Loops ...................................21

9.8 Process Water Heating.....................................21

10. ECONOMIZER CONTROLS (HRC 80)

4.1 General.............................................................22

4

010.4150.0720 08.21

1. PRODUCT INFORMATION

1.1 FUNCTION

The VHX-DR, Vortex Heat Recovery Center, is a unique and

highly efficient economizer system with a built-in bypass.

It is a fully packaged light weight product with a round

configuration for ease of installation. The all 316L stainless

steel construction allows it to be used for both condensing

and non-condensing applications without any modifications.

It is extremely compact compared to traditional economizers

as it utilizes a modular design with one or more heat modules

that each have supply and return connections representing

individual liquid circuits. Individual circuits can be connected

to one or more common headers in accordance with the

specific application.

The modular design allows the economizer to be used for

multiple applications at the same time: one module can be

used for preheating of feedwater, one module for domestic

hot water, and one module for direct pool heating etc.

The unique economizer design creates a turbulent flow

across the module surface, thus maximizing heat transfer.

The modules are designed to handle asymmetric volume

flows with exceptionally high performance and are mounted

in individual slots - an easily serviceable configuration.

A modulating, multi-blade damper design provides bypass

capabilities for use with dual fuel applications, and also

prevents over-heating of the heat modules.

In most applications, the economizer is fully designed and

packaged with an automated mechanical draft system

capable of optimizing the exhaust rate of the appliance to

completely stabilize the appliance efficiency combustion

as well as to assure a proper and constant draft for the

appliance. This allows a single economizer to serve multiple

boilers no matter whether they are of atmospheric, fan-

assisted or forced draft design.

The VHX-DR is virtually maintenance free, having no moving

parts except the internal gas bypass assembly.

The performance of this type of exchanger is ultimately

dependent upon the dynamic conditions of temperature,

pressure and massflow available on both the liquid and gas

side.

The custom transitions offered fit most commercial pre-

fabricated chimney systems.

The VHX-DR Heat Recovery Module should only be used

with appliances operating on Natural Gas, LP-Gas/Butane

or low sulfur fuel oil (#2 through #6). In some exhaust

applications containing debris etc., cleaning may be required

periodically.

5

010.4150.0720 08.21

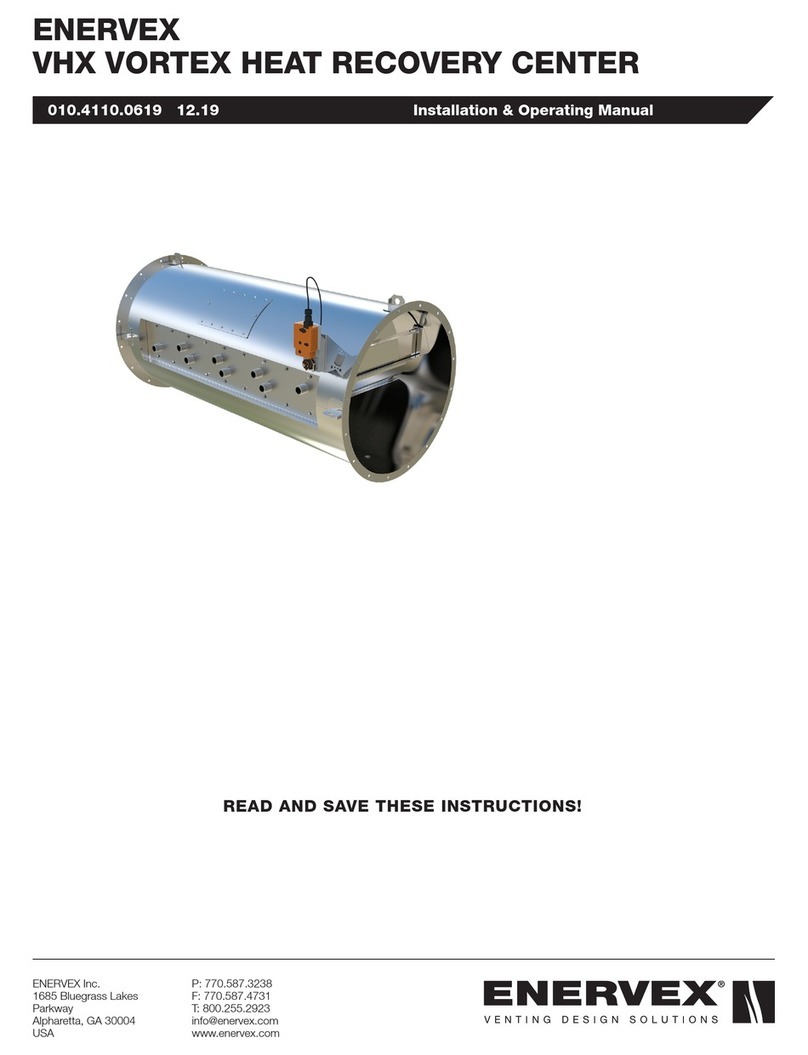

1.2 COMPONENTS

The VHX-DR Heat Recovery Center can be supplied

in several configurations with single or multiple heating

modules. A modulating bypass damper controlled by a

modulating damper actuator is standard for all. The major

components are shown in Fig 1.

Components such as headers, pressure relief valves,

temperatures sensors, flowmeters and controls are optional

but can be supplied by ENERVEX.

1.3 SHIPPING

ENERVEX inspects all equipment prior to shipment and

cannot be held responsible for damage caused in transit. In

addition, all electrical devices are also thoroughly tested to

assure that they operate according to design specifications.

All economizers are shipped via common carrier. Take care

to inspect the economizer when you receive it and make

any claims for damages immediately to the carrier within the

allowable time limit.

The VHX-DR product line units are shipped on pallets. To

remove the economizer, first position the unit, while either

still in the shipping container or on the skid, as close to the

installation site as possible. Then attach a lifting hoist to all

the lifting lugs located on the top of the housing or on the

side.

If other components are shipped, these will appear as

separate items on the shipping packing list.

If there are any questions during the removal and installation

of the exchanger please do not hesitate to contact your

authorized ENERVEX representative for suggestions.

1.4 WARRANTY

2-Year Factory Warranty. Complete warranty conditions are

available from ENERVEX, Inc.

Fig 1

1. Economizer housing

2. Mounting Flanges (bolt flange)

3. Damper (not pictured)

4. Modulating actuator

5. Header (optional)

6. Connection flange

7. Flexible connectors

8. Connection for pressure relief valve

9. Connection for water temperature sensor

10. Cover for heat module chamber

11. Lifting lugs

6

010.4150.0720 08.21

2. SPECIFICATIONS AND DIMENSIONS

2.1 DIMENSIONS AND CAPACITIES

1) NPT adaptors available from ENERVEX, Inc.

Larger sizes available upon request; contact ENERVEX, Inc. with specifications.

Specifications

Double Row Models VHX

1600-22DR

VHX

3200-33DR

VHX

4200-44DR

VHX

5400-55DR

VHX

6400-66DR

VHX

7400-77DR

VHX

8400-88DR

Housing Material ASTM 316L / 1.4404

Heat Exchanger Material ASTM 316L / 1.4404

No. Heat Modules 4 6 8 10 12 14 16

Heat Module Type Cross

30-140

Cross

30 - 140

Cross

30 - 140

Cross

30 - 140

Cross

30 - 140

Cross

30 - 140

Cross

30 - 140

Heat Exchanger Plate

Surface Area Ft2416 624 832 1040 1248 1456 1664

Operating Pressure

Max PSI 230

Water Connection NPT1) 1 1/4” NPT MALE

Weight (Dry) lbs/kg 350 / 159 512 / 232 667 / 303 824 / 374 982 / 445 1139 / 517 1297 / 588

Weight (Wet) lbs/kg 394 / 179 578 / 262 755 / 342 934 / 424 1114 / 5 0 5 1293 / 586 1473 / 668

Length in/mm 39.0 / 991 50.0 / 1270 65.0 / 1651 78.0 / 1981 96 / 2438 102 / 2591 130 / 3302

ID in/mm 36.0 / 914 42.0 / 1067 42.0 / 1067 48.0 / 1219 48 / 1219 54 / 1372 54 / 1372

OD in/mm 39.0 / 965 45.0 / 1143 45.0 / 1143 51.0 / 1295 51 / 1295 57 / 1448 57 / 1448

No. of Flange Bolt Holes 16

Dimensions

flange

7

010.4150.0720 08.21

3. PRE-INSTALLATION INFORMATION

The VHX-DR Heat Recovery Center is used with a liquid in

the circuit with connections and a gas on the open side. The

heat exchanger must operate in line with approved design

parameters: temperatures, pressures and flow rates.

Liquid side

Typical medias are ethylene/propylene glycol, thermal oil,

and water. It is important that the liquid is of good quality

without contamination or corrosive substances. The medias

should not contain particles or any other undissolved matter,

we recommend that a strainer with a size of 16-20 mesh

(number of openings per inch) is installed before the fluid

inlet. The particles could otherwise block the channels,

causing bad performance, increased pressure drop and the

risk of boiling.

Systems with water or another evaporating liquid must

be equipped with the necessary bleed valve mounted in

a position higher than the heat exchanger. Air/gas inside

the liquid channels will reduce heat transfer and water

circulation, which also could cause boiling.

The liquid flow must be constant and with sufficient pressure

to keep its evaporating/boiling temperature above the plate

temperature. Local evaporation/boiling will adversely affect

heat transfer and water circulation, and may lead to a risk of

serious damage to the heat exchanger.

NOTE: The pressure at the coolant outlet must be high

enough to avoid boiling.

The VHX heat modules must always have the cooling fluid

circulating fully before the hot gas enters the heat exchanger.

The coolant must NEVER be allowed to freeze.

Never expose the VHX Heat Modules to excessive liquid

pulsations (i.e. cyclic pressure or temperature changes).

Gas side

The gas media should not be corrosive to the heat modules.

The gas flow must be started after, or simultaneously to, the

start of the liquid flow. If the liquid flow is interrupted, the

gas must be stopped or caused to bypass the VHX heat

modules to avoid boiling on the liquid side.

The VHX-DR Heat Recovery Center must not be operated

in such a manner that stagnant condensate is allowed to

accumulate. Never expose the Cross heat exchanger to

excessive gas pulsations (i.e. cyclic pressure or temperature

changes).

The VHX-DR Heat Recovery Center must NEVER be

operated without a coolant flow.

8

010.4150.0720 08.21

4. MECHANICAL INSTALLATION

4.1 GENERAL

WARNING

Failure to install, maintain and/or operate the

VHX-DR Heat Recovery Center in accordance

with the manufacturer’s instructions may result

in conditions which can produce bodily injury

and property damage.

The VHX-DR must be installed by a qualified installer in

accordance with these instructions and all local codes, or in

their absence, with the latest edition of The National Fuel Gas

Code (NFPA54/ANSI223.1), NFPA 211, NFPA 31 or Canada

CAN/CSA-B149.1-05 National Gas and Propane Installation

Code when applicable. The VHX-DR must be mounted so

the clearance to combustibles is at least 18 inches.

Preferably, the VHX-DR should be installed as close to the

heating appliance as possible — vertically or horizontally in

the breeching. It can also be installed near the termination

or on a roof. In addition, it can be used for sidewall

vented applications where it discharges through a wall. A

condensate drain is provided with the VHX-DR to be installed

by the user.

The VHX-DR is for indoor and outdoor installation. If installed

outdoors, steps must be take to prevent freezing of water

in the VHX-DR housing and pipes (see Section 4.3). The

vent pipe must be installed and supported according to the

chimney manufacturer’s instructions and/or in accordance

with NFPA54, NFPA211 and Canada CAN/CSA-B149.1-05.

4.2 POSITIONING

Consult “2. Specifications” for specific weights and

dimensions to ensure a well designed and safe installation

when either hanging or supporting the exchanger. The

exchanger is shipped ready to be mounted in the vertical or

horizontal position. Make sure to check the actual number of

lugs and their positions on the spec drawings before planning

the installation.

For existing retrofit installations, ensure that the combustion

source has been turned off and has cooled. A condensate

drain connection is provided at the bottom of the unit.

Header manifold inlet/outlet connections for water supply and

return are optional. For retrofit installations the economizer is

installed in line with the existing exhaust stack or duct unless

otherwise noted

Generally a section of the exhaust stack is removed to

accommodate the insertion of the economizer. The remaining

portion of the exhaust stack above the cut should not exceed

a static load of 500 lbs. or exert any moments on the outlet

flange, and must be adequately supported.

In some cases the economizer may be placed directly on top

9

010.4150.0720 08.21

Fig 2

Fig 3

of the combustion source, in effect forming the first section of

the exhaust duct, with the existing exhaust stack lifted or cut

to accommodate the economizer.

NOTE: Structural integrity of the building should be veried (by

others) prior to installing an economizer by suspending from

the ceiling.

4.3 VERTICAL INSTALLATION

For vertical flow units it is recommended that the unit be

completely supported either by a floor support structure or by

threaded rods from the ceiling (design and supply of support

by others).

In no case should the static load on the economizer inlet

or outlet flange exceed 500 pounds. In no case should any

moment be applied to the economizer inlet or outlet. Lifting

lugs are placed on top of the economizer and on each side.

Actual number depends on the model, please refer to the

specification drawing for the specific VHX model.

Apply expansion joints (supplied by others) as required by

the installation to ensure that no outside forces from thermal

expansion to either the exhaust gas connections or to the

piping will be permitted.

4.4 HORIZONTAL INSTALLATION

For horizontal flow units the economizer must be suspended

from the ceiling as permitted or set in place on a structural

support (designed by others) as permitted.

Lifting lugs are placed on top of the economizer and on each

side. Actual number depends on the model, please refer to

the specification drawing for the specific VHX model.

Structural integrity of the building should be verified (by

others prior to installing an economizer by suspending from

the ceiling. Apply expansion joints (supplied by others) as

required by the installation to ensure that no outside forces

from thermal expansion to either the exhaust gas connections

or to the piping will be permitted.

10

010.4150.0720 08.21

4.6 MODULATING BYPASS WITH FLOW CONTROL

The VHX-DR is equipped with a modulating bypass damper

and flow control system.

Fig 5 shows the inlet of the VHX-DR and the damper in

“open” and “closed” positions.

The exhaust flow enters through the top part of the housing,

where it is forced down through the heat modules as long as

the damper is closed (default position).

In the event the heat modules are over-heating or the system

set temperature has been reached, the damper will begin to

open and reduce the flow through the heat modules, which

will provide a a reduction in heat recovery. Eventually, if the

reduction is inadequeate, the damper will open completely

which will make the exhaust flow bypass the heat modules.

Fig 4

Fig 6

4.5 CONNECTION TO THE CHIMNEY (BOLTED

FLANGE)

Exhaust connections are generally mated with optional

mating flanges and/or stack transitions.

Connection to the economizer flange is either by a gasket

provided by others or applying a continuous 1/3 inch bead of

the appropriate sealant around both the economizer flange

and the corresponding chimney flange adaptor.

The chimney flange adaptor is then bolted to the economizer

flange. Please note that neither the gasket nor the required

nuts and bolts are provided with this component. Ensure that

the economizer is level before final bolting into position.

Fig 5

11

010.4150.0720 08.21

Fig 9

Fig 7

5. PLUMBING

5.1 GENERAL

It is not within the scope of this manual to provide specific

plumbing installation instructions as the installation should

follow the design specifications of the design engineer,

architect, or contractor. However, measures must be taken

to prevent the water from stagnating within the economizer

while the boiler(s) are in operation. Also, the water side of

the economizer must be kept free of grease and other foreign

material which can shorten the life of the economizer and

possibly interfere with the operation of controls and safety

devices. Proper feedwater treatment is a major factor in

preventing economizer failure.

Only low sulfur fuels should be used with the VHX-DR. if

fuels other than natural gas are used, there is a risk of “cold

end corrosion” when the entering water temperature falls

enough to cause condensation of the flue gases so verify the

feasibility of the application with the design engineer prior to

installation.

Generally, schedule 40 steel pipe is used in the piping

installation. In some applications other piping material may be

needed. Consider the type of liquid, operating pressures and

temperatures, and any corrosive elements in the liquid or in

the atmosphere when determining the best piping material

for your installation. The use of valves is recommended

where isolation might be required. Non-ferritic piping is

recommended if using non-deaerated water.

5.2 CONNECTING PIPING

Actual piping depends on how the heating modules are

configured. Water should flow counter flow to the exhaust.

If the heat modules are connected to a common header,

supply and return liquid pipes must be connected directly to

the common header. This is shown in Fig 7. Balancing valves

should be installed in order to ensure that the flow is equally

distributed.

If the VHX-DR is used for multiple applications, e.g. one heat

module is used for domestic water while the other is used

for boiler feed-water, each application must be connected

directly to the supply and return connections on the heat

module. See Fig 8.

Liquid connections are connected with NPT threaded fittings.

The maximum allowable connection loads given in Fig 9 are

valid for low cycle fatigue. If high cycle fatique is involved, a

special analysis should be carried out

Liquid piping should include shut-off, drain and bypass valve

piping in the event the exchanger is required to be isolated.

Drain piping should include valves of dependable

manufacture in order to further reduce the possibility of an

undetected leak.

Outlet

Headers Flexible

Water Connection

Inlet

Fig 8

Max. Bending Torque Torque Moment

Connections 20 Nm 70 Nm

12

010.4150.0720 08.21

The installation of a vent valve at the highest point in the

piping system is recommended in order to purge air out

especially during initial start up.

Safety relief valves, as required, should be located at the

exchanger and piped separately and safely to the drain.

5.3 MOUNTING OF TEMPERATURE SENSORS

There are four temperature sensors. Two flue gas high

temperature sensors (PT1000) and two Hi-Temp water

sensors (HT-NTC).

Install the flue gas temperature sensors before and after the

economizer. The minimum recommended distance is three

times the diameter (3xID) of the flue. See Fig 10.

The installation order and parts involved is shown in Fig 11.

Temperature sensors are installed on the water lines inlet

and outlet of the heat exchanger. The water temperature

sensors should be installed as close as possible to the heat

exchanger. See Fig 12.

NOTE: Ensure that the water temperature sensor is

fully inserted into the socket after the electricians have

nished running the wires. If it is not fully inserted the

system will not read the correct temperature and will not

be able to react appropriately.

5.4 SAFETY RELIEF VALVES

A Safety Relief Valve(s) is required for every installation. In a

system with headers, they must be installed according to

Fig 13

NOTE: The safety relief valves must be located between

any isolation valves and the VHX-DR and within close

proximity of the heat module e.g. in the common header.

Liquid piping to and from the heat modules should allow

the heat modules to be lled at all times especially when

ow could stop.

5.5 MOUNTING OF FLOWMETERS (IF APPLICABLE)

A flowmeter is an optional, but highly recommended

accessory. There are multiple models available depending

on flow and pipe size. The Flowmeter should be installed at

the inlet of the heat exchanger. Please refer to the Installation

Manual for HRC 80 Heat Exhanger Controller.

5.5 SPECIAL INSTALLATION CONSIDERATIONS

The VHX-DR economizer may be installed inside or outside

with appropriate drain piping installed for shutdown periods.

If there is a remote chance the temperatures outside might

fall below freezing it is recommended that care be taken to

avoid potentially freezing the heat transfer core.

A condensate drain connection is provided in the bottom

for all economizers and should be piped to a floor drain

using a water trap and neutralizer to prevent the escape of

flue gases. Please note the submittal drawing or consult

ENERVEX regarding location of the economizer condensate

drain.

Fig 10

Fig 12

Fig 11

13

010.4150.0720 08.21

Freeze protection concerns: During a system shutdown

where combustion halts for an extended period of time

(other than normal cycling), cold air will travel back down the

stack and exhaust breechings, through the economizer and

into the combustion source. If the cold air is below freezing,

it could freeze the plates and cause a rupture, ultimately

destroying the economizer. For potential freezing applications

where the water flow might stop, a manual system shut

down routine should be incorporated. It is not recommended

to use solenoid type drain valves for auto draining in subzero

environments unless absolutely necessary.

Do not insulate the economizer where factory insulation has

already been applied or damage to the exchanger can occur.

Insulate piping and exhaust ducting as required.

Ensure that no liquid connections interfere with the opening

of recovery unit trays. Economizer relief valves shall not have

set pressure ratings higher than the rated pressure of the

heat modules. Liquid storage tank relief valves shall not have

discharge pressure ratings higher than the rated pressure of

the storage tank. To avoid safety valve leakage, ensure that

safety valve set pressure is sufficiently higher than dead head

pressure of the feed pump.

It is recommended that the pipe and circulating tank (if

included) be insulated to reduce heat loss.

If existing conditions may subject the heat modules to

internal scale build up, pressure gauges (furnished by others)

should be installed on the liquid inlet and outlet sides of

the economizer. This will enable monitoring of liquid flow

restriction. Capped tees, one on the liquid inlet side and

one on the liquid outlet side, incorporated into the piping

installation may allow a descaling solution to be used with

the economizer in place. Consult the factory for suitable

descaling solutions.

Fig 13

14

010.4150.0720 08.21

6. ELECTRICAL INSTALLATION

6.1 GENERAL

All wiring must be in compliance with the local codes, or, in

their absence, the National Electric Code, NFPA70. All wiring

should be appropriate Class 1 wiring as follows: installed in

rigid metal conduit, intermediate metal conduit, rigid non-

metallic conduit, electrical metallic tubing, ir be otherwise

suitably protected from physical damage.

6.2 MODULATING BYPASS DAMPER

The only electrical part of the VHX-DR is the actuator

serving the Modulating Bypass Damper. The actuator can

be controlled by a 0-10VDC signal either from an ENERVEX

HRC80 or from a third-party supplied controller.

DANGER

Turn off electrical power before servicing.

Contact with live electric components can

cause shock or death.

NOTICE

If any of the original wire supplied with the

system must be replaced, use similar wire

of the same temperature rating. Otherwise,

insulation may melt or degrade, exposing bare

wire.

15

010.4150.0720 08.21

7. STARTUP AND CONFIGURATION

7.1 GENERAL

During the initial startup and before combustion heat can be

applied to the exchanger, ensure that liquid is flowing through

the economizer.

NOTE: ENERVEX recommends that liquid is owing

through the economizer at all times to avoid damage

to the heat module(s) from stack exhaust overheat.

Upon cold startup of a full boiler, provisions must be

made to ensure water ow through the VHX-DR. Assure

sufcient ow to prevent any unwarranted temperature

and pressure buildup within the liquid side of the heat

module. When the boiler reaches the operating steam

pressure of the system and begins to take on feedwater,

normal operation can resume.

! Important

If liquid is introduced into a hot exchanger, severe

damage can result and will void any warranty. Contact

ENERVEX for applications where the exchanger is

requested to run dry.

If the final exhaust temperatures are too low, pressure drop

across the economizer is too high, or if the desired water

temperature is exceeded, adjust the gas bypass damper to

attain the desired objective.

While the exchanger is in a clean, like-new condition, note

and record the following at a specified condition:

• Liquid inlet and outlet temperatures

• Exhaust gas inlet and outlet temperatures

• Pressure gauge reading (if applicable)

This information will provide a point of reference in the event

of a future fouling condition.

MONITORING PERFORMANCE

It is recommended to inspect the core or coil if the

performance (liquid temperatures leaving and Btu/

hr. recovery) begins to decrease. A good practice of

maintenance is to keep a performance schedule starting

when the economizer is installed to compare with any future

changes.

Operational start-up

Make sure that:

If there is a risk of high temperatures, the unit is insulated as

a precaution to avoid injuries.

Installation has been carried out according to the flow

schedule / drawing and recommendations.

• Connections are tight.

• No vibrations or pulsations are transferred to the Cross

30.

• The liquid side is filled and deaerated.

• The flow rate and pressure on the liquid side are correct

before gas flow is started.

• The temperature and flow rates are according to

specification.

• There is appropriate drainage to deal with any

condensation.

NOTE: Ensure that the combustion source is off

and is cool, and the economizer is cool before

attempting to inspect or clean the coil(s).

16

010.4150.0720 08.21

8.1 GENERAL

The VHX-DR economizer is virtually maintenance free.

Nevertheless, periodic inspections will ensure trouble-free

operation and long equipment life.

A routine physical inspection of the heat transfer core area

will depend on the conditions of temperature and the quality

of combustion within the flue gas stream.

NOTE: Ensure that the combustion source is off and is

cool, and that the economizer is cool before attempting

to inspect or clean the heat exchanger.

With clean exhaust conditions, physical inspection will

be minimal if proper combustion at the heat source is

maintained. The inspection and maintenance procedure can

be performed without dismantling any of the piping or the

stack connections.

8.2 REMOVAL OF HEAT MODULES

The heat module(s) is installed in a slot.

Before removing the module, drain the system of water.

Follow this procedure (See Fig 15):

1. To remove module, disconnect flexible piping from the

the heat module.

2. Remove all bolts from the cover plate.

3. Remove the cover plate, which gives full access to the

heat modules.

4. Slide modules out individually.

8.3 MAINTENANCE

The module has no moving parts or electrical components.

The following should be inspected regularly:

• Operational design conditions for the system being

maintained, and meeting the calculated / design values

(leaving temp., pressure drop).

• Increased pressure drop and decreased thermal

efficiency over time are signs of possible fouling.

• Connections for tightness.

• Gas channels for accumulated dirt.

• Plate surfaces for corrosion.

• Seal and gaskets.

• External components such as valves, dampers and

controls.

8.4 CLEANING

The normally high degree of turbulence in the module gives

a self-cleaning effect in the liquid channels, which reduces

fouling and the build-up of contamination, which can

seriously reduce heat transfer capacity and increase pressure

drop.

Cleaning liquid side

In some applications, the fouling tendency can be very high,

for example with extremely hard water at high temperatures.

Fig 15

Header

Flexible

Connectors Cover

Plate Gasket

Removeable

Heat Modules

Fig 14

8. MAINTENANCE AND TROUBLESHOOTING

17

010.4150.0720 08.21

In such cases, the module can always be cleaned by:

• Circulating a cleaning liquid (CIP – Cleaning In Place).

• A solution of 5% phosphoric acid or 5% oxalic acid in

water is recommended to chemically clean the channels.

• The flow rate of the cleaning liquid should be greater

than the design liquid flow, and the flow should be in the

opposite direction through the heat exchanger relative to

the flow in normal operation.

ATTENTION: After cleaning, it is very important to flush the

heat exchanger thoroughly with clean water before start-up.

Cleaning gas side

Heavy condensation can have a self-cleaning effect, washing

the Cross and reducing dirt build-up on the gas side. The

module has open gas channels at both ends that can be

checked visually. For dry dirt such as carbon, ashes or

dust, most of the dirt sticks to the inlet surface. Cleaning

with compressed air or high-pressure water up to 200 bar

is normally effective. Exhausts from diesel, vegetable oils or

biogas combustion may require regular cleaning.

For greasy dirt such as oil, a suitable cleaning liquid is

recommended. When using cleaning liquid it is important to

flush the module thoroughly with clean water before start-up.

Storage

Some users store spare modules that are used to replace

dirty modules to reduce downtown.

The module must always be stored in a dry and protective

environment. The temperature should not be below 35°F

(1°C) and not above 120°F (50°C) for extended periods of

time (4 weeks or more).

During long operational stand-by periods, the system should

be inspected for contamination on the liquid and gas sides.

If necessary, clean the module according to the cleaning

instructions.

Liquid sides containing water should always be drained.

18

010.4150.0720 08.21

9. APPLICATION EXAMPLES

9.1 PREHEATING BOILER RETURN WATER

9.2 PREHEATING CIRCULATING FEED WATER

19

010.4150.0720 08.21

9.3 PREHEATING BOILER MAKE UP WATER

9.4 PREHEATING STEAM BOILER FEEDWATER WITH MODULATING FEED WATER VALVE

20

010.4150.0720 08.21

9.6 CONDENSATE RETURN HEATING

9.5 CIRCULATING MAKE UP WATER HEATING

This manual suits for next models

7

Table of contents

Other ENERVEX Heating System manuals

Popular Heating System manuals by other brands

ThermoSoft

ThermoSoft NeverFreeze SX-0810-24 manual

aldes

aldes EXHAUSTO InspirAIR Top Assembly instructions

Horizon Fitness

Horizon Fitness ecoSAVER Installation & operation manual

Daikin

Daikin Rotex E-Pac EP HT 3H manual

Patlite

Patlite NE-24A Series Complete Operation Manual

Suburban

Suburban P-40 installation instructions

Heatit

Heatit HIP 24-12A manual

AirTechnic

AirTechnic ENERGY BOX - TO 350 Assembly & maintenance guide

Daikin

Daikin VRV R-407C PLUS Series Service manual

Envirovent

Envirovent heatSava installation guide

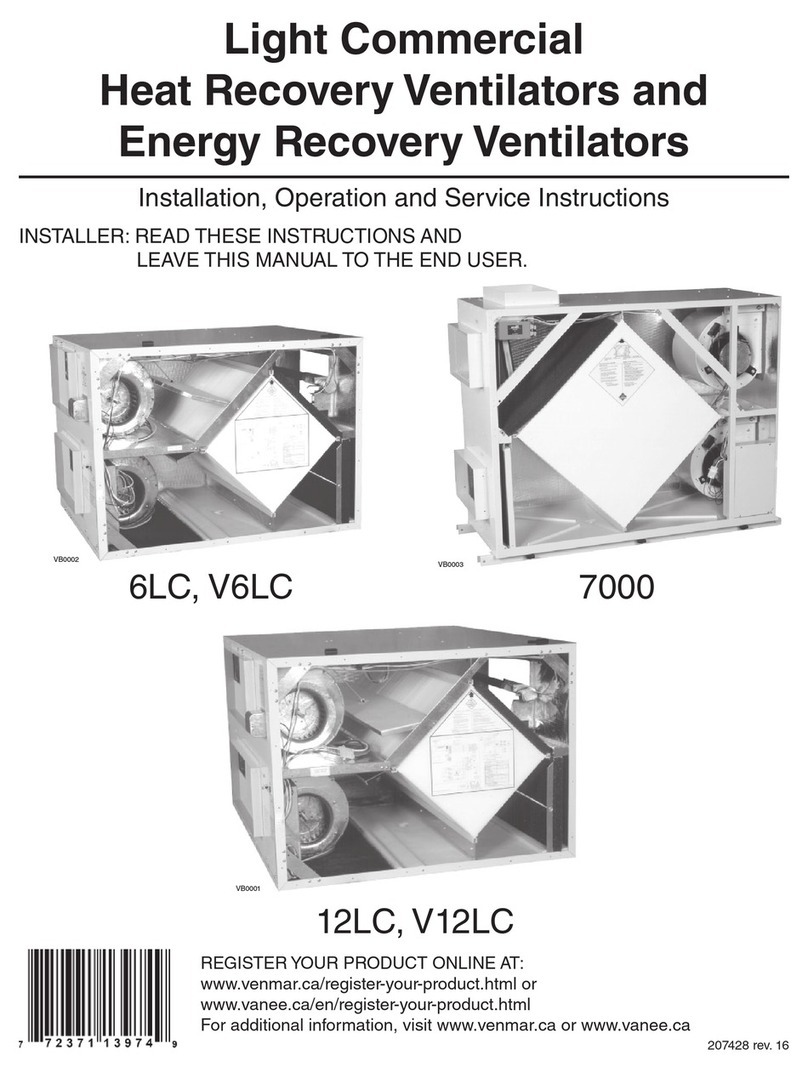

Venmar

Venmar 6LC Installation, operation and service instructions

Bard

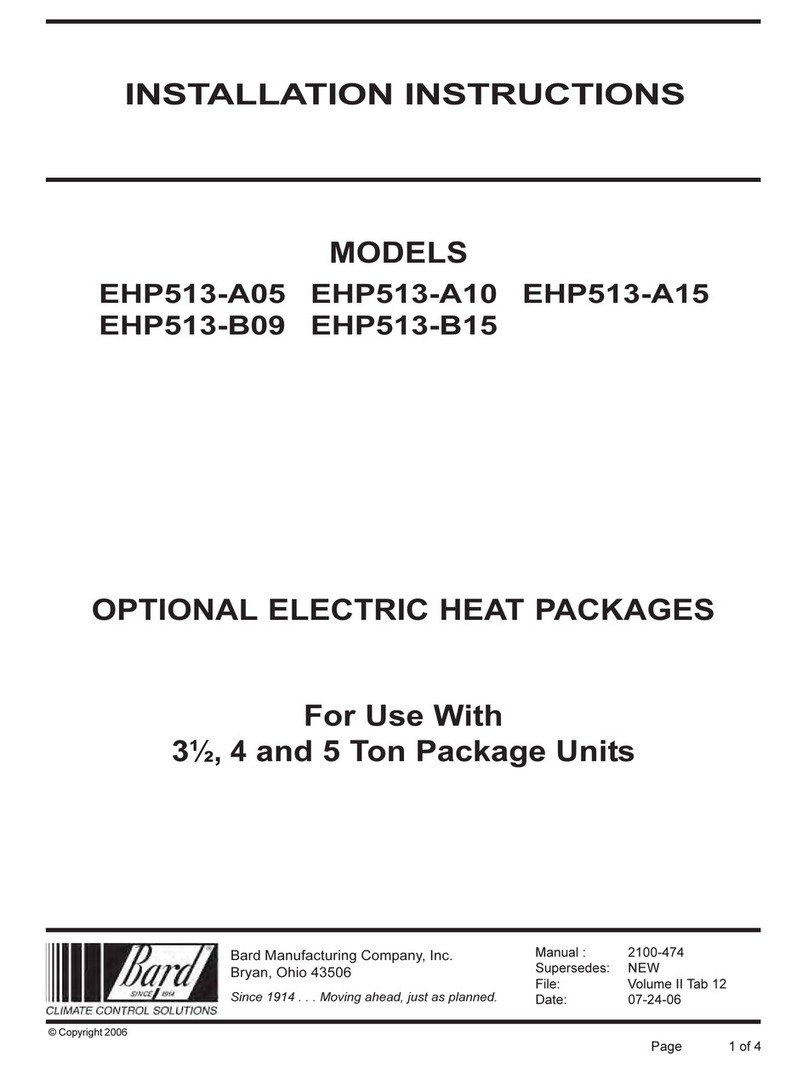

Bard EHP513-A05 installation instructions