6

Installation Requirements

The heaters may only be installed in compliance with

the relevant regulations, especially regulations go-

verning the installation and operation of fireplaces and

furnaces.

Observe also any national/local emission control legis-

lation/regulations.

Use prototype-tested WLE-type oil burners or gas

burners only.

If the heater is supplied from the factory with an oil or

gas burner, it comes with separate instructions for the

burners.

Choice of the Place of Installation

When choosing the place of installation, observe the re-

quirements with regard to:

a) fire protection and operational hazards

b) function

(e.g. room heating, free-blowing or duct system,

above or below atmospheric pressure in the installa-

tion room)

c) operational requirements

(heat requirement, nominal air volume flow, need of

circulating air or supplied air, humidity, room tem-

perature, air distribution, space requirement)

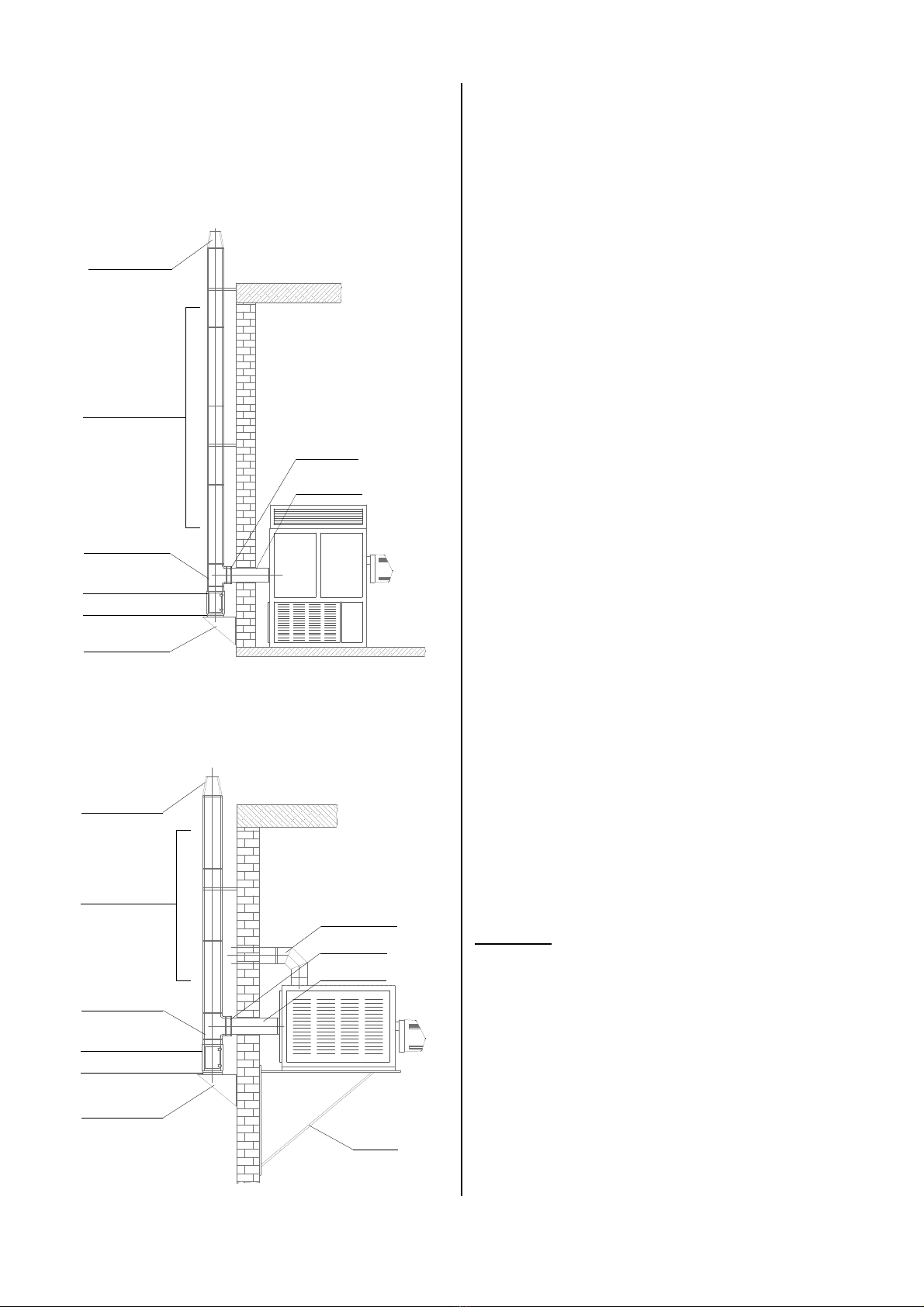

d) connection to the chimney

e) installation, repair and maintenance

f) ratio of room volume to total nominal thermal output,

especially in rooms with natural ventilation.

Always install the heaters so that they are easy

to access for repair and maintenance.

Heaters with a nominal thermal output of up to 50 kW

may generally be installed outside heating rooms, pro-

vided that the national/local regulations governing the

installation and operation of fireplaces are complied

with. Heaters with a nominal thermal output of over 50

kW must be installed in heating rooms; this does not

apply to devices which are designed for installation

outside heating rooms or which are installed in in-

dustrial/commercial areas. Follow the building authori-

ties’ "guidelines for the installation of fireplaces with a

total nominal thermal output of more than 50 kW in

rooms other than heating rooms" (applicable in Ger-

many). These guidelines prohibit the installation of fire-

places in the case of hazardous concentrations of dan-

gerous substances according to the working media or-

dinance.

Before the installation of heatings is prohibited, the haz-

ardous concentration in the installation room and in the

adjacent rooms with openings to this room must be ex-

amined.

For rooms where readily flammable substances or mix-

tures are processed, stored or manufactured at such

quantities that their ignition causes hazards, exceptions

may be allowed when appropriate measures have been

taken to ensure that the fireplace cannot ignite the sub-

stances or mixtures.

Installation

−Install the heaters in a stable position on a non-

inflammable surface and outside thoroughfares as

well as e.g. outside the reach of cranes.

−Install and operate the heaters so as to avoid any

hazard to the personnel by fumes and radiation heat,

well as to avoid any risk of fire.

−Install the heaters so that they do not cause any

hazards and are no source of any unacceptable an-

noyance, e.g. through shocks, vibration or noise.

−Install the heaters that they are easy to access for

repair and maintenance.

−Any control elements whose improper operation may

cause dangerous operating conditions and which

are generally accessible must be protected against

unauthorised operation.

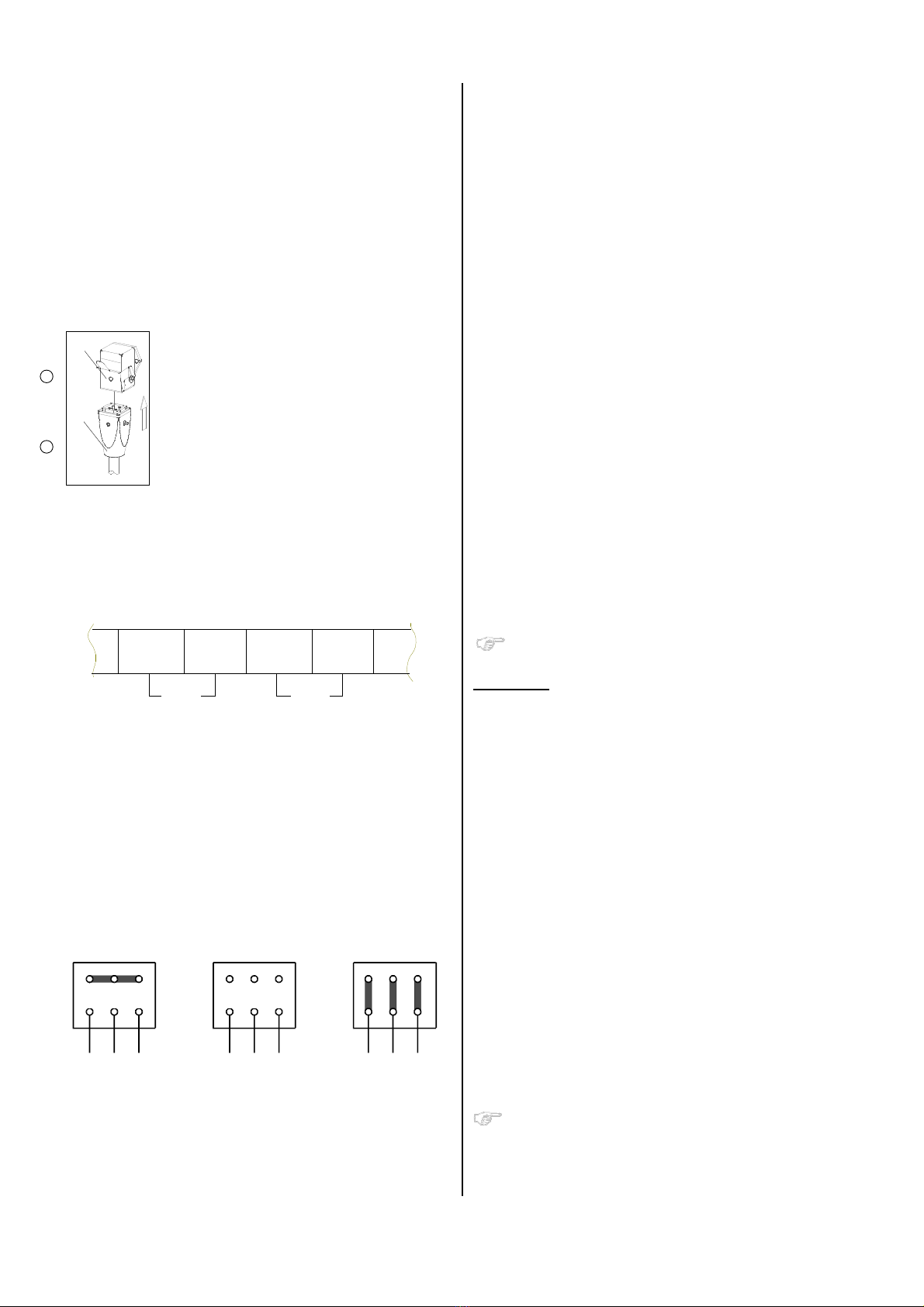

−If mixed-air valves (accessories) are installed, en-

sure that they are asynchronously coupled and pro-

vide a minimum cross section for an adequate out-

side-air rate.

−Heaters in rooms other than heating rooms must be

installed so that they can be constantly kept under

observation.

−Do not install or operate the heaters in rooms or ar-

eas exposed to fire or explosion hazards.

−The heaters may only be installed and operated in-

side rooms if they are supplied with sufficient air for

combustion and if the flue gases escape into the

open through flues.

The air supply is sufficient for combustion when, for ex-

ample, the cubic capacity of a room is at least ten times

the nominal thermal load of all heaters in the room, and

a natural exchange of air is ensured by means of win-

dows and doors.

The airing is sufficient when, for example,

1) the room capacity in m³ is at least 30 times the nomi-

nal thermal load in kW of all heaters in the room, and

a natural exchange of air is ensured by means of

windows and doors, or

2) there are air inlet and outlet openings, which cannot

be closed, near the ceiling and the ground; the size

of which in m² must be at least 0.003 times the nomi-

nal load in kW of all heating devices in the room.

G