EngA Engineered Air XES-SC Series User manual

A

IOM-58 June 14 R5

INSTALLATION, OPERATION

AND MAINTENANCE MANUAL

FOR

XES-SC SERIES

INDOOR INDIRECT GAS FIRED

SEPARATED COMBUSTION HEATING UNIT

UNIT MODEL NO. _________________

UNIT SERIAL NO. _________________

SERVICED BY: ___________________

TEL. NO: ________________________

CANADIAN

HEAD OFFICE

AND FACTORY

USA

HEAD OFFICE

AND FACTORY

CANADIAN

FACTORY

1401 HASTINGS CRES. SE

CALGARY, ALBERTA

T2G 4C8

Ph: (403) 287-4774

Fx: 888-364-2727

32050 W. 83rd STREET

DESOTO, KANSAS

66018

Ph: (913) 583-3181

Fx: (913) 583-1406

6130 97th STREET

EDMONTON, ALBERTA

T6E 3J4

Ph: (780) 430-0310

Fx: (780) 434-6272

SALES OFFICES ACROSS CANADA AND USA

Retain instructions with unit and maintain in a legible condition.

Please give model number and serial number when contacting

factory for information and/or parts.

www.engineeredair.com

A XES SC MANUAL

IOM-58 2 of 30 June 14 R5

TABLE OF CONTENTS

You Have Responsibilities Too .....................................................................................................................................................3

Introduction .................................................................................................................................................................................3

Warranty ......................................................................................................................................................................................5

Parts .............................................................................................................................................................................................6

Receiving ......................................................................................................................................................................................6

Temporary Storage.......................................................................................................................................................................6

Installation....................................................................................................................................................................................7

Codes............................................................................................................................................................................................7

Minimum Clearance For Service And To Combustibles ...............................................................................................................8

Mounting......................................................................................................................................................................................8

Shipping Materials........................................................................................................................................................................9

Suitable Locations ........................................................................................................................................................................9

Assembly Of Two Piece Xess ........................................................................................................................................................9

Separated Combustion...............................................................................................................................................................10

Combustion Air Duct ..................................................................................................................................................................11

Venting Products Of Combustion...............................................................................................................................................12

Natural Gas And Propane Installation........................................................................................................................................18

Gas Line Testing (External To The Unit) .....................................................................................................................................18

Electrical Installation ..................................................................................................................................................................18

Split Unit Wiring .........................................................................................................................................................................19

Recommended 24v Field Wiring Size: ........................................................................................................................................20

Duct Mounted Te-6000-Ea3 Temperature Sensor .....................................................................................................................21

Before Start-Up ..........................................................................................................................................................................21

Start-Up Check List .....................................................................................................................................................................21

Operation ...................................................................................................................................................................................23

Combustion And Final Unit Check For Units Without Trac Controls..........................................................................................23

Unit Shut-Down Instructions......................................................................................................................................................24

Service Shut Down .....................................................................................................................................................................24

Maintenance ..............................................................................................................................................................................25

Electrical.....................................................................................................................................................................................25

Operating Instructions ...............................................................................................................................................................25

Belt Adjustment .........................................................................................................................................................................26

Set Screws ..................................................................................................................................................................................26

Bearing Setscrew Torques..........................................................................................................................................................26

Fan Lubrication...........................................................................................................................................................................27

Motor Lubrication ......................................................................................................................................................................27

Inspection And Cleaning.............................................................................................................................................................27

Filters..........................................................................................................................................................................................27

Controls......................................................................................................................................................................................27

Outdoor Air Intakes, Mixing Sections And Dampers..................................................................................................................28

Safety Shutoff Valve Leak Test:..................................................................................................................................................28

Troubleshooting .........................................................................................................................................................................29

Start-Up Record..........................................................................................................................................................................30

© Airtex Manufacturing Partnership. All rights reserved.

A XES SC MANUAL

IOM-58 3 of 30 June 14 R5

YOU HAVE RESPONSIBILITIES TOO

This installation, operation and maintenance manual cannot cover every possibility, situation or

eventuality. Regular service, cleaning and maintaining the equipment is necessary. If you are not capable

of performing these tasks, hire a qualified service specialist. Failure to perform theses duties can cause

property damage and/or harm to the building occupants and will void the manufacturers’ warranty.

INTRODUCTION

Engineered Air units are high quality products designed and manufactured to provide many years of

trouble-free operation. Engineered Air recommends that is manual be read thoroughly to ensure proper

installation, efficient operation and proper maintenance of this equipment. The submittal record is

considered to be part of the Installation, Operation and Maintenance Manual. Please report any

omissions to the national service manager.

SAFETY PRECAUTIONS

Read, understand and follow the complete manual before beginning the installation, including all safety

precautions and warnings.

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could result in serious injury, death or property damage.

Be sure to read and understand the installation, operation and service instructions in this manual.

Improper installation, adjustment, alteration, service or maintenance can cause serious injury, death or

property damage.

—Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other

appliance.

—WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

Do not touch any electrical switch; do not use any phone in your building.

Leave the building immediately.

Immediately call your gas supplier from a phone remote from the building. Follow the gas

supplier’s instructions.

If you cannot reach your gas supplier, call the fire department.

—Installation and service must be performed by a qualified installer, service agency or the gas supplier.

A XES SC MANUAL

IOM-58 4 of 30 June 14 R5

Warning:

Pool, laundry and common cleaning products often contain fluorine or chlorine

compounds. When these chemicals pass through the heater, they can form strong acids.

The acid can eat through the heat exchanger wall, causing serious damage and

presenting a possible threat of flue gas spillage into the building.

Warning:

This unit is connected to high voltages. Electrical shock or death could occur if

instructions are not followed. This equipment contains moving parts that can start

unexpectedly. Injury or death could occur if instructions are not followed. All work

should be performed by a qualified technician. Always disconnect and lock out power

before servicing. DO NOT bypass any interlock or safety switches under any

circumstances.

A XES SC MANUAL

IOM-58 5 of 30 June 14 R5

WARRANTY

LIMITED WARRANTY

ENGINEERED AIR will furnish without charge, F.O.B. factory, freight collect, replacement parts for, or

repairs to products covered herein which prove defective in material or workmanship under normal and

proper use for a period of twelve (12) months from the initial start-up or eighteen (18) months from the

date of shipment, whichever expires sooner, provided the customer gives ENGINEERED AIR written notice

of such defects within such time periods and provided that inspection by ENGINEERED AIR establishes the

validity of the claim and all pertinent invoices have been paid in full. The repairs or replacements will be

made only when the complete product(s) or part(s) claimed to be defective are returned to ENGINEERED

AIR or a depot designated by ENGINEERED AIR, transportation charges prepaid. Repairs or replacements

as provided for by this paragraph shall constitute fulfillment of all ENGINEERED AIR's obligations with

respect to this warranty. The refrigerant charge is not included in any part of this warranty. This warranty

does not apply to any products or parts thereof that have been subject to accident, misuse or

unauthorized alterations, or where ENGINEERED AIR's installation and service requirements have not been

met.

The foregoing warranty is in lieu of all other warranties, express or implied. ENGINEERED AIR specifically

disclaims any implied warranty of merchantability and/or fitness for purpose. Under no circumstances

shall ENGINEERED AIR be liable to, nor be required to indemnify, Buyer or any third parties for any claims,

losses, labour, expenses or damages (including special, indirect, incidental, or consequential damages) of

any kind, resulting from the performance (or lack thereof) of this Agreement or the use of, or inability to

use the goods sold hereunder, including, but not limited to, damages for delay, temporary heating/cooling

costs, loss of goodwill, loss of profits or loss of use. Furthermore, the parties agree that the Buyer's sole

remedy under this Agreement shall be limited to the limited warranty set forth in the preceding paragraph

relating to the repair or replacement of any defective goods. Under no circumstances shall any claim or

award against ENGINEERED AIR exceed the original contract price whether awarded through arbitration,

litigation or otherwise.

ENGINEERED AIR Warranty is void if:

1. The unit is not installed in accordance with this manual.

2. The start-up and operation of the unit is not performed in accordance with this manual.

3. The unit is operated in an atmosphere containing corrosive substances.

4. The unit is allowed to operate during building construction.

5. The unit is allowed to operate in atmospheres where chlorine or chlorine compounds are present

or which contain any contaminant (silicone, aluminum oxide etc.) that adheres to the spark ignition

flame sensing probe.

A XES SC MANUAL

IOM-58 6 of 30 June 14 R5

PARTS

WARNING:

Any replacement part must be of equivalent listing or certification and be functionally

equivalent. The replacement part must meet the original’s specification in terms of

functionality including certifications, timing, input and output range, accuracy and

operation.

Failure to replace parts or components with equivalent parts can cause property

damage, injury or death.

1. Motors:

Motor manufacturers have service centers that will repair or replace motors as required.

2. Parts Other Than Motors:

Contact the nearest Engineered Air sales office or factory. Be sure to include Model Number, Serial

Number, date of installation and nature of failure along with the description of the parts required.

Some parts may not be stocked items that must be made or ordered.

RECEIVING

Refer to the back of the packing slip for receiving unit instructions.

On receipt of the unit, check for damage. Inspect protective covers for punctures or other signs that there

may be internal damage. Remove protective covers and check for internal damage. Replace covers if the

unit is not being assembled or installed at this time. Open access doors and check for internal damage.

Close access doors when the inspection is complete.

All units are pre-tested at the factory immediately prior to shipping and are ensured to be in good

operating condition at that time. If damage is found follow the instructions on the packing slip.

On receipt of the unit, check electrical characteristics (see rating plate) to make sure the unit voltage is

compatible with that available for the unit. All parts for field installation are listed on the shipping order

form.

TEMPORARY STORAGE

If a unit is to be stored prior to installation the following precautions are required:

•Store in a well drained area that will not accumulate surface water.

•Store in an area where the unit will not get damaged.

•The entire perimeter and any full height cross members of the unit must be supported by a level

surface and the supporting surface must be adequate for supporting the entire weight of the unit.

•All protective coverings that were provided for shipping must be in place.

•Protect from rain and snow.

A XES SC MANUAL

IOM-58 7 of 30 June 14 R5

INSTALLATION

Warning:

This unit is not rated for hazardous locations and cannot be installed in areas requiring

any hazardous location rating.

Caution:

All wiring, piping and fuel line installation must be completed by qualified persons in

accordance with all federal, state, provincial and/or local codes.

Note: Installation shall be in accordance with this manual and all other associated component and

control Installation, Operation and Maintenance Manuals.

CODES

In Canada:

1. The installation of this unit shall be in accordance with the latest edition of the Canadian Electrical

Code, Part 1 –C.S.A. Standard C22.1, Provincial and Local Codes, and in accordance with the local

authorities having jurisdiction.

2. This unit shall be electrically grounded in accordance with the latest edition of the Canadian

Electrical Code, Part 1 –C.S.A. Standard C22.1, Provincial and Local Codes, and in accordance with

the local authorities having jurisdiction.

3. The installation of this unit shall be in accordance with the latest edition of the Canadian Natural

Gas and Propane Installation Code, C.S.A. Standard B149.1, Provincial and Local Codes, and in

accordance with the local authorities having jurisdiction.

4. In accordance with local authorities having jurisdiction or CSA. Standard B149.1 a readily accessible

approved manual shut-off valve shall be installed in either the drop or riser as close as possible to

the valve train (gas manifold).

5. The installation of this unit shall be in accordance with the latest edition of the National Plumbing

Code of Canada, Provincial and Local Codes, and in accordance with the local authorities having

jurisdiction.

6. The installation of this unit shall be in accordance with all other National, Provincial and Local

Codes, and in accordance with the local authorities having jurisdiction.

In USA:

1. The installation of this unit shall be in accordance with the latest edition of the National Electrical

Code (ANSI/NFPA 70), State and Local Codes and in accordance with the local authorities having

jurisdiction.

A XES SC MANUAL

IOM-58 8 of 30 June 14 R5

2. This unit shall be electrically grounded in accordance with the latest edition of the National

Electrical Code (ANSI/NFPA 70), State and Local Codes and in accordance with the local authorities

having jurisdiction.

3. If the unit has not been provided with an electric disconnect switch, one of adequate ampacity

shall be installed in accordance with Article 430 of the National Electrical Code (ANSI/NFPA 70).

4. The installation of this unit shall be in accordance with the latest edition of the National Fuel Gas

Code ANSI/Z223.1/NFPA 54, State and Local Codes and in accordance with the local authorities

having jurisdiction.

5. In accordance with local authorities having jurisdiction or NFPA 54 an accessible approved manual

shutoff valve shall be installed within 6 ft (1.8 m) of the valve train (gas manifold).

6. The installation of this unit shall be in accordance with the latest edition of the National Standard

Plumbing Code (NSPC), State and Local Codes and in accordance with the local authorities having

jurisdiction.

7. The installation of this unit shall be in accordance with all other National, State and Local Codes,

and in accordance with the local authorities having jurisdiction.

MINIMUM CLEARANCE FOR SERVICE AND TO COMBUSTIBLES

For Safety and Service, the following minimum clearances on the units shall be observed, in inches (mm):

Heaters must be installed to meet at least the minimum clearances shown on the rating plate. The rating

plate is located in the burner compartment. Be sure to allow enough clearance in front of the unit for

removing the burners and above for removing fan motors and blades.

MODEL

COMBUSTIBLE CLEARANCE

SERVICE CLEARANCE

TOP

FRONT

BACK

SIDE

BOTTOM

FLUE

SERVICE/

BURNER

SIDE

CONTROL

PANEL Þ

XES

1" (25)

6" (152)

0

0

C‡

6" (152)

24"

(610)

42”

(1068)

Þ - As required by the Canadian Electrical Code or the National Electrical Code.

* - Service Clearance For Burner & Blower Access, 24" (610).

‡- XES with suffix CF on combustible floor requires special base Part# CB(2,3,4,5,7,8, & 10).

MOUNTING

Units must be mounted level. Failure to do so can cause operational problems that can void warranty.

Failure to do so can result in injury or death, damage to the equipment and/or building and can be a cause

of poor indoor air quality. Equipment must be installed so that sufficient working clearance and

component access is provided. Consult the Submittal Record for specific unit mounting.

A XES SC MANUAL

IOM-58 9 of 30 June 14 R5

SHIPPING MATERIALS

Remove shipping materials. Shipping materials may include, but are not limited to:

-Protective covers over openings, inlets etc.

-Protective covers over split sections if provided.

-Tie-down bolts, straps and blocks on fan vibration isolators.

-Indirect fired heat exchangers may be supported with wood for shipping. Remove.

SUITABLE LOCATIONS

These appliances are suitable for use in aircraft hangars, parking structures and repair garages when

marked and installed, as applicable, in accordance with:

-Standard on Aircraft Hangars, ANSI/NFPA 409

-Standard for Parking Structures, ANSI/NFPA 88A

-Standard for Repair Garages, ANSI/NFPA 88B

-Installation Code for Natural Gas and Propane Installation Code, CSA B149.1

ASSEMBLY OF TWO PIECE XESs

This procedure covers the required field assembly of XES units.

HB (HIGH BOY) UNITS

a) Place the heat section on top of the fan section so the heat section is 1/2" (13 mm) behind the fan

section.

b) Carefully slide the heat section forward until the back and sides of the heat and fan section are

flush. This will lock the two pieces together at the back as the locking clip engages. Do not damage

foam tape which acts as air seal between sections.

c) Remove the fan section door, then lift the front of the heat section and block the front open about

4" (102 mm).

d) Feed the motor wires through the grommet between the sections and allow the wire to hang in the

fan compartment.

e) Lower the heat section back onto the fan section. Check alignment of the pieces then drive sheet

metal screws up from the fan section into the heat section. Holes are provided in the fan section at

the front sides for locating screws. Make sure the motor wires are not pinched between sections -

but feed smoothly from one section to the other.

f) The unit is now one piece locked together at the rear by a clip and at the front by two sheet metal

screws.

g) Follow the wiring diagram on the unit to connect motor wires to motor.

h) Inspect and test electrical components and motor operation.

CF (COUNTER FLOW) UNITS

a) Place the fan section on top of the heat section so the fan section is 1/2" (13 mm) forward of heat

section.

A XES SC MANUAL

IOM-58 10 of 30 June 14 R5

b) Carefully slide the fan section back until the back and sides of the heat fan section are flush. This

will lock the two pieces together at the back as the locking clip engages. Do not damage foam tape

which acts as air seal between sections.

c) Remove the outer fan door, vent pipe, shipping cardboard and inner fan door. Drive sheet metal

screws from the fan section into the heat section. Holes are provided in the front vestibule at sides

for locating two sheet metal screws.

d) The unit is now one piece locked together at back by clip and at front by two sheet metal screws.

e) Motor wires and upper limit control wires are clipped at top of heat section. Feed both of these

wire pairs into the fan compartment, through the hole provided. Wires should be neatly clipped in

place and taut so they will not contact the hot draft hood parts.

f) Connect the motor wires to the motor and upper limit control wires to the limit as shown on wiring

diagram.

g) Install the inner fan door.

h) Connect the vent pipe between the heat section and the top collar of the fan section. The vent

connector piece should be secure and located at the top of the fan section.

i) Inspect and test the electrical components and motor operation.

SEPARATED COMBUSTION

Warning:

Separated combustion equipment is not designed or approved for use in

atmospheres containing flammable or chlorine vapors.

Warning:

The installation of separated combustion systems must be completed by

qualified persons in accordance with all federal, state, provincial and/or local

codes.

Warning:

Do not operate this heater without all combustion air and flue gas piping

installed.

The heater shall not be connected to a venting system serving any other gas, liquid or solid fuel fired

appliance. Installation shall be in accordance with the requirements of authorities having jurisdiction and

ANSI Z2231/NFPA 54 or CSA B149.1. The vent shall be installed in such a manner that access to the

appliance or unit rating plate is not obstructed.

A XES SC MANUAL

IOM-58 11 of 30 June 14 R5

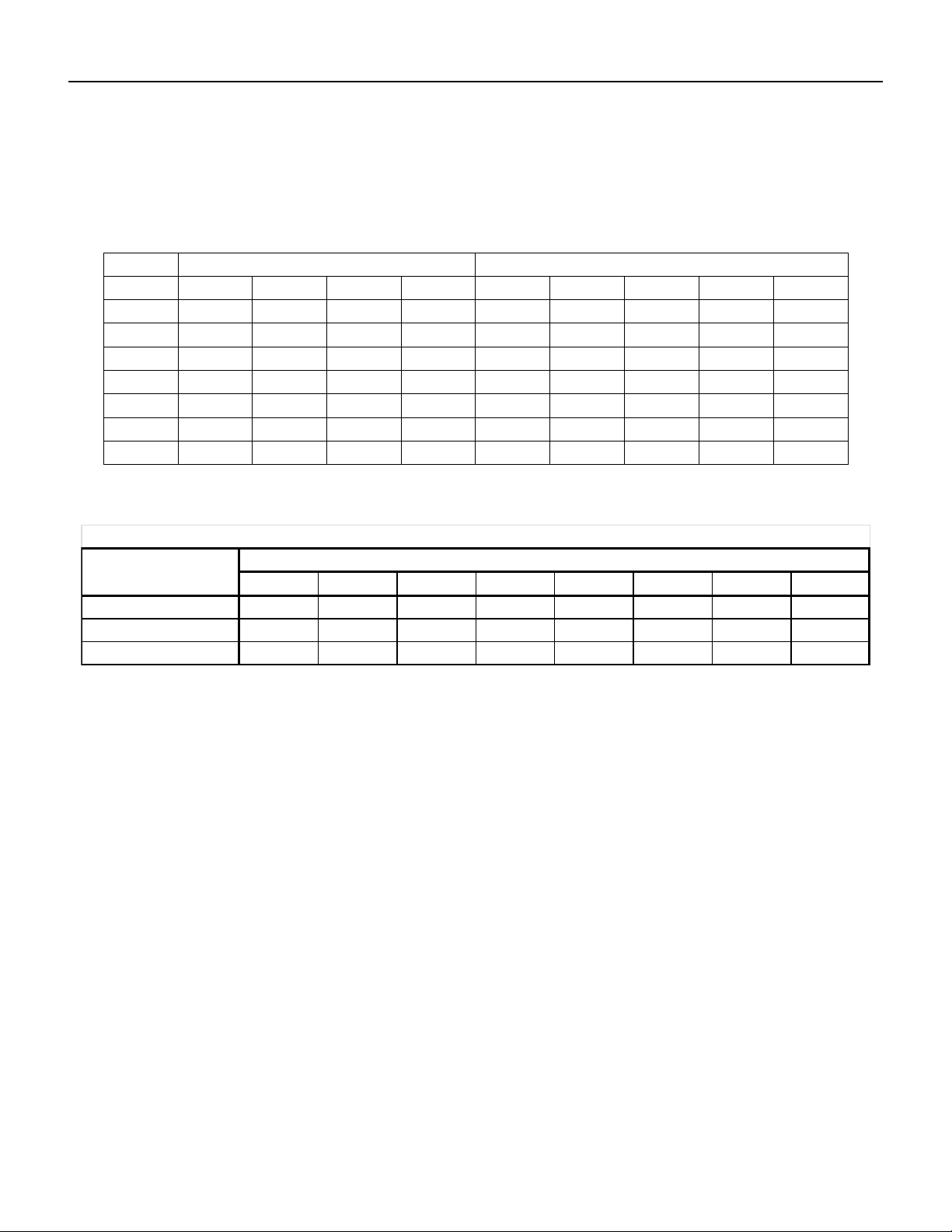

Table I indicates the maximum equivalent length of the various sizes of vent and combustion air for each

furnace model. Equivalent length equals the total length of straight pipe, plus the values for the fittings as

shown in the Table II below.

Table I

Maximum Equivalent Feet

Vent Diameter (inches)

Combustion Air Diameter (inches)

3

4

5

6

4

5

6

7

8

XES65

150

-

-

-

100

150

-

-

-

XES100

75

150

-

-

25

125

150

-

-

XES130

50

150

-

-

25

100

150

-

-

XES160

25

150

-

-

-

50

125

150

-

XES225

-

100

150

-

-

25

100

150

-

XES255

-

50

150

-

-

-

50

150

-

XES320

-

25

125

150

-

-

25

100

150

Table II

Example: System Pipe Size = 5"

2 –90° Elbows (5") = 2 x 9 = 18 ft.

5 - 4 ft. Lengths of 5" = 20 Ft.

Total Equivalent Feet = 18 ft. + 20 ft. = 38 ft.

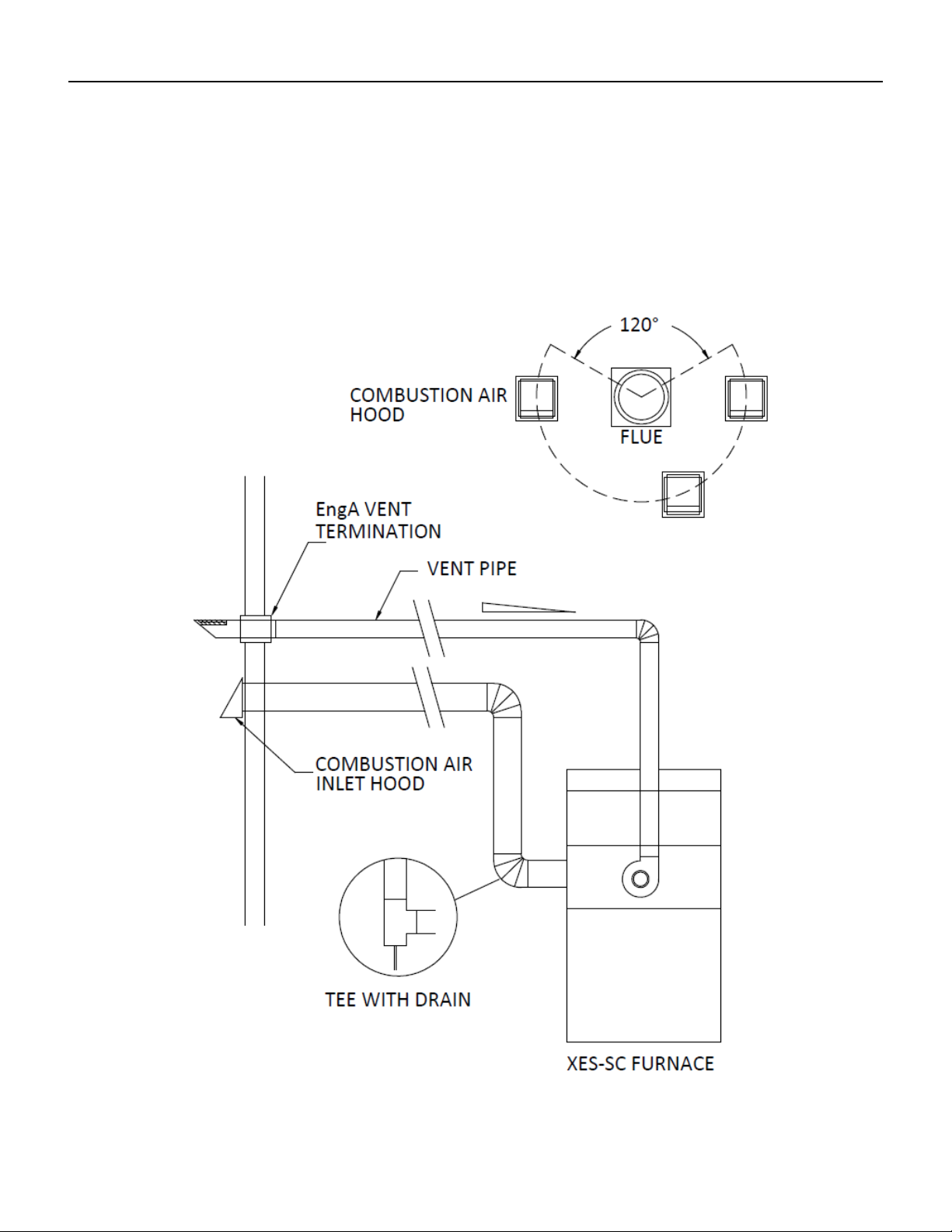

This manual describes two options for separated combustion systems:

Side Wall Vent

oEngA Supplied

oBy Others

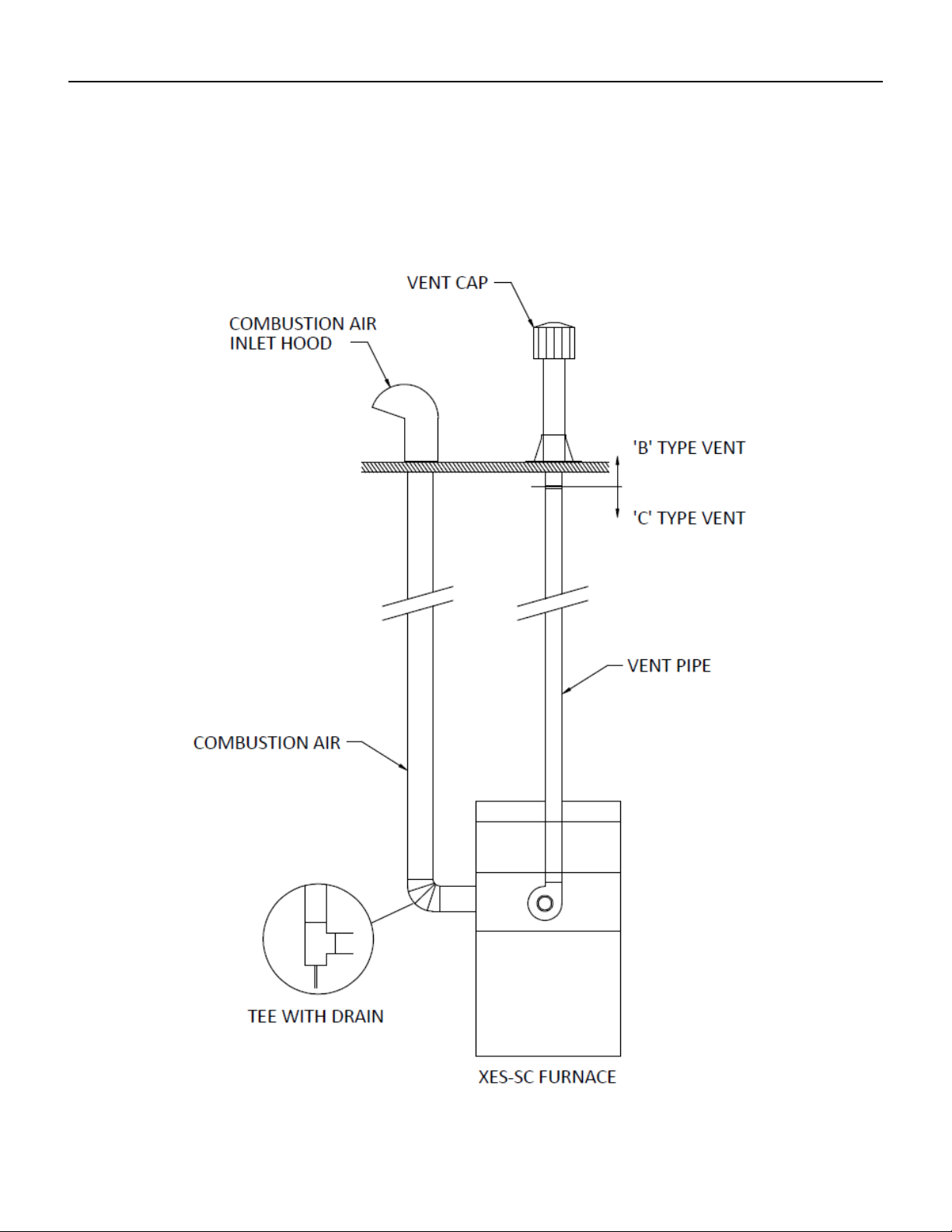

Vertical Vent

COMBUSTION AIR DUCT

Each separated combustion XES heater shall be equipped with its own combustion air supply. It must not

connect to any other air intake systems.

Use single wall pipe constructed of minimum 24ga galvanized steel or a material or equal durability and

corrosion resistance. Single wall combustion air duct may be externally insulated, as required.

Each slip joint shall be secured with corrosion resistant screws or rivets, and sealed with an adhesive

silicon sealant and/or aluminum tape.

For horizontal combustion air systems longer than 5 ft (1.5m) the piping must be supported every 3 ft

(1m).

3 4 5 6 7 8 9 10

811 14 15 18 21 23 26

5 7 9 10 12 14 15 17

3 4 5 5 6 7 8 9

90°

45°

Equivalent length (feet) of vent or combustion air fittings

Fittings

Vent or Combustion Air Diameter (inches)

Tee

A XES SC MANUAL

IOM-58 12 of 30 June 14 R5

VENTING PRODUCTS OF COMBUSTION

Each heater must have its own vent system, and must not be connected to other venting systems or

chimney.

Use ‘C’ Vent. All joints must be secured with corrosion resistant screws or rivet, and sealed with sealant

and/or aluminum tape rated to 500°F (290°C).

Warning:

Do not use PVC, ABS or any other non-metallic pipe for venting.

Any run of single wall vent pipe passing through an unheated space should be insulated with insulation

rated for at least 550°F (280°C) to prevent condensing. In cases where condensing is expected, install a

Tee at the bottom of the vertical section, with a drain for condensate.

Horizontal lengths of the vent system must be installed and sloped ¼”per foot (2%) to prevent the

accumulation of condensate.

Maintain a minimum of 6” (150mm) clearance from any combustible material.

Do not install dampers or other restrictive devices in the flue vent pipe.

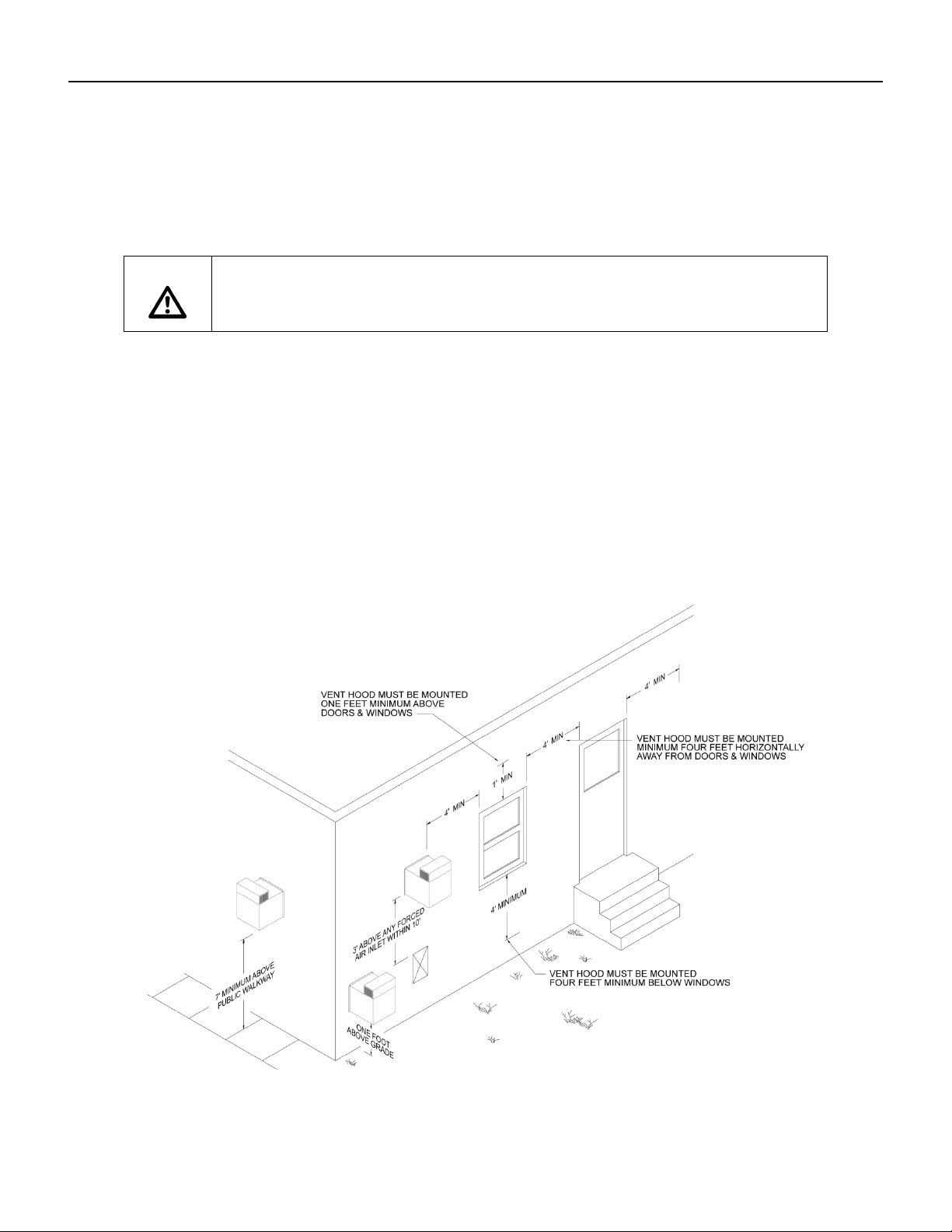

Figure 1: EngA Concentric Vent Termination

A XES SC MANUAL

IOM-58 13 of 30 June 14 R5

Figure 2: Separated Approved Vents By Others

A XES SC MANUAL

IOM-58 14 of 30 June 14 R5

Side Wall Vent –Engineered Air

Engineered Air supplied through-wall concentric vent terminations are recommended and approved for

use with XES furnace models.

A XES SC MANUAL

IOM-58 15 of 30 June 14 R5

A XES SC MANUAL

IOM-58 16 of 30 June 14 R5

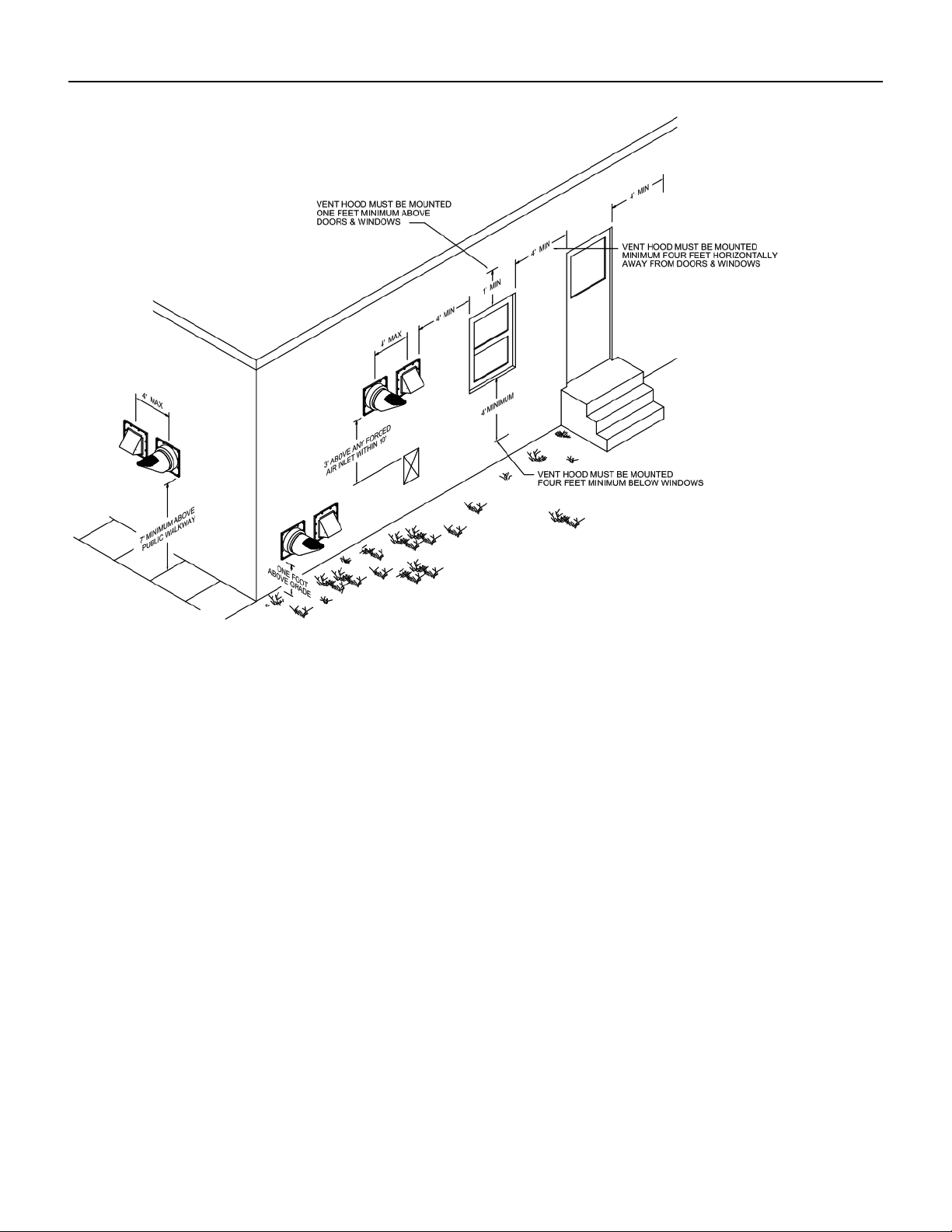

Side Wall Vent –Approved By Others

Where the Engineered Air supplied concentric flue termination cannot be used, separate approved wall

terminations may be supplied and used by the installing customer. Installation of the fresh air intake

relative to the combustion outlet must conform to the diagram shown below:

A XES SC MANUAL

IOM-58 17 of 30 June 14 R5

Vertical Vent

An approved vent cap (eg. Breidert), furnished by the customer, must be installed at the termination point

of the vertical vent system. The vent in this arrangement is category 1. ‘B’ Vent is acceptable. Installer

may seal joints as required.

Refer to the sketch below.

A XES SC MANUAL

IOM-58 18 of 30 June 14 R5

NATURAL GAS AND PROPANE INSTALLATION

1. Installation must be made in accordance with the requirements of the authorities having jurisdiction.

2. Check the unit rating plate and confirm fuel type, supply pressure, input rating and temperature rise.

3. Refer to the heater rating plate for determining the minimum gas supply pressure for obtaining the

maximum gas capacity for which this heater is specified.

4. Gas supply pressure higher than the unit rating plate requires an additional field supplied gas

regulator.

5. Install an approved appliance shutoff valve on the gas supply in accordance with the requirements of

the authorities having jurisdiction.

6. Gas lines shall not interfere with unit access. The gas line connection at the heater shall have an

approved drip leg with screwed cap.

7. A minimum 1/8 inch NPT plugged tapping, accessible for test gauge connection, must be installed

immediately upstream of the gas supply connection to the unit.

GAS LINE TESTING (EXTERNAL TO THE UNIT)

The appliance and its individual shutoff valve must be disconnected from the gas supply piping system

during any testing of that system at test pressures in excess of 0.5 psi (3.5 kPa).

The appliance must be isolated from the gas supply system by closing its individual shutoff valve during

any testing of that system at test pressure equal to or less than 0.5 psi (3.5 kPa).

ELECTRICAL INSTALLATION

Do not install anything that will interfere with equipment access or the rating plate.

All penetrations through the unit walls must be caulked and sealed to prevent air from entering the

unit.

The unit must be electrically grounded and all wiring must be installed in accordance with the National

Electrical Code, ANSI/NFPA 70, and/or the Canadian Electric Code CSA 22-1 and to the approval of the

authorities having jurisdiction. Field wiring diagrams, internal wiring diagrams and operating functions are

included in the control cabinet. The power requirements are indicated on the rating plate. Where field

wiring of control circuits is required, take care to size the field wiring for a maximum 10% voltage drop.

The control circuit ampacity is noted on the field wiring diagram. See the field wiring diagram for

requirements for shielded or twisted pair wire for solid state devices.

A XES SC MANUAL

IOM-58 19 of 30 June 14 R5

All wiring shall be installed according to the requirements of the authorities having jurisdiction. Field

wiring, internal wiring diagrams and unit operating functions are included in the control cabinet of the

unit. The power requirements are indicated on the rating plate.

SPLIT UNIT WIRING

All split wiring must be completed by an electrician prior to starting the equipment. A number of

different methods are used to reconnect the wiring.

Power wire: this wiring is generally not broken or spliced, and will extend from the device back to the

contactor or terminal block inside the electrical panel(s). The wire will be tagged to identify which panel it

extends to and will be numbered to the corresponding connection.

The location of the equipment split line may result in the wire being disconnected at the device it is

feeding. The wire bundle will be tagged and identified. Confirm correct rotation of 3 phase devices after

the wiring connections has been completed.

Control wire: this wire is typically broken near the split line, to be reconnected at either a enclosed

terminal block, junction box or extended to a nearby control panel. Each wire or wire bundle will be

tagged and numbered to indicate the location it is sent to.

Sensor wire shield: The drain wire from the shield must be grounded (at one end only). A ground

connection point is available for connection at the point of termination.

All loose wiring must be securely fastened to the equipment casing upon completion.

Caution:

Temporary Power Generation

The warranty will be void if the voltage being fed from any temporary generator is not

within 10% of the nominal rated nameplate voltage and voltage imbalance shall be

limited to 2%. A power monitor shall be installed by others to properly monitor power

quality and conditions.

All generator sets shall be provided with overcurrent and earth-fault protection. The

protective apparatus should be capable of interrupting, without damage, any short-

circuit current that may occur.

Warning:

No unspecified external load shall be added to the control transformer circuit(s) or to

the main power circuit(s).

A XES SC MANUAL

IOM-58 20 of 30 June 14 R5

Recommended 24V Field Wiring Size:

Copper conductors only

Circuit

Load

(Amps)

(1)

Maximum Total Length of Run

< 50 Ft

< 100 Ft

< 150 Ft

< 200 Ft

< 250 Ft

< 300 Ft

< 350 Ft

< 400 Ft

< 450 Ft

< 500 Ft

(~ 15 m)

(~ 30 m)

(~ 45 m)

(~ 60 m)

(~ 75 m)

(~ 90 m)

(~ 105 m)

(~ 120 m)

(~ 135 m)

(~ 150 m)

1

16 AWG

16 AWG

16 AWG

16 AWG

16 AWG

16 AWG

14 AWG

14 AWG

14 AWG

12 AWG

2

16 AWG

16 AWG

16 AWG

14 AWG

12 AWG

12 AWG

12 AWG

10 AWG

10 AWG

10 AWG

3

16 AWG

16 AWG

14 AWG

12 AWG

12 AWG

10 AWG

10 AWG

10 AWG

4

16 AWG

14 AWG

12 AWG

10 AWG

10 AWG

10 AWG

5

16 AWG

12 AWG

12 AWG

10 AWG

6

16 AWG

12 AWG

10 AWG

10 AWG

7

14 AWG

12 AWG

10 AWG

8

14 AWG

10 AWG

10 AWG

9

14 AWG

10 AWG

10

12 AWG

10 AWG

11

12 AWG

10 AWG

12

12 AWG

10 AWG

13

12 AWG

14

12 AWG

15

12 AWG

Notes:

1) The field wiring load depends on the actual load on a particular control circuit the field wiring is

connected to. Refer to the internal wiring diagram of the unit.

2) The table above is based on a maximum 10% voltage drop on a 24V control circuit. Wire size was

calculated using the following formula:

CM = (25 x I x L ) / V

Where CM is circular mils of conductor for a constant load of Iamps, wire length L in feet from the

unit to the field device and back, and voltage drop V.

When connecting to a three phase power supply, check for the correct rotation of all motors and fans. If

the rotation is incorrect, reverse the rotation at the incoming power only. All electrical conduit outlets in

the control panel must be sealed to prevent moist building air from migrating to the control panel.

DO NOT install any devices in a manner that interfere with access to the rating plate or door opening.

Replacement wiring must be equivalent to original wire. See field wiring diagram for requirements for

shielded or twisted pair wire for solid state devices.

This manual suits for next models

7

Table of contents

Popular Heat Pump manuals by other brands

Immergas

Immergas Rapax 300 V2 Instruction and recommendation booklet

ClimaCool

ClimaCool SHC onDEMAND Series Installation operation & maintenance

Nordyne

Nordyne T5BD Series user manual

Carrier

Carrier 50ZHA024-060 Installation & service instructions

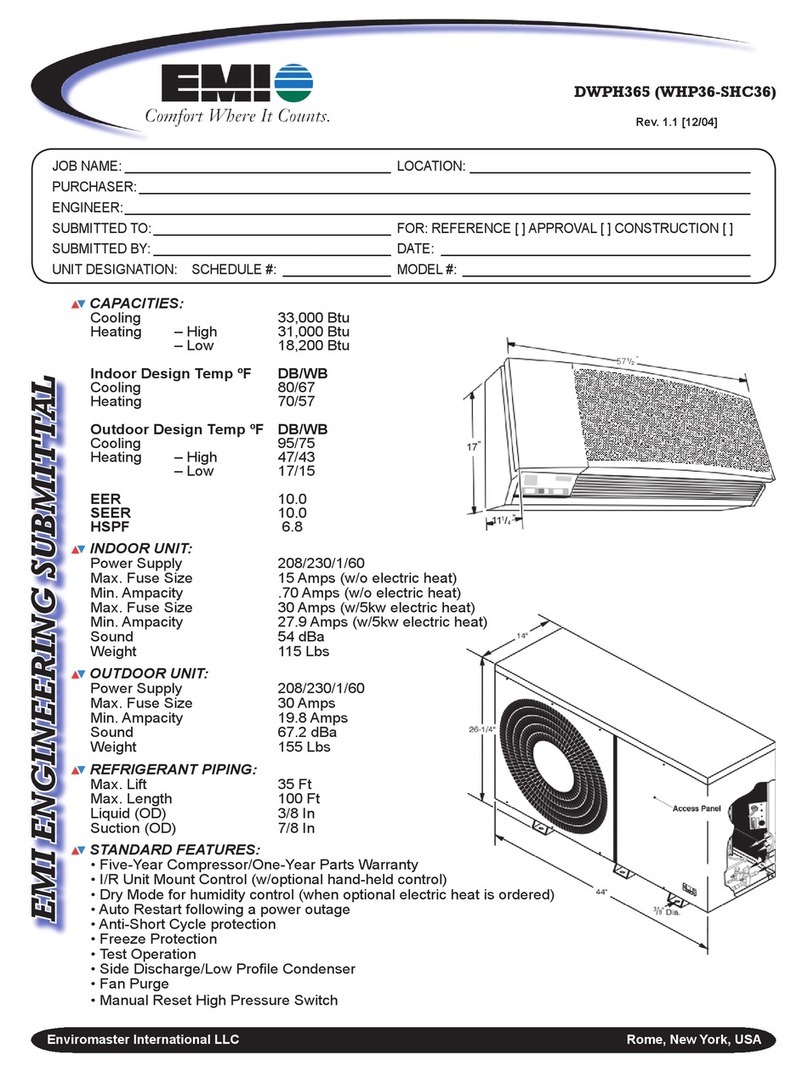

EMI

EMI DWPH365 (WHP36-SHC36) specification

auer

auer HRC 70 32 three-phase /3 Installation and user manual