ENGINEERING PRODUCTS 50-206 User manual

ENGINEERING

PRODUCTS

CO.,

INC.

Waukesha,

Wisconsin

OWNER'S

MANUAL

for

MODEL

50-206

42"

SNOWBLOWER AUGER

ASSEMBLY

and

MODEL

50-207

HITCH

ASSEMBLY

WARNING

READ THESE SAFETY

INSTRUCTIONS

CAREFULLY

AND

FOLLOW

THEM

CLOSELY, FAILURE TO

ADHERE

TO

THESE RULES COULD RESULT IN LOSS

OF

VEHICLE CONTROL. PERSONAL

INJURY

TO

YOURSElF.

BYSTANDERS, PROPERTY

DAMAGE

OR

DAMAGE

TO THE EQUIPMENT.

SAFETY RULES

1.

Read and

follow

operating and service

Instructions

carefully.

Be

thoroughly

familiar

with

all

controls

and

their

proper use.

2.

Never

allow

children

to operate

this

machine.

Do

not

permit

adults

to operate

equipment

without

proper

instruction.

3. Do

not

carry passengers.

4. Keep

the

area clear

of

all people not uSing

the

equipment,

children

and pets in

particular.

5.

Never

direct

discharge

toward

bystanders or

allow

anyone

near

the

vehicle

during

operation.

6. Be

sure

the

tractor is in good

working

condition, all

safety

devices and shields are

In

place and

working,

and

the

equipment

has

been

properly

adjusted.

7.

Never

attempt

to make any

adjustments

while

machine

is

running.

8.

Inspect

area to

be

cleared

for

debrIS,

doormats,

sleds,

boards,

wire,

etc.

9Be

sure

all

equipment

and

clutches

are in a

neutral

position

before

starting

engine.

10.

Wear

adequate

winter

clothing.

Wear

footwear

that

will

Improve

footing

on slippery surfaces.

11.

Handle

gasoline

with

care,

it's

highly

flammable.

12. Do

not

run

engine

in an enclosedarea-

exhaust

fumes

are

deadly.

13.

Adjust

skid shoes to

clear

gravel or

crushed

rock surfaces.

14.

Disengage

power

equipment

and

turn

off

engine

before

leaving

drlver's

position.

15.

Disengage

PTO,

turn

off

engine, and remove key before

attempting

to remove any clog.

16. Take all possible

precautions

before leaving

tractor

unattended.

Disengage

PTO,

lower

snow

blower,

turn

off

engine, and set

parking

brake. Remove key

from

ignition.

17.

After

striking

a

foreign

object, stop

the

snow

blower,

turn

off

the

engine

and

carefully

Inspect for damage.

18.

Should

the

tractor

start

to

vibrate

abnormally,

stop

the

snow

blower,

turn

off

the

engine,

and

determine

the

cause

immediately.

Vibration

is a

sign

of trouble.

19.

Always

clear

snow

up

and

down

the

face

of

aslope,

never

across

the

face of aslope. Use

extreme

caution

when

changing

directions

on aslope. Do

not

attempt

to clear

steep slopes.

98-7128

20. Disengage PTO, raise

snow

blower

before

transporting.

21. Never operate

the

snow

blower

when

visibility

or

lighting

is

poor.

OPERATING

INSTRUCTIONS

Read and

understand

the

safety

rules

and

assembly

instructions.

2. For best

snow

removal

results,

the

tractor

should

be placed

in

first

gear

with

the

engine

RPM

at

3/4

to

full

speed.

3.

Determine

the

best

snow

removal

pattern. Consider

the

size, shape, and

terrain

to be cleared

and

the

obstructions

in

the

area.

4. Drive

forward

and back.

The

long

direction

is

usually

the

best to

minimize

turning.

5.

Whenever

possible, begin

snow

removal on

the

upwind

side of

the

driveway

or

sidewalk

so

it

is

not

necessary to

blow

snow

over an already cleared area.

6.

The

Deflector

should

be

rotated to

discharge

the

snow

downwind,

not

into

it.

Always

adjust

the

Deflector

so

that

you

are

well

out

of

the

path

of

the

snow

stream.

7. Deposit

the

snow

beyond

the

area to be cleared

if

possible.

8. For

light

to

medium

snow

depths,

the

snow

blower

may

be

used

with

minimum

auger overlap

from

your

previous

path.

With

deep and very heavy

snow

conditions,

the

amount

of

overlap

should

be increased so

not

to force more

snow

into

the

unit

than

it

will

easily

handle

without

clogging.

9.

Should

the

snow

blower

become

clogged, disengage

the

PTO,

turn

off

the

engine

and

remove

the

key.

Get

off

the

tractor

and

dislodge

the

clog.

Return

to

the

tractor

and

proceed to

clear

the

snow.

10. The

snow

blower

should

be transported in araised

position

with

the

PTO

disengaged.

By

following

these

instructions,

you

should

have asafe and

effective

piece

of

equipment.

lM-9/82

ASSEMBLY

INSTRUCTIONS

PURPOSE:

This

Snowblower

is

manufactured

by

Engineering

Products

Co., Inc.

and

the

Haban

Manufacturing

Co.,

for

use on

Power

King Tractors.

It

is

intended

for use in the

removal

of

snow

from

sidewalks,

driveways,

and

other

moderately

large areas in a

safe and

effective

manner.

Strict

adherence

to the assembly,

safety,

and

operating

instructions

will

ensure

that

the

unit

will

have along and safe life.

ASSEMBLY:

The

Auger

Assembly

and

Chute

Deflector

are

contained

in

one

carton,

while

the

Hitch

and

Lift

Link

Assemblies

are in

another.

Be

sure

you have both cartons.

1.

Remove

the

AUGER ASSEMBLY,

Chute

DEFLECTOR (Item

60),

and

Chute

Direction

Control

ROD (Items

79,80,81

and

82)

from

the

first

carton. To

attach

the

Deflector

to

the

Auger

Assembly, loosen

the

four

(4) SCREWS (Item 76)

at

the

base of

the

Deflector, apply a

small

amount

of

grease

to

the

inside

of

the

Deflector

Base, and place it on

the

Auger

Assembly.

Tighten

the

four

Screws

previously

loosened.

2.

Attach

the

ends

of

the

Deflector

Control CABLE (Item

B)

to

the

opposite side (left

with

Snowblower

facing

forward)

of

the

Deflector

by

removing

Cable BOLT (Item 63)

and

WASHER (Item 62). Place both cable loops over the

weld

nut

and

replace the

bolt

and

washer.

3. Loosen

the

six Item

"C"

SCREWS

on

the

bottom

and sides

of

the

Auger

Assembly

Channel.

Also

loosen

two

Item

"B"

SCREWS on

either

side of

the

Channel. From a

position

behind

the

Auger

Assembly, slide

the

Hitch

Assembly

into

the

Channel,

making

sure

the

EYEBOLTS (Item 57)

with

one

NUT (Item 59) on

the

Channel

Side of each, are in

the

holes

in

the

Hitch

Adjusting

Blocks on

the

Hitch

Frame. Place

second NUT (Item 59) on Eyebolt

outside

of

Hitch

Adjustment

Blocks.

NOTE: Due to

manufacturmg

variation

on

the

widlh

of

the

Auger

Assembly

Channel, it

may

be necessary

on some

units

to

adjust

the

distancebelweenthe

two

Hitch

bars

that

enter

the

Auger

Assembly

Channel

In

order

to get a

sliding

fit. This can be

accomplished

by

carefully

bending

the bars.

This

will

not

affect

the

performance

of

the

unit.

Patience and care in

this

matter

will

make later

belt

adjustment

much

easier.

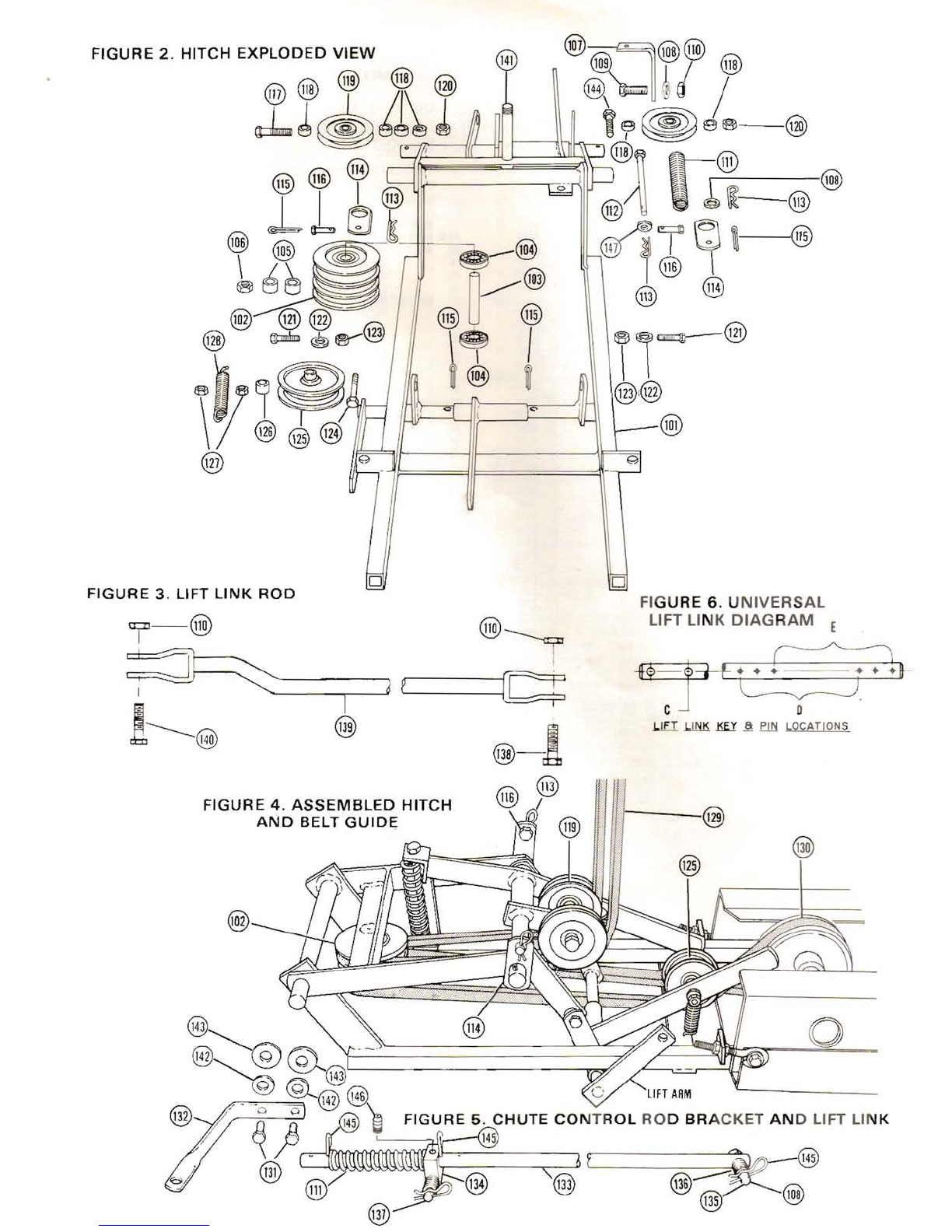

4. Remove the Channel COVER (Item 83). Place the shorter,

driven

BELT (Item

130)

around

the

Auger

Assembly

SHEAVE (Item

47)

and

the

lower

groove

of

the

three-groove

SHEAVE (Item

102)

at

the

rear of the

Hitch

Assembly

(see

Figure

4).

By loosening

and/or

tightening

the

Nuts

on

the

Eyebolts,

position

the

Hitch

Assembly

so

that

Belt

tension

is

properly

adjusted. Pull up on the

spring

loaded Idler

Arm

and place the belt

under

the

Idler PULLEY (Item 125). Tool

tighten

the

Screws

on sides

and

bottom

of

Auger

Assembly

Channel, and

the

Nuts

on

the

Eyebolts.

5.

With

the

Hitchl

Auger

Assembly

in a

position

under

the

tractor,

Idtthe

rear

of

the

Hitch

into

the

Rear

Hitch

Blocks

on

the

frame

of

the

tractor. Raise the

front

of

the

assembly so

that

the

front

crossbar

fits

into

the Front

Hitch

Blocks on

the

frame

of the tractor. Secure

with

Safety

LATCHES {Item

114) by

Inserting

aBlank

BOLT(ltem

116)throughthe

latch

and sma

II

upper hole in Front

Hitch

Block and

retaining

with

a

Quick

Change

KEY

(Item 113).

6.

Relieve

tension

on

driven

BELT (Item

130)

by

removing

it

from

under

Idler PULLEY {Item 125).

Allow

it

to

temporarily

drop off

of

lower

groove

of

the

three-groove

SHEAVE (Item

1021.

Disconnect

the

safety

chain

and

electrical

wire

harness

from

the

Electromagnetic

Clutch

at

the

front

of

the

tractor

engine.

Loop the longer,

Drive

BELT (Item 129) over

the

rearmost

belt

groove of

the

Electromagnetic

CIU1Ch

Pulley (except the 16 hp model

where

the

front

belt

groove

should

be

used). Thread

the

Drive

Belt

under

the

right

Idler

PULLEY (Item

119)

and

around

the

top

of

the

three-groove

SHEAVE.

Lift

up on

the

spring loaded

lefl

Idler

Arm

and

place

the

belt

under

the

left

Idler PULLEY (Item

119)

and

release arm.

This

will

a

utomatically

apply

proper

tensIOn to

Drive Belt. Replace

driven

Belt in

lower

groove of

three-

groove Sheave

as

provided in paragraph 4.

7. For

Model

1612

and all

other

tractors

with

serial

numbers

before

52589,

place

the

tractor

lift

in

such

a

position

that

the

bottom

of

lift

arm

is

as

far

forward

as possible.

Attach

the

Lift

Link

to

the

Lift

Arm

on the

right

side

of

the

Hilch

Assembly

using

the

Blank BOLT (Item 135),

1"

SPRING

(Item 136), WASHER (Item lOB) and a

Quick

Change KEY

(Item 145). Referring to

the

Universal

Lift

Link

diagram

(Figure 6). use positions Cand E

for

model

1612,

and

positions

Cand 0for

other

tractors.

8. For

tractors

other

than

the

Model

1612

and

with

serial

numbers

after

52589,

attach

the

Lifl

Li nkROD (Item

139)

to

the

Lift

Arm

with

aSCREW (Item

138)

and NUT (Item 110).

Connect the

other

end of

the

Rod

to

the

hole avai'lable in the

Rear

Lift

Link

Rod

just

in

front

of

where

it is

attached

to

the

Lift

Assembly

Arm

(as

shown

In

Tractor

Owner's

Manual).

using

the

SCREW (Item

140)

and

aNUT (Item 110).

9.

Mount

the

Chute

Control Rod BRACKET (Item

132)

to the

right

side

of

the

flywheel

housing

using

two

SCREWS (Item

131).

two

lock WASHERS (Item 142) and

two

flat

WASHERS (Item 143).

Insert

upper

section

of

ROD (Item 79)

through

the

Bracket.

Attach

the

lower

section

of

the

ROD

(Item 82) to EYEBOLT (Item 9) on

the

Auger

Assembly

and

slide

the

two

sections

of

the

Rod together.

Install

Quick

Change

KEY

(Item 81) in hole in

upper

section

below

Bracket.

10.

Adjust

the

height

of

the Skid SHOES (Item

2)

by

loosening

the

two

Screws

holding

the

Shoes

tothe

Auger

Assembly. If

the

Snowblower

IS

to be used on a

smoolh

surface, such as

concrete

or

asphalt, the

Shoes

should

be adjusted so

that

lhe

Scraper Blade is resting flat on

the

surface. If

the

intended

use is

on

agravel

or

loose

material

surface,

the

Shoes

should

be adjusted

to

allow

for a

1"

clearance

between

the

Blade and

the

surface.

To

do this,

lift

the

Snowblower

and place a

1"

thick

board

under

the

Scraper

Blade.

Lower

the

Snowblower

and

adjuslthe

Skid Shoes so

that

they

are resting on the surface.

11. Check

the

adjustment

of

the

Auger

Drive CHAIN (Item 34). If

correct,

the

chain

will

have a

slight

amount

of slack In It. In

the

event

the

Chain is not

properly

adjusted, loosen the

NUTS (Item 50) on

the

back of the

Auger

Assembly.

By

moving

these

Nuts

In

orout

you

will

be

moving

the

jackshaft

and

adjustIng

the

Drive Chain.

When

the Chain is

properly

adjusted,

tighten

the

Nuts

loosened previously.

NOTE.

If

there

was

an excessive

amount

of

adj

ustment

reqUired, go back to step 4and

readjust

the

belt

tension.

---\

\\

E.

E \ I

\\\

~~

\ I I

89~

FIGURE 6.

UNIVERSAL

LIFT LINK

DIAGRAM

E

~

~~i'+

LIFT

LINK

KEl'

~

.Em

LOCATIONS

o

@-!

,G\@

~I

@

FIGURE

4.

ASSEMBLED

HITCH

AND

BELT

GUIDI;

@~

0

@)@@.'1-'---'--------------§

~

~

@

~~-

--

~--{LJI

,..

_~

~

@l

C'

LIFT

ARM

"--------

@)f/

~O

flO

@)

~

FIGURE 5.

CHUTE

CONTROL

ROD

BRACKET

AND

LIFT LINK

?

~

"I

@

~i

,@}

1

@------~®

\3'

~

@

~

'ill)

FIGURE

3. LIFT LINK ROO

i-@

@~

~~-

-----..,-f=J----;

p'-----~ti

!-----@

@

FIGURE

1,

2,

3,

4,

5

42"

SNOW

BLOWER

AND

HITCH

PARTS LISTS

NOTE:

·ONLY

THOSE

PARTS

WHICH

HAVE

"NEW

PART

NO."

ARE

AVAILABLE

FROM

ENGINEERING

PRODUCTS.

ORDER

REPLACEMENT

PARTS

DIRECT

FROM

HABAN

MANUFACTURING

CO.,

2100

NORTHWESTERN

AVE,

RACINE,

WISCONSIN

53404.

PHONE

NO.

(414)

637-8388

FOR

ANY

PART

MARKED

WITH

AN

ASTERISK

BY

THE

OLD

PART

NUMBER.

PARTS LIST

AUGER ASSEMBLY FIGURE 1

HITCH

FIGURE 2, 3, 4, 5

OLD

PART

NO.

.

..

4409'

.

..

4119'

..

GMl80018'

..

..

SW-4A

..

...

9713'

..

8203'

..

8204'

......

3430'

.8206'

..

10913'

..

GM446363'

...

10915'

........

.....

.6643'

...

7090'

...

GM271178'

DESCRIPTION

WELDMENT

....

..

Hitch

SHEAVE..

...3

Groove

SPACER

1"

OD

x3/4"

ID

x

1·

tl8"lg

BEARING

Ball

SPACER

rx3/4" x1/2"

NUT......

..3/4

NF.

Hex

lock

BRACKET.

..... .

Lower

Ang

Ie

WASHER.

.

..

7/16"

SAE

Flat

SCREW..

.7/16"

NF

x

1-1/4"

HHC

NUT.

.... .

..

7/16".

Hex

lock

SPRING.

.. .

..

Compression

6"

BOLT.... .

7/16"

Blank

x

7"

Ig.

KEY.

.... . .

Small,

Quick

change

LATCH

.

Hitch

PIN

....

.

..

Cotter

BOLT...

.318"

Blank

x

1·1/2"

Ig.

SCREW.

.

...

5/8"

NF

x2·3/4"

HHC

SPACER.

.

..

7/8" x5/8" x

3/8"

PULLEY

..

Idler,

left

and

right

NUT.

.. .5/8"

NF

Hex

lock

SCREW.

.. . 1/2"

NF

x

1-1/2"

HHC

WASHER

1/2"

Std.

Flat

NUT.... .1/2"

NF.

Hex

lock

SCREW

3/8"

NF

x

2-1/2"

HHC

PULLEY

. ..Idler

SPACER

518"

00

x

9116"

Ig.

NUT.

.... .

318'

NF.

Hex

lock

SPRING.

. .

EXlension

BELT.

... .

..

Drive,

72"

BEL

T...... .

..

Connecting

68"

SCREW..

..,

.3/8"

NF

x

718"

HHC

BRACKET

Chute

Control

Rod

LINK

Lift.

Universal

front

46"

BRACKET

Lift

Link

BOLT

7/16"

Blank

x

2"

SPRING

Compression

1"

BOLT... .. .7/16"

Blank

x

3"

SCREW... .7/16"

NF

x

2"

ROD...

..

.Lift

SCREW..

.

...

7/16"

NF

x1·1/4"

SCREW.

.3/4"

NF

x

5"

WASHER

.3/8"

lock

WASHER

....

3/8"

std.

flat

SCREW

.5/8"

NF

x

2"

KEY.

.... ..

Quick

change.

large

FITTING

.Grease.

1/4"

NF.

short

DESCRIPTION

SPACER

.

UT.

Hex

lock

.25

-

20.

..

....

.

....

BOL

T,

Hex

head

.25

-

20

x

.62

..

WASHER.

Locking

25

.

DECAL.

Caution

.

ROD.

Crank

......................•...

GRIP,

Crank

rod

. .

PIN,

Hair

colter. ..... .

.......•...

,.

ASSY.

Extension.

crank

rod. ...•..

..

.

...

COVER,

Rear

channel. .. .. . .... ...

..

..

WASHER.

Flat

.37

..

STRAP,

Cover

mounting

.

BLADE,

Scraper

.

BOL

T,

Carriage

.25

.

20

x

.62

.

ASSY,

Nut

and

lockwasher

.25

.

20

hex

.

RETAINER

BELT

NEW

ITEM

PART

NO. NO.

74

75

76

77

84-3040

78

79

80

81

82

83

84

85

86

87

88

89

50-0132

ITEM

PIN

101

50-2900

102

50-7100

103

83-D044

104

80-0029

105

83-0021

106

84-0175

107

50-0506

108

84-3060

109

84-2171

110

84-0120

111

83-D124

112

84-1090

113

84-4032

114

51-4705

115

84-4020

116

84-1101

117

84-1043

118

83-1024

119

86-0003

120

84-0140

121

84-1171

122

84-3~1

123

84-0130

124

84-2151

125

86-0~1

126

83·0127

127

84-0110

128

83-D125

129

81-0074

130

81-0070

131

84-2110

132

50-0505

133

50-4701

134

15-0505

135

84·1111

136

83-0024

137

84·1121

138

84-2180

139

50-2503

140

84-2171

141

84-2390

142

84-3020

143

84-3037

144

84-1042

145

84-4031

146

03-2102

OLD

PART

DESCRIPTION

NO.

HOUSING.

Header.

. ... ... ... . . ... .. .. .. ... .

..

.

8580'

SHOE.

Skid. .. .. .. ... ....

..

..

..

.3045'

BOLT.

Carnage

.31

-

18

x

.75

.. .. ... ..

....

.. .

7953'

ASSY.

Nut

and

lac

washer

.31

.

18

'lex

. .

GM271184'

ASSY.

Stack

drive...........

.

.9363'

SHROUD,

Stack

drive. ....... .

9030'

ASSY.

Tube

and

bracket.....

.

9032'

ASSY.

Cable,

tube.

and

sleeve.

.

8233'

EyEBOLT....

..

..3955'

WASHER.

Flat

.37

SAE

' ,. ...

GM120388'

WASHER.

Spring..................

...

4772'

NUT.

Eyebolt

.37·16..

.

.SN-4

U-BOLT,

(Level

wind)... .

8236'

STRAP.

Friction.........

.

.8299'

NUT.

Hex

lock

.25·20...

.

4119'

BOLT.

Carriage

.37

-

16

x

.75

.... .. . .

GM126227'

ASSY,

Nut

and

lockwasher

.37

-

16

hex.

.

GM271190'

BOL

T,

Carnage

.37

-

16

x

1.00

...........

...

.. ..

...

.

..

.

..

GM

120915'

ASSY.

Nut

and

lockwasher

.37

-

16

hex

GM271190'

WASHER.

Flat

.41

4506'

ASSY,

Auger....

..

.

..

8176'

SHAFT.

Auger.........

..

8181'

BEARING.

Auger.......

.

5474'

WASHER.

Flat

1.09..

..

.4143'

FLANGE.

Bearing.. ..

..

5473'

BOL

1,

Hex

head

.31

.

18

x

75.

...

.

..

GM18oo77'

WASHER,

Lock

.31

•

SW-l

SPROCKET.

Auger

35

tooth........

..

8287'

PLATE.

Auger

mountlllg

..

8185'

BOLT,

Hex

head

.31

-

18

x

.62

.

..

GM18007S'

BOLT,

Hex

head

.50

-

13

x

1.25

.. ,

GMl80175'

WASHER.

Lock

.50

.. ... ..... . .

SW-l1

CHAIN.

Auger

drive.

70

IlIlks

..

...

3028'

LINK,

Connec1or

(Used

for

repair

only)

..

..

8456'

GUARD.

Chain. .

3036'

SCREW,

Hex

washer

head

.25·20 x

.50

self

tapping. .

GM9414012'

ASSY.

Jackshaft

hOUSing

With

bearings.. .

8393'

BEARING,

Needle

8689'

FITTING.

Grease

.25

-

28

straight ,.... .

..

.

F·2

ASSY.

Jackshaft

and

sprocket

. ..

..

....• . .. .

8396'

BOLT,

Hex

head

.37

-16 x.75

GM180120'

WASHER,

Flat

.43......

.. .. ..

GM

120388

WASHER.

Lock

.37...

..

GM120382

WASHER.

Flat

.75.......

.

SW-7

KEY.

Drive

pulley

.18

square

x

1.00

. .

3259'

ASSY,

Pulley

and

hub...

.

3035'

SCREW,

Set-square

head

cap

point

.31

.

18

x

50....

.

..

GM142671'

WASHER.

Flat

.50......

..

SW-6A

NUT.

Hex

.50

-

13

. ... .

SN-5

PLATE.

Relllforcement

. .. .. .. ... .• ... .

..

8329'

PLUG.

Bulton

...... ..... ... .

..

7677'

BRACKET

ASSY.

Channel. .... .

..

....

.

..

.

...

...

7577'

BOLT.

Hex

head

.37

-

16

xl

00

GMl80122'

WASHER,

Lock

.37

...

..

..

..

..

.. .. ..

.. .

SW-2

BOLT.

Hex

head

.37

·16

x 2

.......

..

.GMl80130

EYEBOLT

..

... .. .......

.3955'

TRUNNION................

..

3700'

NUT.

Hex

.37

-

16

.

GM120377'

ASSY.

Deflector

and

elbow.

.... ..

..

..

.. .

8584'

ASSY.

Elbow

and

PiVOt.

.

8585'

WASHER.

Cable.

.3903'

BOL

T.

Cable

25 -

20

x.50..

..

... ...

5B-l

B

ASSY.

Deflector

and

decal. ..

..

. .

...

9737'

DECAL.

Warning.............

..

..

9663'

MOLDING,

Deflector. .......... .

.6558'

BOLT,

Carnage

.31

-

18

x100. .. ...

GM126358'

WASHER.

Lock

int/ext

tooth

.37

.

GM178566'

WASHER.

Flat

.37..

.....

.. ..

SW-2

STRAP.

Locking

.8198'

NUT.

Hex

locking

.31

-18. .."

SN-l0A

HOOK.

Lift

spring

...

3076'

BOL

T,

Hex

head

.25

-

20

x

1.25

. ...

SS-35A

NEW

ITEM

PART

NO. NO.

2

3

4

5

6

7

8

9

10

11

12

84-0040

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

84-3010

28

30

31

32

33

84-3110

34

35

36

37

38

39

40

03-2102

41

42

43

84-3060

44

84-3020

45

84-3070

46

47

48

49

84-3061

50

84-0050

51

52

53

54

55

84-3020

56

84-2102

57

58

59

60

61

62

63

84-1012

64

65

66

67

68

69

84-3020

70

71

84-0101

72

73

84-2350

MAINTENANCE

INSTRUCTIONS

1.

The

snow

blower

has a

grease

fitting

located

on

the

Auger

Jackshaft

(Item

40,

Figure

1)

which

should

be greased every

10

hours

or use

with

a

multi-purpose

grease.

2. Once a

year

or

more

often

depending

on

usage,

the

chain

tension

should

be checked

and

adjusted

if

required

and

lubricated.

3.

Drive

belt

tension

should

be checked

periodically

and

adjusted

when

needed. The

belts

should

be checked

for

wear

also

at

this

time.

Replace

worn

and frayed belts.

4.

To

store

the

snow

blower

for

the

off-season,

remove

the

snow

blower

from

the

tractor.

Use

water

and

a

brush

to

thoroughly

clean

the

Auger

Assembly

and

Hitch.

Paint

any

chips

or

worn

areas,

and

put

a

light

coat

of

oil

on

the

unit

to

prevent

rust.

Lubricate

all

moving

parts,

bearings,

sheaves,

cross shafts. etc. Cover

with

atarp

or

plastic

and store

in

a

dry place.

This manual suits for next models

1

Table of contents