4

IMPORTANT! READ AND FOLLOW ALL INSTALLATION AND MAINTENANCE INSTRUCTIONS, INCLUDING CLEANING THE UNIT AS SPECIFIED, AND

REPLACING GASKETS ANNUALLY, AND PARTS AS NEEDED.

ENGLANDER IS NOT RESPONSIBLE FOR ANY DAMAGE OR INJURY INCURRED DUE TO NEGLECT, OR DUE TO UNSAFE INSTALLATION OR USAGE OF

THIS PRODUCT. CALL TECHNICAL SUPPORT WITH ANY QUESTIONS.

Welcome!

Introduction

•Thank You ......................................... 4

Specifications

•Heating Specifications ....................... 5

•Dimensions ........................................ 5

•EPA Compliance................................. 5

Installation

•Installation Overview...................6

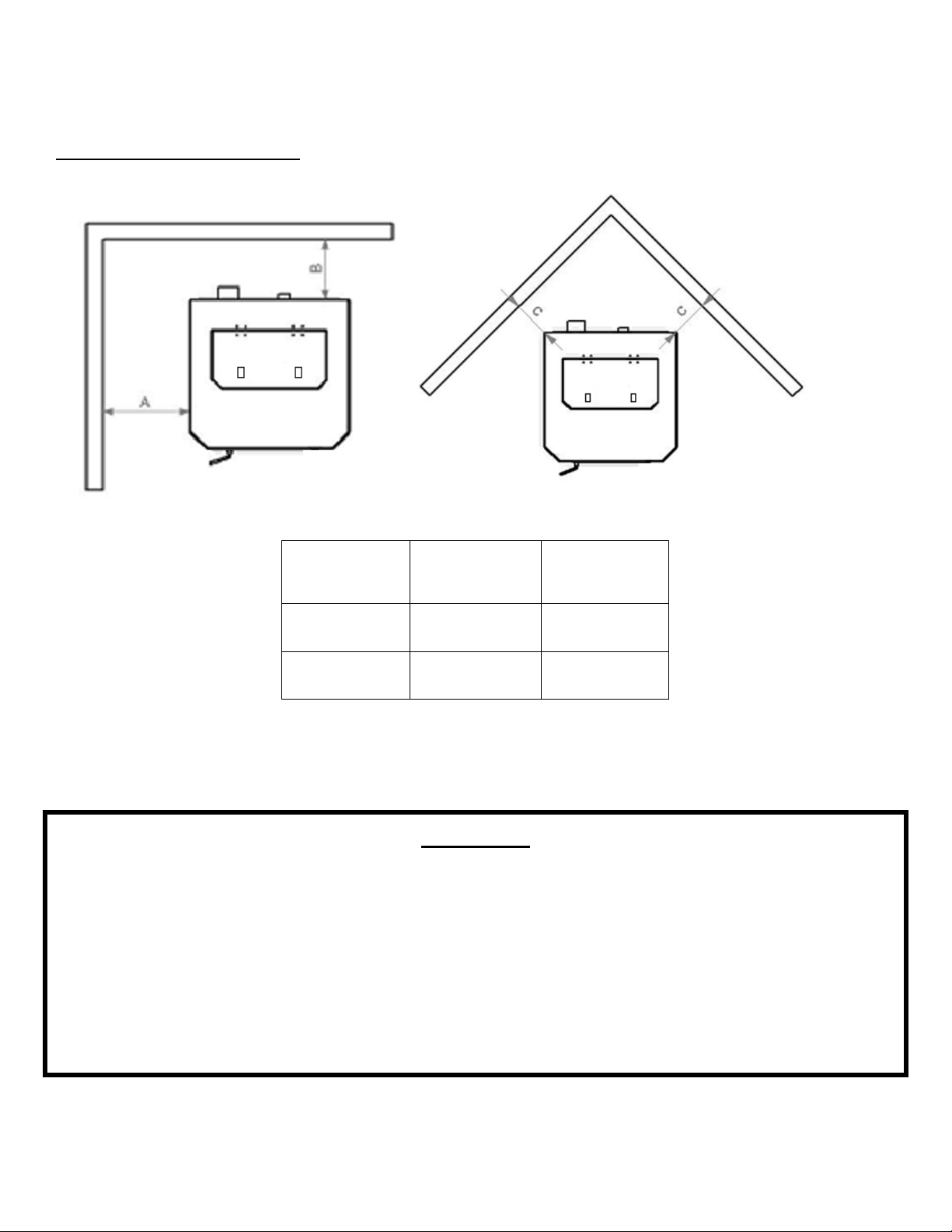

•Clearances to Combustibles.........7

•Venting Introduction................... 8

•Venting Guidelines.......................8

•Additional Venting Information....9

•Approved Venting Methods

•Through the Wall ...........10

•Through the Ceiling........11

•Existing Chimney............ 12

•Mobile Home Installation............ 13

•Vent Termination Clearances...... 14

•Outside Air Hookup..................... 15

•Floor Protection........................... 16

Daily Operation

•Control Board Types ………………… 17

•Getting Started............................ 18

•Lighting a Fire.............................. 18

•Daily Operation Notes ……………… 19

Control Board

•Top Mount Board Settings........... 21

•Error Codes (Top Mount) ............ 23

•Diagnostic Mode (Top Mount) ....29

•Side Mount Board Settings........... 31

•Side Mount Error Codes ............... 32

•Power Failure ............................... 33

Maintenance

•Daily

•Important Notes.............. 34

•Daily Ash Removal............ 34

•Cleaning the Burn Pot …...35

•Weekly

•Baffle Removal................. 36

•Monthly

•Venting Pipe Cleaning ….. 37

•Yearly

•Important Notes.............. 38

•Burn Pot ……….................. 39

•Exhaust Blower …………….. 39

•Convection Blower........... 40

•Finish ………….................... 40

•Gaskets ………………………… 40

•Basic Troubleshooting ....................... 41

Replacing Components

•Convection Blower ............................43

•Auger Motor ……….............................44

•Combustion Blower............................45

•Vacuum Switch...................................46

•Igniter.................................................48

•Gaskets...............................................49

•Glass...................................................50

•Control Board (Top Mount) ...............51

•Control Board (Side Mount)...............53

•Hopper Lid Latch ….............................55

Illustrated Parts Detail

•Exploded Parts Diagram……………………56

•Parts List……………………………………..….. 57

Warranty

•Serial Tag Sample…………………….………..59

•Warranty Details……………………………....60

•Important Notice………….…….....…………62

•Warranty Reg. Form………………………….63